Superheat and sub-cooling control of refrigeration system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

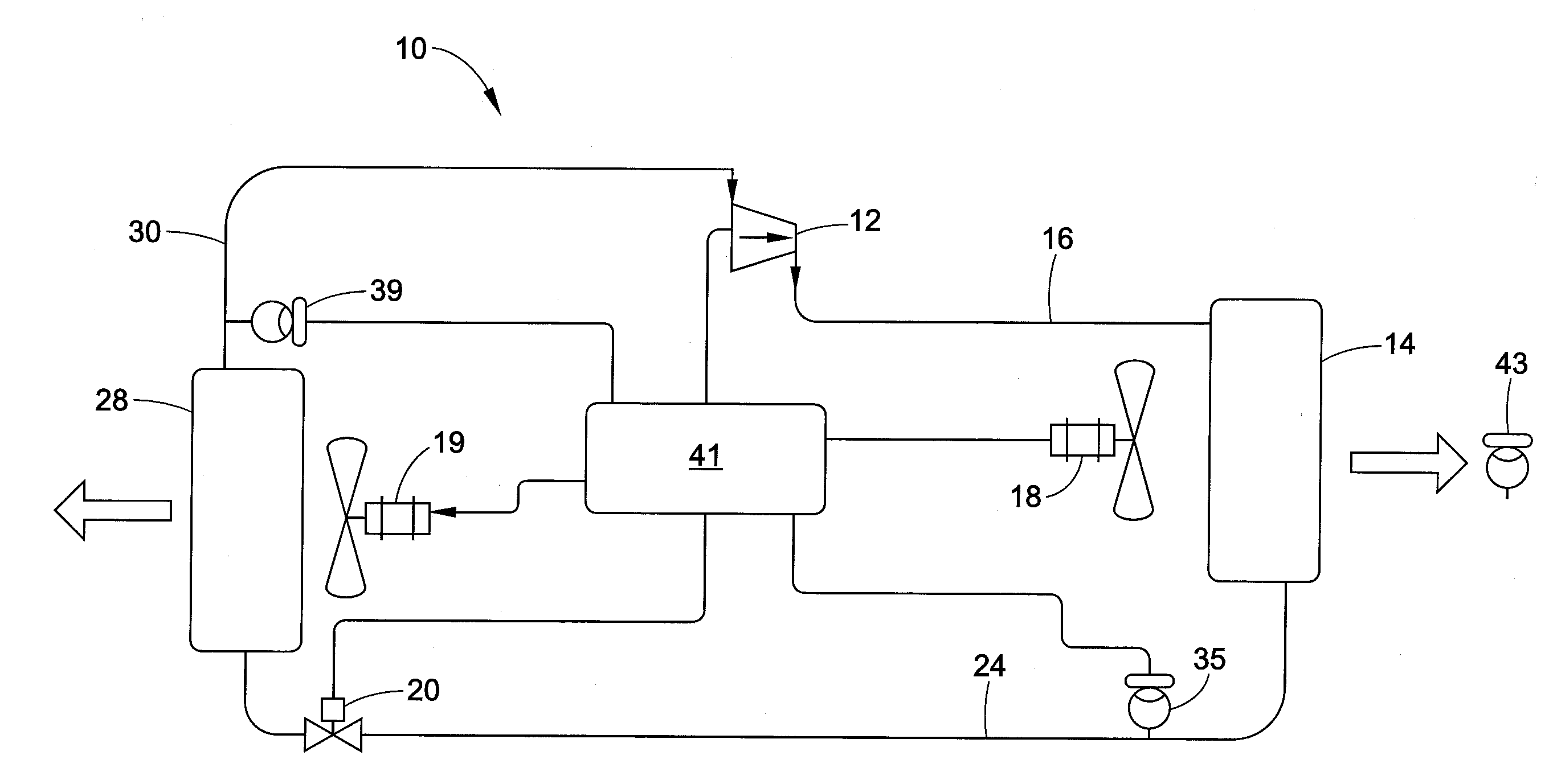

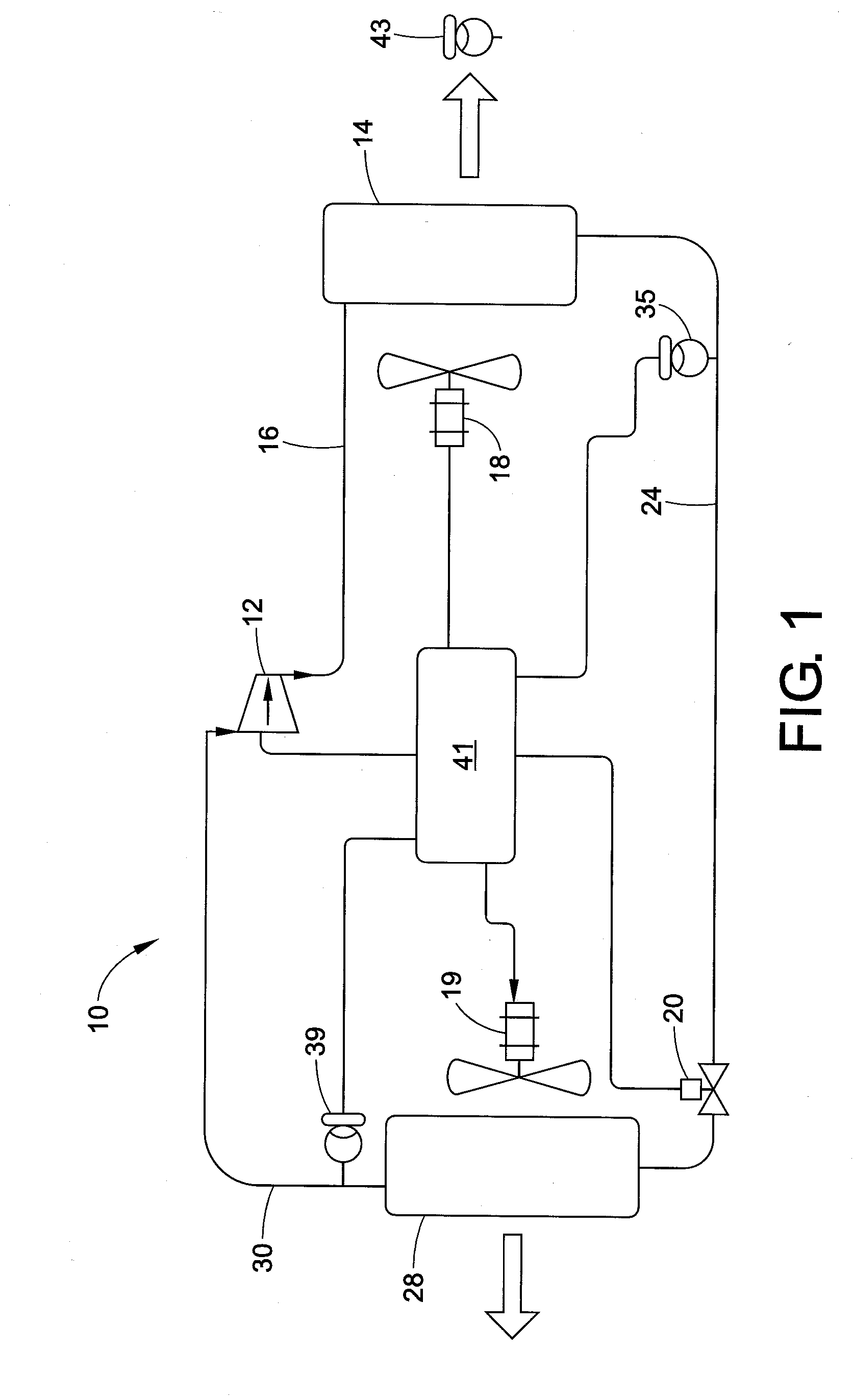

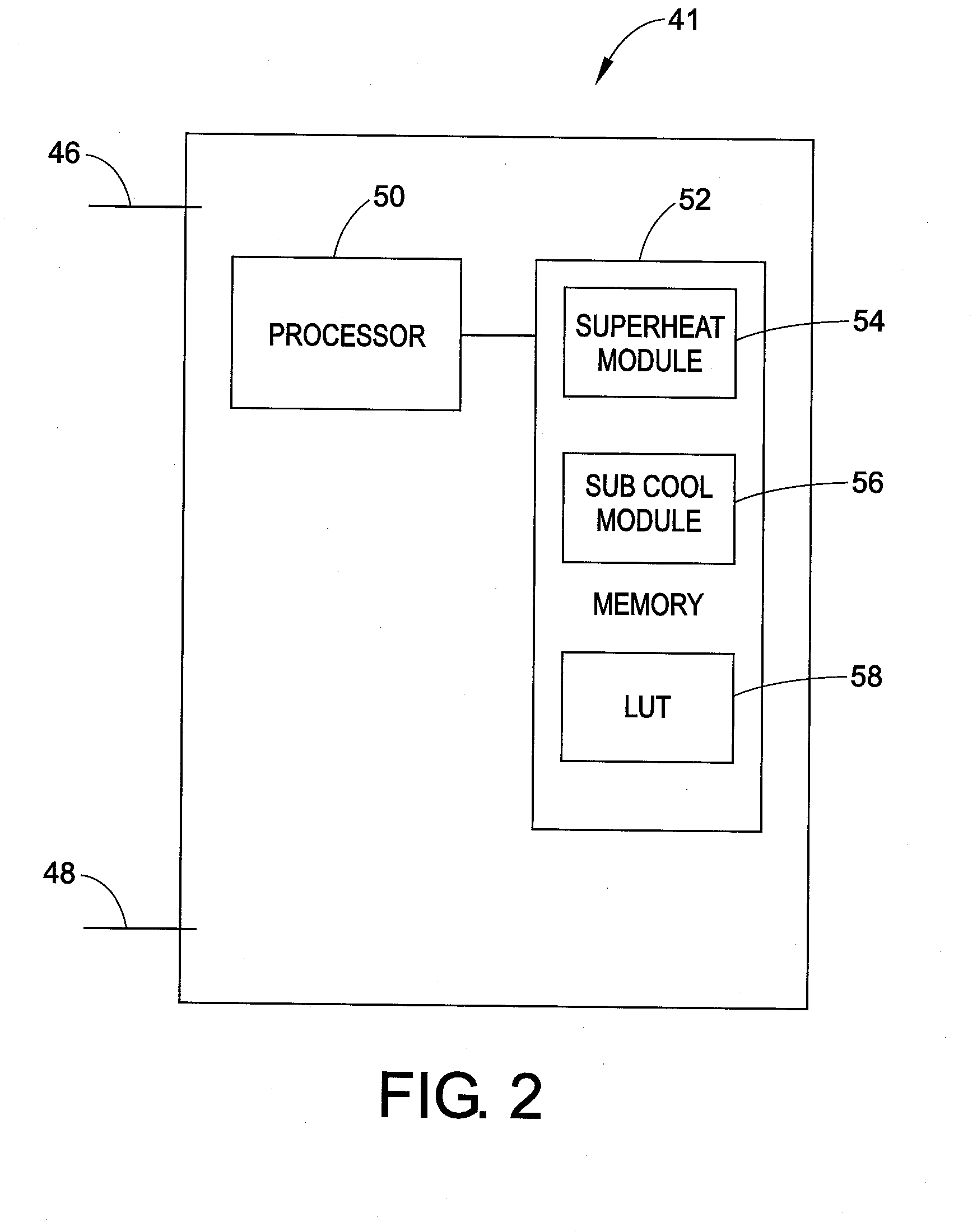

[0022]With reference to FIG. 1, a variable capacity refrigeration system is identified generally by reference numeral 10. It will be appreciated that the illustrated system is just one of a variety of refrigeration systems, and that aspects of the disclosure are applicable to a wide variety of such systems. The system 10 includes a compressor 12, which can be a modulating variable speed compressor or a tandem compressor system, for example. The compressor 12 is fluidly connected to a condensing coil 14 (heat exchanger) by a compressor refrigerant discharge tubing 16. The condensing coil 14 is located in close proximity to a condensing fan assembly 18, which includes a fan blade and a fan motor. The condensing fan motor can be a fixed speed, multiple speed or variable speed design. The outlet of the condensing coil 14 is fluidly connected to an inlet of an expansion valve 20 by refrigerant liquid tubing 24. The expansion valve 20 controls the flow of refrigerant into an evaporator co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com