Fan serial connection structure

a serial connection and fan technology, applied in the direction of axial flow pumps, non-positive displacement fluid engines, pump components, etc., can solve the problems of high heat generation of internal components of electronic products such as computers and laptops, and the inability to change the vibration state of the fan, so as to reduce the noise caused by the vibration of the series fan, the reading efficiency of the hard disk is enhanced, and the co-vibration of the series fan is greatly reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

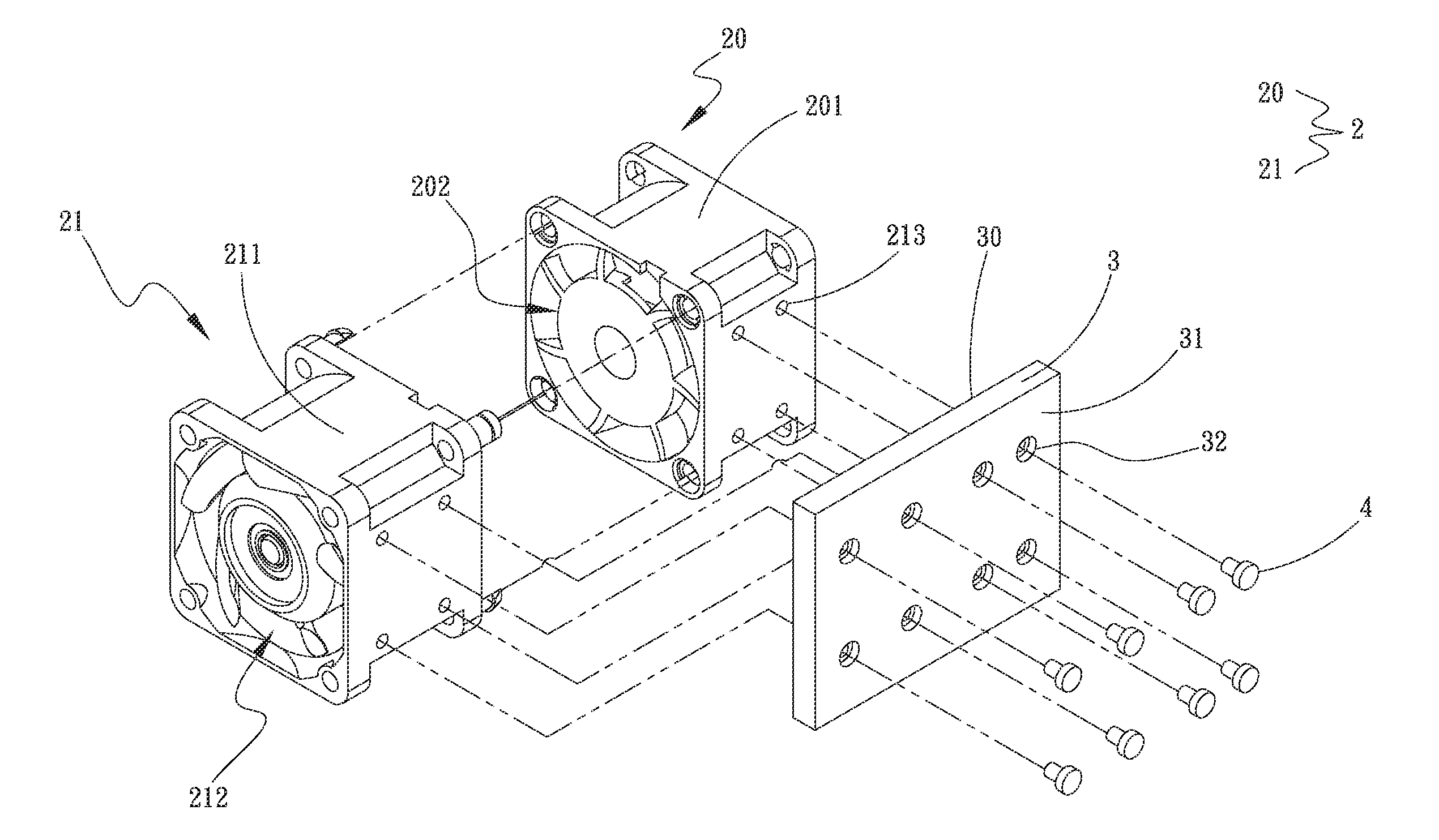

[0035]In this embodiment, the assembling member 5 is disposed between the second and fourth openings 2022, 2122. The first end face 50 is assembled with the second opening 2022, while the second end face 51 is assembled with the fourth opening 2122. The passageway 52 correspondingly communicates with the first and second flow passages 202, 212. In this embodiment, the series fan assembly 2 is assembled with the assembling member 5 by means of engagement. In practice, the first and second fans 20, 21 can be assembled with the first and second end faces 50, 51 by any other means that can securely connect the first and second fans 20, 21 with the first and second end faces 50, 51, for example, by means of slide rail (as shown in FIGS. 4A and 4B, the present invention), locking, insertion, adhesion or latching. This is not limited.

[0036]Please now refer to FIGS. 5A and 5B. FIG. 5A is a perspective exploded view of a fourth embodiment of the fan serial connection structure of the present...

fifth embodiment

[0037]In this embodiment, the series fan assembly 2 is assembled with the assembling members 5 by means of locking. In practice, the first and second fans 20, 21 can be assembled with the first and second end faces 50, 51 by any other means that can securely connect the first and second fans 20, 21 with the first and second end faces 50, 51, for example, by means of slide rail (as shown in FIGS. 6A and 6B, the present invention), engagement, insertion, adhesion or latching. This is not limited.

[0038]According to the above structural design, the connection sections 214 of the series fan assembly 2 are correspondingly assembled with the connection member 3 and the assembling sections 53 of the assembling members 5. Accordingly, the series fan assembly 2 can be more securely connected with the connection member 3 and the assembling members 5. In this case, when the fans operate, the vibration frequencies of the fans are unified to offset or restrain the co-vibration of the series fan s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com