Hard-Mounted EM Telemetry System for MWD Tool in Bottom Hole Assembly

a telemetry system and tool technology, applied in the field of em telemetry system 40, can solve the problem that components may not be retrievable via wirelin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

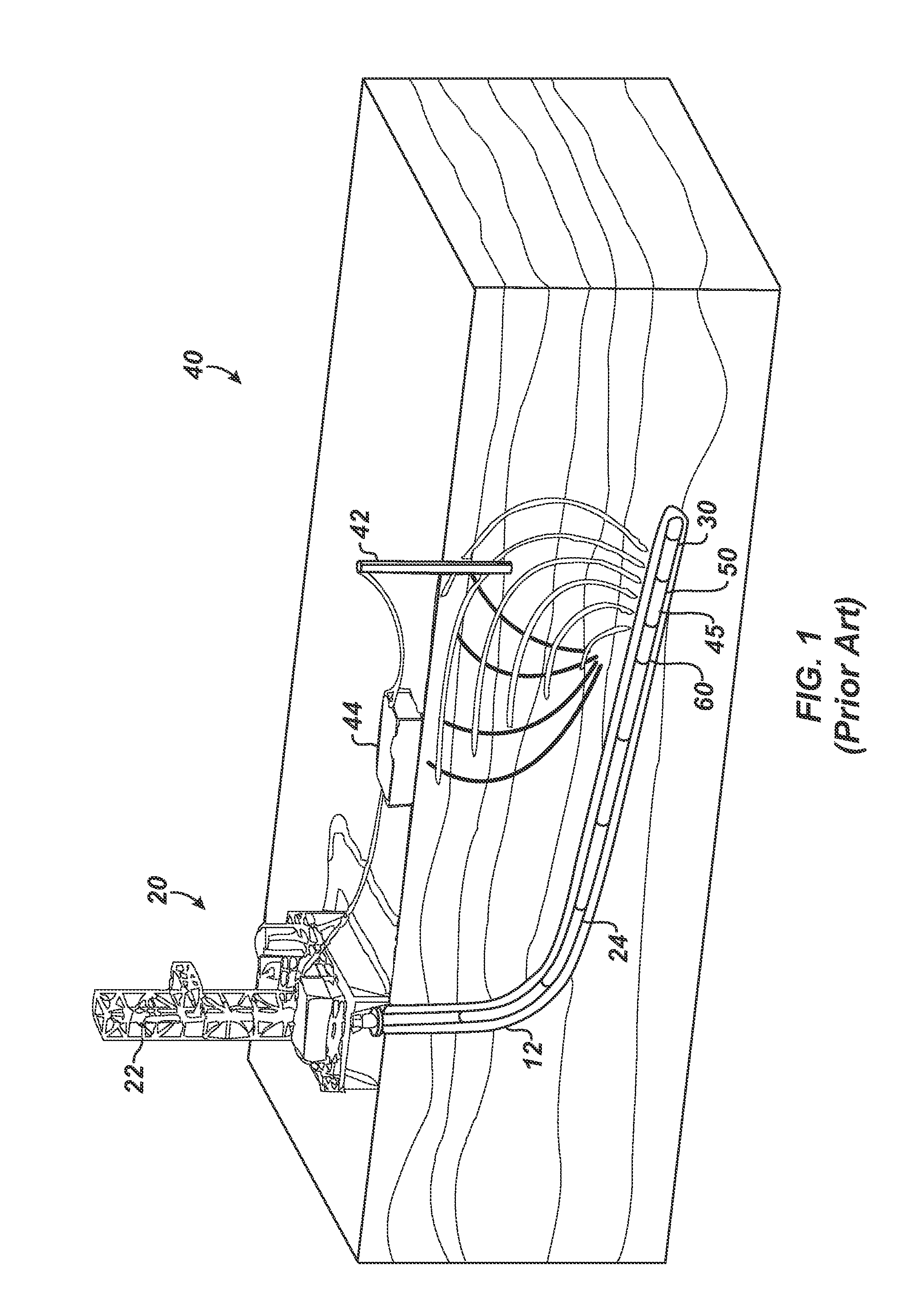

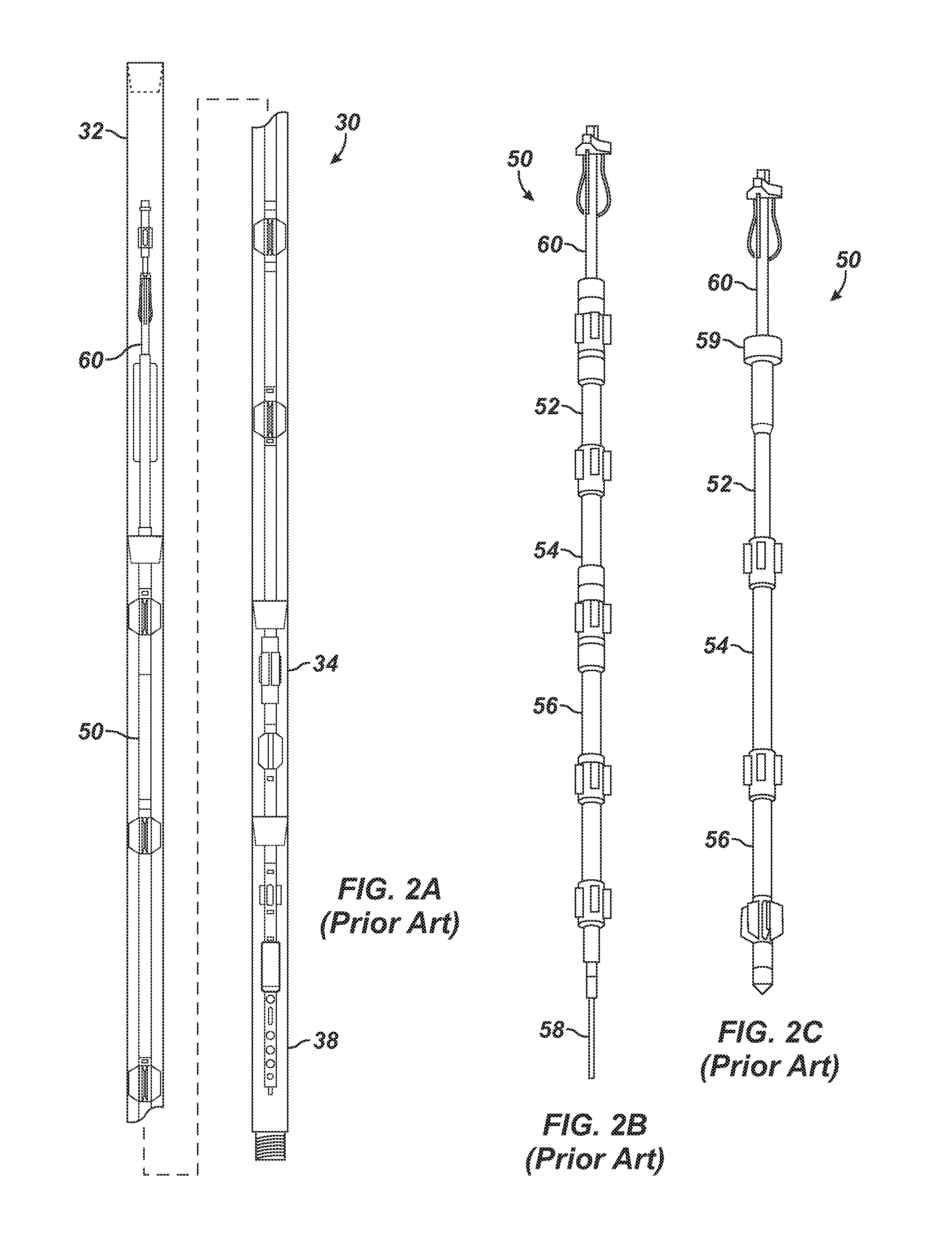

[0041]FIG. 4A illustrates a drilling assembly 100 according to the present disclosure having an air hammer bit 101, a drilling motor 102, an electromagnetic (EM) MWD assembly 104, and a jet sub 108. FIG. 4B schematically illustrates the drilling assembly 100 of FIG. 4A showing an MWD tool 150 and a hard-mounted antenna 170 incorporated into the EM MWD assembly 104.

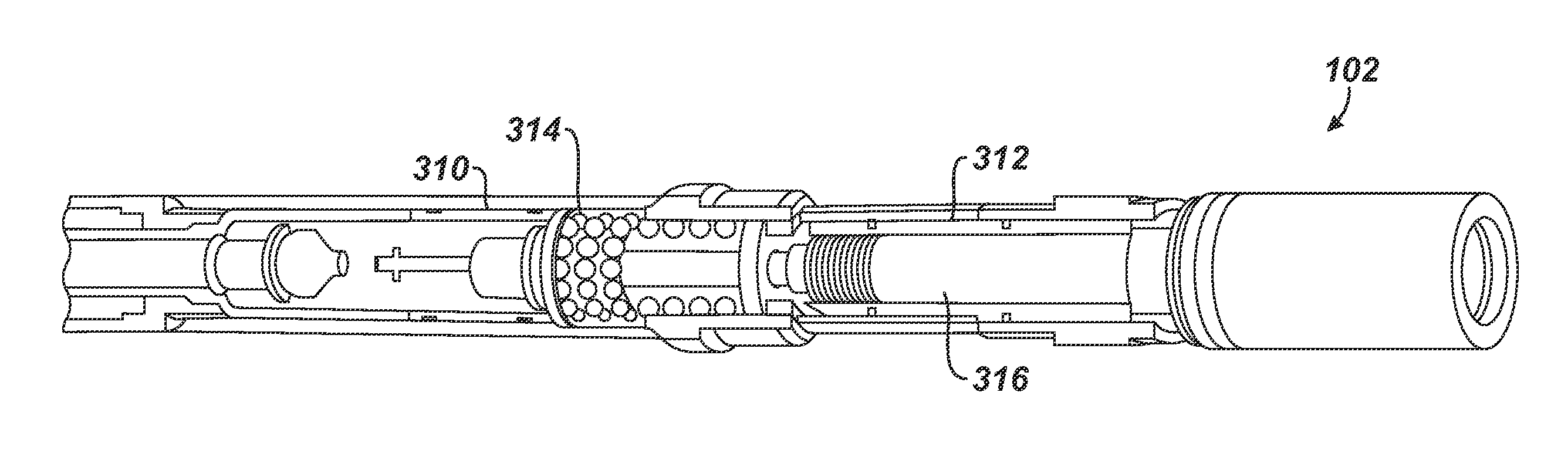

[0042]The air hammer 101 couples to the drilling motor 102 that is adapted for air drilling, and the drilling motor 102 couples with a shock sub 103 to the MWD assembly 104. A non-magnetic pony collar (not shown) may be used to connect the MWD assembly 104 to the shock sub 103. The MWD assembly 104 includes a mule shoe sub 110, such as a universal bottom hole orientation (UBHO) sub for supporting the MWD tool 150. A double pin connector 105 connects a tool carrier 120 to the UBHO sub 110, and an emitter sub 130 is coupled to the tool carrier 120. As best shown in FIG. 4B, the MWD tool 150 is supported in the tool carrier 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com