Exhaust muffler for vehicle

a technology for exhaust mufflers and vehicles, which is applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of high cost and difficult manufacture of spark arresters, and achieve the effect of avoiding an excessive increase in the diameter of the exit communication pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

[Overall Structure]

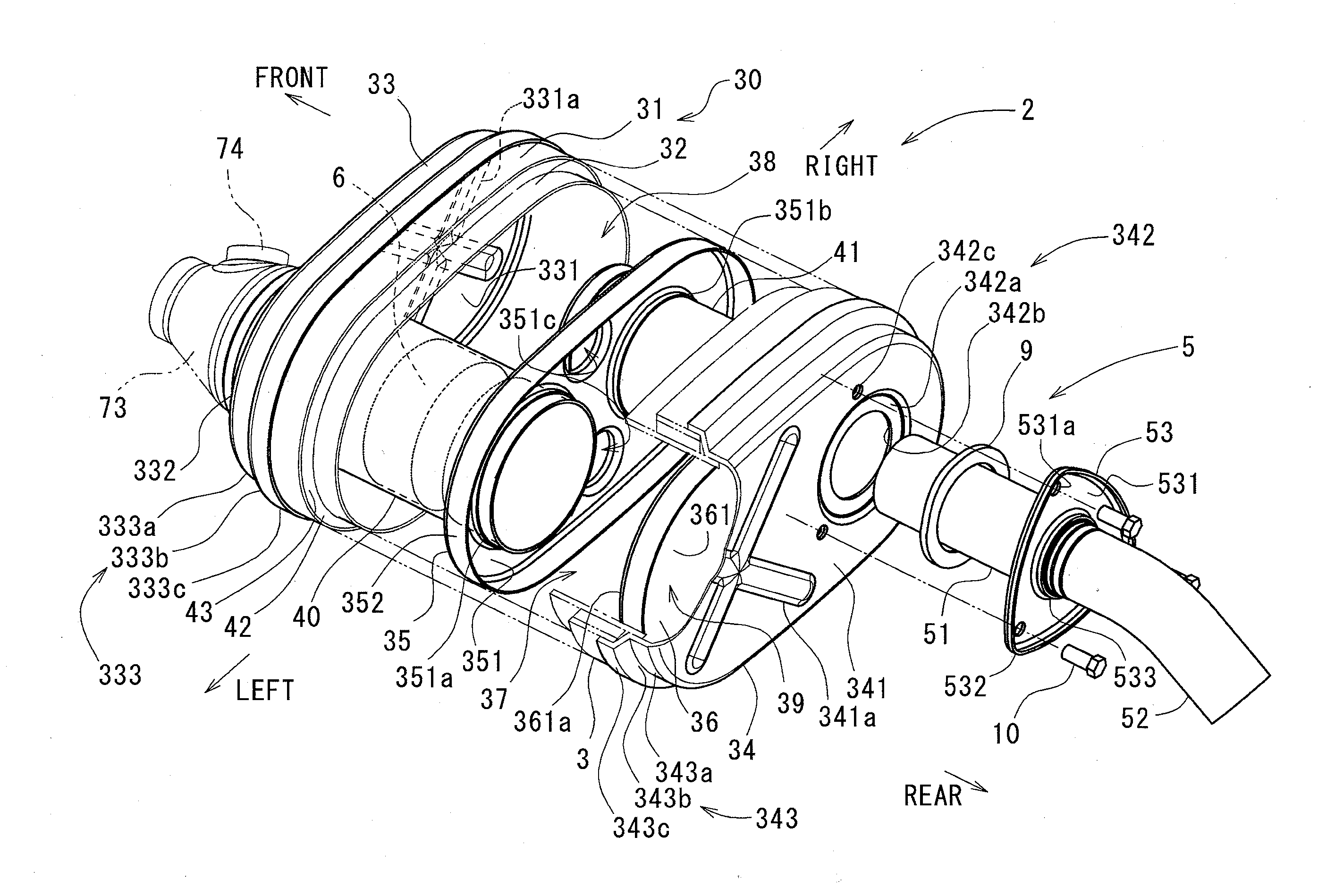

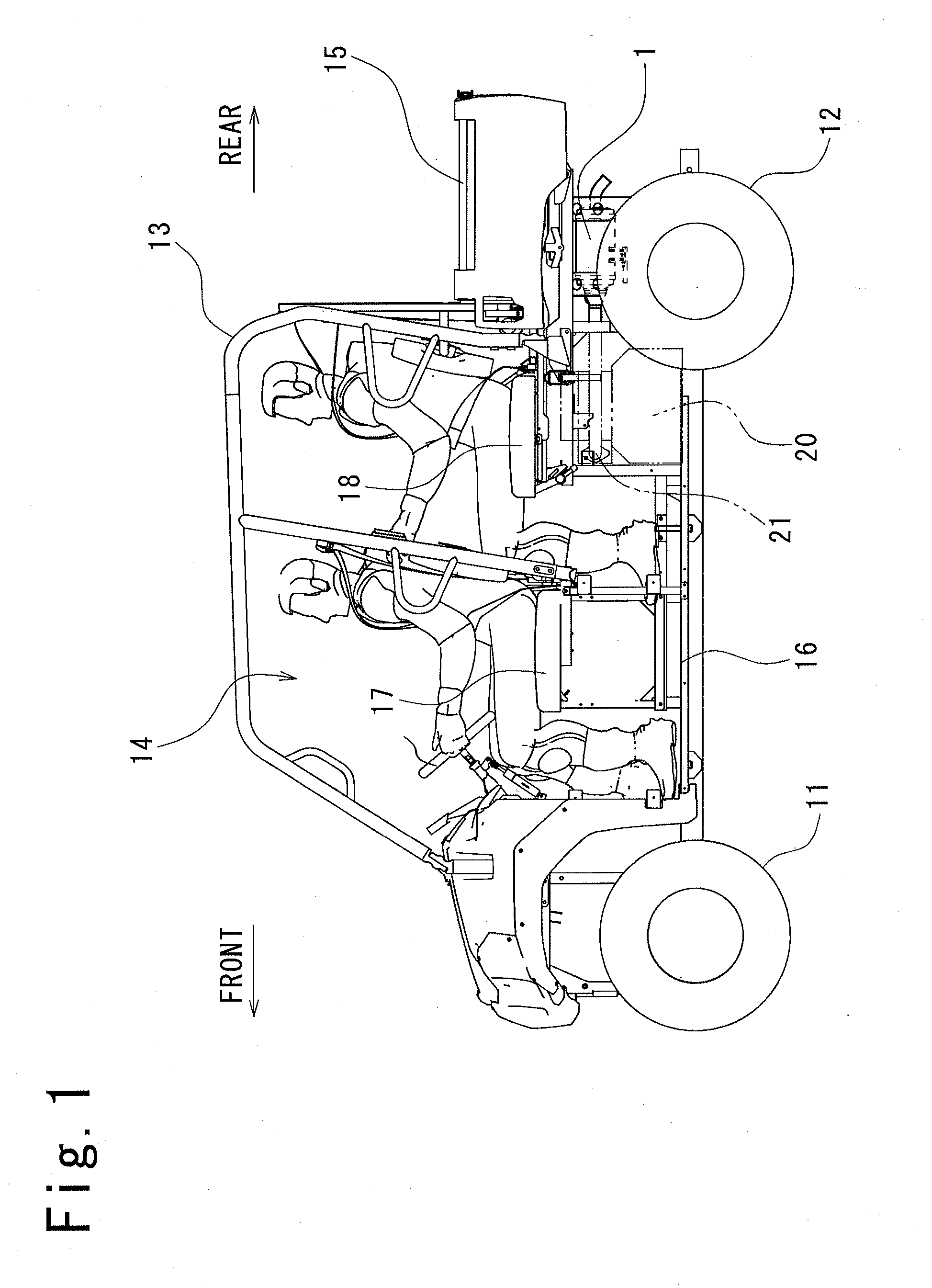

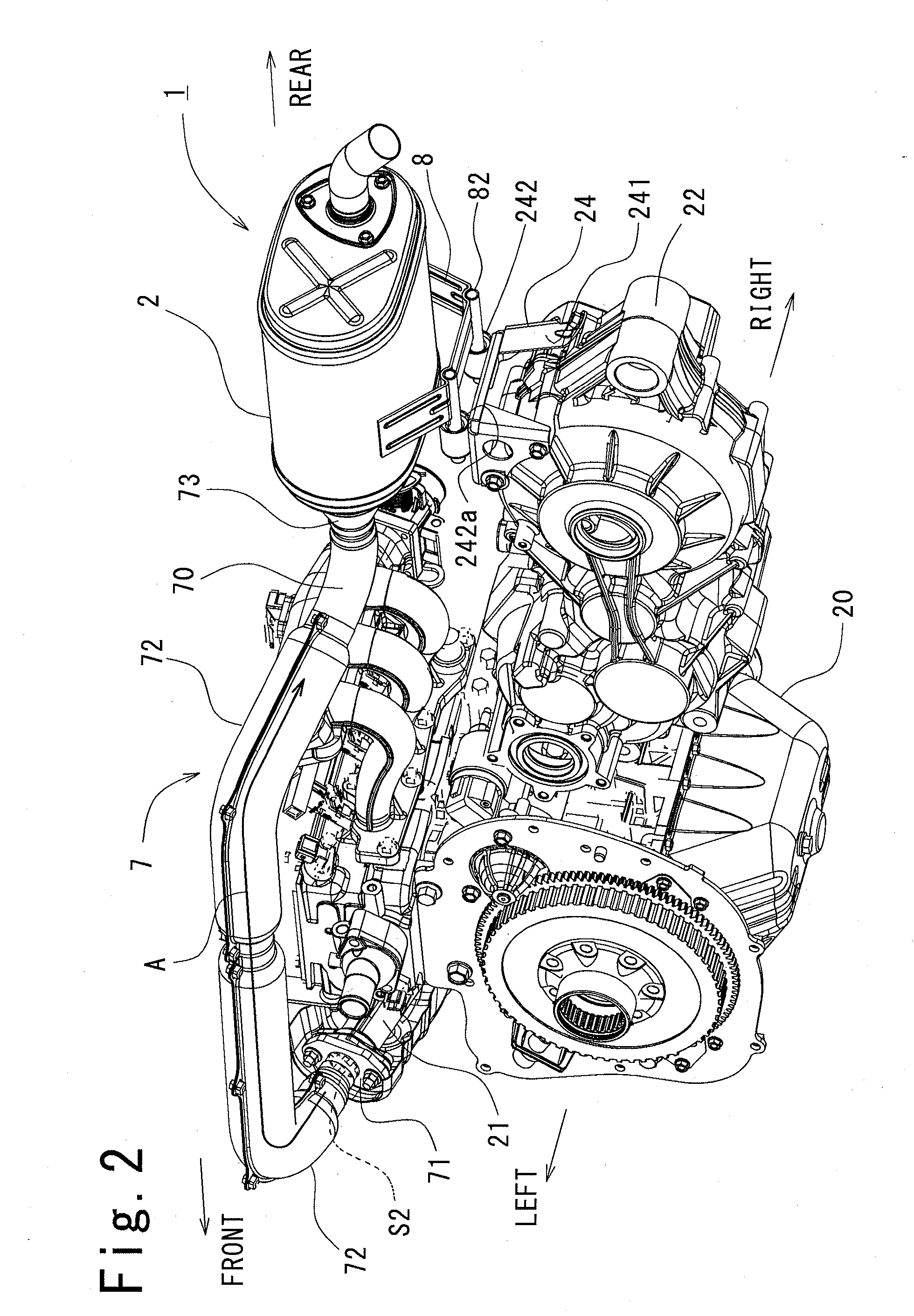

[0030]In the following, with reference to the accompanying drawings, a description will be given of one embodiment of the present invention. Note that, for the sake of convenience in describing, the following description is based on the premise that the front-rear direction of a vehicle is applied to the front-rear direction of the exhaust muffler and other components, and that the right-left direction in connection with the vehicle-width direction (the right and left sides as seen from the rear of the vehicle) as seen from the passengers on the vehicle is applied to the right-left direction of the exhaust muffler and other components.

[0031]FIG. 1 is a left side view of a utility vehicle according to the present embodiment, with shell constituent members such as doors being removed. As shown in FIG. 1, the utility vehicle includes: a right and left pair of front wheels 11 on the front side and a right and left pair of rear wheels 12 on the rear side; a passenger s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com