Light receiving element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

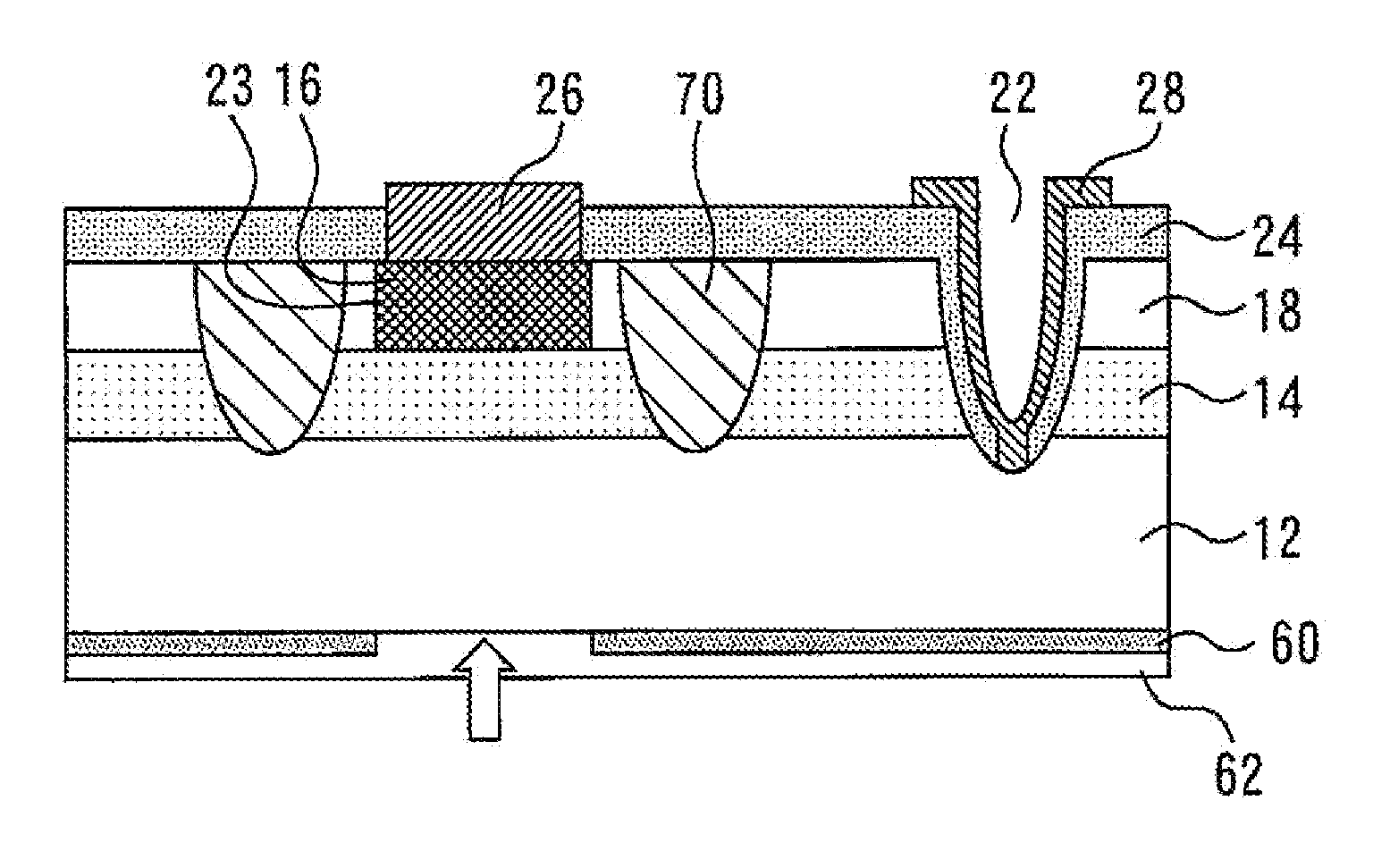

[0017]FIG. 1 is a sectional view of a light receiving element 10 according to a first embodiment of the present invention. The light receiving element 10 has a substrate 12 of a first conduction type. The substrate 12 is, for example, n-type InP. A light absorbing layer 14 of the first conduction type is formed on the substrate 12. The light absorbing layer 14 has a bandgap smaller than that of the substrate 12. The light absorbing layer 14 is, for example, n-type InGaAs.

[0018]A diffusion layer 16 of a second conduction type is formed on a portion of the light absorbing layer 14. The diffusion layer 16 is, for example, p-type InP. A window layer 18 of the first conduction type is formed on the light absorbing layer 14. The window layer 18 is formed so as to surround the diffusion layer 16 as viewed in plan. The window layer 18 has a bandgap larger than that of the light absorbing layer 14. The window layer 18 is, for example, n-type InP.

[0019]Grooves 20 and 22 are formed on the uppe...

second embodiment

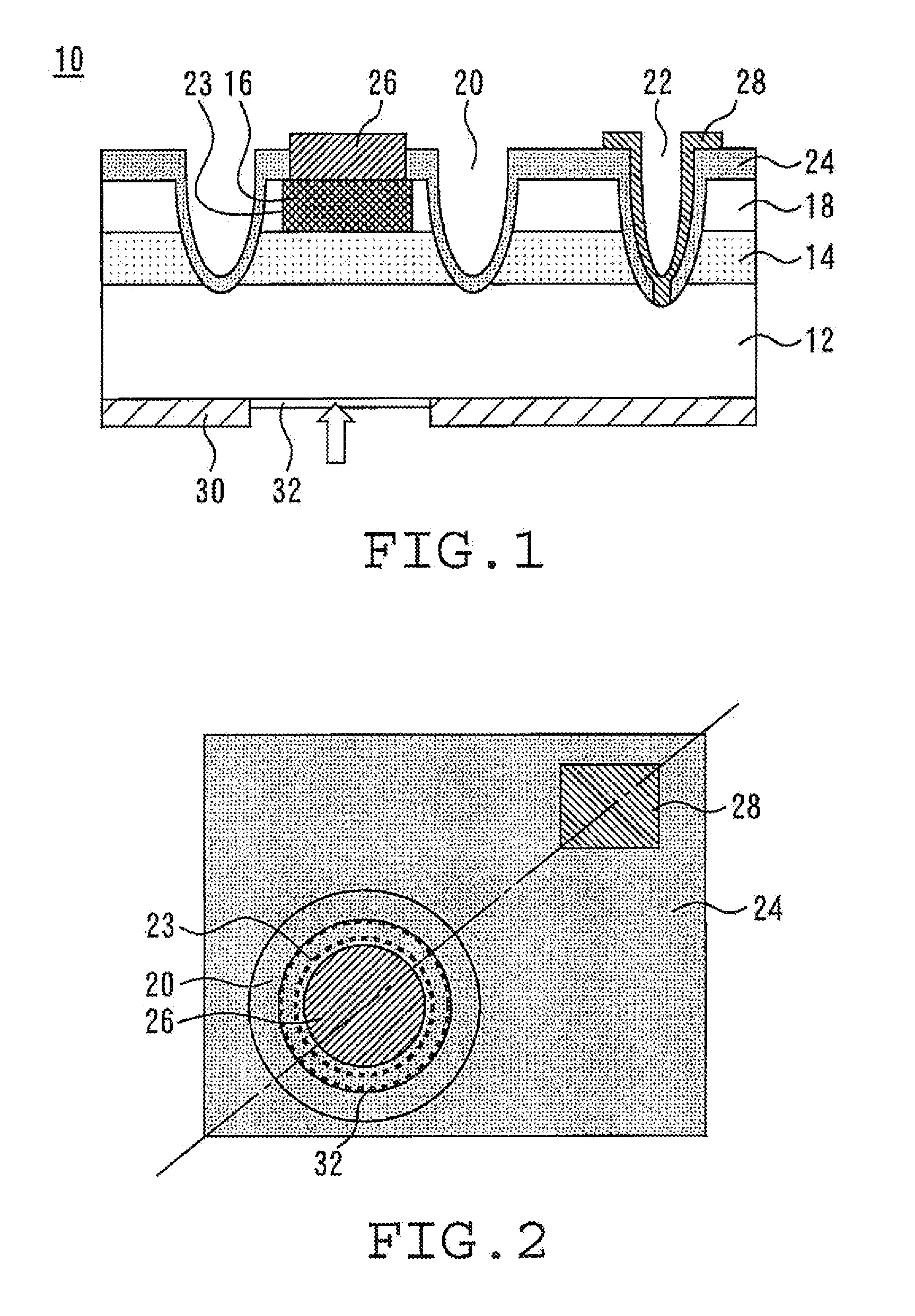

[0032]FIG. 3 is a sectional view of a light receiving element according to a second embodiment of the present invention. A portion of the lower surface of the substrate 12 is covered with an epitaxial layer 60. The material of the epitaxial layer 60 is not particularly limited as long as it is capable of absorbing light. However, the material of the epitaxial layer 60 is, for example, n-type InGaAs. The epitaxial layer 60 has an opening right below the diffusion layer 16. A low-reflection film 62 is formed in this opening.

[0033]The metal mask 30 in the first embodiment reflects light and there is a possibility of the reflected light interfering with the incident light. However, in the second embodiment of the present invention, such reflection of light can be prevented since the epitaxial layer 60 capable of absorbing light is formed.

third embodiment

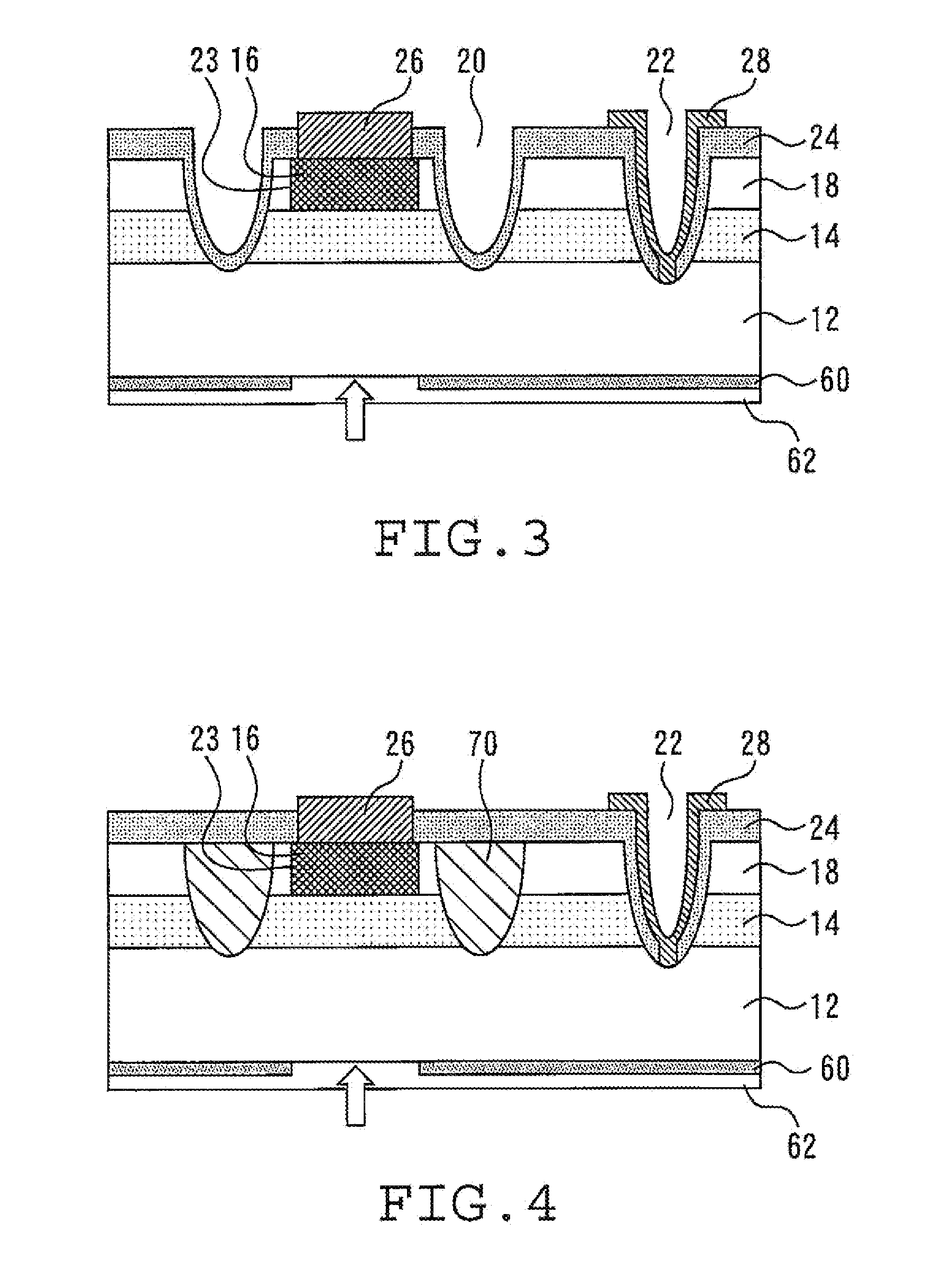

[0034]FIG. 4 is a sectional view of a light receiving element according to a third embodiment of the present invention. This light receiving element is provided with an ion-implanted portion 70 formed, for example, by implantation with Ti and the like. The ion-implanted portion 70 surrounds the boundary between the diffusion layer 16 and the window layer 18 as viewed in plan, and extends through the window layer 18 and the light absorbing layer 14 as viewed in section. When light enters the ion-implanted portion 70, no carriers are generated. Also, the ion-implanted portion 70 shuts off the flow of carriers. FIG. 5 is a plan view of the light receiving element shown in FIG. 4. The ion-implanted portion 70 indicated by a broken line surrounds the boundary 23 between the diffusion layer and the window layer as viewed in plan.

[0035]The ion-implanted portion 70 has the same function as that of the groove 20 in the first embodiment. In addition, the ion-implanted portion 70, can easily b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com