Bullet and method for expanding a bullet

a technology of expanding bullets and bullets, which is applied in the field of bullets, can solve the problems of significant drawbacks of the use of prior-art bullets, increased trauma generated by high flying velocity of bullets, and unpredictable direction of travel and very small penetration, etc., and achieves short displacement time of tissue mass, low advancing resistance, and high penetration of bullets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

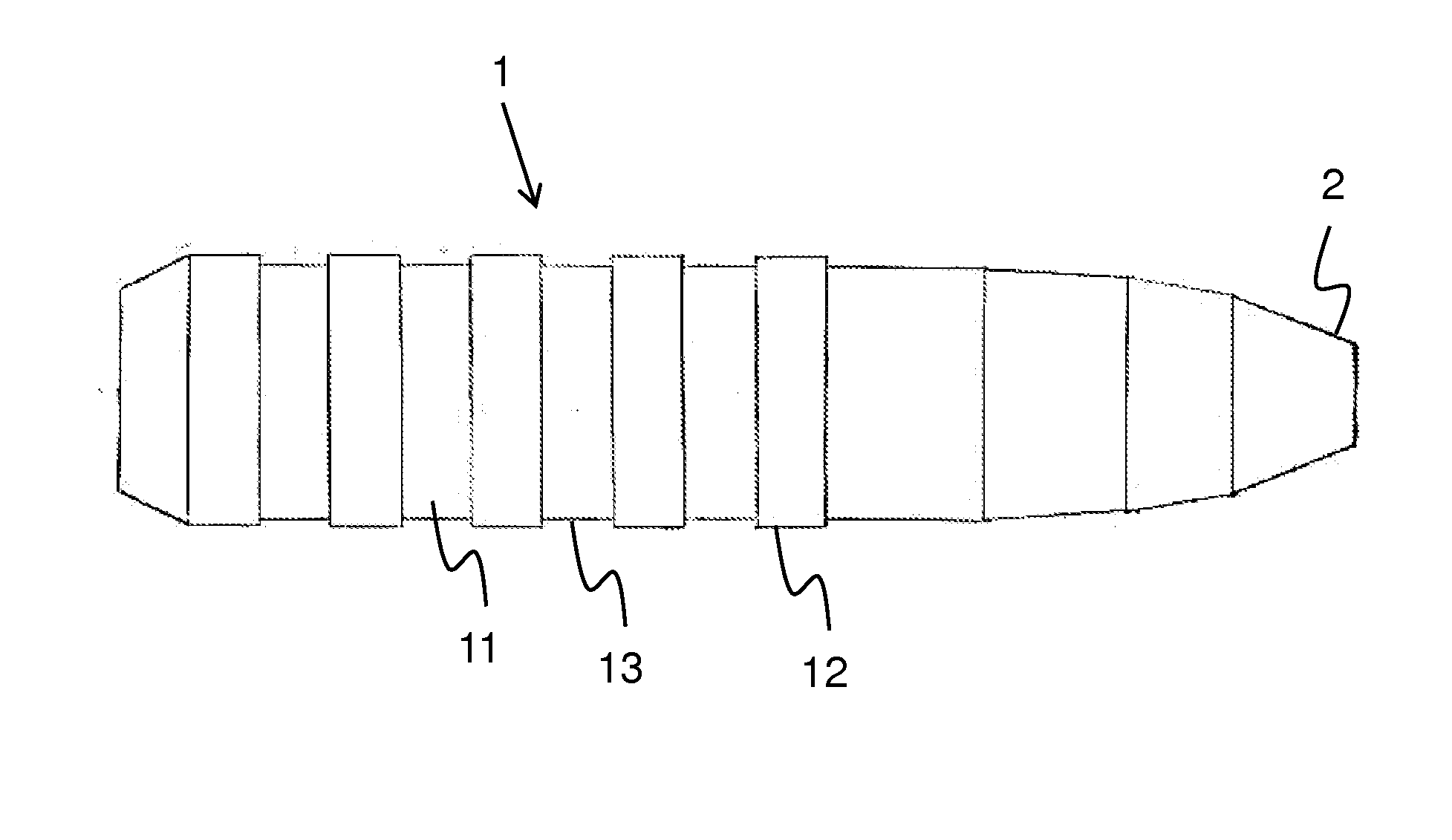

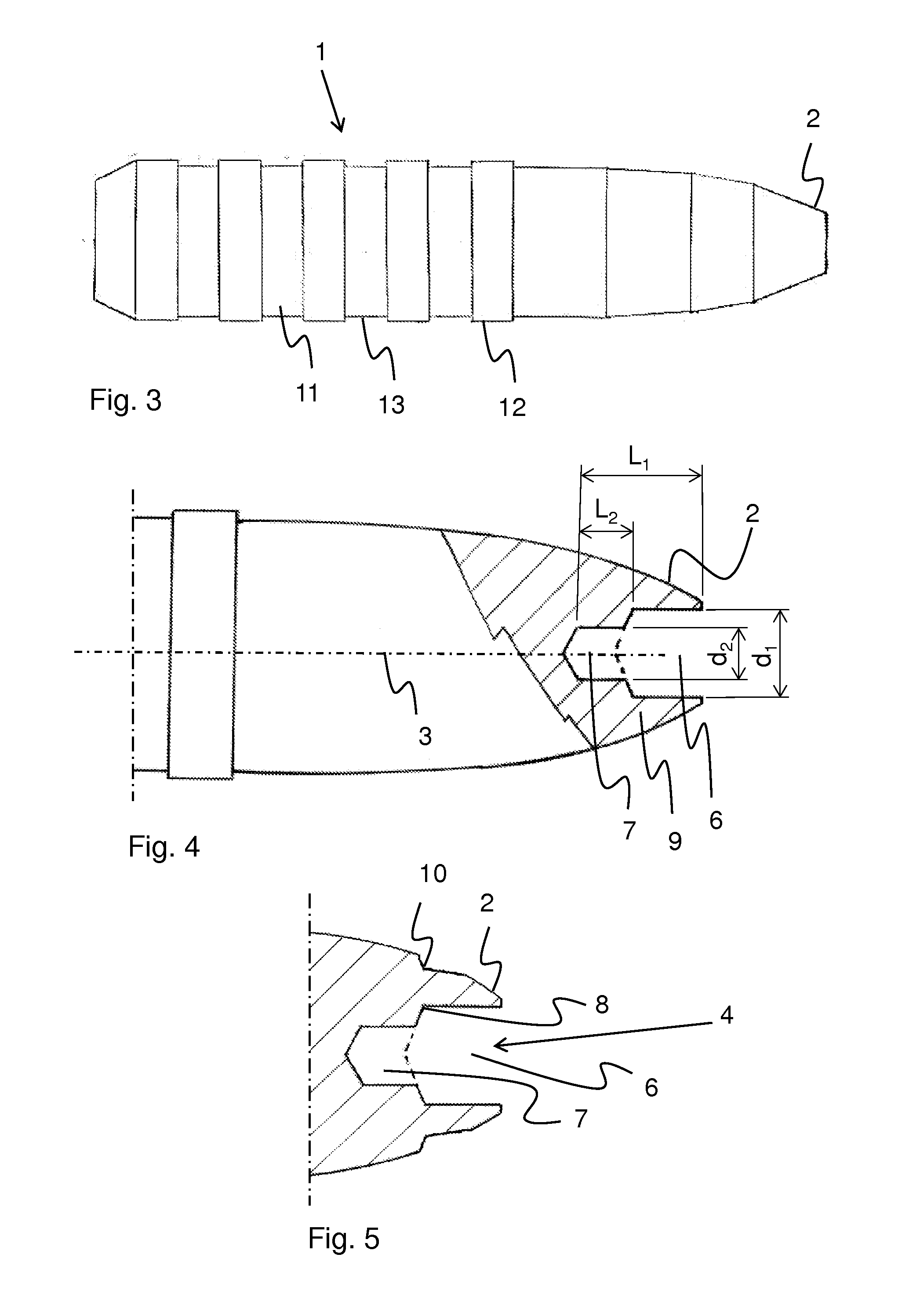

[0026]The present figures do not show the bullet and method for expanding the bullet in scale, but the figures are schematic and illustrate the structure and operation of the preferred embodiments in principle. Structural parts indicated by reference numerals in the accompanying figures then correspond to structural parts provided with reference numerals in this specification.

[0027]When designing the present bullet, the starting point was to create a bullet 1 that combines good terminal ballistics, minor flesh damage regardless of the impact, good feed reliability in all weapons, even in semiautomatics, and sufficient external ballistics and muzzle velocity so as to achieve a firing distance of at least 300 m with so-called normal calibres.

[0028]The above goals are achieved by a solid-material bullet that does not have a separate plastic nose that could bend, detach or cause imbalance. The bullet 1 also has a longish smooth nose 2 that is sufficiently small to achieve reliable feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com