Hydrostatic displacement unit with reduced hysteresis

A displacement unit, hydraulic technology, applied in the direction of circuit components, liquid variable capacity machinery, fluid pressure actuators, etc., can solve problems such as not optimal, complex system, increased space requirements, etc., to achieve the effect of reducing hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

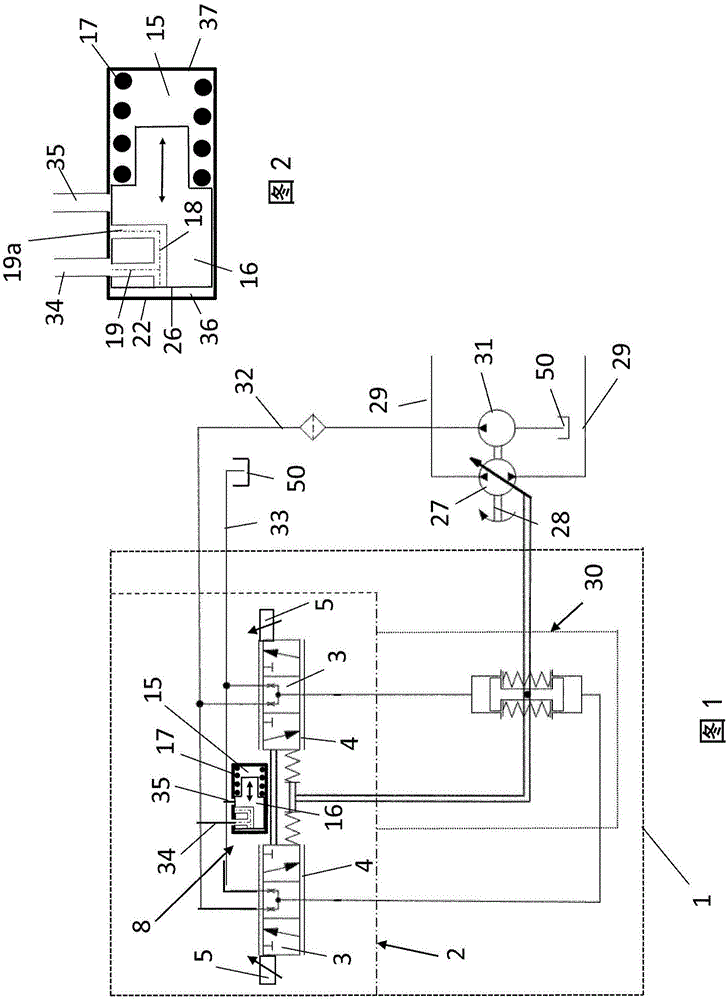

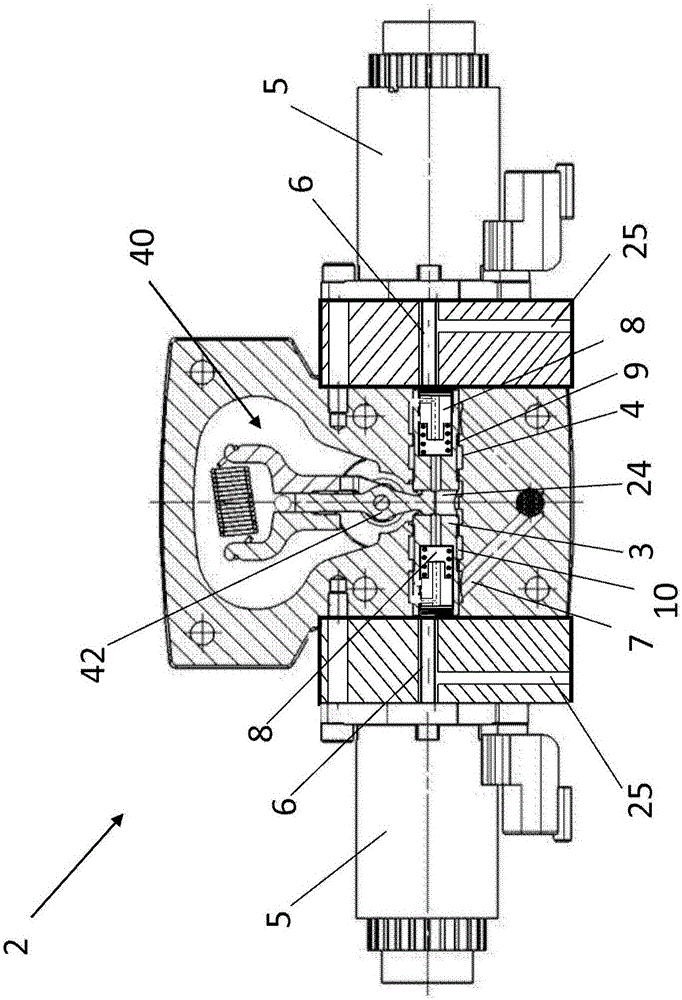

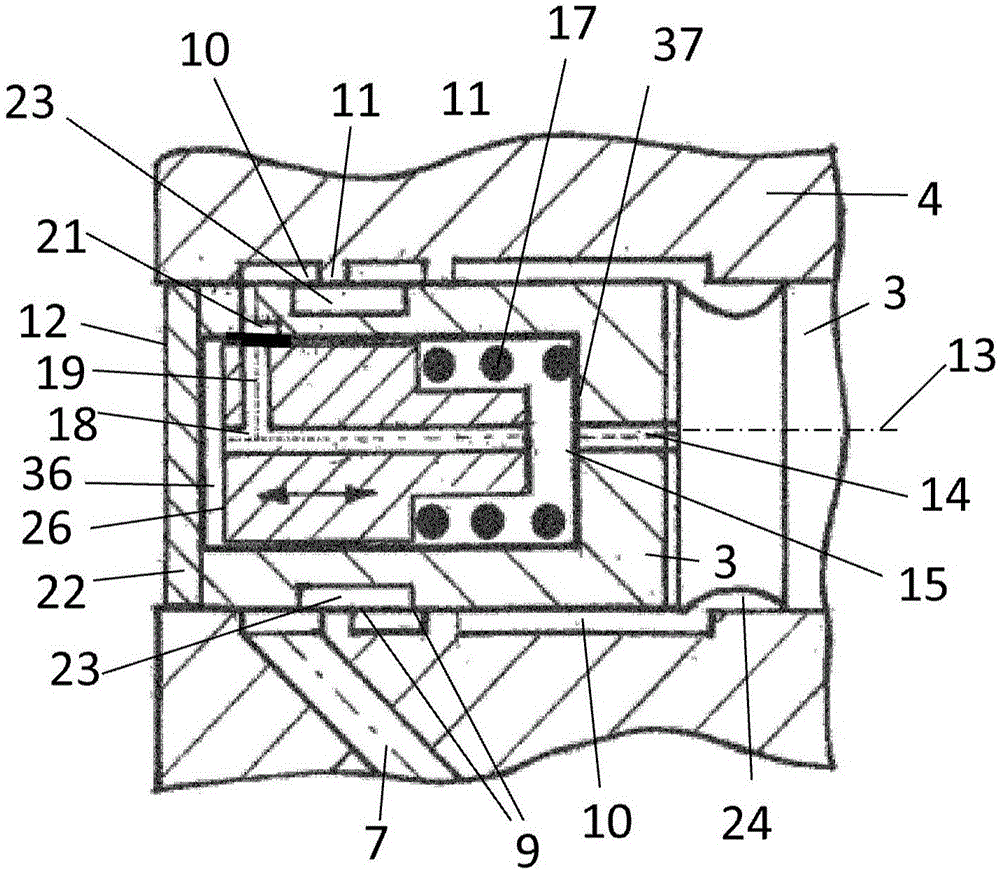

[0029] FIG. 1 shows a schematic diagram of a hydraulic machine 27 adjustable in two conveying directions with a displacement unit 1 according to the invention. The hydraulic machine, which can be a hydraulic motor or a hydraulic pump, comprises a drive or driven shaft 28 , for example for a pump, which is driven by a not shown internal combustion engine. In this case, the pump delivers fluid to and from the consumer part via line 29 . Thus, the servo displacement unit 30 is used for the adjustment of the discharge volume and delivery direction of the hydraulic fluid, which adjustment can be done, for example, by changing the displacement angle of the swash plate or the bending axis of the pump. The control of the servo displacement unit 30 is effected by the control unit 2 having two control cylinders 4 , in each of which a control slide valve 3 is movably mounted longitudinally. Thereby, the two control spool valves 3 are rigidly connected to each other, so that a displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com