High-strength cold-rolled steel sheet, high-strength hot-dip galvanized steel sheet, and high-strength hot-dip galvannealed steel sheet excellent in formability and shape fixability, and methods for manufacturing them

a technology of high strength and cold rolling steel, which is applied in the field of high strength cold rolling steel sheet, and high strength hot rolling steel sheet excellent and can solve the problems of deterioration in formability and shape fixability cannot ensure the properties of steel sheets having high strength, etc., to achieve excellent formability and shape fixability, and is suitable for automobile parts. excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0116]The present invention will be illustrated in further detail with reference to several examples (experimental examples) below. It should be noted, however, that the examples are by no means intended to limit the scope of the invention; that various changes and modifications can naturally be made therein without deviating from the spirit and scope of the invention as described above and below; and all such changes and modifications should be considered to be within the scope of the invention.

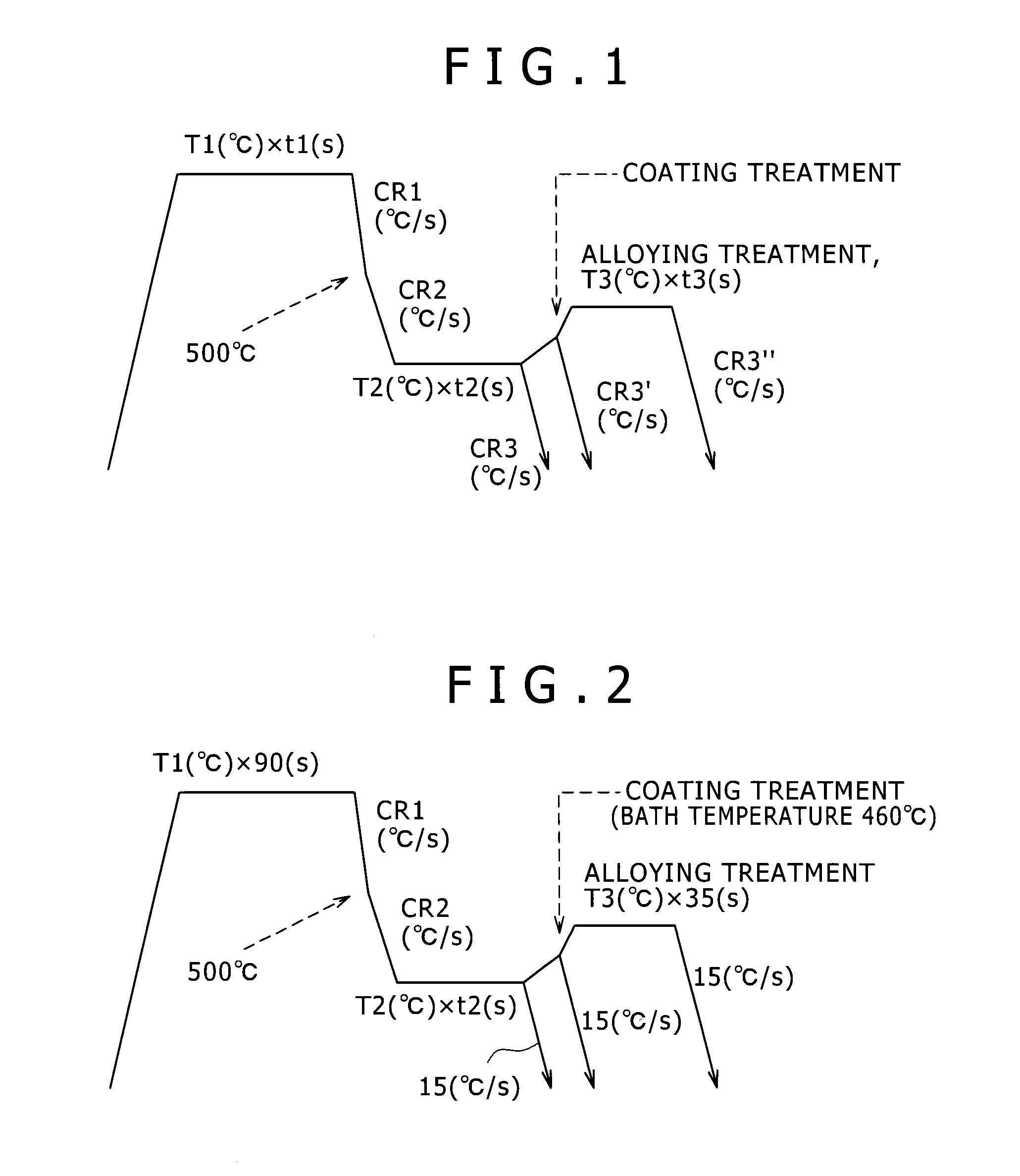

[0117]While simulating an actual machine, steel ingots having chemical compositions given in Table 1 were made by vacuum ingot-making, heated to 1250° C., subjected to hot rolling which was completed at a finish rolling temperature of 880° C., cooled down to a coiling temperature of 600° C., held at that temperature for 30 minutes, cooled by furnace cooling, and thereby yielded hot-rolled steel sheets. The hot-rolled steel sheets were subjected to acid wash to remove surface scales, subjecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com