Combinative Diamond Jewelry and Making Method Thereof

a diamond and jewelry technology, applied in the field of diamond jewelry making, can solve the problems of increasing the price of diamonds of large size, difficulty for a normal consumer to buy jewelry inlaid with diamonds having weights of more than 1 ct, and gaps between the central diamond and small diamonds, so as to prevent dus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

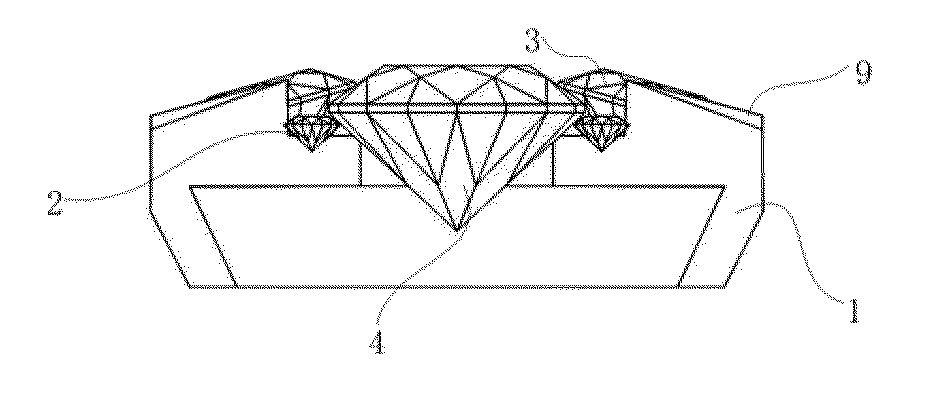

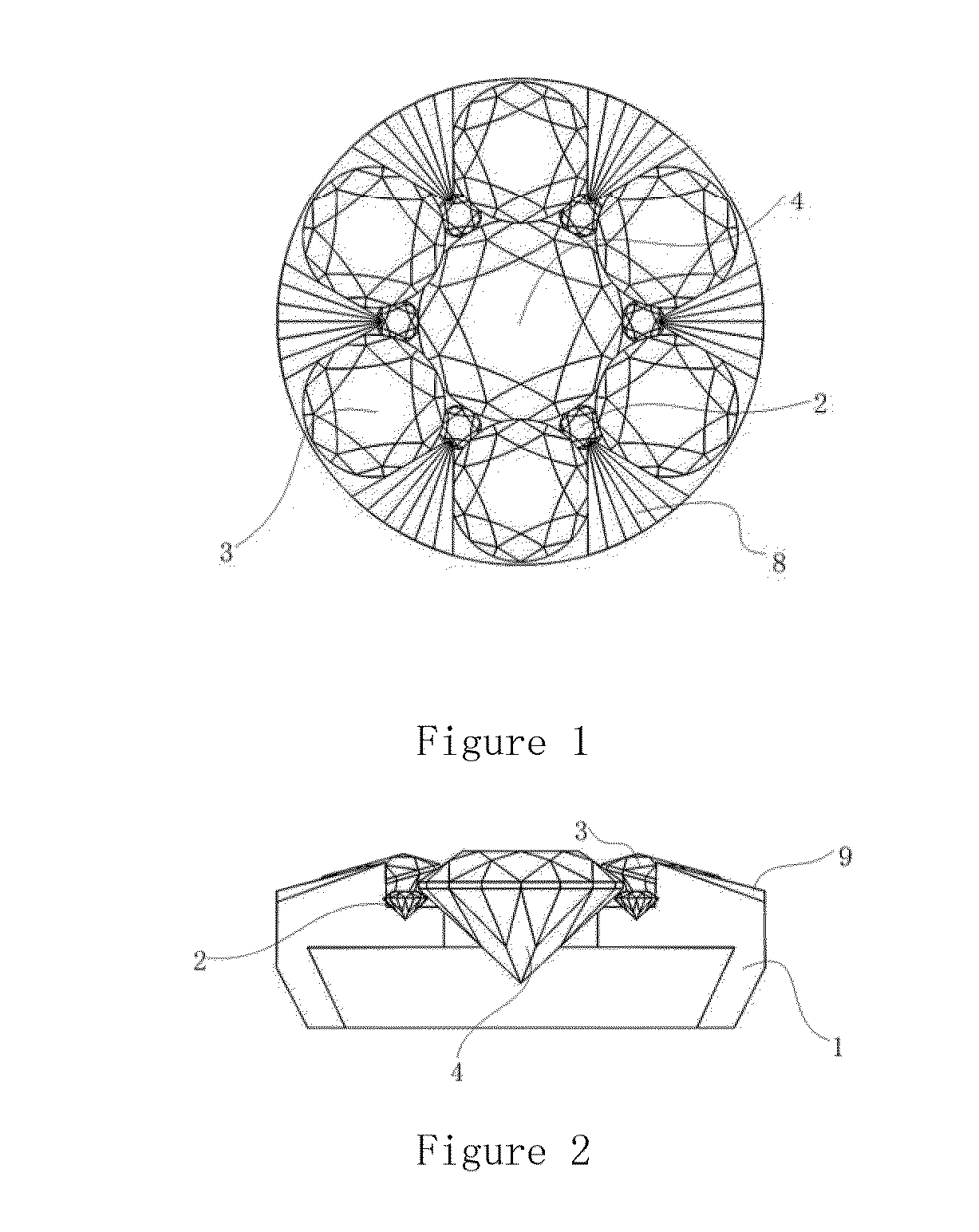

[0051]As shown in FIGS. 1-3, combinative diamond jewelry of the present invention includes a noble metal supporting base 1 of circular cross section. A side surface of the supporting base 1 is machined according to side structure of large sized diamond, thus effectively enhancing shape simulation of large sized true diamond.

[0052]A large inlay opening 7 is defined in a central location of the supporting base 1. Six intermediate inlay openings 61 are evenly defined circumferentially and around the large inlay opening 7. In other words, centers of the six intermediate inlay openings 61 locate on a same circle. In addition, twelve small cylinders 5 are evenly and circumferentially distributed around the large inlay opening 7. Every two small cylinders 5 are categorized as a group and therefore there are totally six groups of small cylinders 5. A metal claw 8 with specific refraction angle is disposed between two adjacent intermediate inlay openings 61. Each metal claw 8 is craved with ...

second embodiment

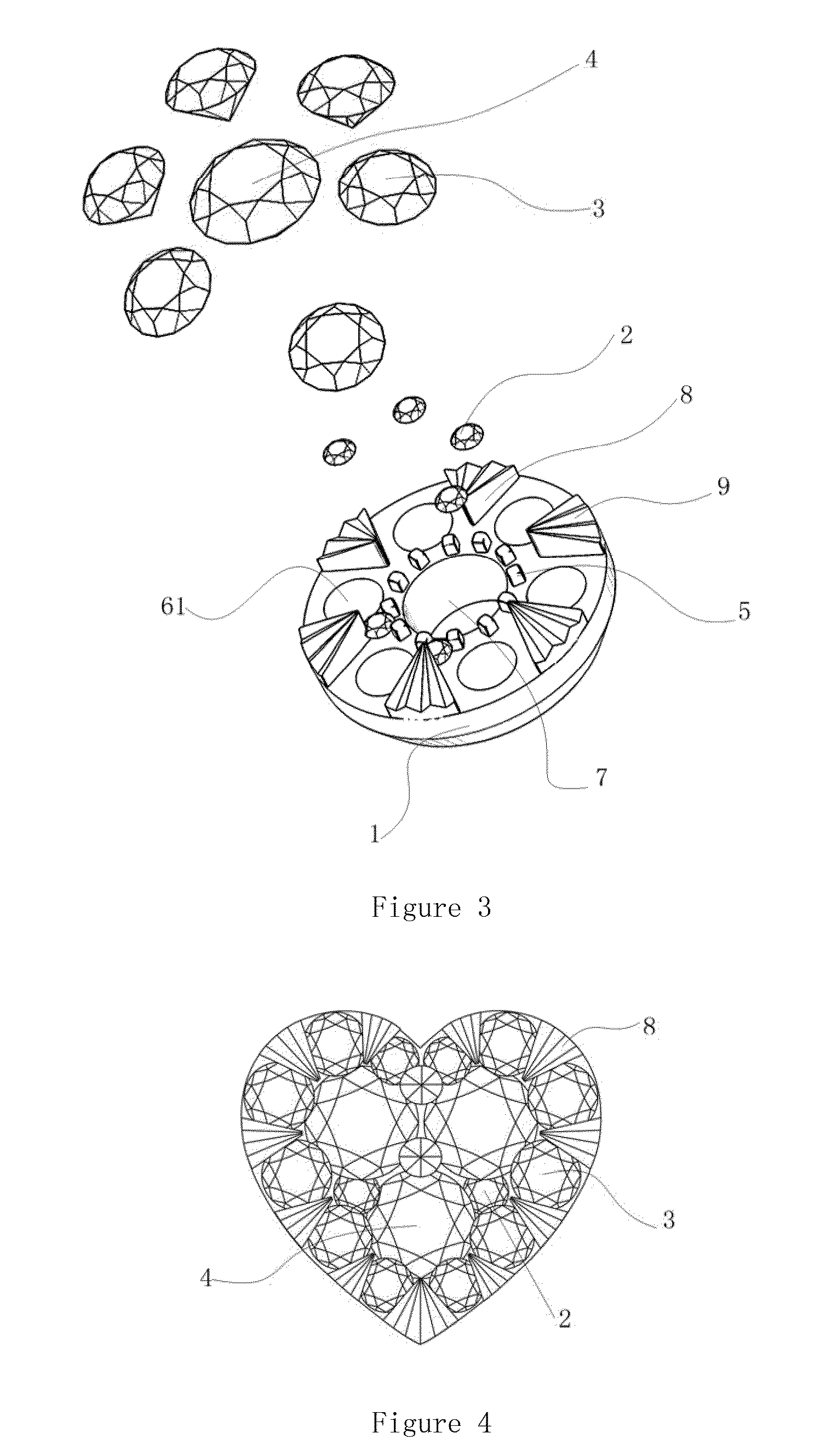

[0060]As shown in FIGS. 4-6, combinative diamond jewelry of the present invention includes a noble metal supporting base 1 of heart cross section. A side surface of the supporting base 1 is machined according to side structure of large sized diamond, thus effectively enhancing shape simulation of large sized true diamond.

[0061]Twelve metal claws 8 are distributed around the supporting base 1. Among these metal claws, two metal claws 8 located on a tip portion of the heart shape are combined to form a unity, and the rest metal claws 8 are uniformly arranged such that an identical angle is defined between two adjacent claws 8. An intermediate inlay opening 61 is disposed between every two adjacent metal claws 8. At half and one fourth locations of a symmetrical line of the supporting base 1 small cylinders 5 are disposed respectively. The height of the small cylinders 5 is identical to that of the metal claws 8. Carvings are formed on the top of each cylinder 5, and the carvings are p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com