System and method for implementing intrinsic safety in rotating machine

a technology of intrinsic safety and rotating machines, applied in the field of rotating machinery, can solve the problems of heavy and bulky structures for containment of fragments, catastrophic failure of rotating structures, and rotor thick and bulky, and achieve the effect of preventing any chance of a disk burst and great safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008]The primary object of the embodiments herein relate to a system and method for providing an intrinsic safety to the rotating machines against the failure of high speed rotating structures.

[0009]Another object of the embodiments herein is to provide a method and system for preventing failure of rotating structures.

[0010]These and other objects and advantages of the embodiments herein will become readily apparent from the following detailed description taken in conjunction with the accompanying drawings.

SUMMARY

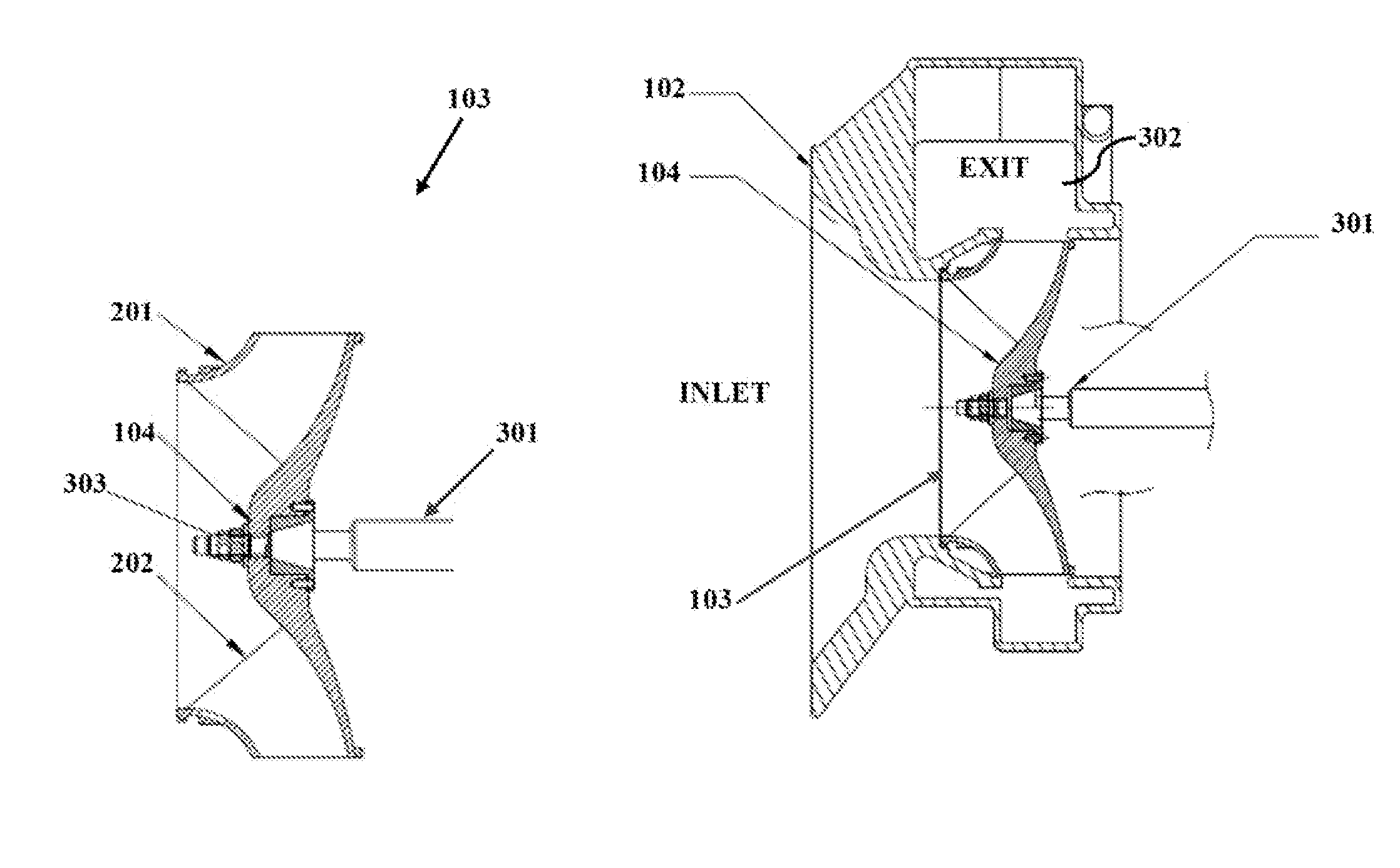

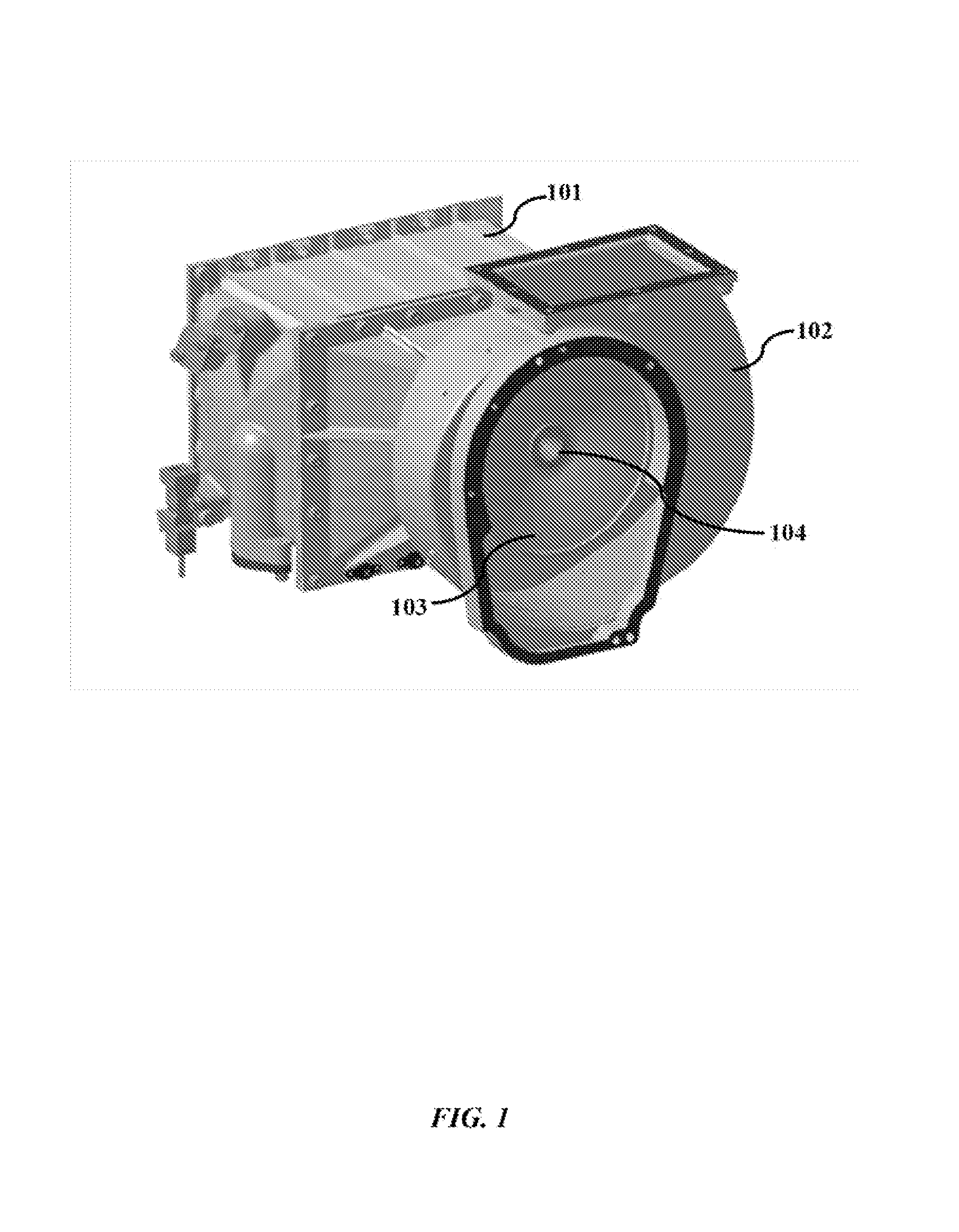

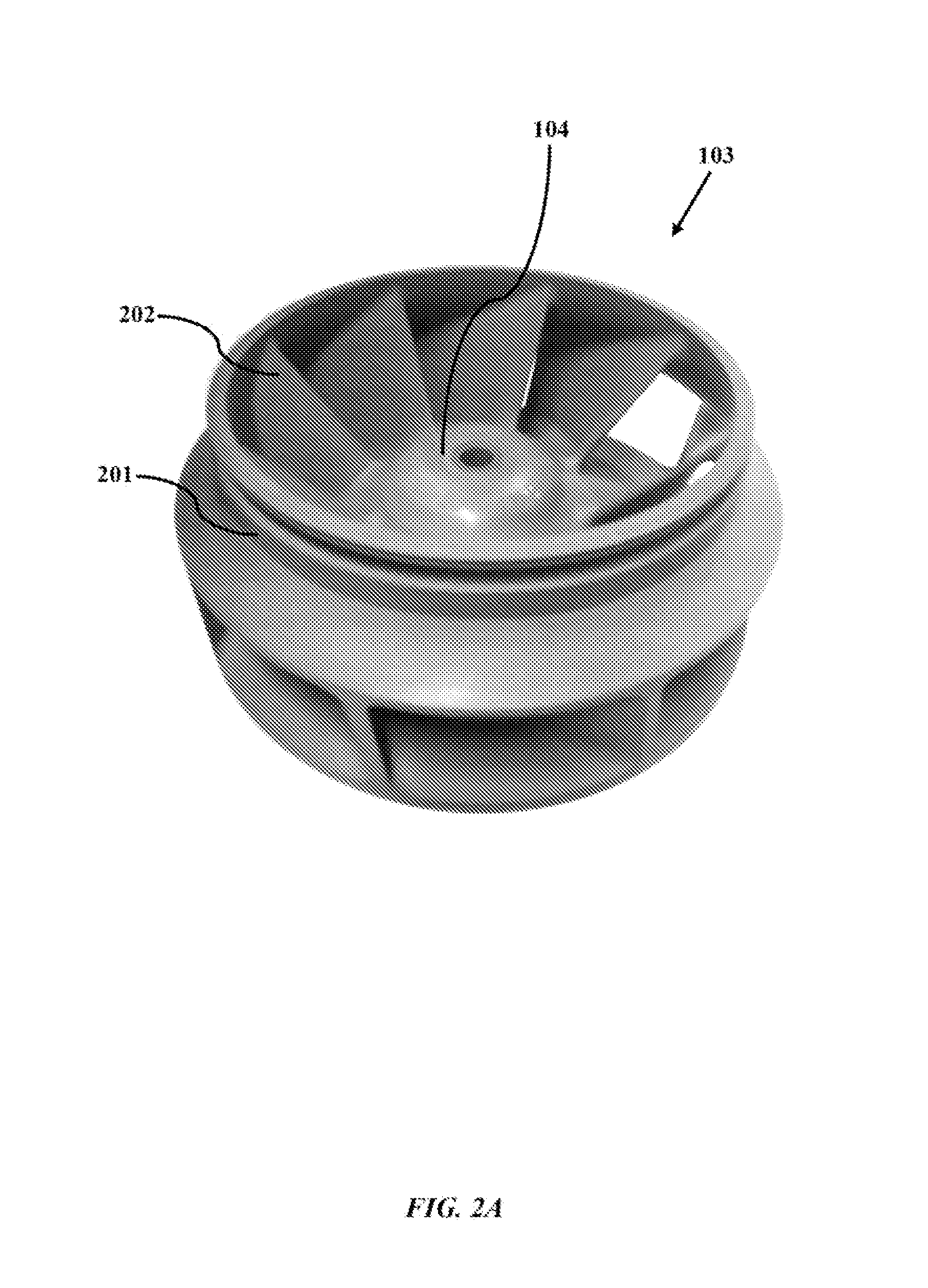

[0011]The various embodiments of the embodiments herein provide a system and method for providing an intrinsic safety to a rotating machinery from the failure of internal high speed rotating structures. The intrinsic safety system for a rotating machine comprises a blower fan which is a rotating structure and a blower casing for holding the blower fan. The blower fan is rotated under the influence of pressure from an incoming fluid. The blower fan further comprises a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com