Method for producing a pipe connection by means of press fitting, and pressing tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

with reference to preferred embodiments.

BRIEF DESCRIPTION OF THE DRAWINGS

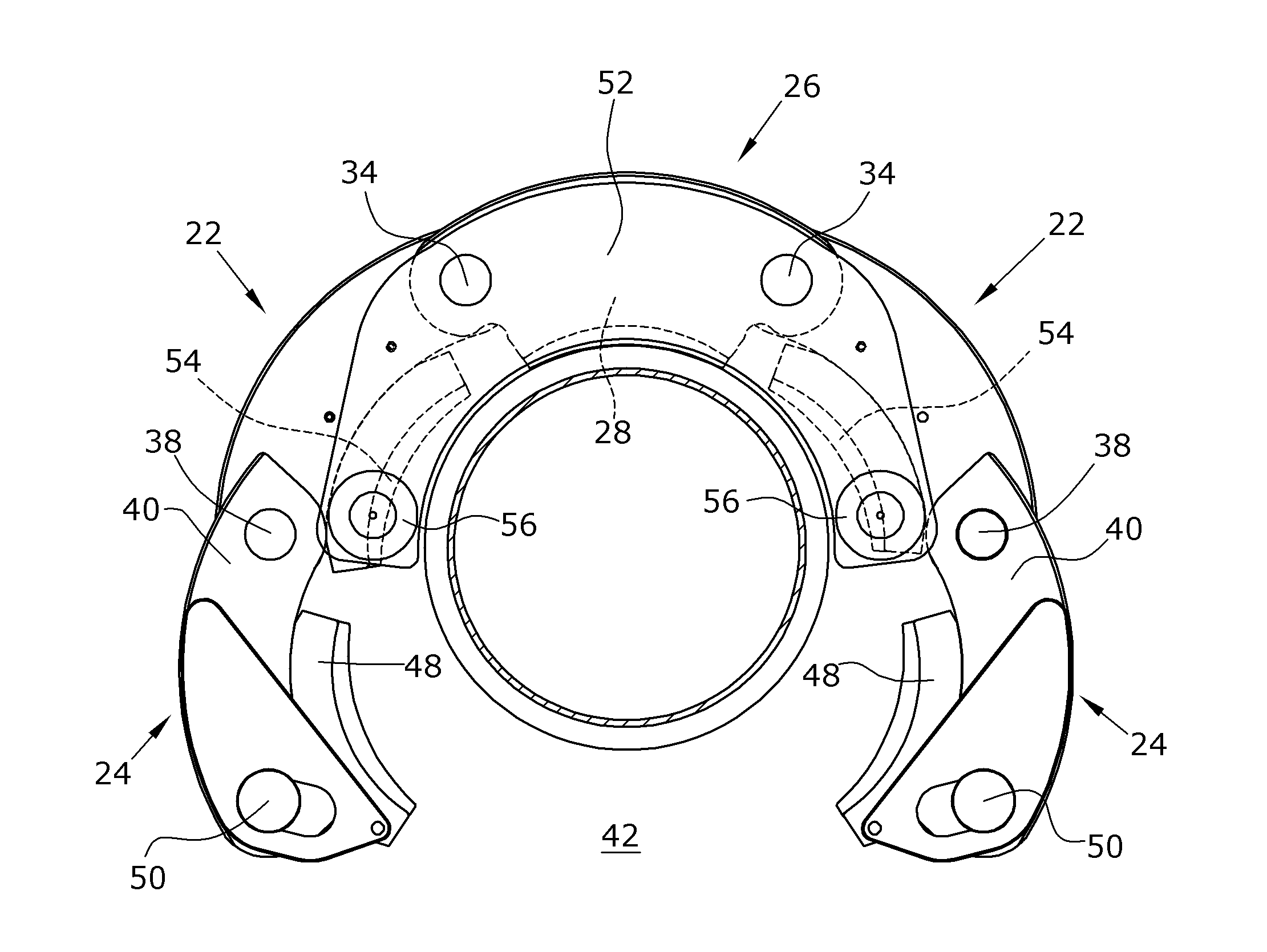

[0020]FIG. 1 is a schematic sectional view of a press fitting connection, not compressed on one side and after a first compression operation on the other side,

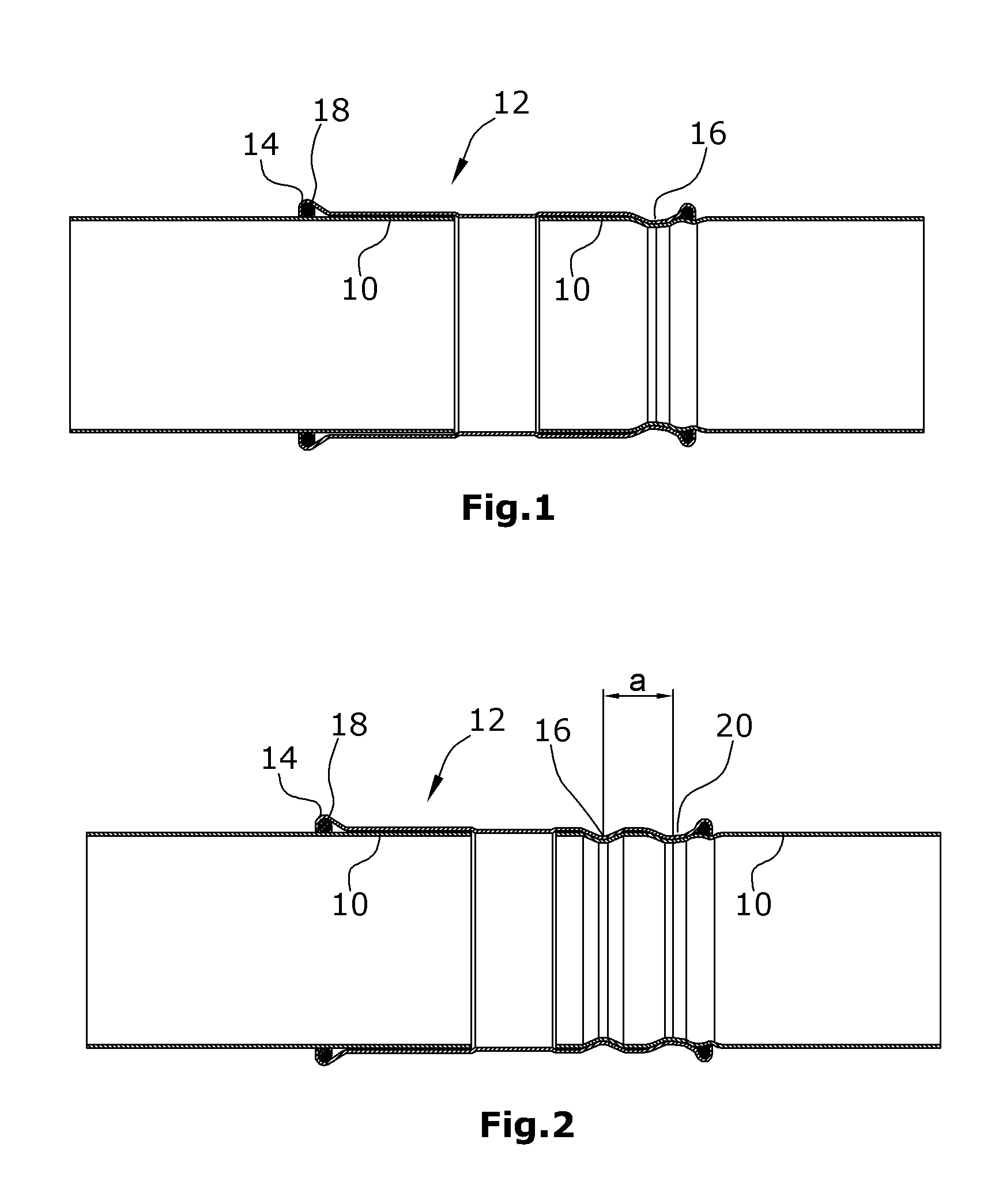

[0021]FIG. 2 is a schematic sectional view of a press fitting connection, not compressed on one side and after a first and a second compression operation on the other side,

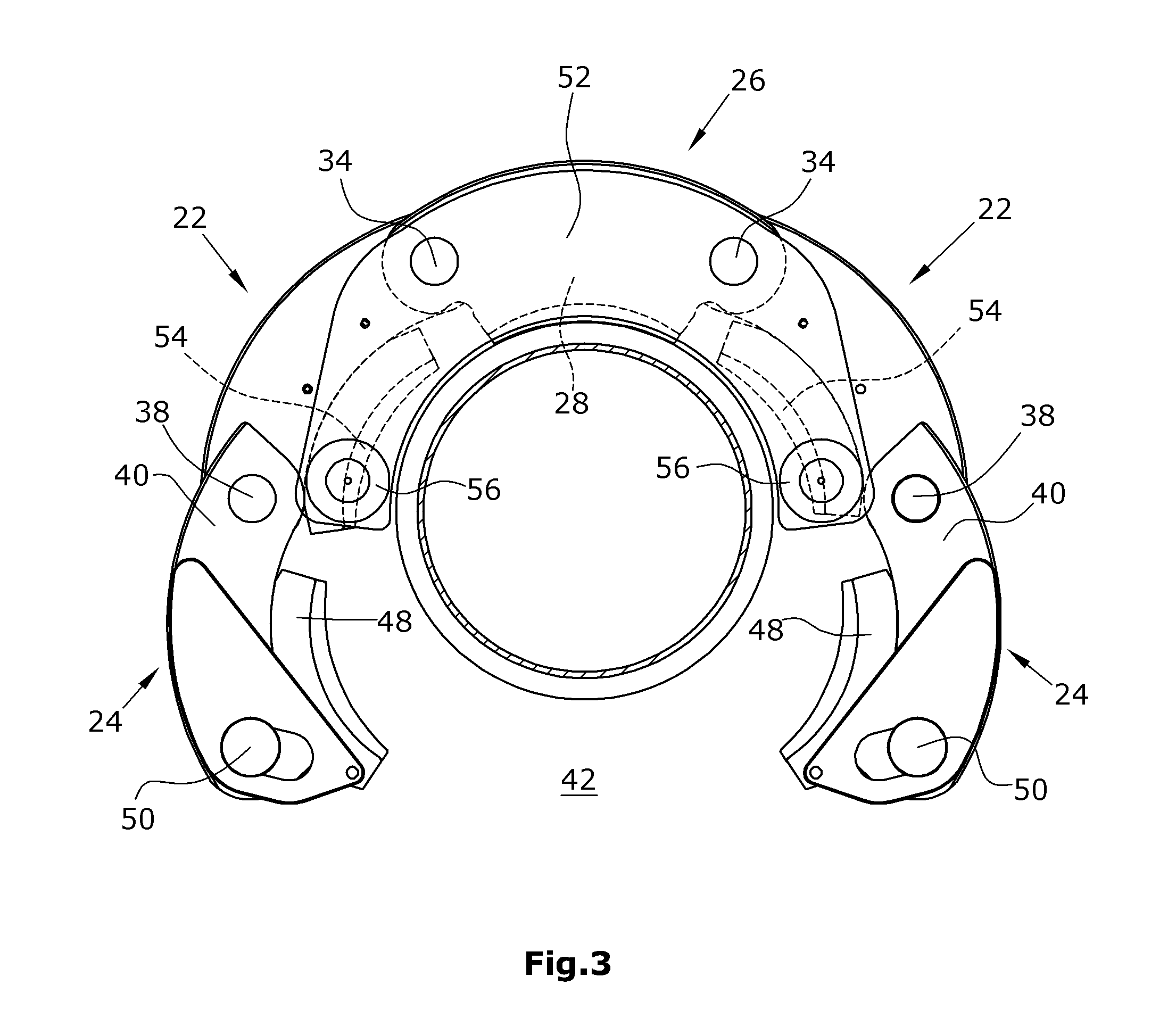

[0022]FIG. 3 is a schematical top plan view of a pressing sling of the present disclosure,

[0023]FIG. 4 is a schematical side elevational view of the pressing sling illustrated in FIG. 3, and

[0024]FIG. 5 is a schematical side elevational view of a driving means for connection with the pressing tool.

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

[0025]In a first method step, an initially not deformed press fitting 12 is set onto both pipe ends 10. Thereafter, a first compression operation is performed in which, on the one hand, the bulge 14 is deformed and, on the other hand, the first i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap