Cam phaser with eccentric lantern gear component

a technology of cam phaser and gear component, which is applied in the direction of machine/engine, valve details, valve arrangement, etc., can solve the problems of weakened tooth base and only relatively small transmission force, and achieve the effect of large reduction ratio and good self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

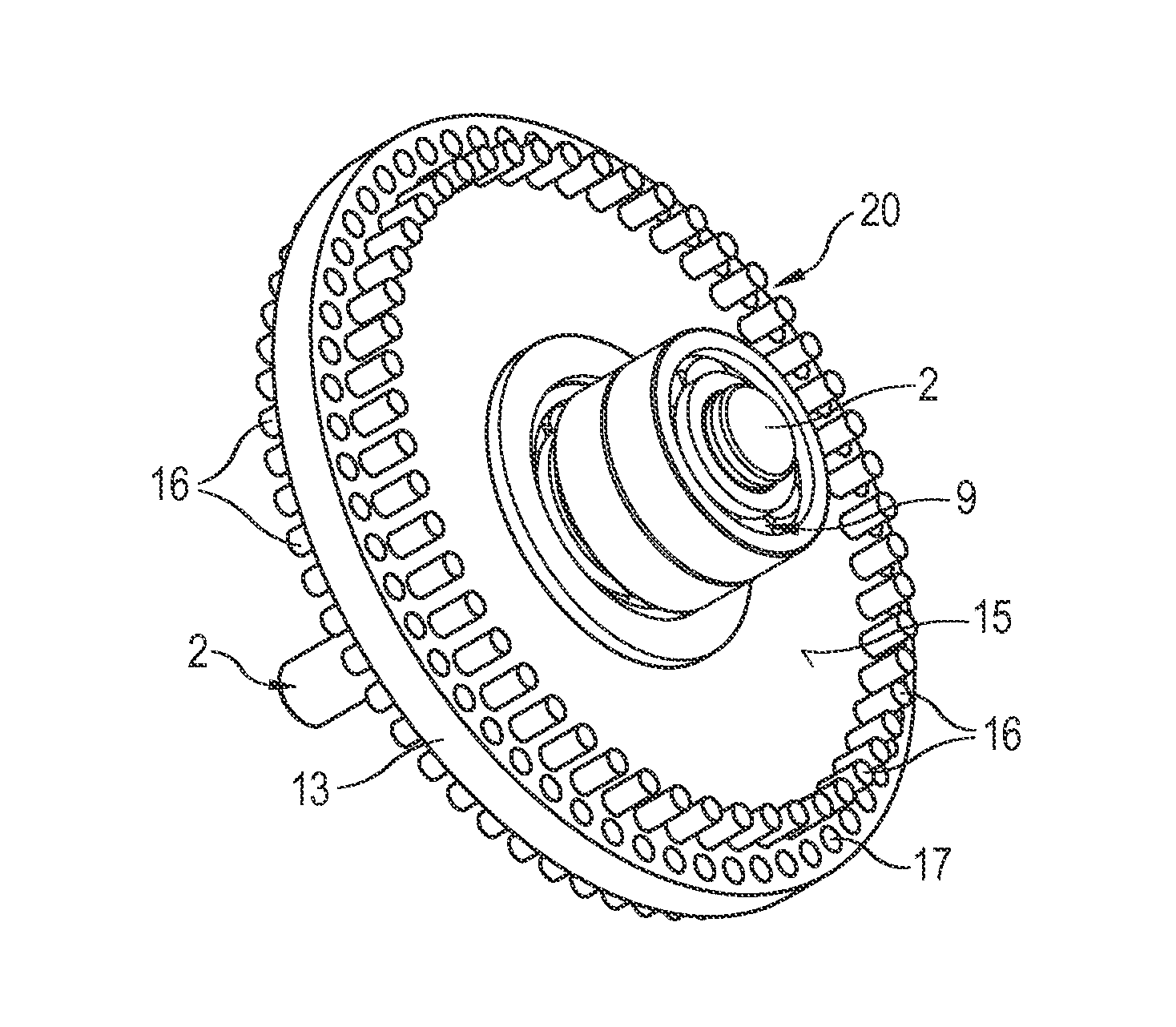

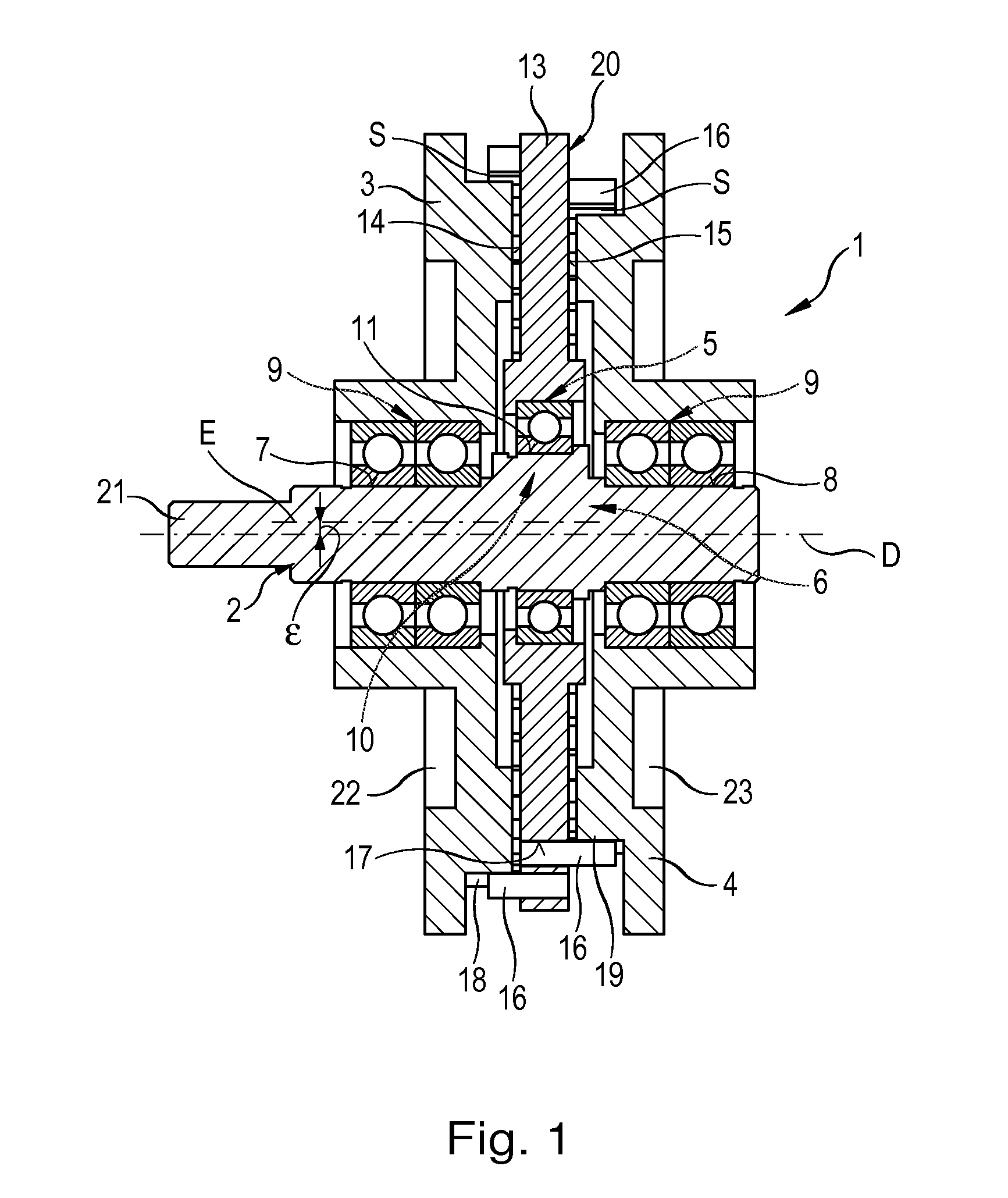

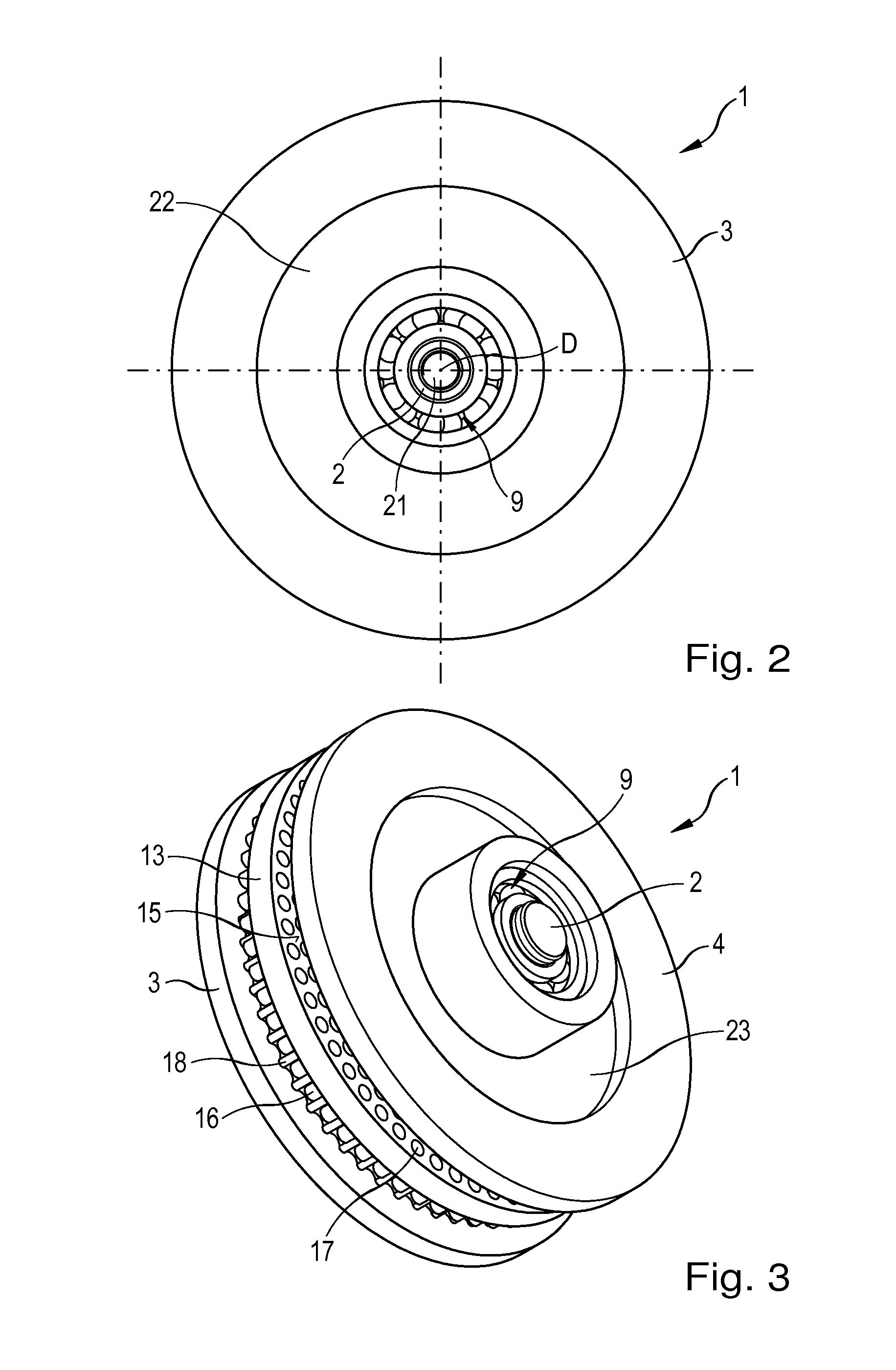

[0030]The sectional view in FIG. 1 shows an embodiment of a transmission device 1 adjustable in the angle of rotation according to the invention with an axis of rotation D that can be used as a cam phaser 24 in an internal combustion engine. The transmission device 1 shown in this sectional view comprises a power take-off shaft 2 of a actuating device 6 positioned along the axis of rotation D, and a drive gear 3 and a output gear 4 which are rotatably mounted on the power take-off shaft 2, as well as a transmitter element 5 enabling engagement in sections with the drive gear 3 and the output gear 4. The power take-off shaft 2 comprises a drive bearing seat 7 and an output bearing seat 8 which are each provided with a double ball bearing 9 on which in turn the drive gear 3 and the output gear 4 are positioned coaxial to the axis of rotation D and mounted rotatably relative to the power take-off shaft 2. An eccentric portion 10 is provided on the power take-off shaft 2 between the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com