Flat heat pipe

a heat pipe and flat technology, applied in the field of flat heat pipes, can solve the problems of difficult to ensure the vapor passage is sufficiently strong, the heating site is dried out, and the difficulty of phase changeable working fluid to be circulated, so as to reduce the thermal resistance to transport heat, improve the hydrophilicity of the inner face of the container in the evaporating portion, and spread the working fluid over the inner face smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0029]Hereinafter, preferred examples of the flat heat pipe according to the present invention will be explained in more detail with reference to the accompanying drawings.

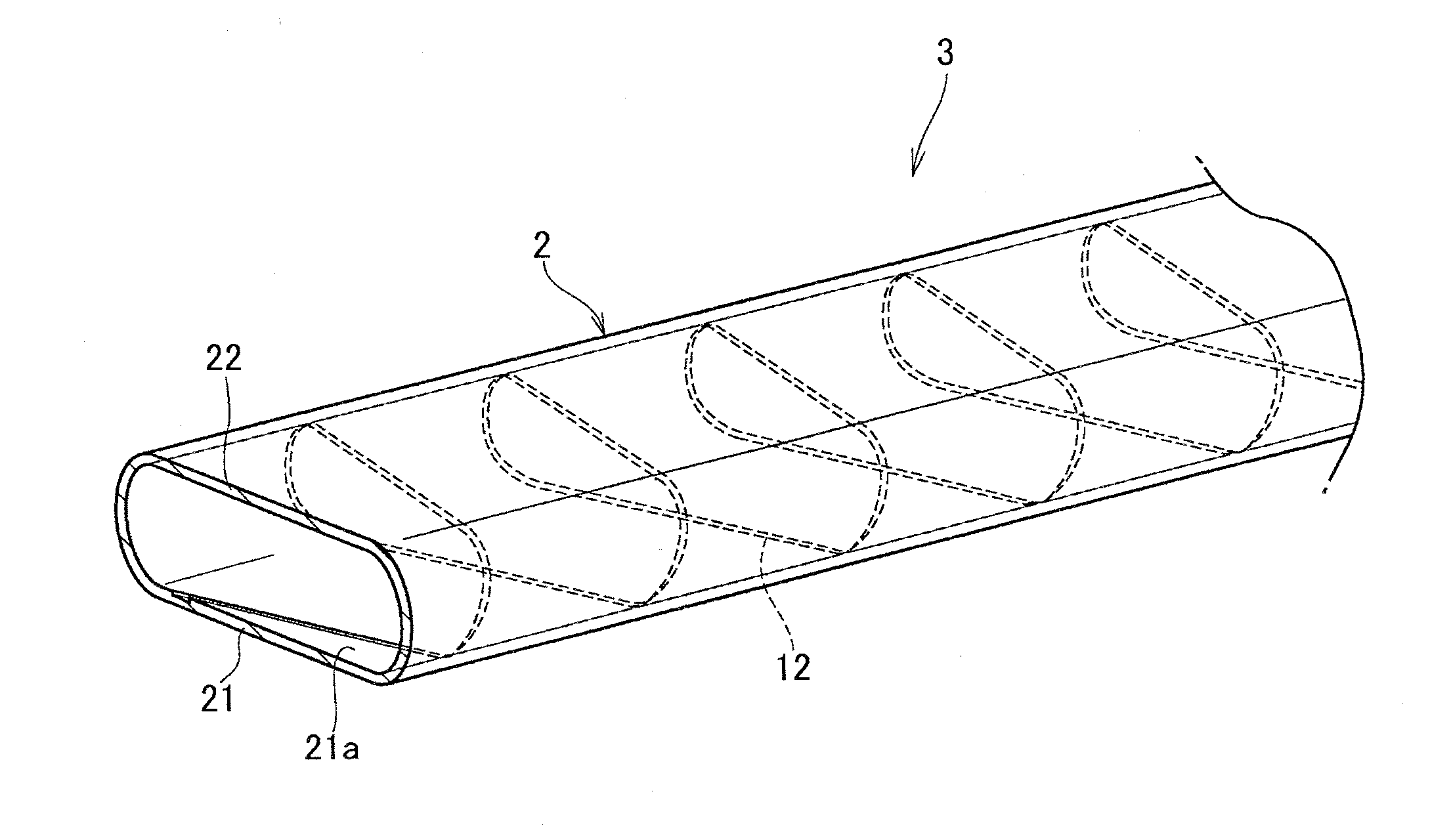

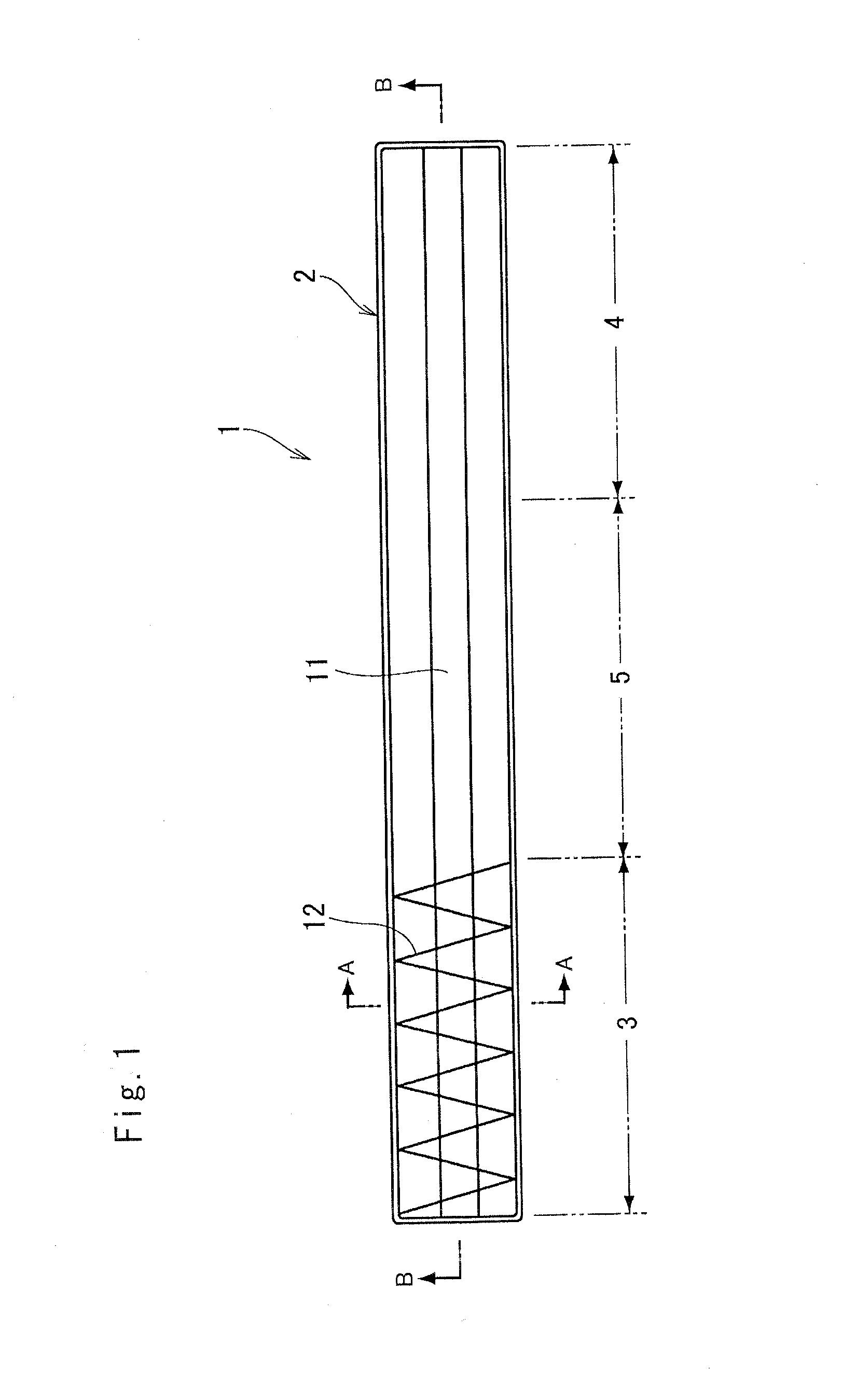

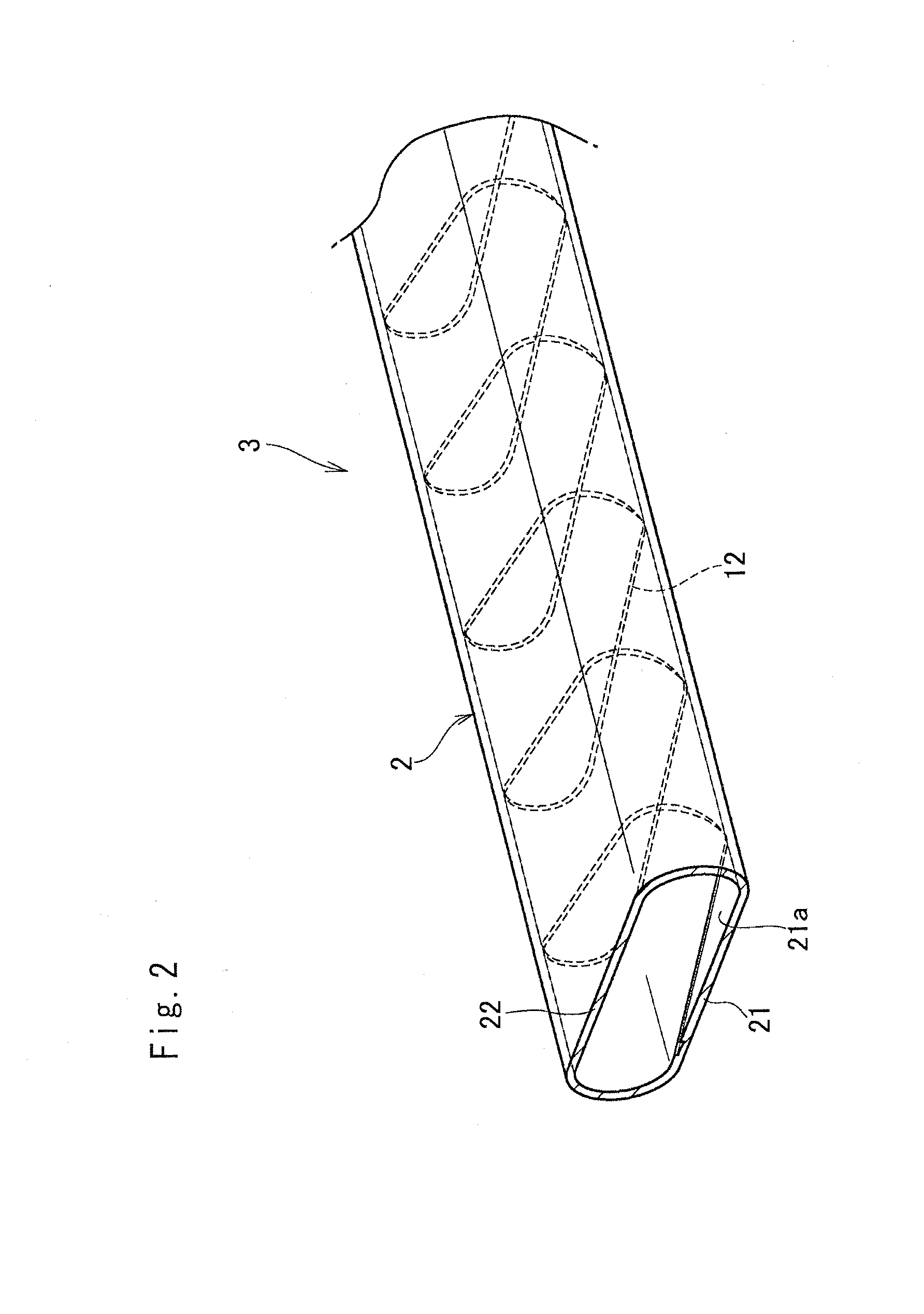

[0030]Referring now to FIG. 1, there is shown a heat pipe 1 according to the preferred example. The heat pipe 1 shown therein is a heat transport device adapted to transport heat in the form of latent heat of phase changeable working fluid encapsulated in a sealed container 2.

[0031]The container 2 is flattened to have flat longitudinal walls, and both ends are closed. In the heat pipe 1, one of the end portions serves as an evaporating portion 3 and the other end serves as a condensing portion 4, and an insulated portion 5 therebetween is insulated from an external heat.

[0032]The evaporating portion 3 is brought into contact to a heat generating element, and the working fluid held therein is heated by a heat of the heat generating element. According to the preferred example, approximately third part of the contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com