Method and apparatus for determining a need for a change in a pixel density requirement due to changing light conditions

a technology of pixel density and light conditions, applied in the field of camera surveillance, can solve the problems of only valid pixel density requirements and density requirements that may not be enough to ensure legal validity of objects, and achieve the effect of increasing monitoring efforts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

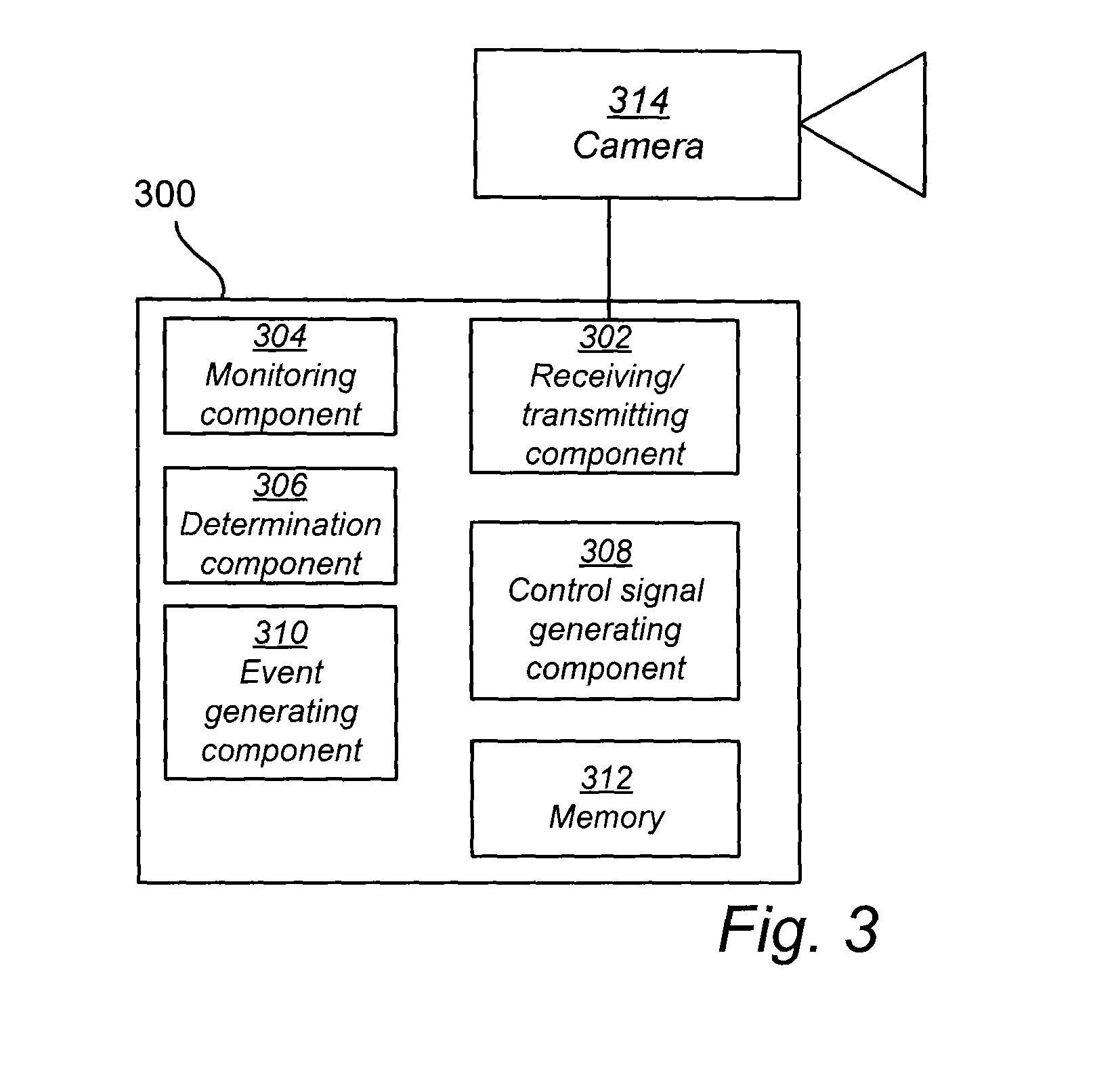

[0045]The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which currently preferred embodiments of the invention are shown. The systems and devices disclosed herein will be described during operation.

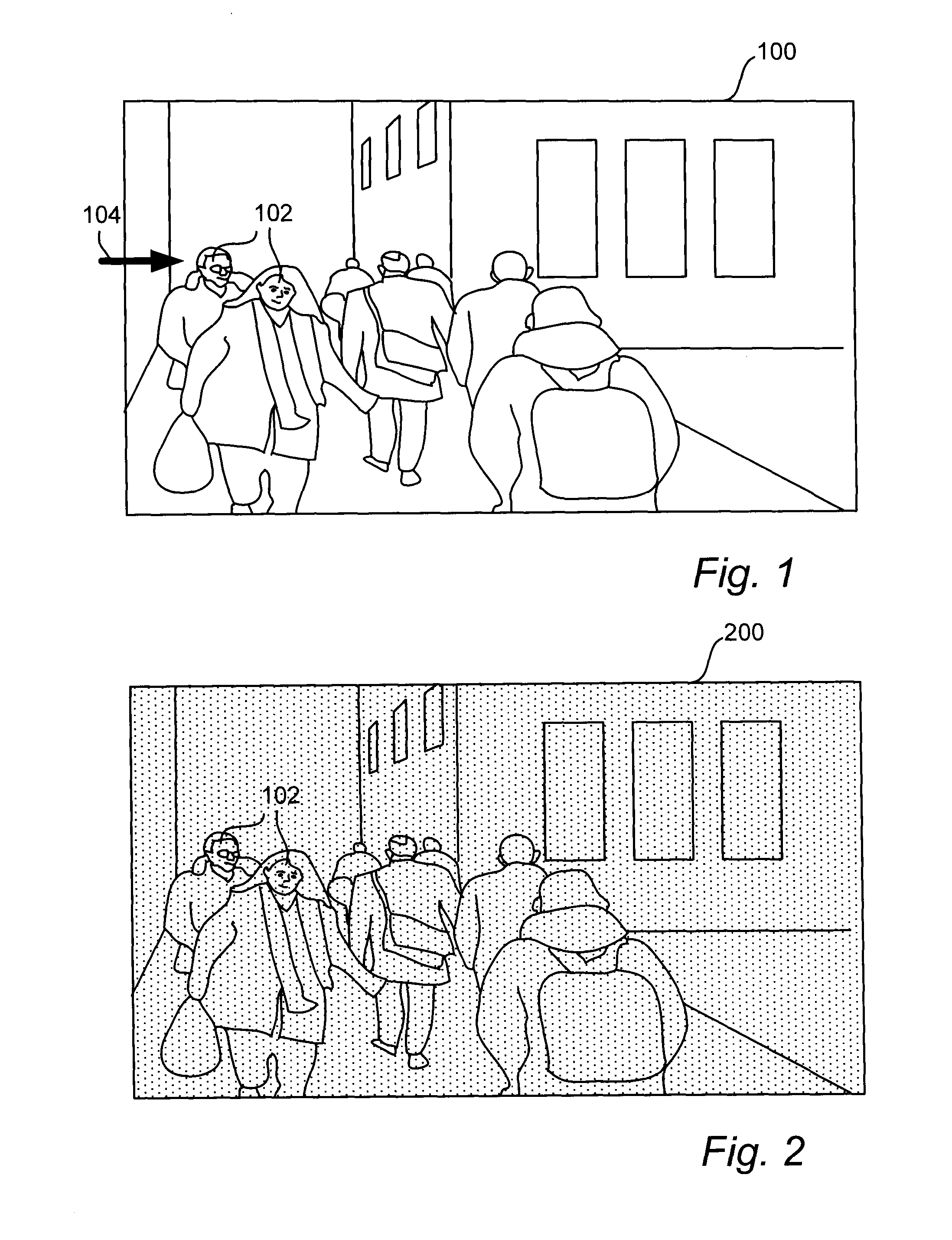

[0046]FIG. 1 illustrates an image 100 of a field of view of a surveillance camera. The image 100 includes objects 102, in this case faces, which potentially need to be identified from images captured by the camera. The image 100 is assumed to be captured during day time when the light condition, i.e. the light level, is optimal or close to optimal, such as at least 100 lx. It is assumed that the gain of the camera is equal to 0 dB under such conditions.

[0047]Under these light conditions, there is a certain pixel density requirement which enables identification of the objects 102 in the image 100. For example, there may be a requirement that a face needs to be captured at 250 pixels / m in order to ensure correct identification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com