Shingle with dual sealant

a technology of shingle and sealant, applied in the direction of roofs, building materials handling, construction, etc., can solve the problems of structural instability of the entire roofing system, the risk of occupants in the building, and the cost of repair of structurally unstable roofing systems, so as to achieve greater ease and space-saving packaging, the effect of increasing the strength of the bond or sealan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific example embodiments

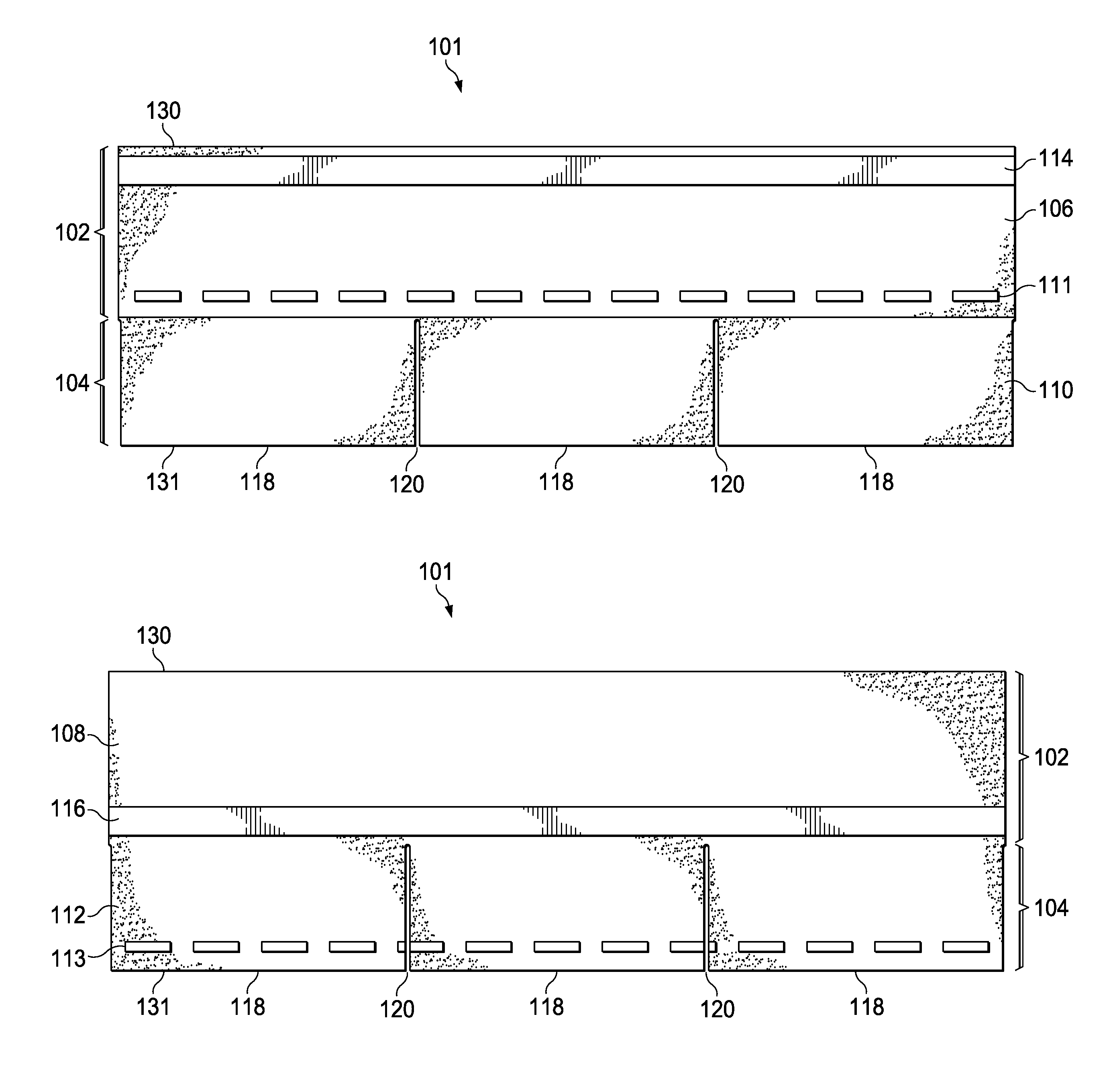

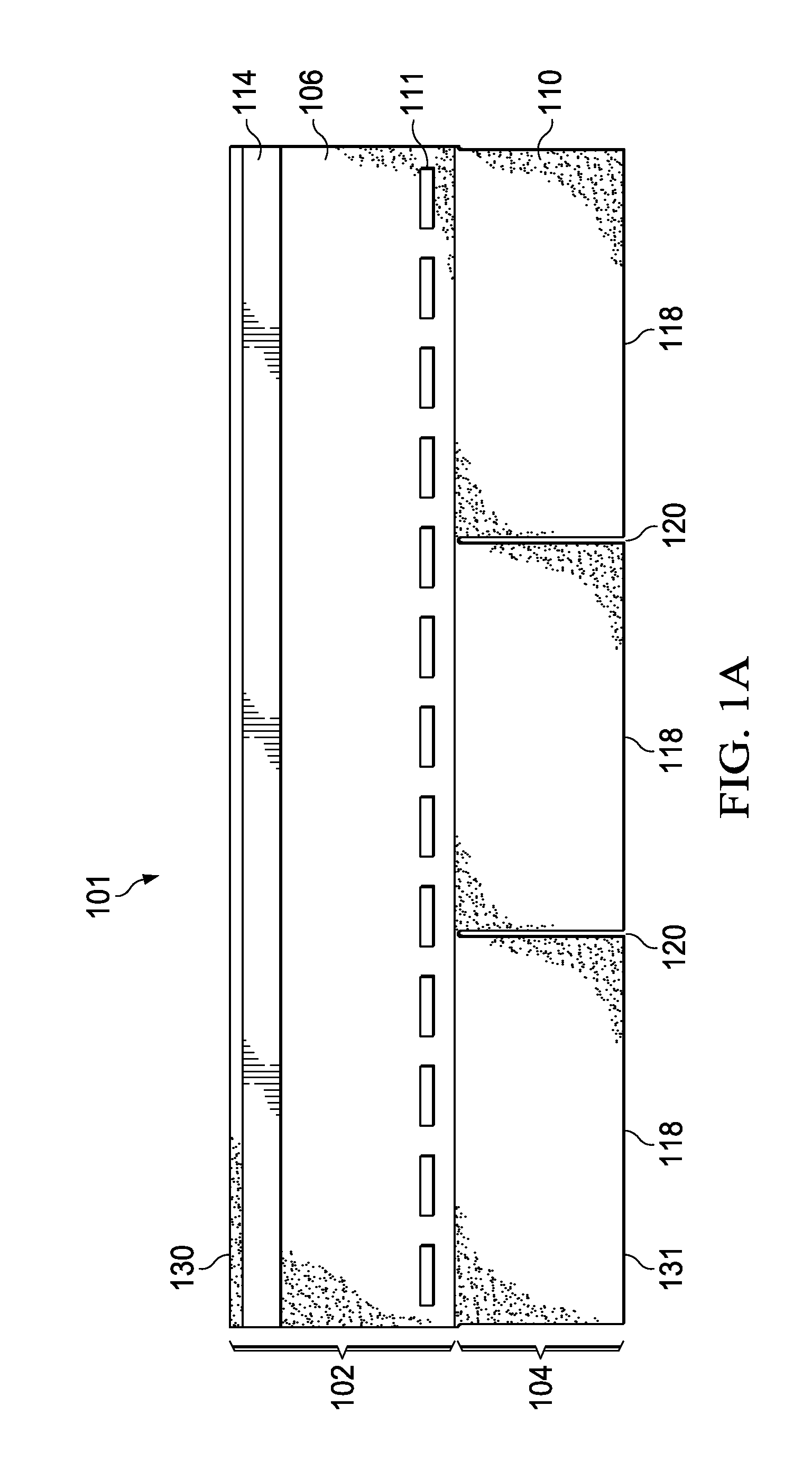

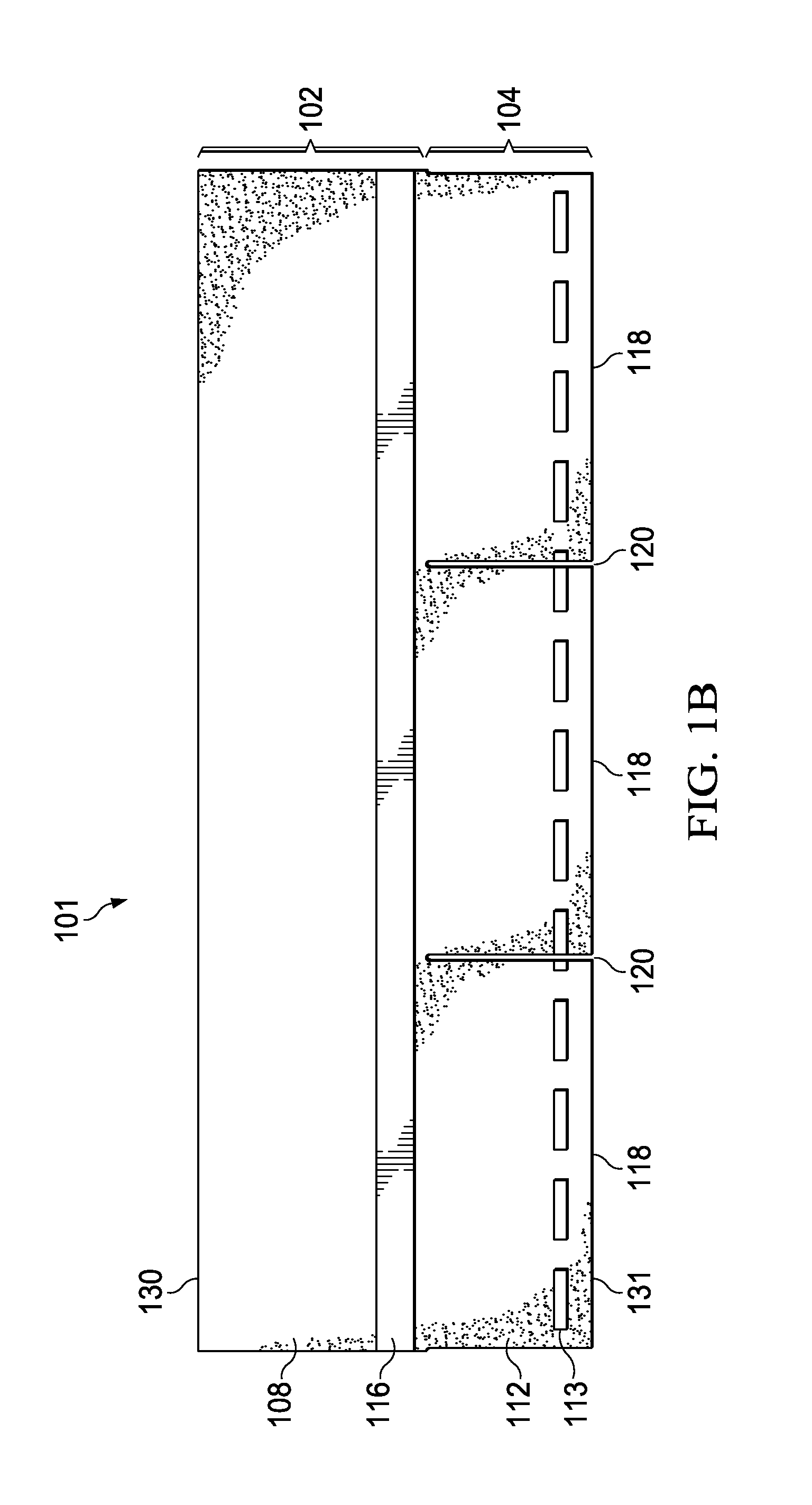

[0057]Specific example embodiments of a shingle with dual sealants are illustrated in FIGS. 1-7. FIG. 1A illustrates a top view of shingle 101 according to an example embodiment of the disclosure. FIG. 1B illustrates a back view of shingle 101 shown in FIG. 1A. Shingle 101 may comprise headlap region 102 and buttlap region 104. Headlap region 102 may comprise top headlap surface 106 and opposite-facing back headlap surface 108. Buttlap region 104 may comprise top buttlap surface 110 and oppositely facing back buttlap surface 112. As seen in FIG. 1A, top headlap surface 106 may include sealant 111 and tape 114. As seen in FIG. 1B, back headlap surface 108 may include tape 116. Back buttlap surface 112 may comprise sealant 113 positioned along the lower edges of tabs 118. As seen in FIG. 1A and FIG. 1B, in some embodiments, sealant 111 and sealant 113 may have substantially stripe-shaped geometries. In some embodiments, sealant 111 and sealant 113 may have the same shape and size.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com