Multiple-plate clutch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

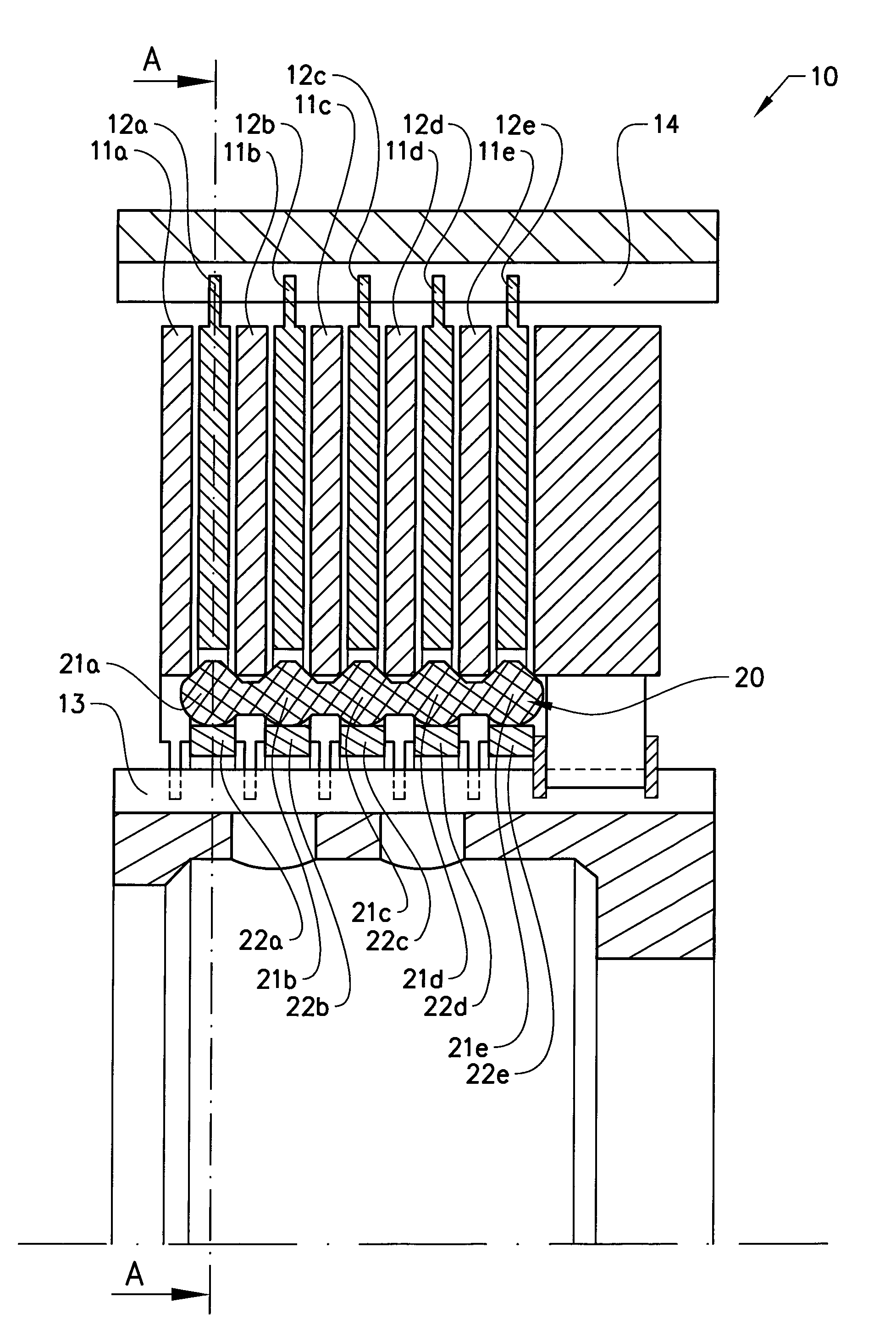

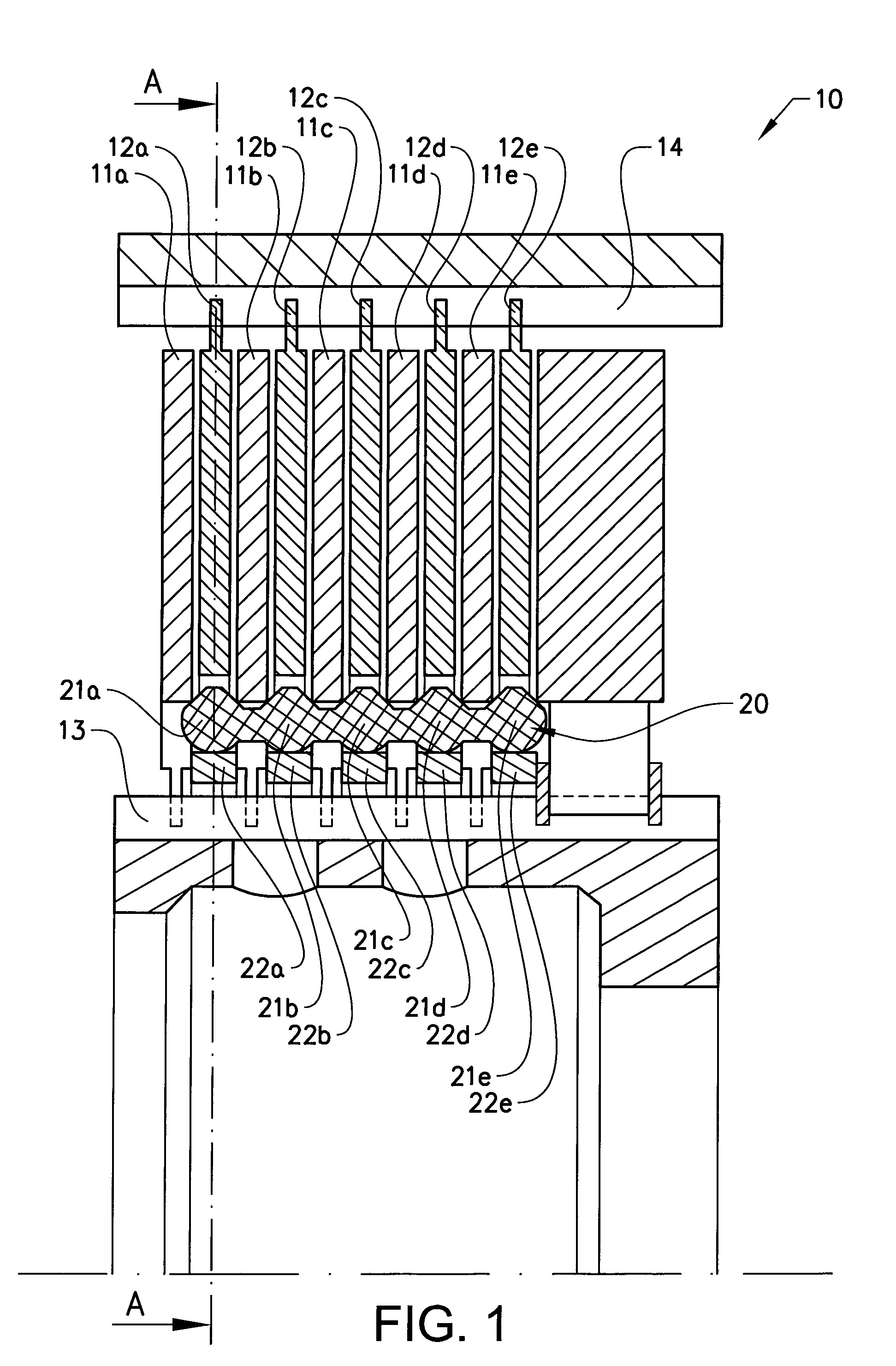

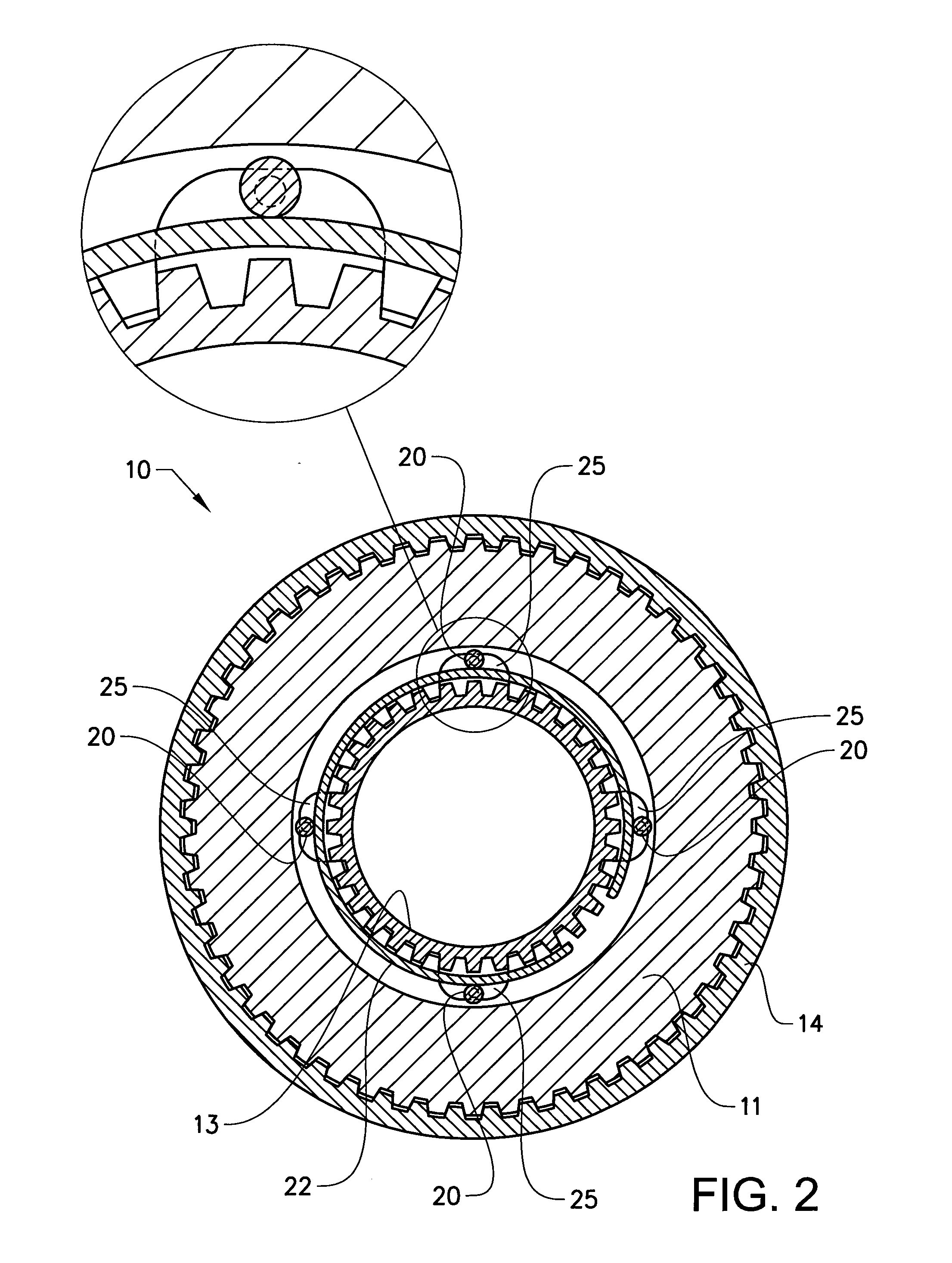

[0041]FIG. 1 discloses a part of a multiple-plate clutch 10, having an inner clutch set 11 provided with a plurality of inner clutch plates 11a, b, c, d, e and an outer clutch set 12 provided with a plurality of outer clutch plates 12a, b, c, d, e. The multiple-plate clutch is provided within a not shown clutch housing. The inner and outer clutch sets 11, 12 are arranged upon an inner and outer plate carrier 13, 14 upon which the clutch plates 11a-e, 12a-e are arranged such that the clutch plates 11a-e, 12a-e are rotationally fixed thereupon and displaceable in axial direction. The general features and functions of a multiple-plate clutch 10 are known and will therefore not be further explained.

[0042]The multiple-plate clutch 10 disclosed in FIG. 1 is provided with a separating means 20, which is provided as an axially extending bar provided with protrusions 21a-e intended to protrude in between the individual inner clutch plates 11a-e. The separating means 20 can also be provided s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com