Patents

Literature

33results about How to "Hysteresis effect is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

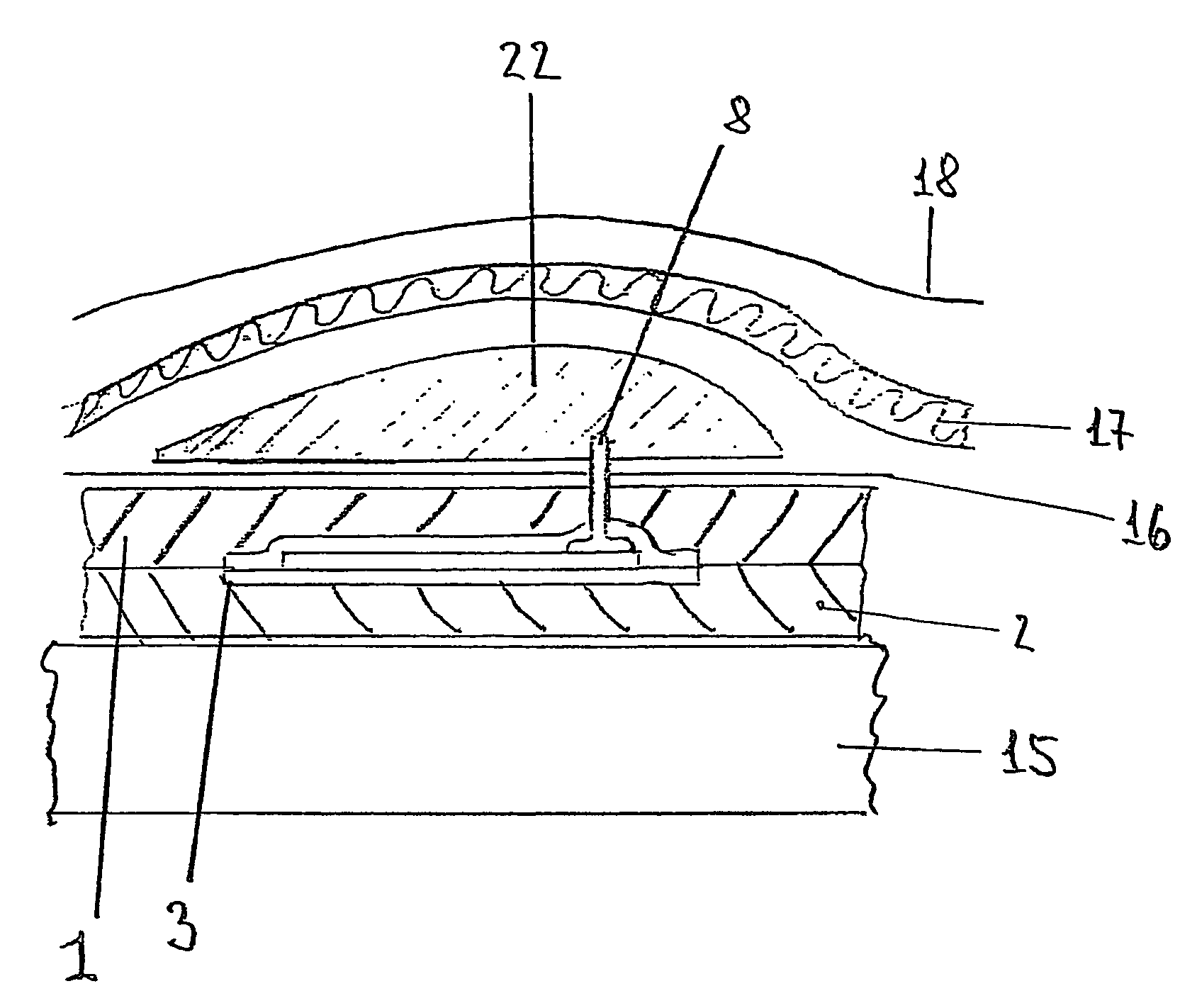

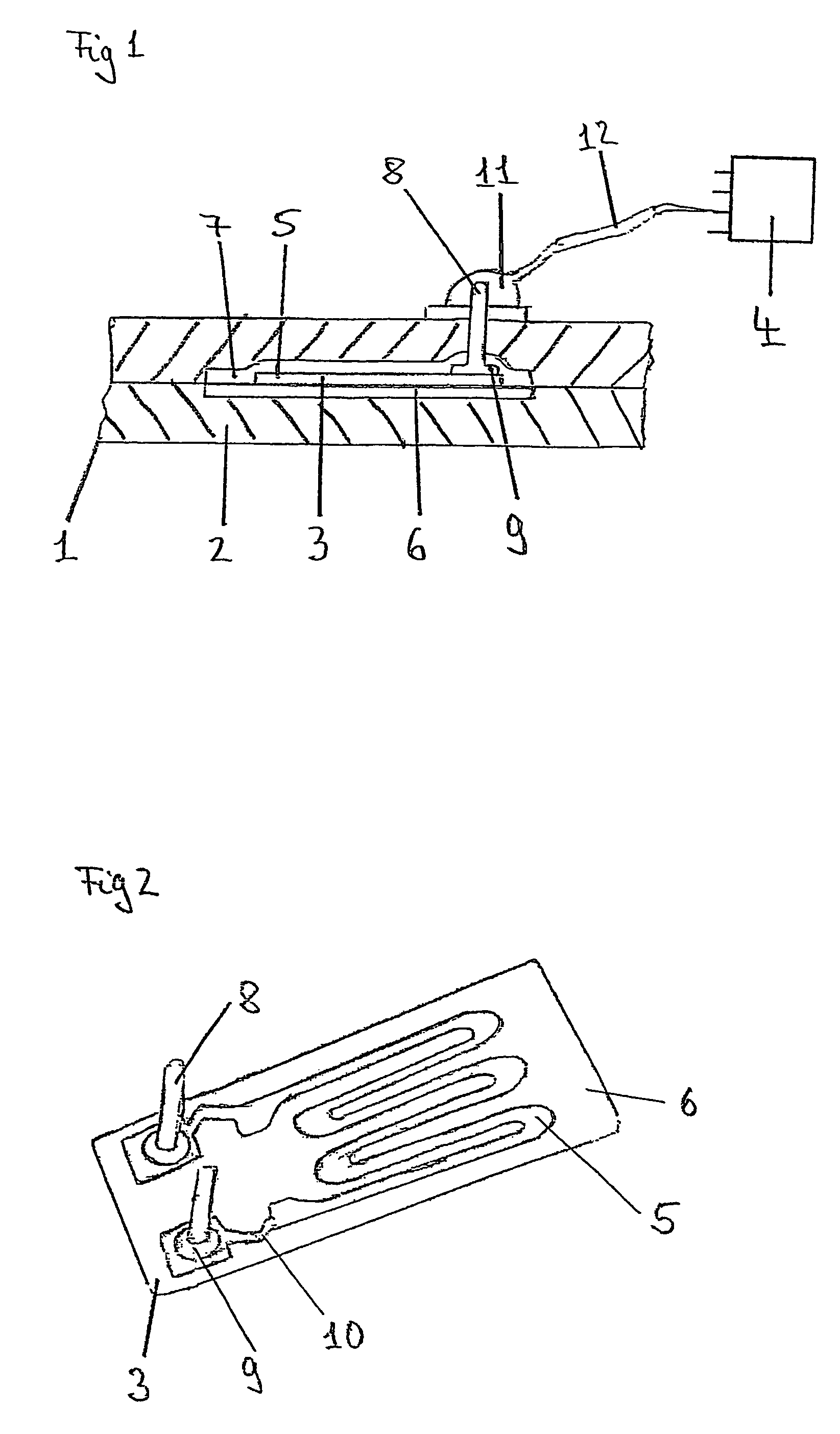

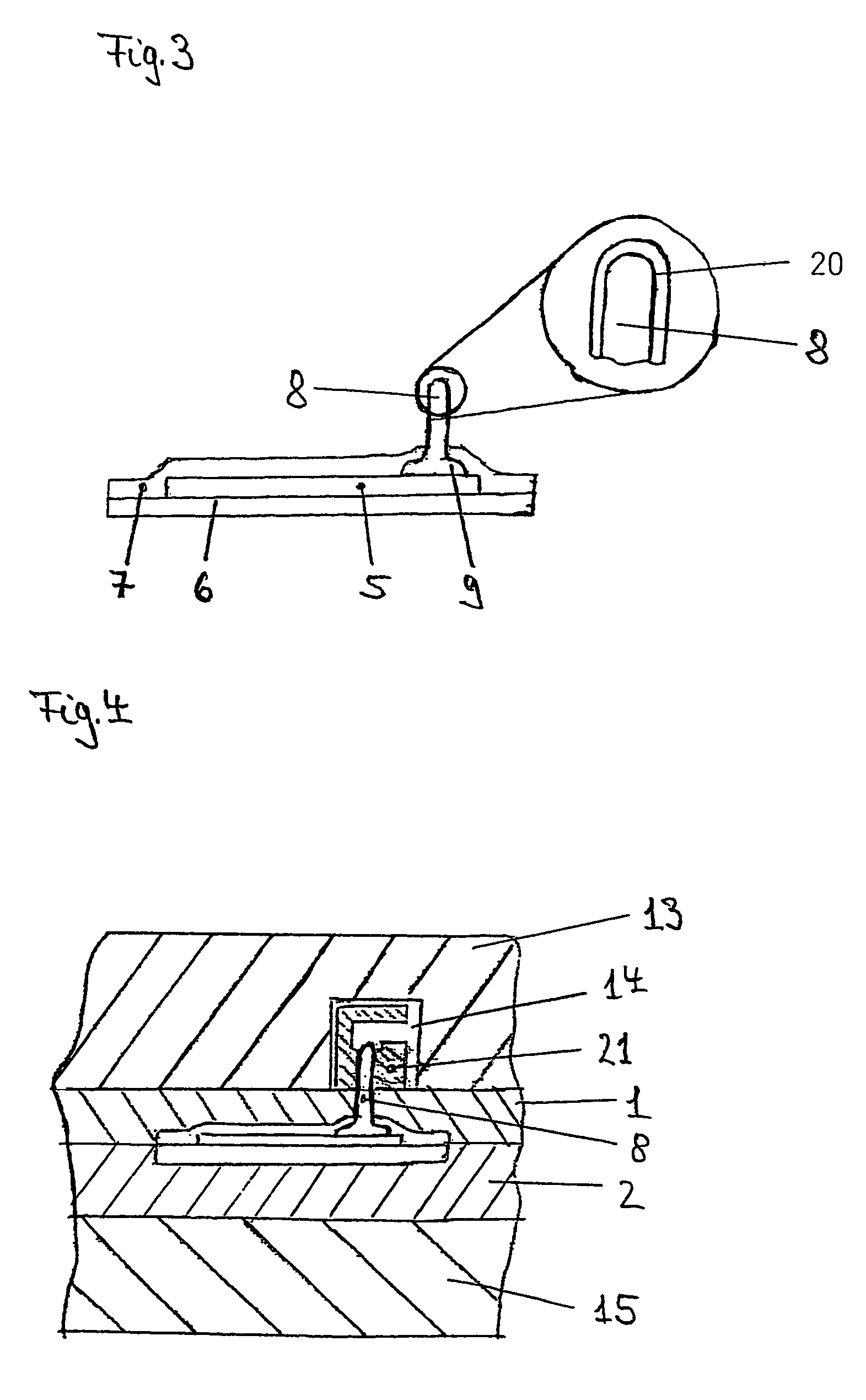

Device for determining strains on fiber composite components

InactiveUS7552644B2Hysteresis effect is smallHigh measurement accuracyForce measurementMaterial strength using tensile/compressive forcesFibrous compositesMechanical engineering

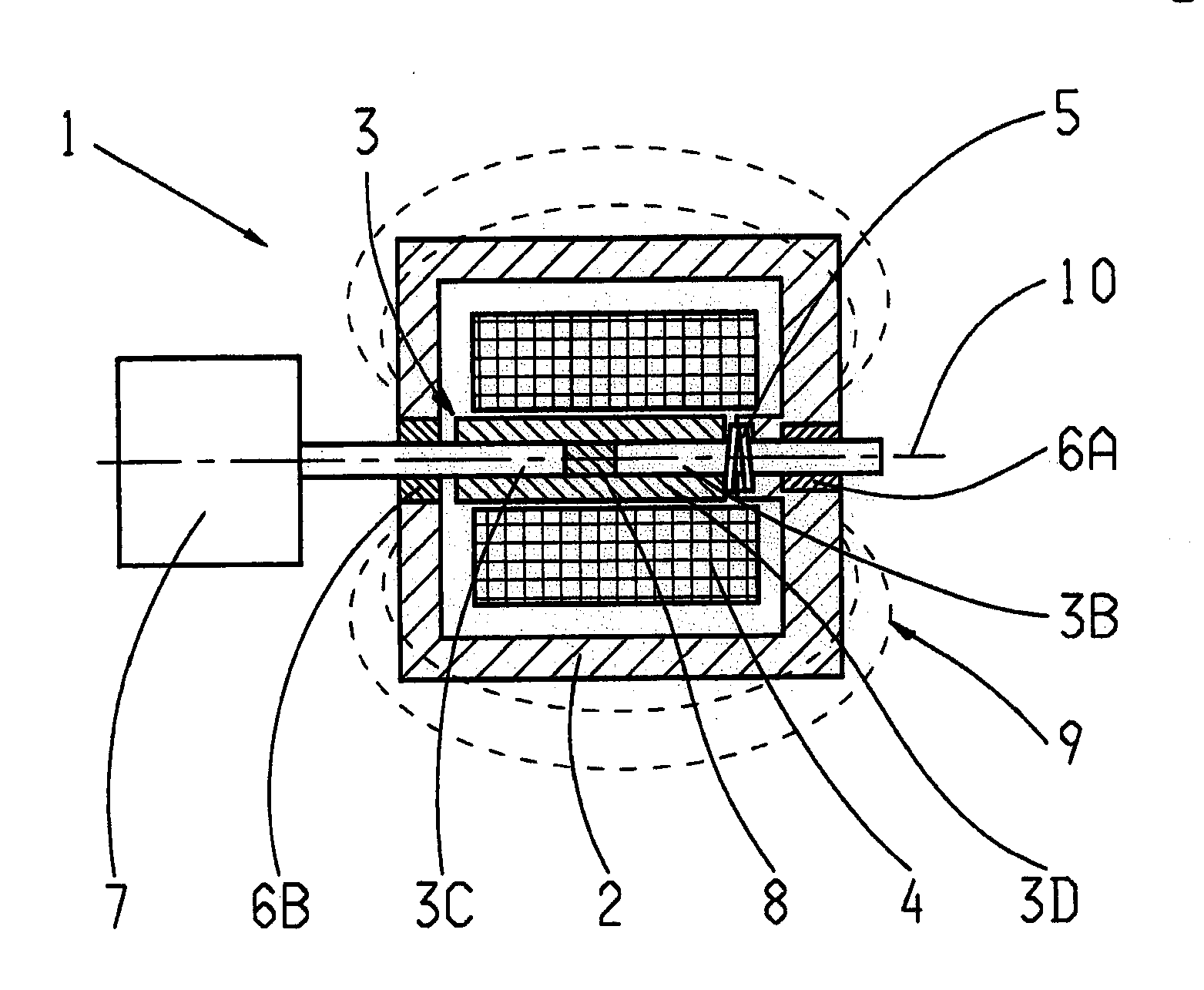

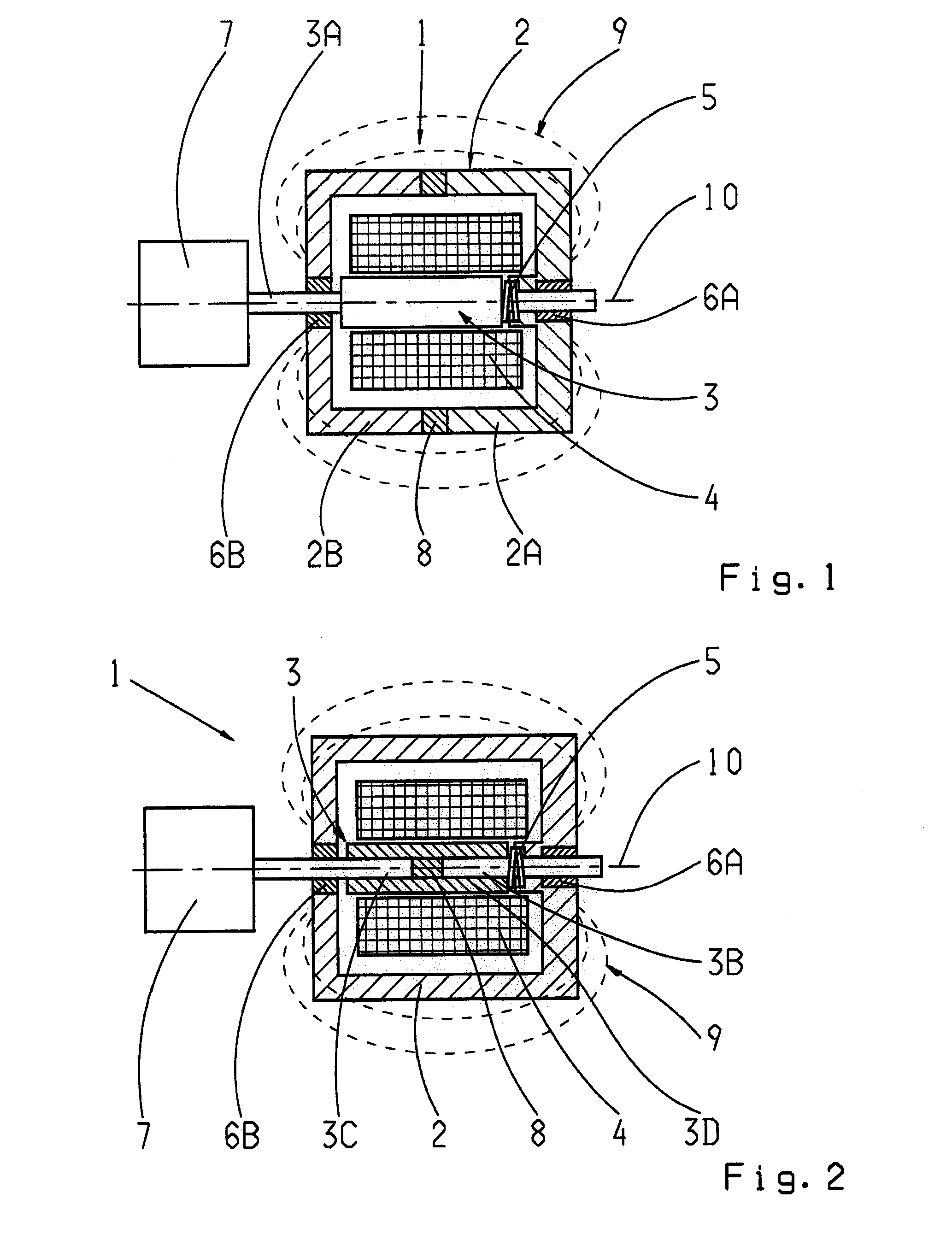

In an apparatus for determining loads on fiber composite components (1), especially of vehicle and aircraft parts, strain gages (3) are integrated in the components (1) for determining strains. The strain gages (3) are connected with an evaluating apparatus (4), for monitoring and determining loads that tend to cause damage. The strain gages (3) are preferably integrated into the fiber composite component (1) such that the measuring grids (5) thereof are laid between individual fiber layers (2) and are guided out of the component (1) ready for connection via special connecting pins (8) to the associated evaluating apparatus (4) via loose cable connections (12).

Owner:HOTTINGER BALDWIN MESSTECHNIK GMBH

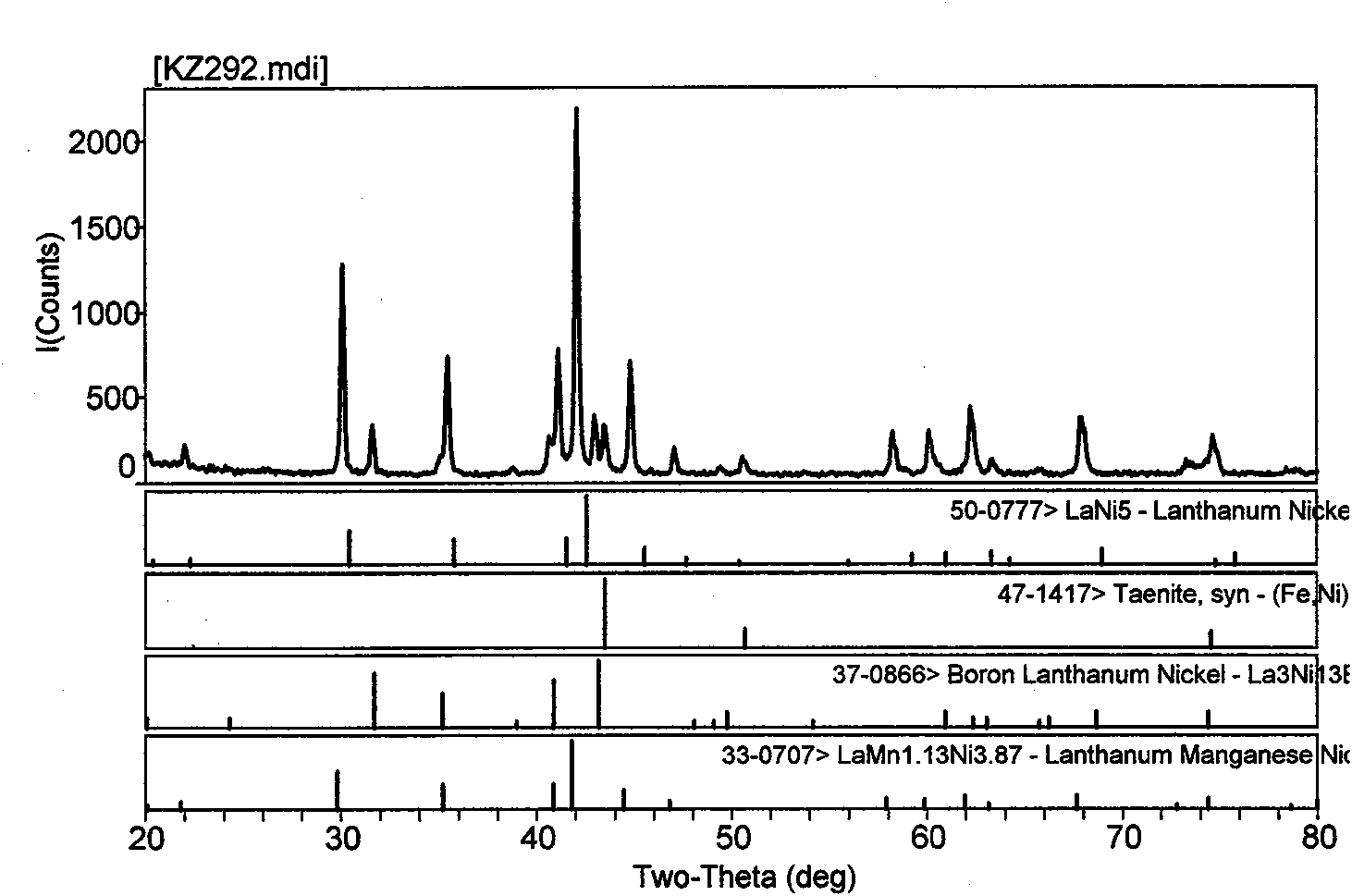

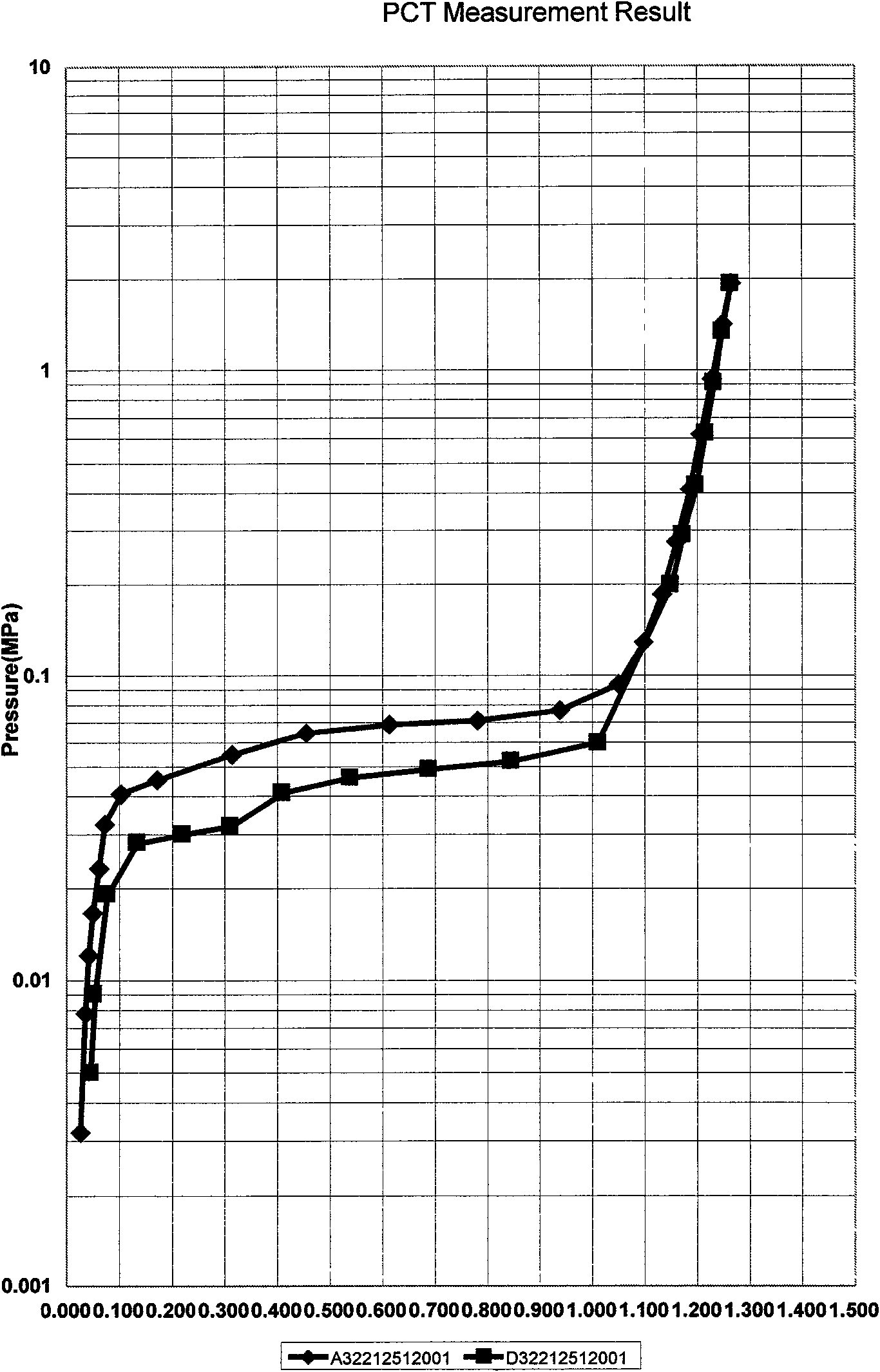

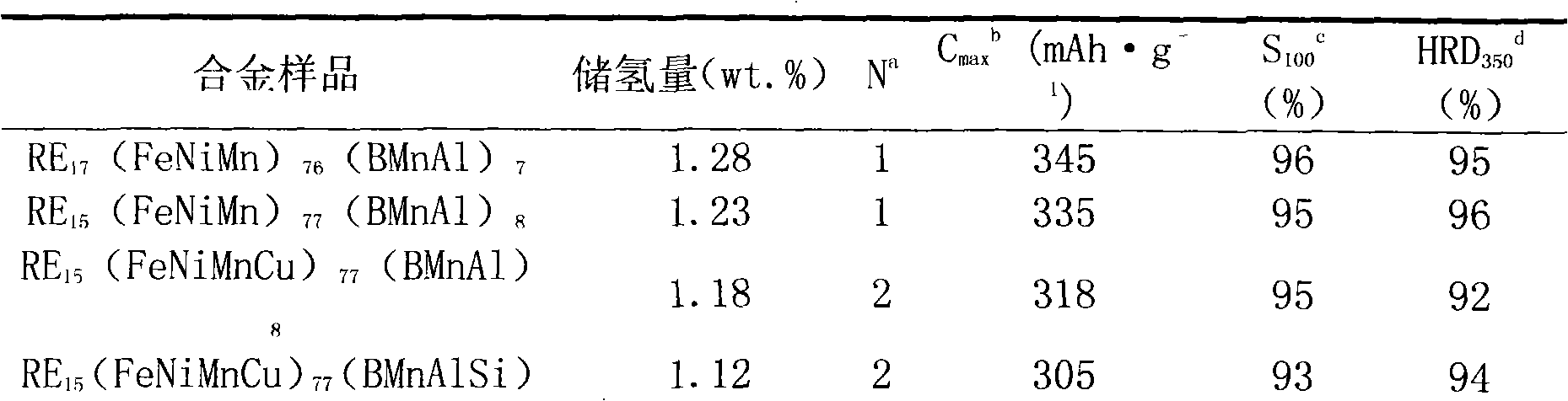

Preparation method of RE-Fe-B part hydrogen storage alloy

InactiveCN101633985AImprove corrosion resistanceSmall hydrogen absorption and desorption expansion ratioChemical compositionGas phase

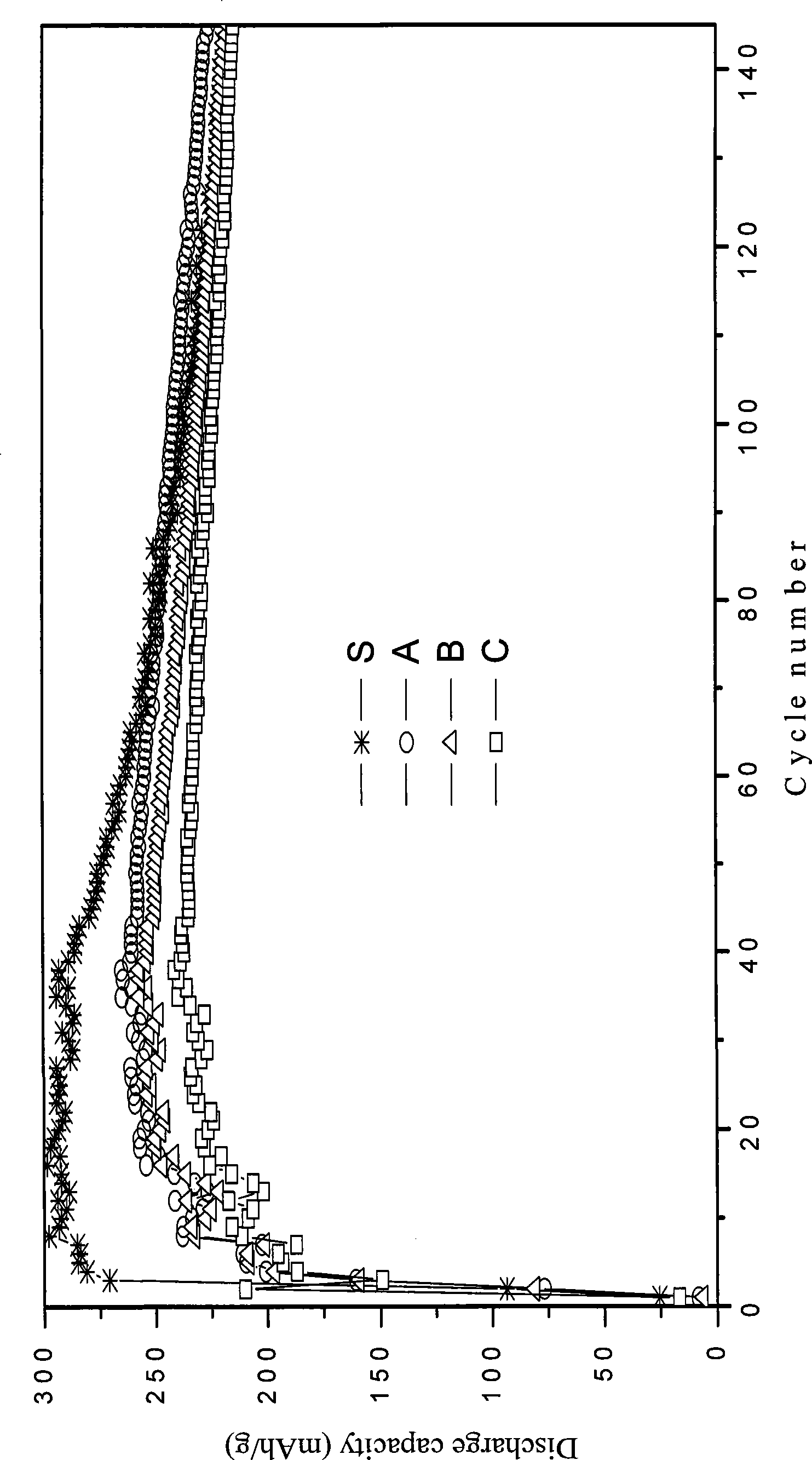

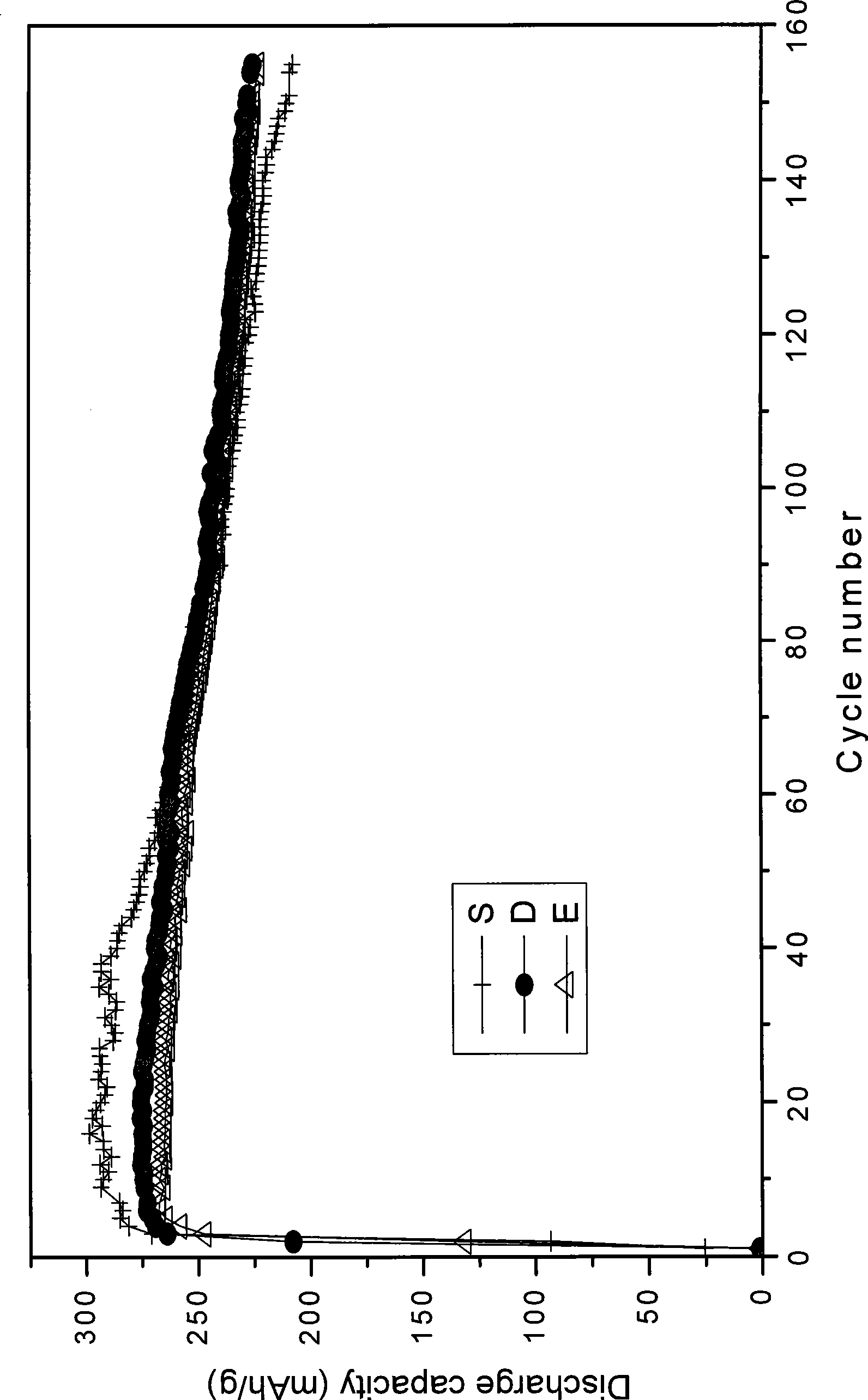

The invention relates to a preparation method of an RE-Fe-B part hydrogen storage alloy, which is characterized by comprising the following materials: RE contained in the RE-Fe-B part hydrogen storage alloy, a replaced element of the RE, B, a replaced element of the B, an RE-Fe alloy, a B-Fe alloy, a B-Ni alloy, an RE-Fe-B alloy, a LaNi5 type alloy and other preliminary alloys containing composition elements, wherein two or more materials are selected to be prepared according to a chemical composition formula of the RE-Fe-B part hydrogen storage alloy; one of a high-temperature smelting casting method, a high-temperature smelting-quick-quenching method, a high-temperature smelting-gas atomization method and a powder sintering method or a mechanical alloying method is adopted to manufacture the RE-Fe-B part hydrogen storage alloy; and the preparation process needs to be carried out under the protection of inert gas or a vacuum environment. The RE-Fe-B part hydrogen storage alloy is in a multiphase structure and comprises a LaNi5 phase, a La3Ni13B2 phase, a rich Fe or rich Ni phase, and the like. The prepared RE-Fe-B part hydrogen storage alloy has good activation property due to the special composition and structure, large current discharge capability, low-temperature electrochemistry property and charge / discharge or hydriding / dehydriding circulating stability, the maximum discharge capacity of the RE-Fe-B part hydrogen storage alloy can reach 400mAh.g<-1>, and the cost of the RE-Fe-B part hydrogen storage alloy is lower than that of other known hydrogen storage alloys; and in addition, the prepared RE-Fe-B part hydrogen storage alloy is used for battery negative pole materials, gaseous phase hydrogen storage materials and heat pump materials.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS +1

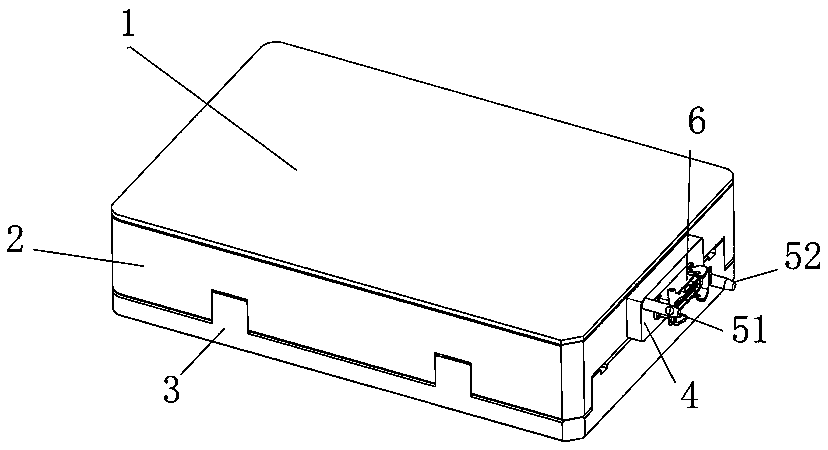

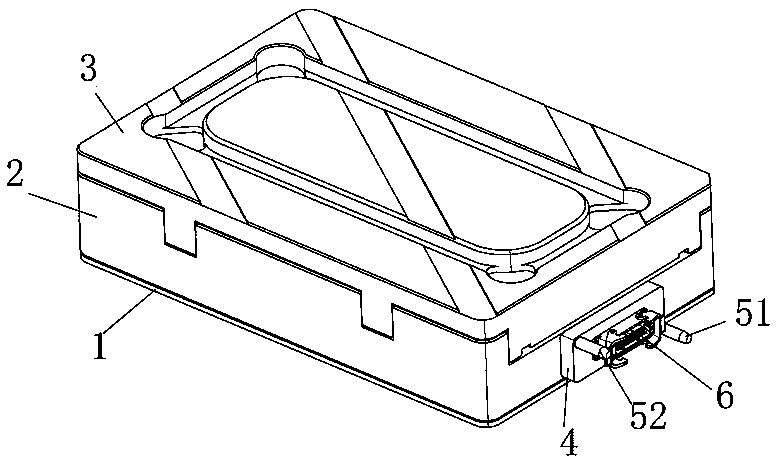

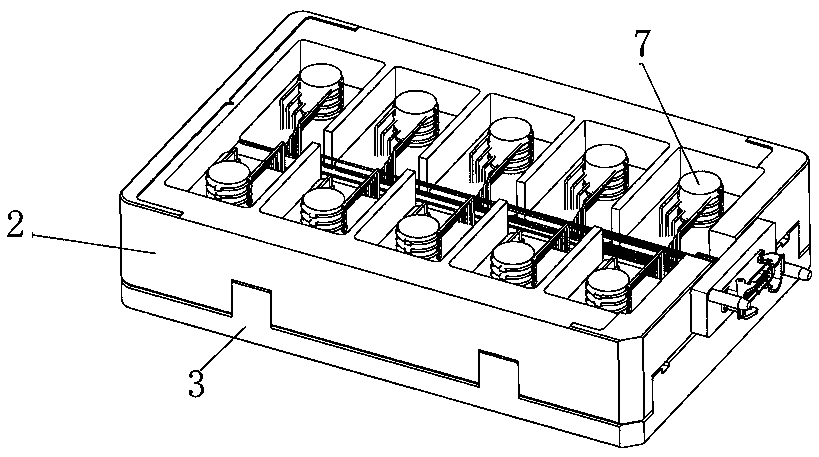

Intelligent temperature control mold for hot bending of 3C member, and control method thereof

PendingCN109970326AEasy to controlUniform temperatureGlass reforming apparatusGlass productionTemperature controlHysteresis

The invention discloses an in intelligent temperature control mold for hot bending of a 3C member, and a control method thereof. The mold comprises an upper mold and a lower mold, the upper mold is stitched on the lower mold, an accommodating cavity is formed between the upper mold and the lower mold, the upper mold and the lower mold are respectively connected with a primary heating device, a secondary heating device is arranged in the lower mold, a heat conducting seal plat is mounted at the bottom surface of the lower mold, and the mold is heated by the control of the primary heating deviceand the secondary heating device in order to effectively control the temperature. The mold and the control method have the advantages of high temperature rising rate, small hysteresis effect, and easiness in realization of temperature regulation.

Owner:GUANGDONG HUST IND TECH RES INST

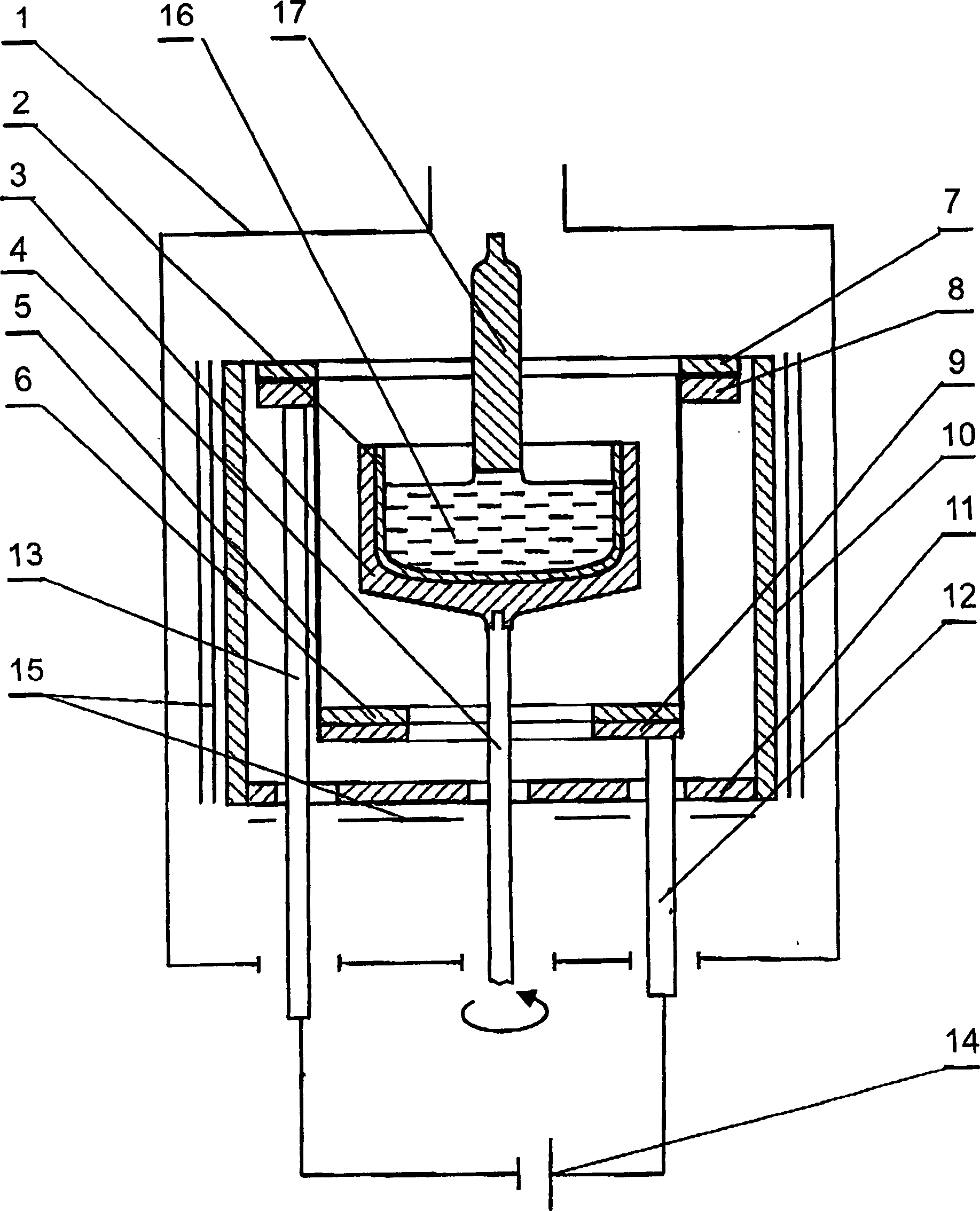

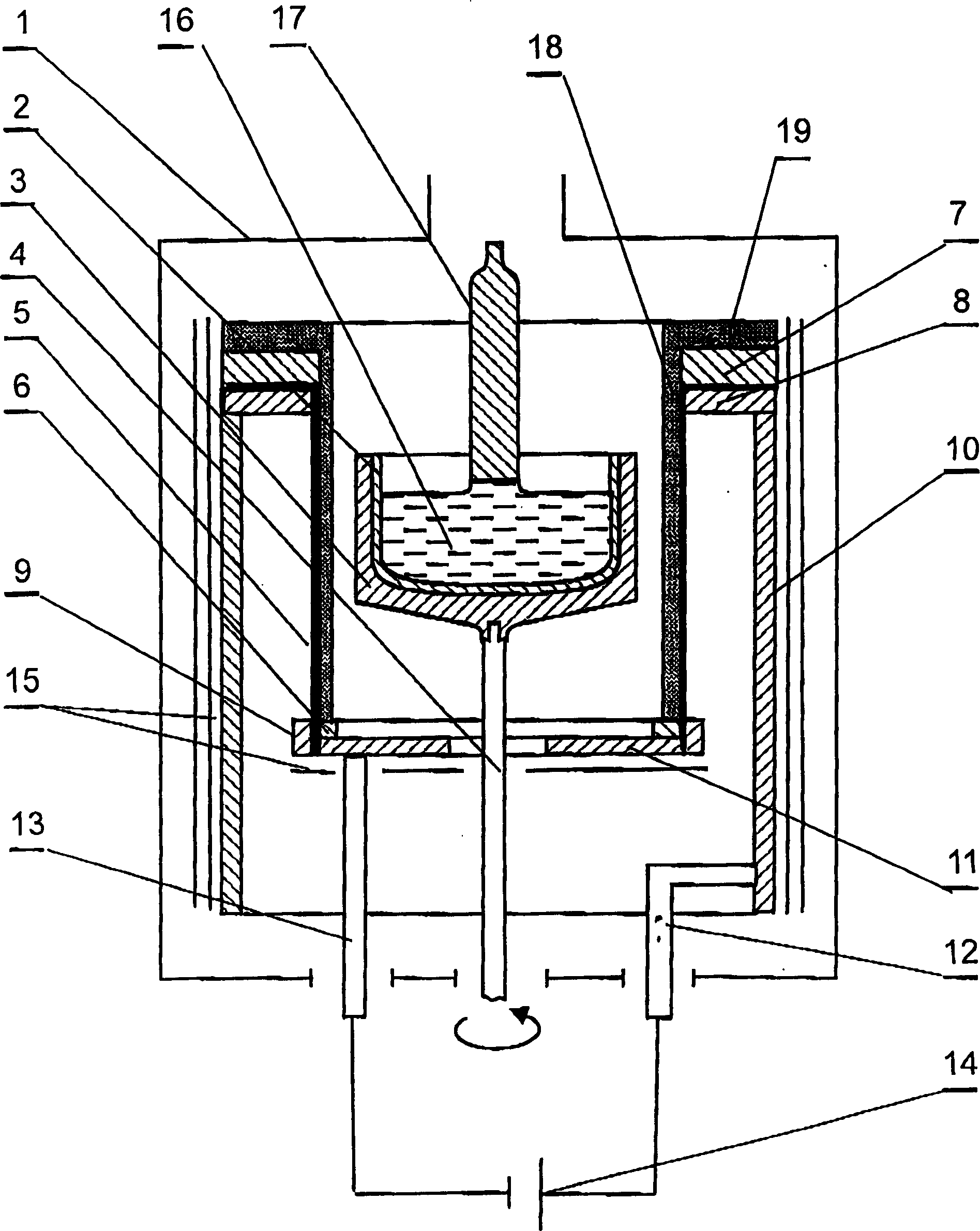

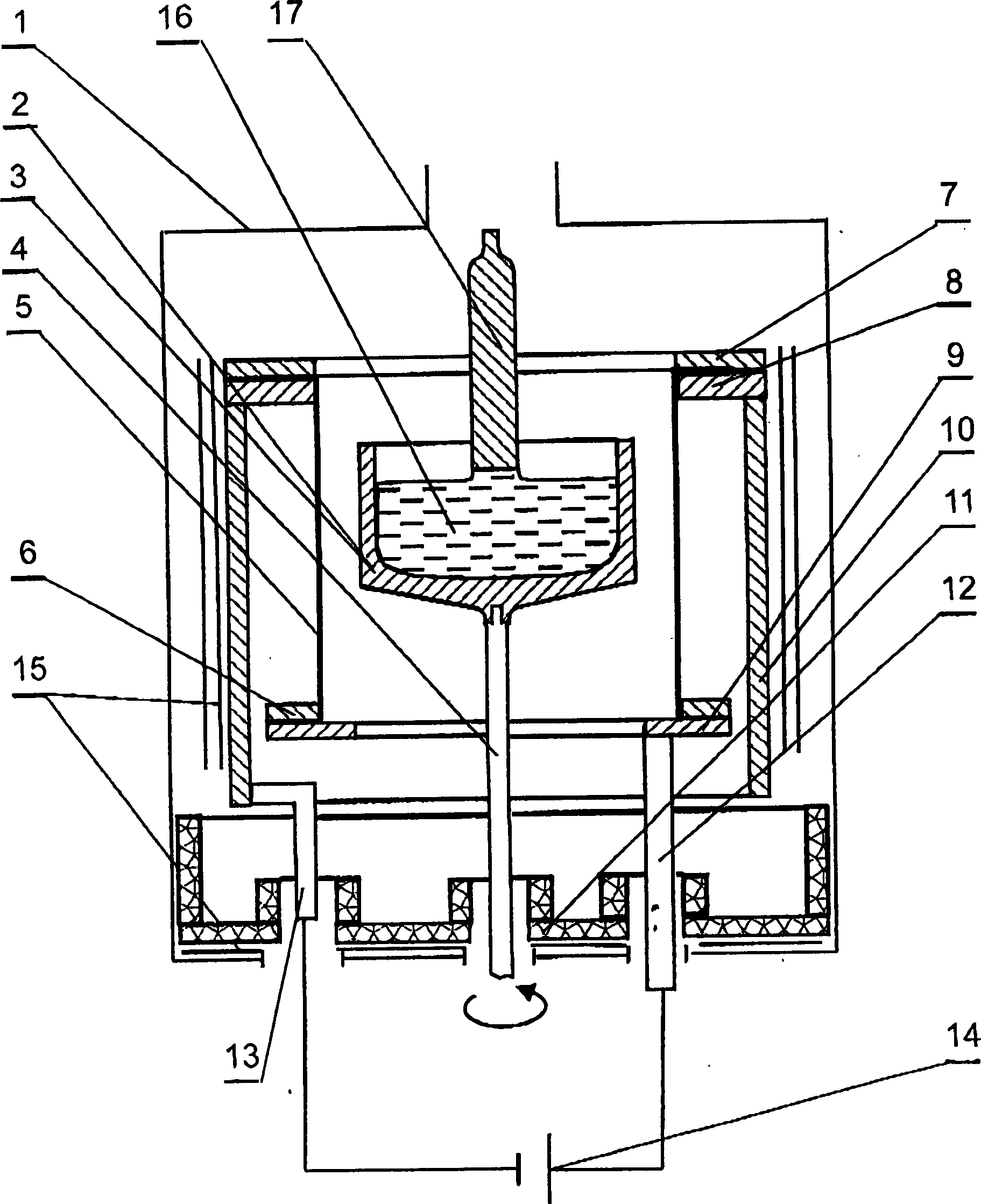

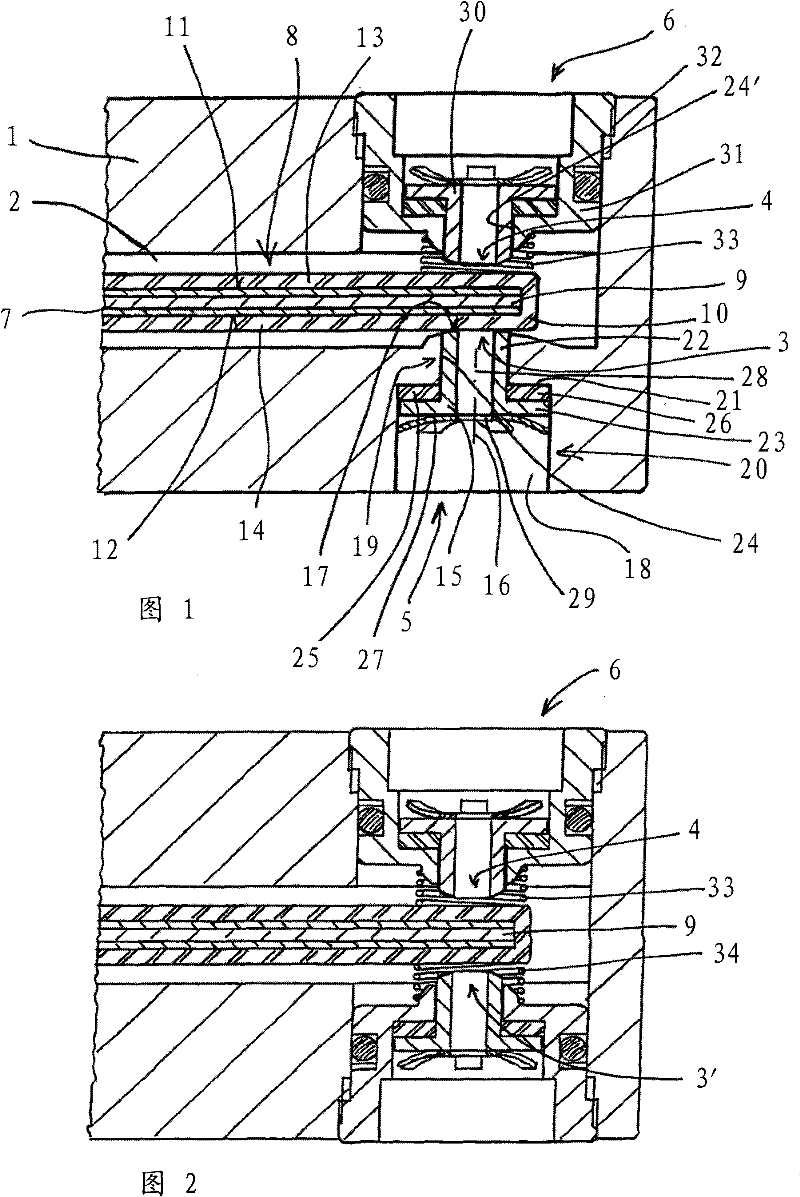

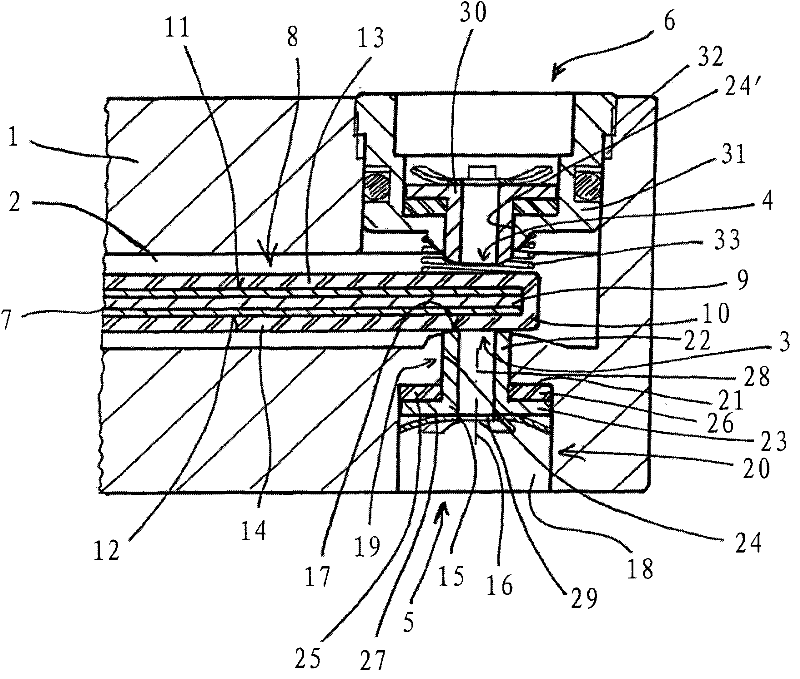

Device for pulling monocrystals

InactiveCN1656258ASolve operational problemsLight in massAfter-treatment apparatusPolycrystalline material growthCrucibleWorking temperature

The device comprises a crucible with a support, a heater and at least one heat-insulating screen, wherein, according to the invention, the heater is made of a starting flexible carbon-bearing material in the form of a cylinder whose ends are fixed between coaxially arranged rigid rings of carbon material that are connected to a power supply. And, the heater is made so that the wall thereof has its thickness determined from the relationship: delta . rho - c = 500 to 8500 J / m<2>. K, where: <> delta - heater wall thickness, m; rho - density of the material the heater is made of, kg / m<3>; and c - specific heat of the material the heater is made of (at working temperature), J / kg.K.

Owner:弗拉基米尔・弗拉基米罗维奇・科斯京 +1

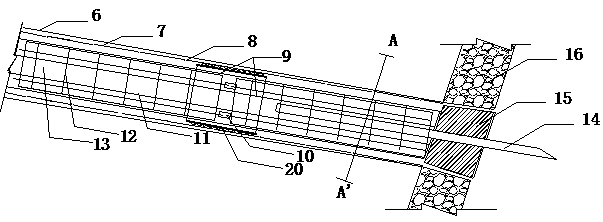

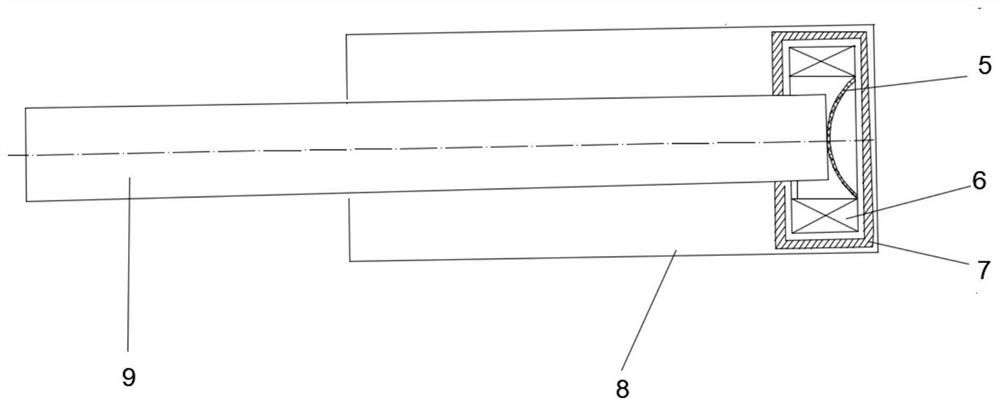

Optical strain gauge strips

InactiveCN101228421AReduce areaReduce distanceForce measurement by measuring optical property variationGratingElectrical conductor

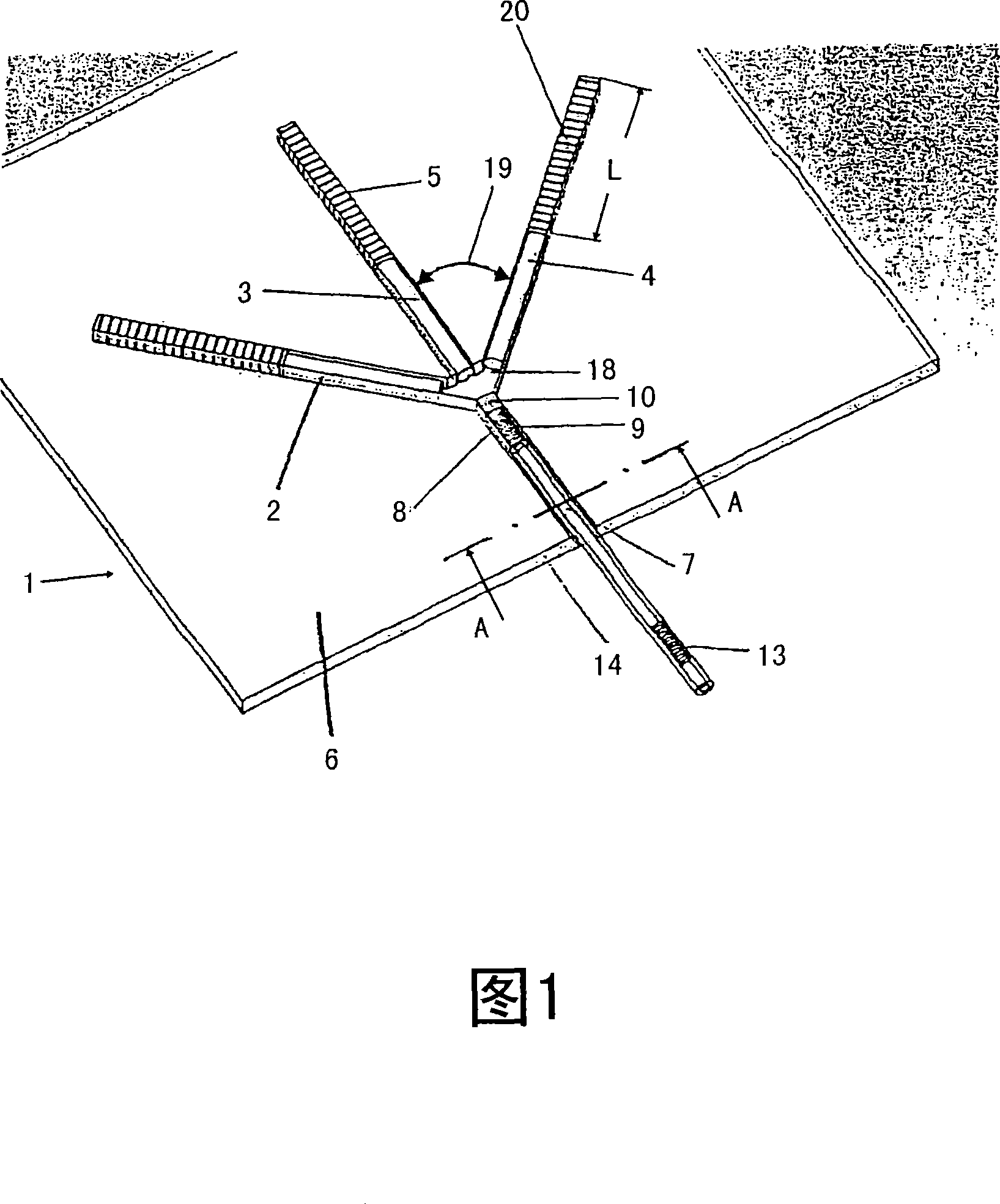

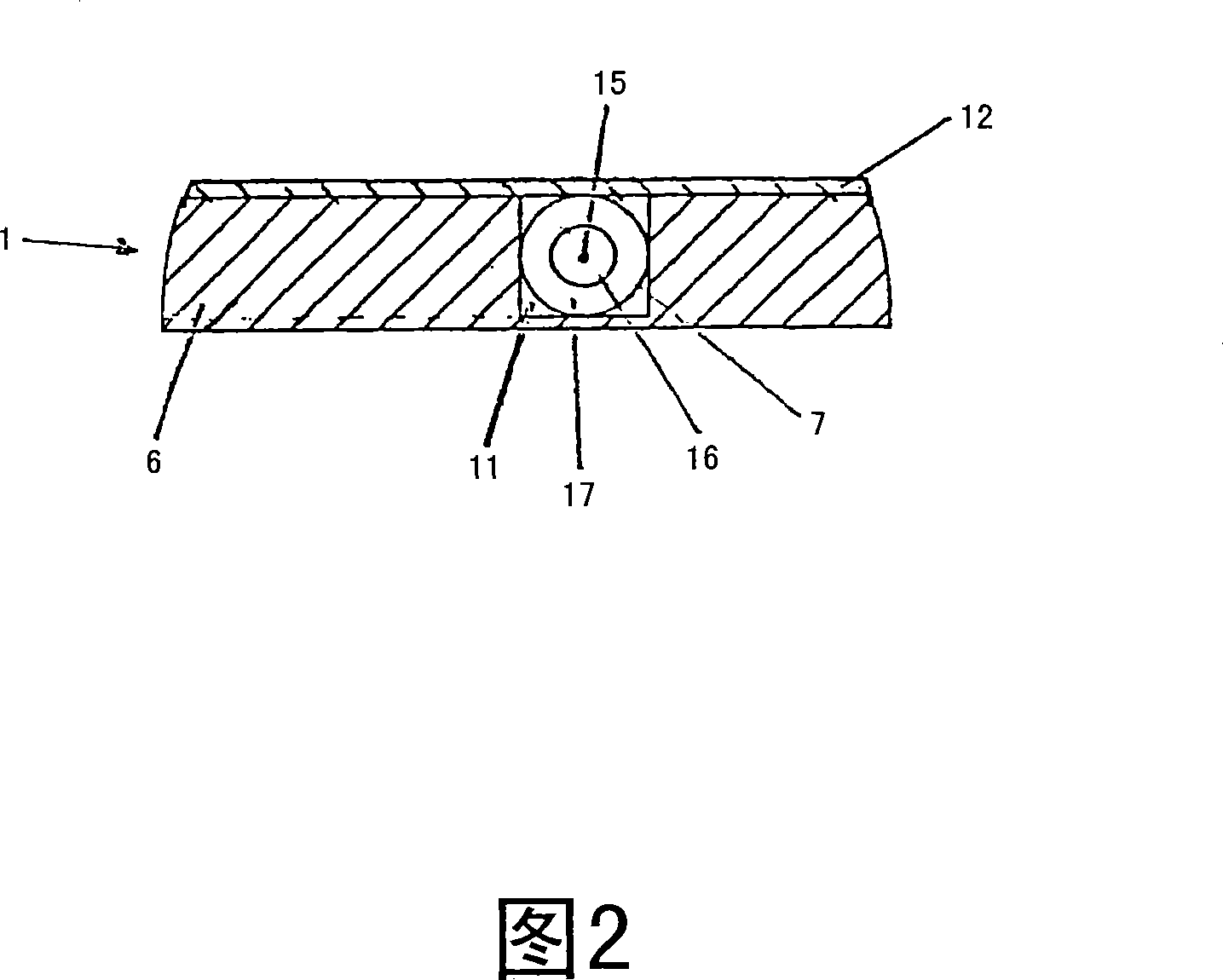

The invention relates to an optical strain gauge strip (1) for multi-axis strain measurement, comprising at least two straight optical fibre sections (2, 3, 4) with Bragg gratings (5), arranged adjacent to each other at a given angle (19) of 90 DEG or 45 DEG on a support layer (6) and supplied with light waves from a common injection optical fibre section (7). The invention is characterised in that all optical fibre sections (2, 3, 4, 7) are preferably provided on the support layer (6) in straight lines and a beam dispersion element (8) is arranged between the injecting optical fibre section (7) and the measuring optical fibre sections (2, 3, 4) with the Bragg grating (5).

Owner:HOTTINGER BALDWIN MESSTECHNIK GMBH

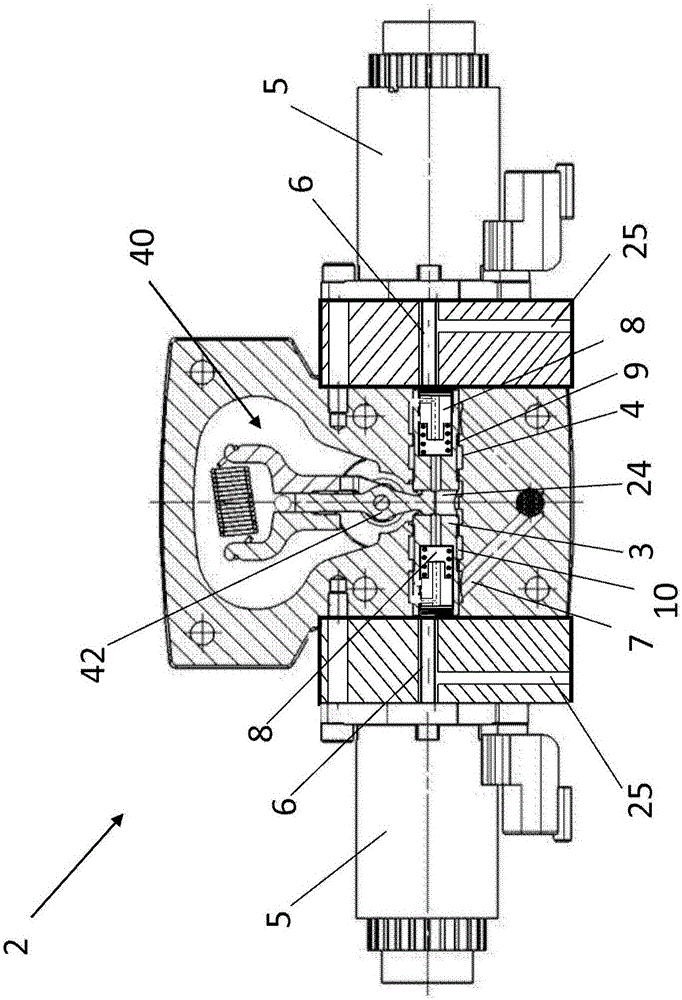

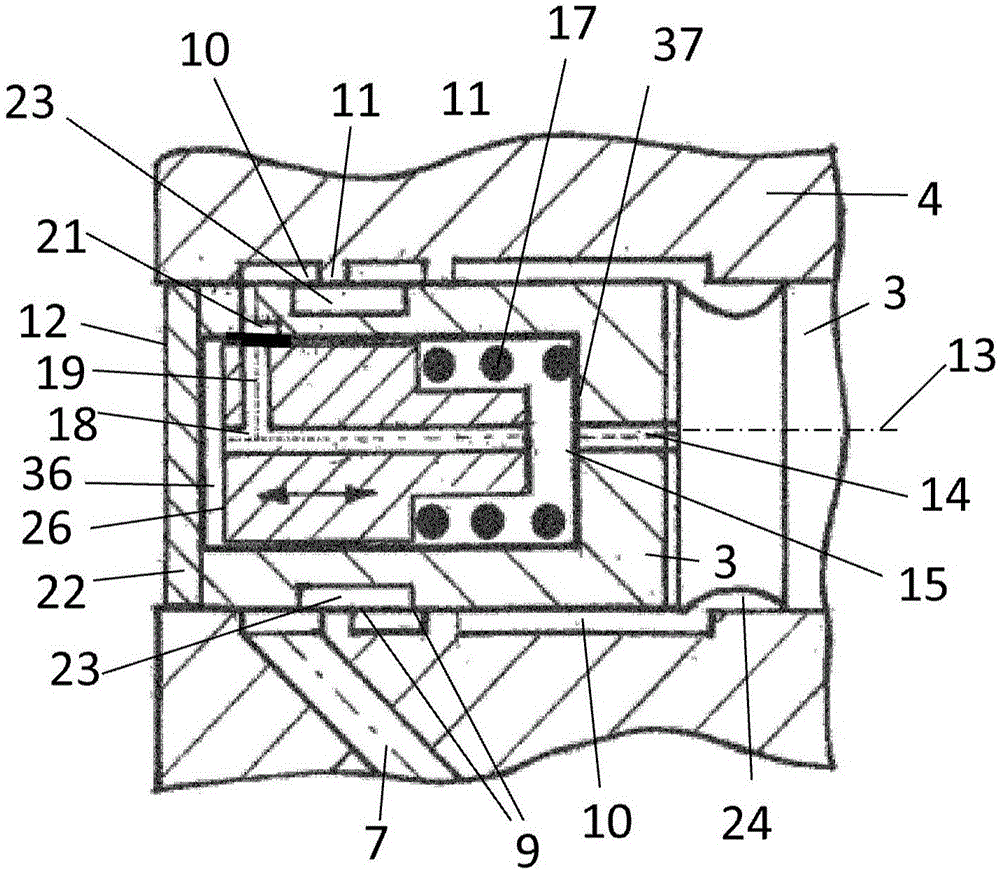

Piezoelectric valve

ActiveCN101755157ALow reliabilitySmall flow powerOperating means/releasing devices for valvesThin material handlingNozzle

The invention relates to a piezoelectric valve having a housing (1), comprising an inner chamber (2) through which a medium can flow, wherein at least one nozzle (3, 3'; 4) that communicates with an associated connection (5; 6) for the flow medium and having a sealing seat with a seat surface ends in said chamber. The inner chamber of the housing receives a piezoelectric flexible element (7) deformable by electric energization such that the nozzle (3, 3'; 4) can be closed by a section (9) of the flexible element, the section being moveable relative to the nozzle due to the deformation of the flexible element (7). The flexible element comprises a support (13; 14) in the region opposite the nozzle, the support being made of an elastic resilient material. The sealing seat is arranged on a nozzle insert (15; 30) on the front side, said insert being movably arranged substantially perpendicular to the seat surface (17) in a receptacle (24; 24') on the housing, wherein between the receptacle and the associated nozzle insert, a thermally expandable compensation member (25) acts.

Owner:HOERBIGER FLOW CONTROL GMBH

Rare-earth series hydrogen storage alloy

InactiveCN101532102APrevent oxidationReduce microhardnessAlkaline accumulator electrodesRare earthCo element

The invention discloses a rare-earth series hydrogen storage alloy. The chemical formula of the alloy has the following general formula: Ml1-xDyx(NiaCobAlcMndCueFefSngCrhZni), wherein x is more than 0 and less than 0.3; a is more than 2 and less than 4; b is more than 0 and less than 0.3; c is more than 0.2 and less than 0.4; d is more than 0.2 and less than 0.5; e is more than 0 and less than 0.2; f is more than 0 and less than 0.25; g is more than 0 and less than 0.22; h is more than or equal to 0 and less than 0.18; and i is more than 0 and less than 0.28; and Ml is mixed rare earth. The alloy uses Cu, Cr, Zn, Fe and Sn to replace Co element in the rare earth series hydrogen storage alloy, can obviously improve the circulation stability of the hydrogen storage alloy, reduces the content of Co in the hydrogen storage alloy by over 60 percent compared with commercial hydrogen storage alloy MlNi3.55Co0.75Mn0.4Al0.3, and greatly reduces the production cost.

Owner:HENAN UNIV OF SCI & TECH

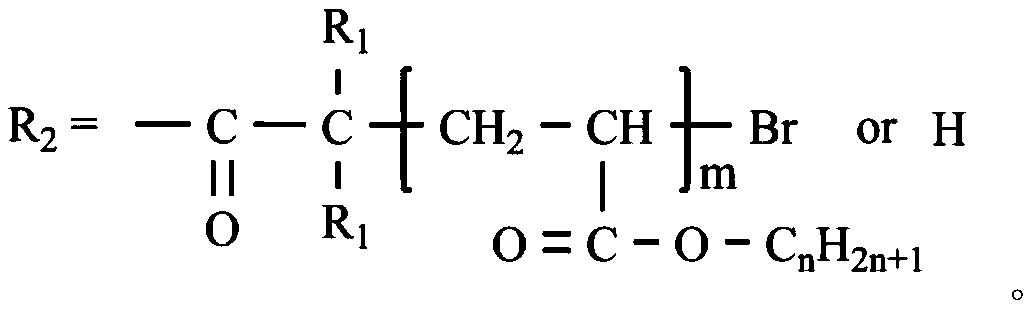

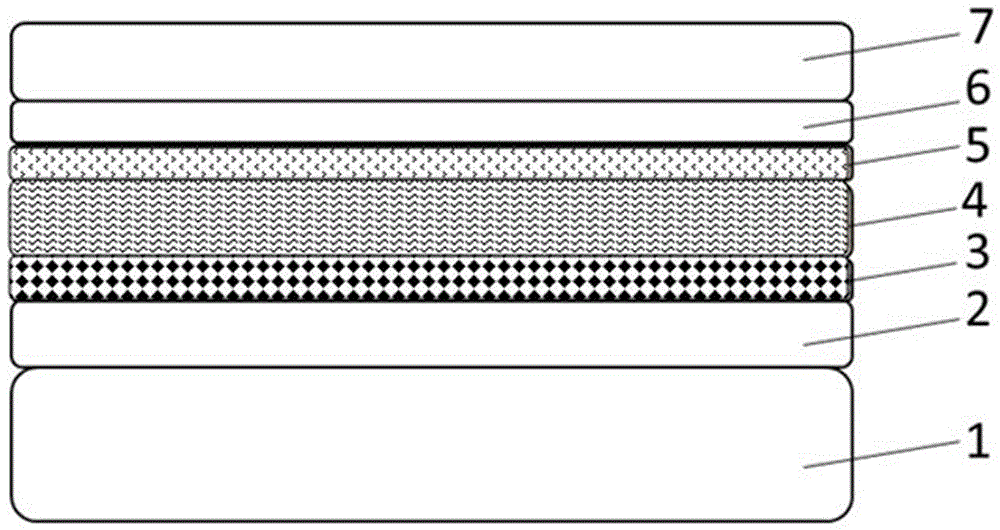

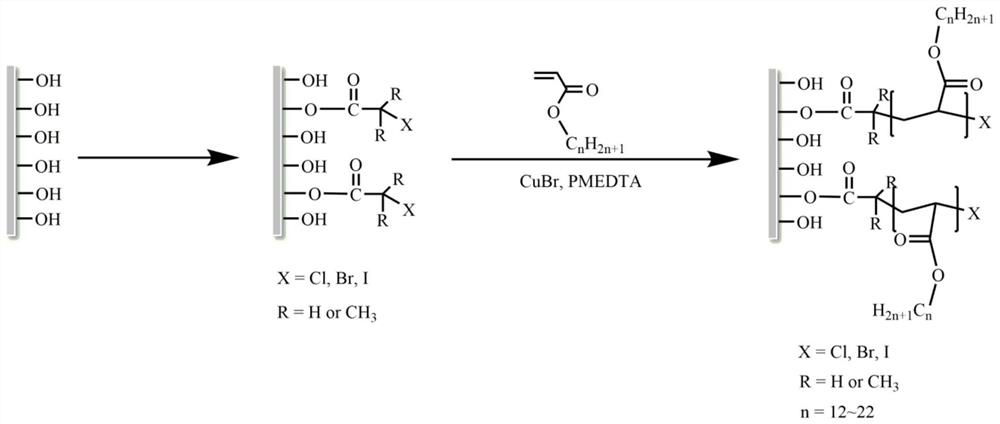

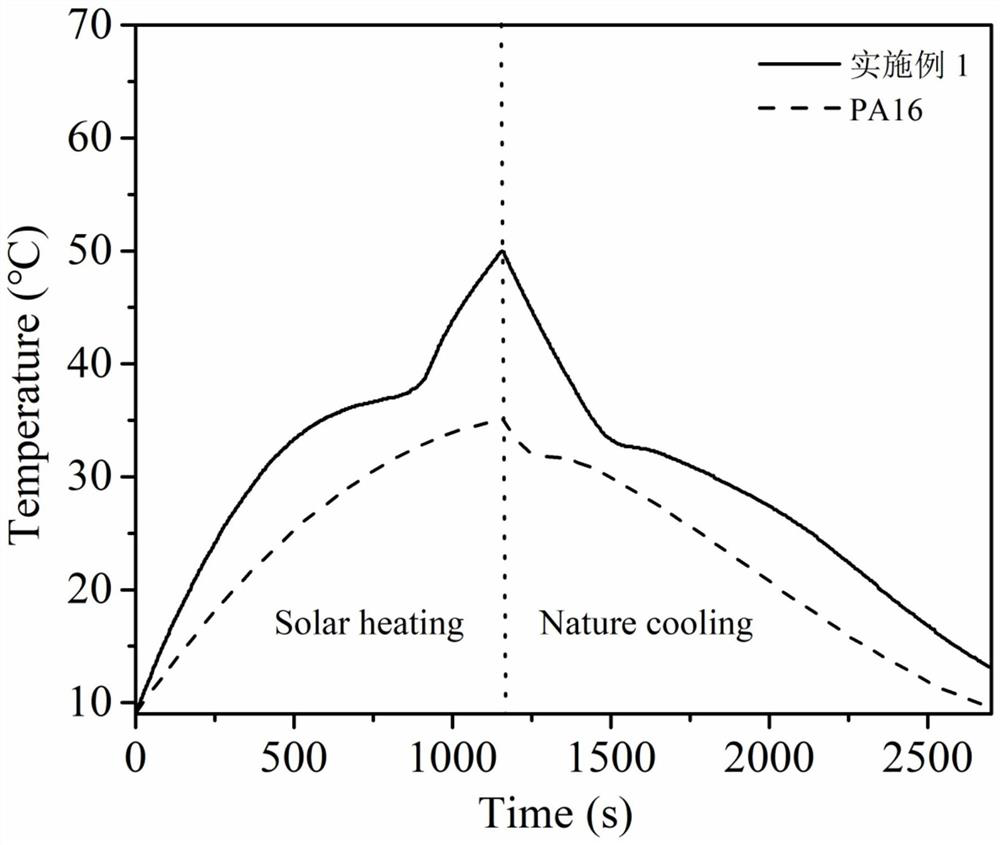

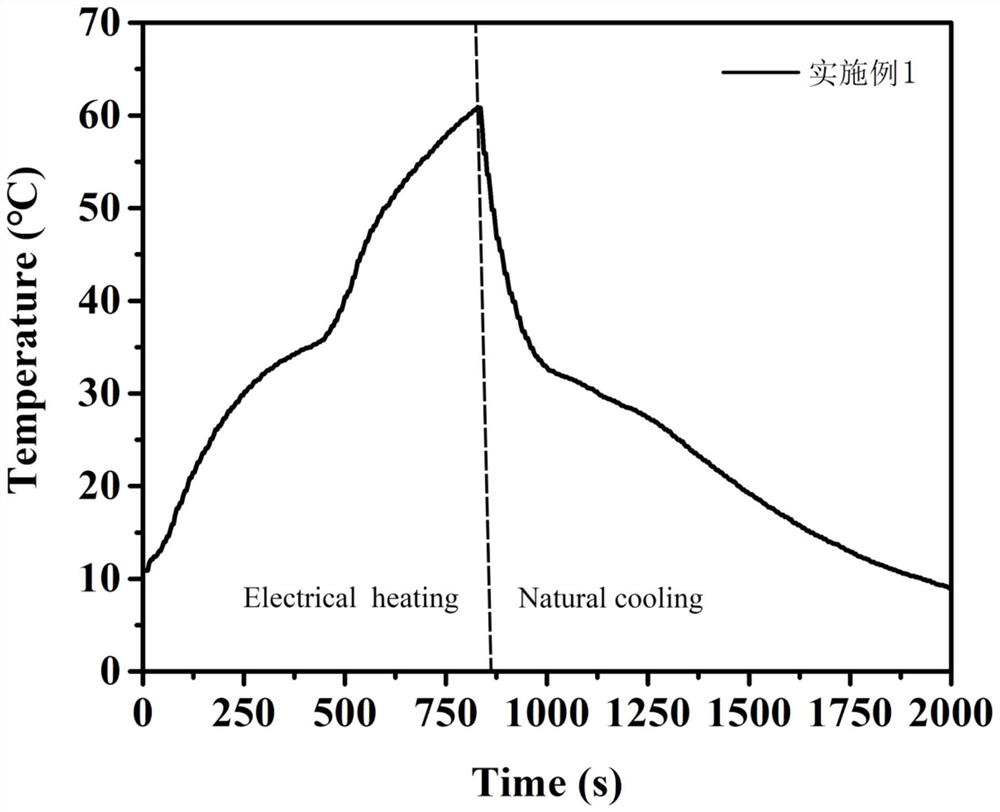

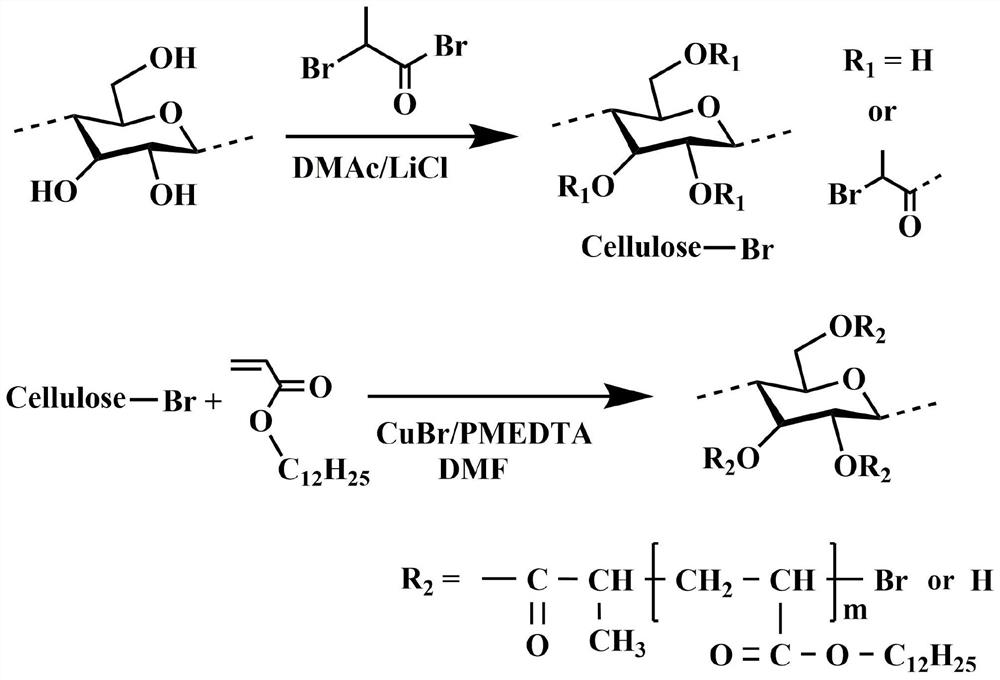

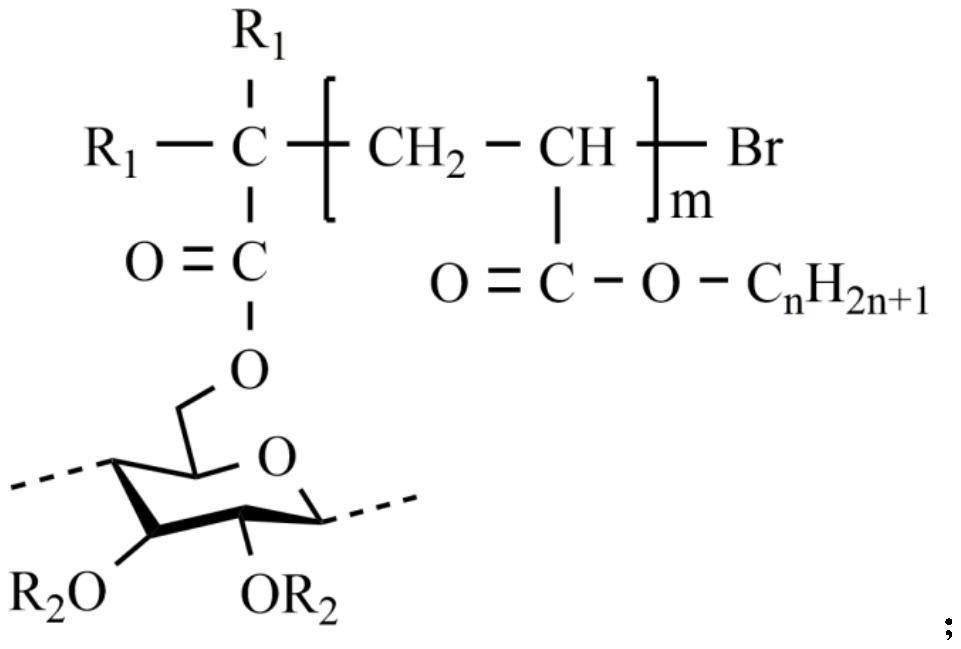

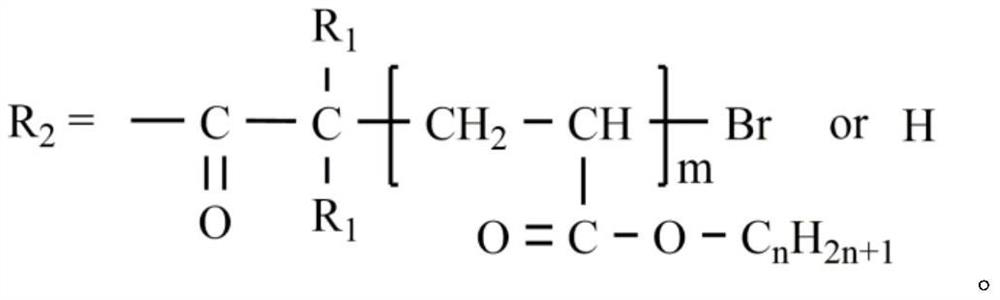

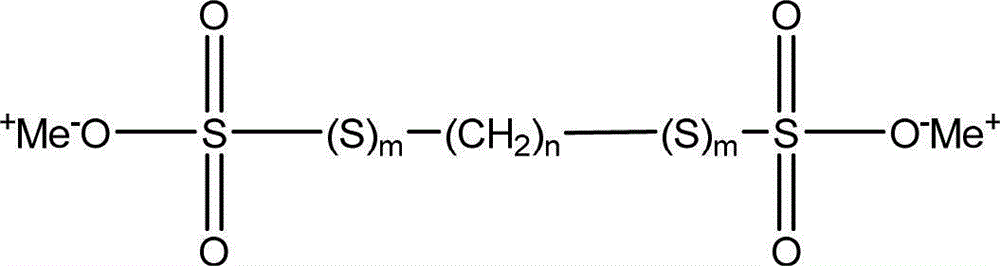

GN@cellulose based solid-solid phase change material and preparation method and application thereof

ActiveCN110698597AImprove solubilityRealize secondary processingHeat-exchange elementsMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

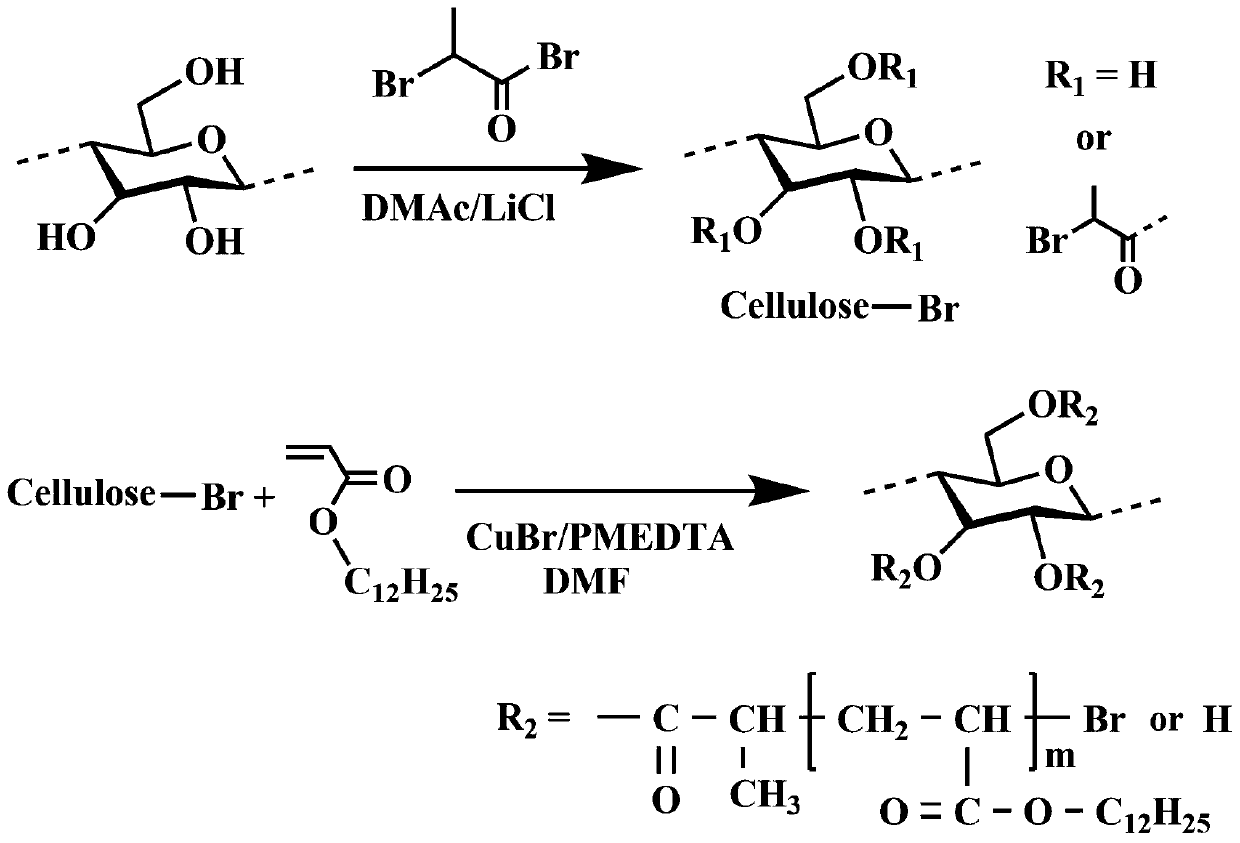

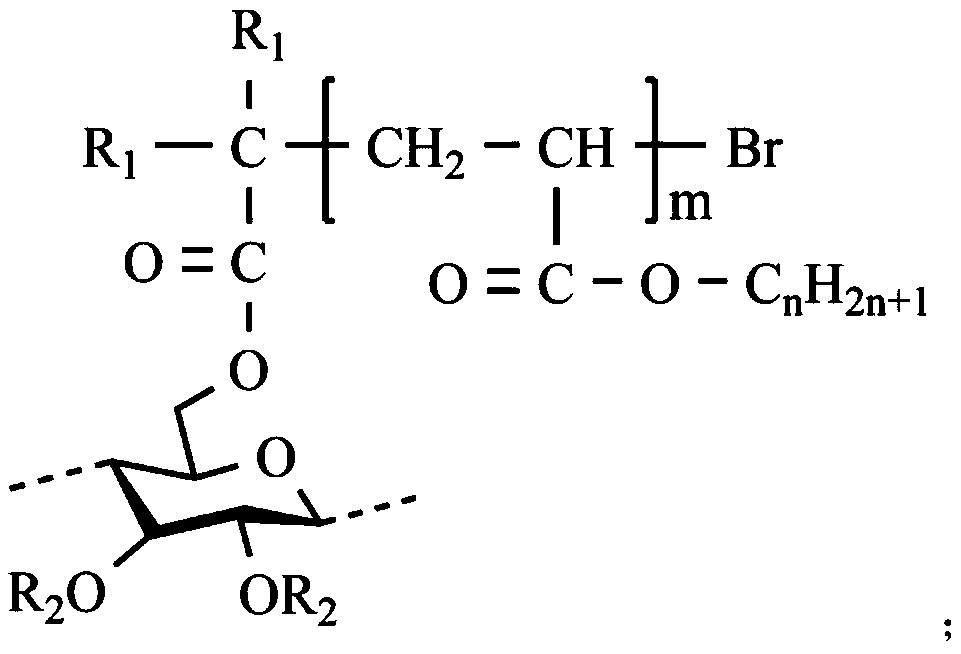

The invention discloses a GN@cellulose based solid-solid phase change material and a preparation method and application thereof. The method comprises the following steps of (1) dissolving cellulose; (2) carrying out homogeneous phase grafting modification: reacting a halogenated acyl halide monomer with cellulose to obtain cellulose ester; (3) carrying out ATRP method reaction: uniformly dispersing the cellulose ester, GN and a solvent B obtained in Step (2), and then adding a ligand, a catalyst and alkyl acrylate to react to obtain a reaction mixture; and (4) carrying out purification: purifying the reaction mixture obtained in Step (3) to obtain a GN@cellulose-g-polyalkylacrylate copolymer. The copolymer is subjected to melt extrusion spinning to obtain a solid-solid phase change fiber.The copolymer is is subjected to electrostatic spinning to obtain a film. According to the method, cellulose fibers are used as a substrate, halogen functional groups are grafted through an acylationreaction, alkyl acrylate is grafted on a cellulose skeleton through ATRP, graphene is used as a reinforcing material, and later-stage processing is not needed, so that the fibers with flexibility, high thermal conductivity and high enthalpy value are prepared, and secondary processing is facilitated.

Owner:TIANJIN POLYTECHNIC UNIV

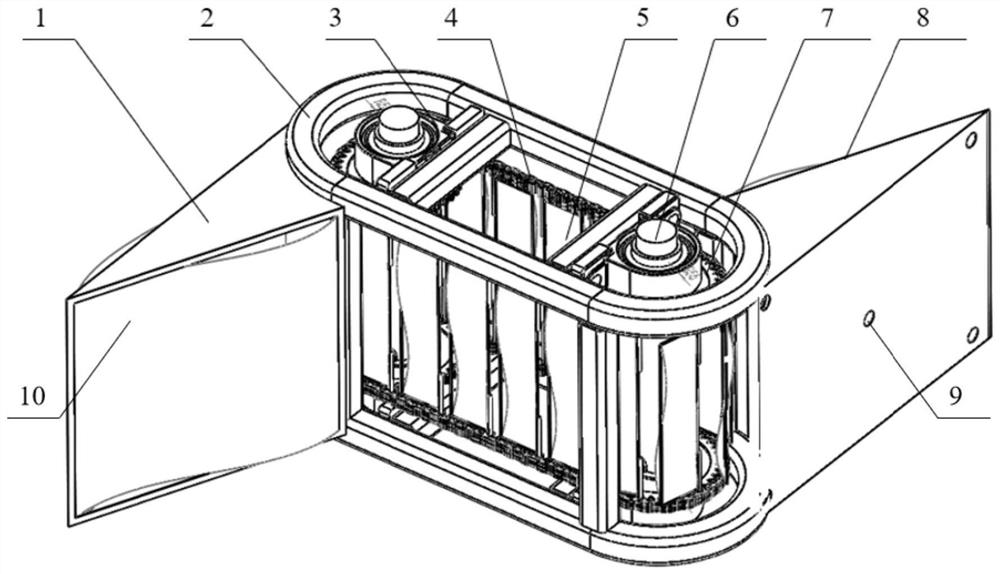

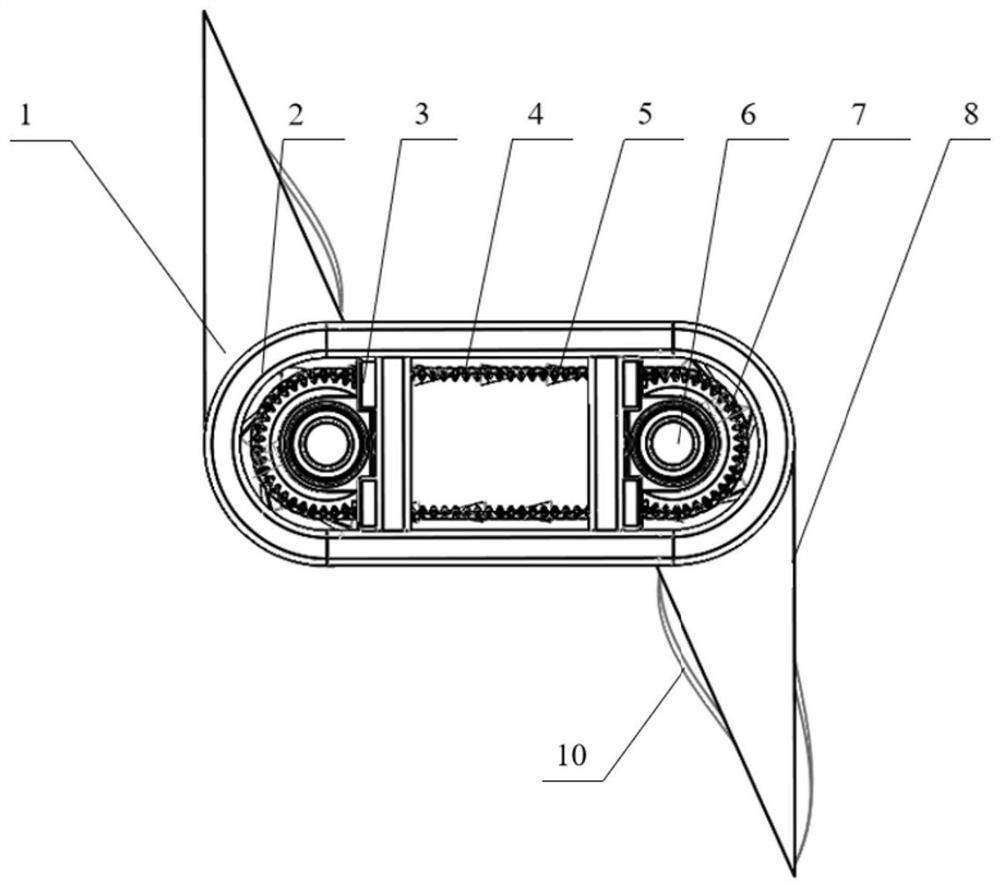

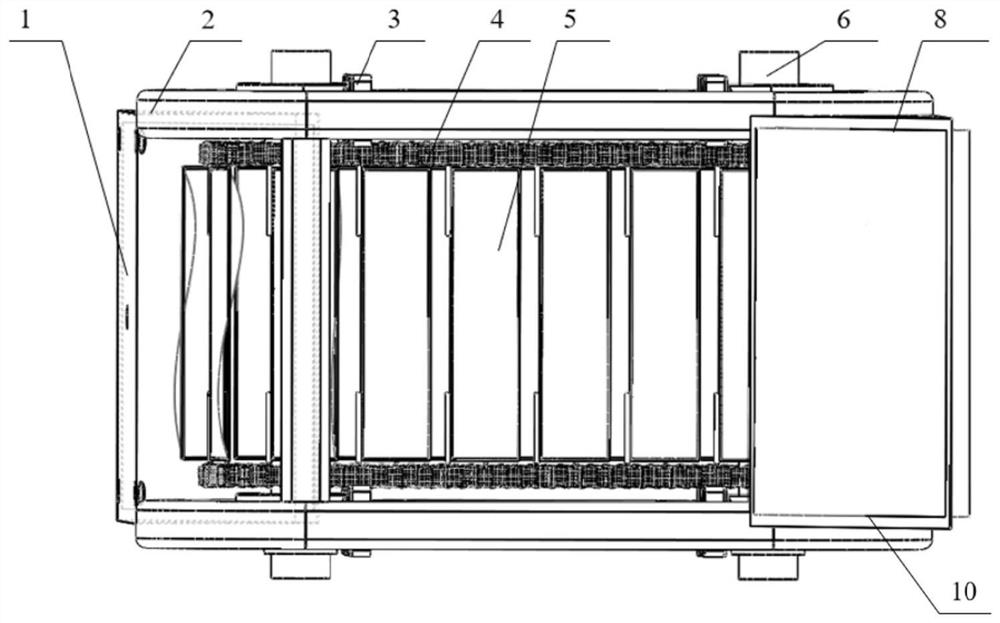

Diversion type double-shaft membrane oscillating water turbine

ActiveCN112879198AImprove efficiencyReduce resistanceHydro energy generationReaction enginesAcute angleEngineering

The invention discloses a diversion type double-shaft membrane oscillating water turbine. A water turbine structure with a diversion function is formed by diversion covers, a water turbine support and a membrane blade structure. One diversion cover is arranged on each of the two sides of the water turbine support, and a rectangular opening is formed in one side of each diversion cover. An included angle between the plane where the side, provided with the rectangular opening, of each diversion cover and the plane where the axes of two rotary supporting shafts are located is an acute angle. Diversion blades are arranged at the openings of the diversion covers, and the diversion blades on the diversion covers, namely the arrangement position of the diversion covers are used for diverting water flow entering the water turbine support and accelerating water flow flowing to the upstream face. Meanwhile, the water flow flowing to the downstream face is reduced, and resistance is reduced. The membrane blade structure is combined, the same-direction torque can be borne on the downstream face and the upstream face, and therefore the efficiency of the whole machine is greatly improved. The water turbine is simple in structure, the flow velocity of the water flow flowing into the water turbine support can be increased through the diversion covers, therefore energy-gathered transmission is conducted, and the conversion rate of water flow transmission is effectively improved.

Owner:XI AN JIAOTONG UNIV

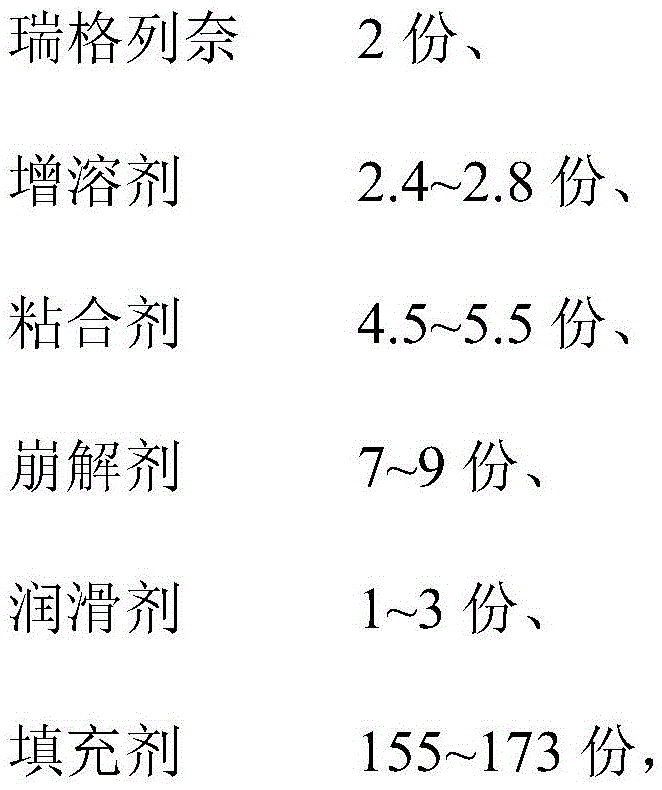

A common repaglinide tablet and preparation method thereof

ActiveCN103919739BReduce degradationGuaranteed disintegrationOrganic active ingredientsMetabolism disorderFiller ExcipientSolvent

The invention relates to the field of pharmaceutical preparations, and discloses repaglinide common tablets and a preparation method thereof. The repaglinide common tablets comprise the following raw materials by weight: 2 parts of repaglinide, 2.4-2.8 parts of a solubilizer, 4.5-5.5 parts of a binder, 7-9 parts of a disintegrating agent, 1-3 parts of a lubricant, and 155-173 parts of a filler, wherein the disintegrating agent is calcium carboxymethylcellulose, and the lubricant is sodium stearyl fumarate. In the prior art, the repaglinide has characteristics of poor stability, oxygen unstability and hygrothermal unstability. According to the present invention, the calcium carboxymethylcellulose is adopted as the disintegrating agent and the stabilizing agent so as to increase the stability of the tablets, effectively delay repaglinide degradation and ensure drug quality; the sodium stearyl fumarate is adopted as the lubricant, such that the hydrophobicity is weak, the delayed effect is low, and the influence on the repaglinide is low; and the repaglinide common tablets of the present invention have characteristics of rapid disintegration, complete dissolution and good stability, and provide more excellent various indexes compared with the existing repaglinide common tablets.

Owner:ZHEJIANG YATAI PHARMA

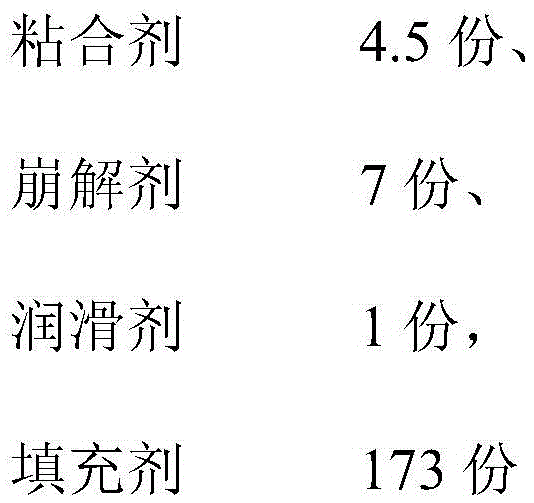

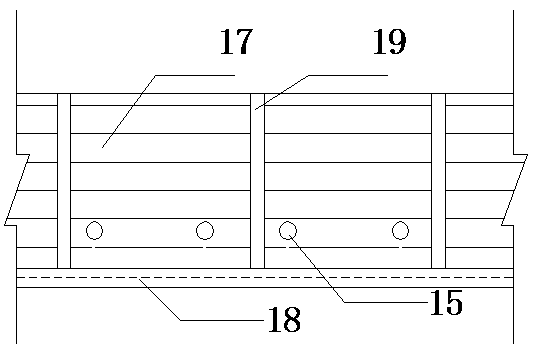

Double-front-baffle three-cavity brush seal structure

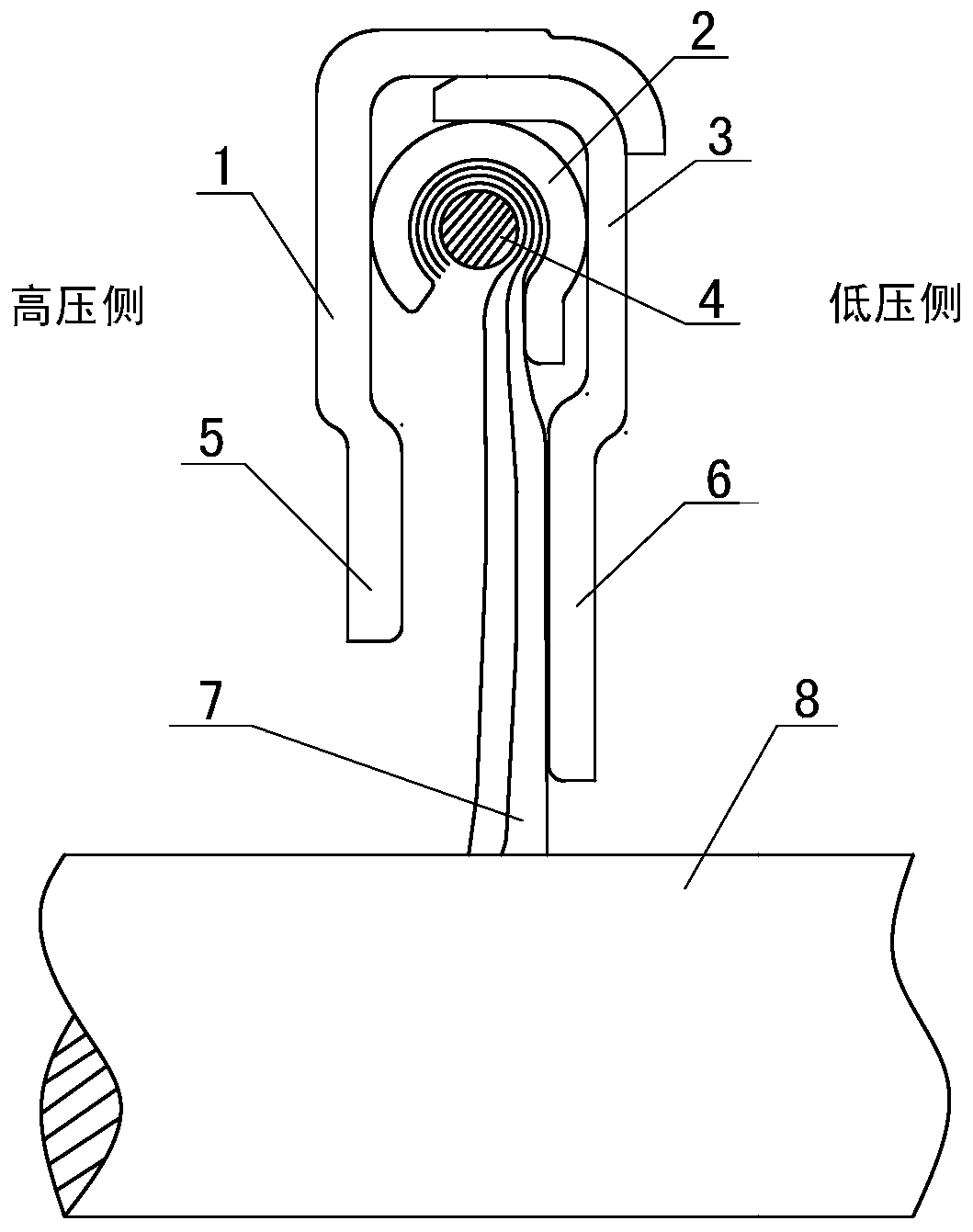

InactiveCN110067602AReduce lateral flowReduce direct leakageLeakage preventionMachines/enginesHysteresisBristle

The invention discloses a double-front-baffle three-cavity brush seal structure. The brush seal structure comprises a first front baffle (1), a second front baffle (2), a rear baffle (5), a fusion welding area (7) and a bristle bundle (8). The first front baffle (1), the second front baffle (2) and the rear baffle (5) are sequentially arranged side by side. A first front cavity (3) is formed between the double front baffles, namely the first front baffle (1) and the second front baffle (2). A second front cavity (4) is formed between the second front baffle (2) and the bristle bundle (8). A rear cavity (6) is formed between the rear baffle (5) and the bristle bundle (8). Bulges and chamfers are correspondingly arranged at the inner diameter ends of the second front baffle (2) and the rearbaffle (5). The double front plates and the rear baffle (5) are correspondingly located on the two sides of the bristle bundle. By the adoption of the technical scheme, the hysteresis effect of a conventional brush seal is eliminated and reduced, the friction between the bristle bundle and a rotor is reduced, the service life of the brush seal is prolonged, the structure is simple and processing is easy.

Owner:SOUTHEAST UNIV

Electromagnetic actuator having a magnetostrictive element and method for operating the electromagnetic actuator

InactiveUS20110148553A1Hysteresis effect is smallRemove restrictionsMagnetostrictive relaysMagnetostrictive devicesEngineeringRelative motion

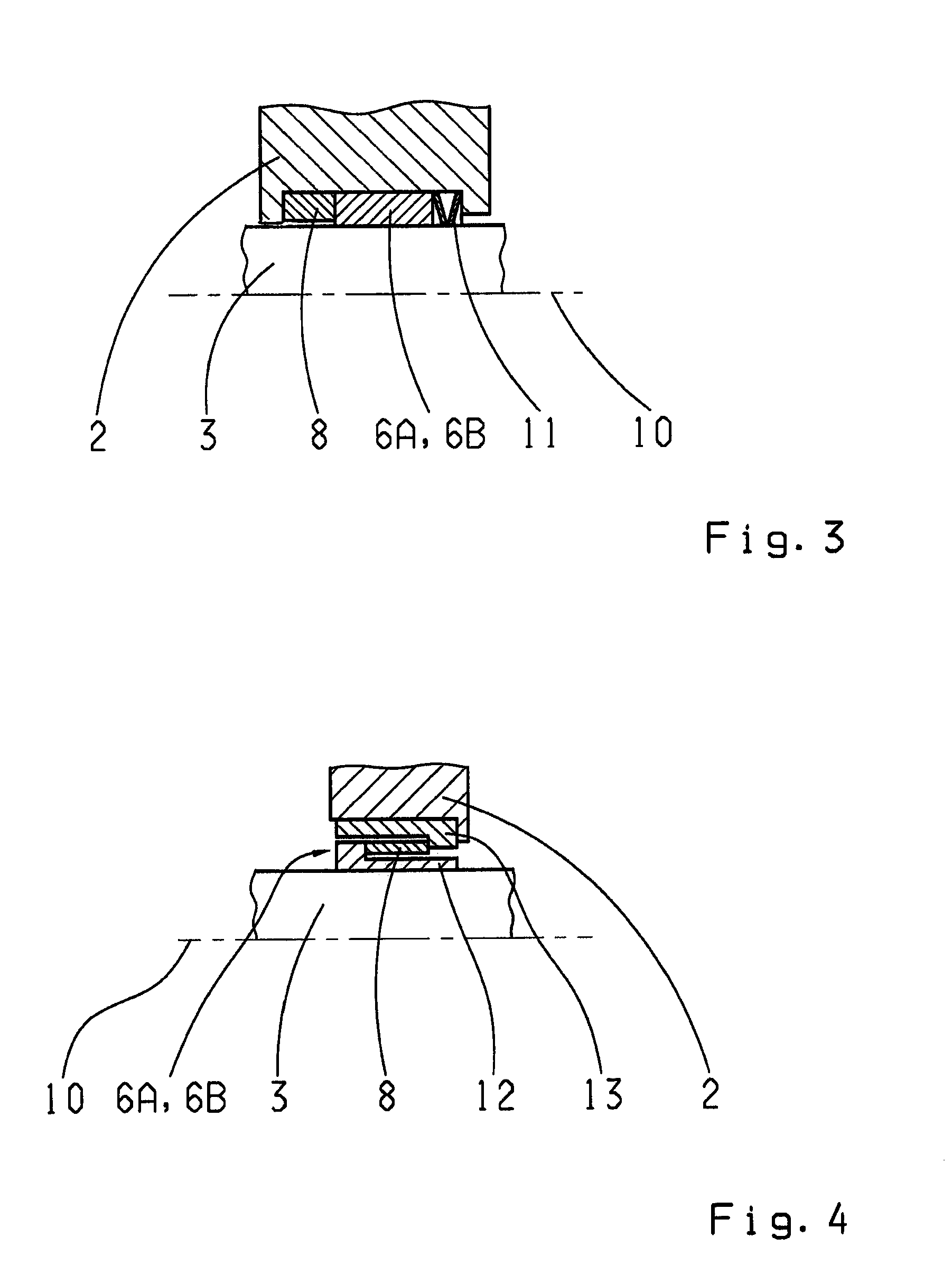

An electromagnetic actuator (1) with an armature (3) mounted so that the armature can be moved by virtue of a bearing arrangement (6A, 6B) and an electric coil (4) is provided for moving the armature (3). A magnetostrictive element (8) is provided, by which relative movement between the armature (3) and at least part of the bearing arrangement (6A, 6B) is produced.

Owner:ZF FRIEDRICHSHAFEN AG

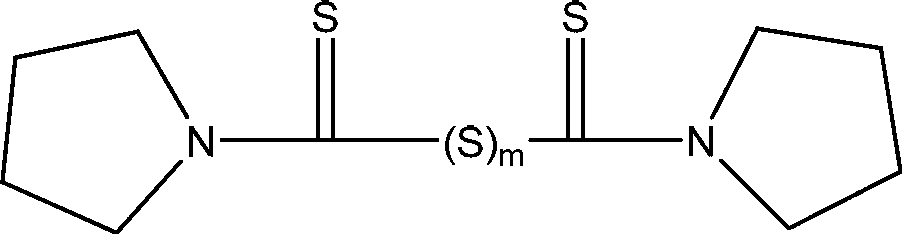

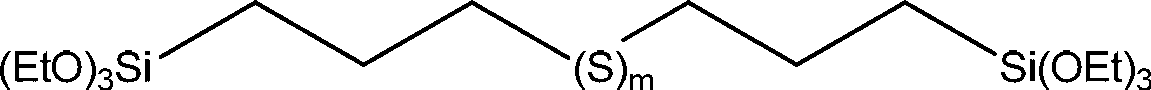

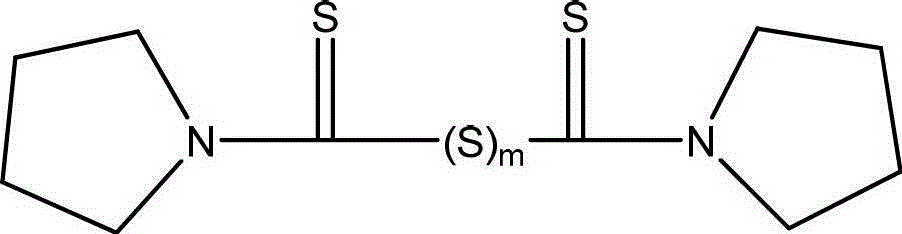

Rubber composite used for bonding belt ply of tire and tire manufactured with the composite

The invention relates to rubber composite used for bonding a belt ply of a tire and the tire manufactured with the composite. The rubber includes 100 parts by weight of raw material rubber; 0.01 to 10 parts by weight of aromatic polyamide short fiber particles formed by more than two strands of aromatic polyamide short fiber and containing rubber penetrated between the twisted aromatic polyamide short fibers. The rubber composite used for bonding the belt ply of the tire can improves the rigidity of rubber used for bonding the belt ply of the tire, reducing bonding thickness and reducing hysteresis effect of the rubber used for bonding the belt ply of the tire, so that energy loss caused by the rotation of the tire can be reduced.

Owner:HANKOOK TIRE WORLDWIDE

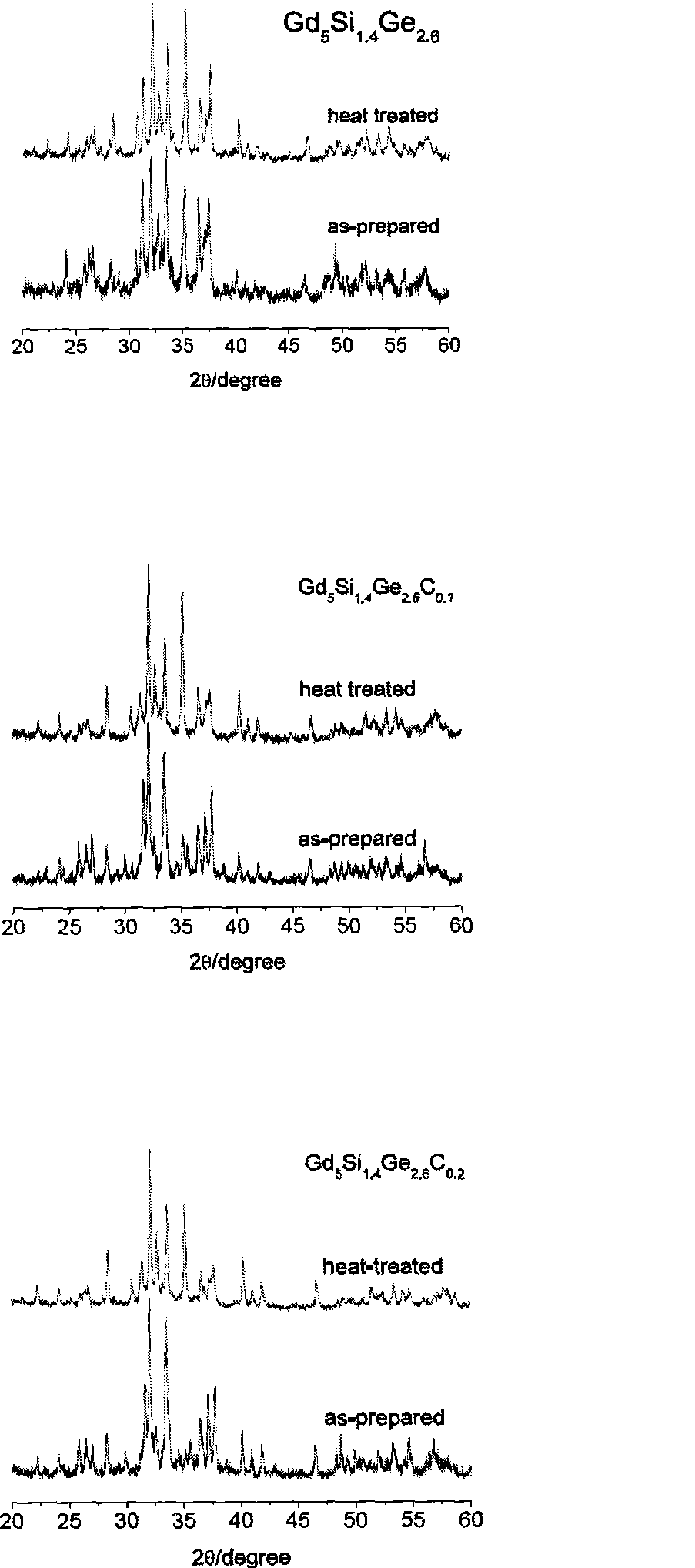

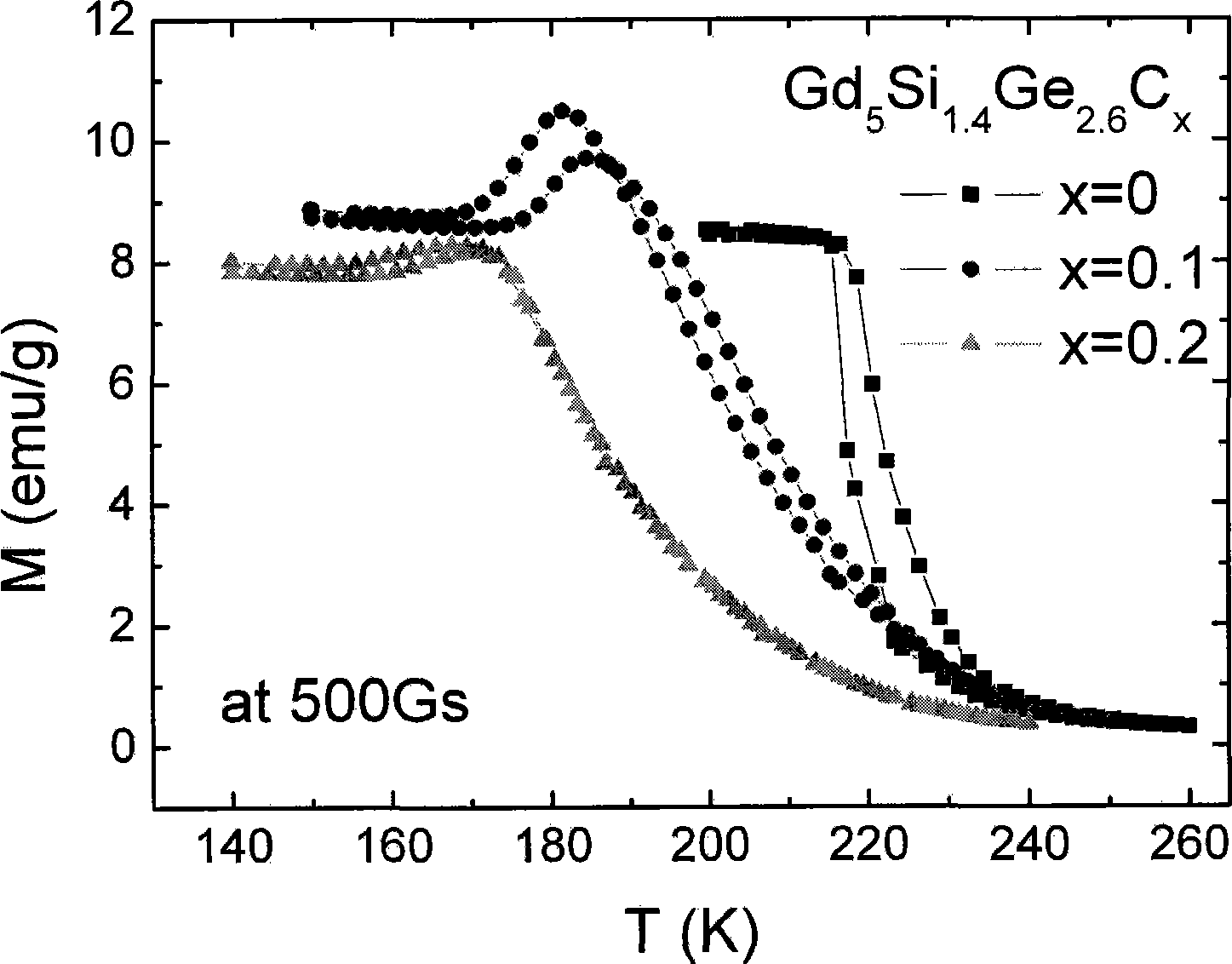

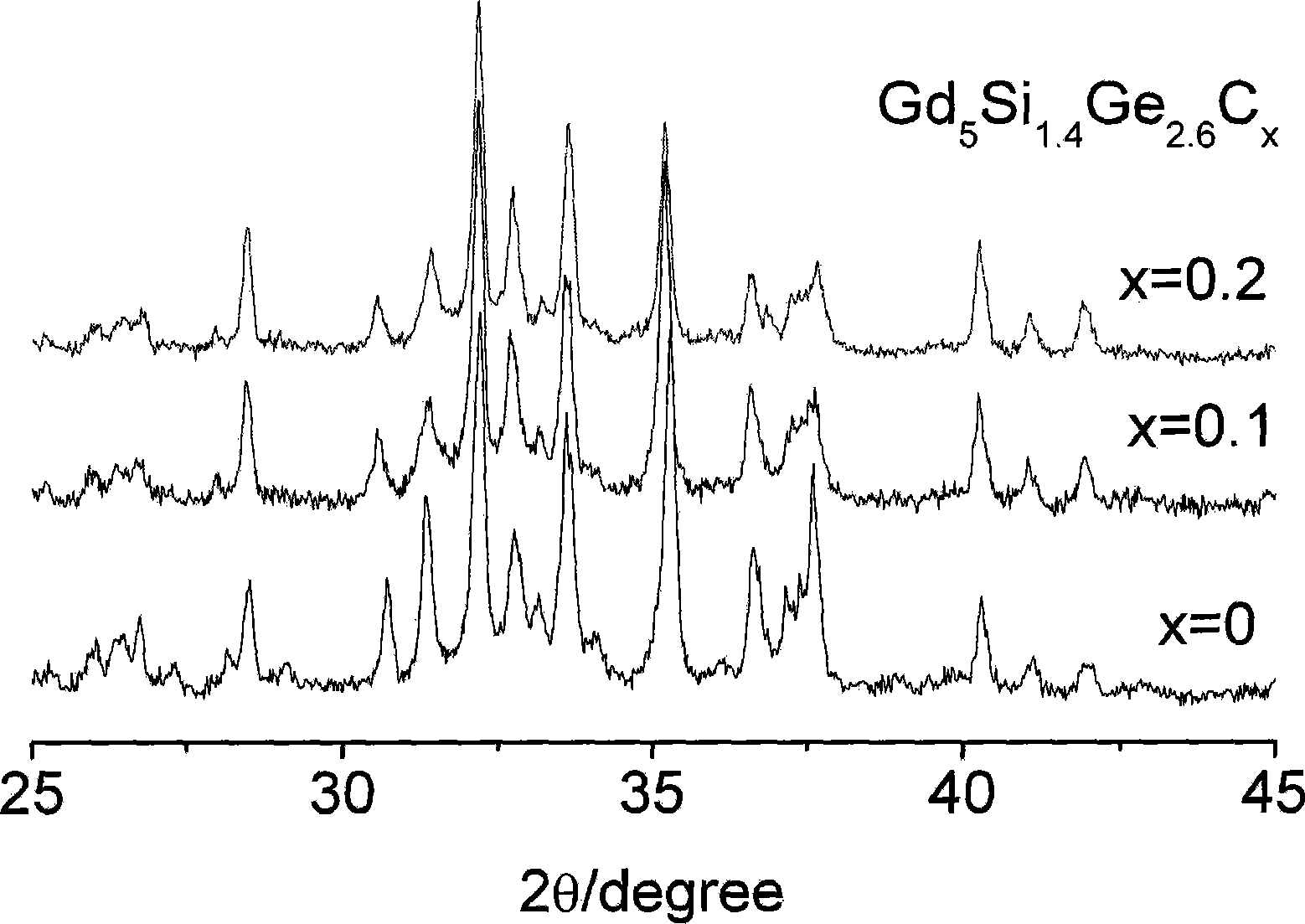

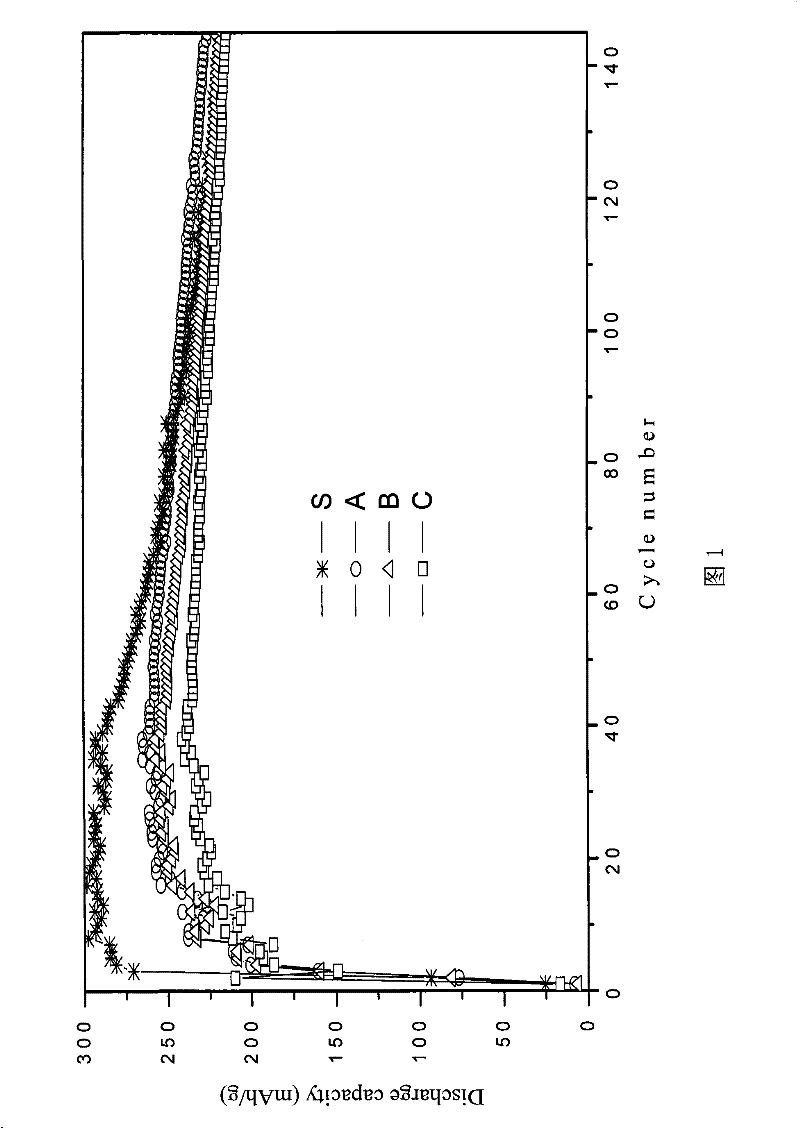

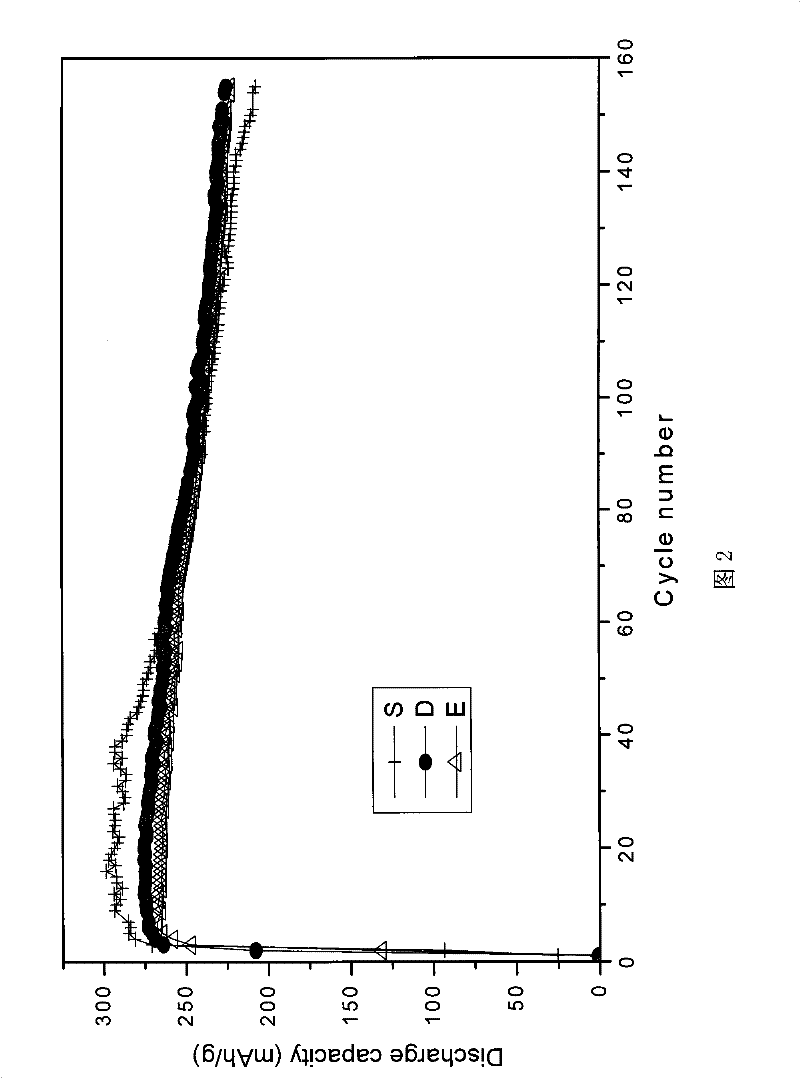

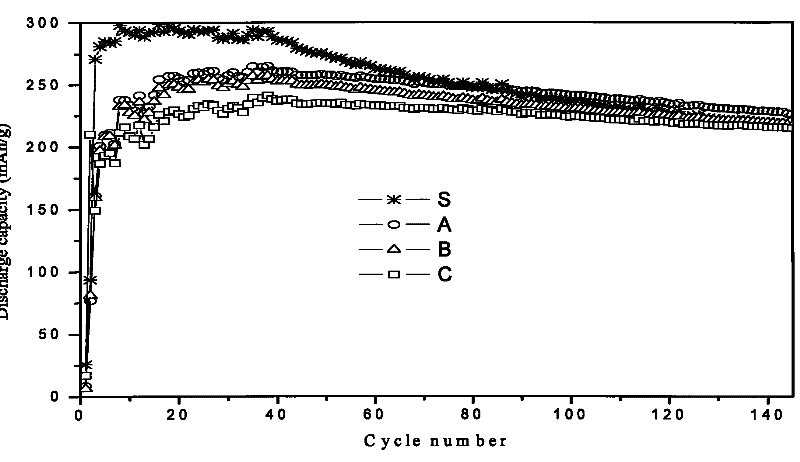

Clearance type Gd-Si-Ge magnetic cooling material and manufacturing method thereof

ActiveCN101532109AHysteresis effect is smallMaintain a large magnetocaloric effectThermoelectric devicesTa elementTantalum

The invention belongs to the technical field of magnetic cooling material and a manufacturing method thereof, particularly relates to a clearance type Gd-Si-Ge magnetic cooling material and a manufacturing method thereof. The method comprises the steps of batching, smelting and heat treatment; the chemical general formula of the material is clearance type Gd5Si1.4Ge2.6Cx compound, wherein, x is 0.01-2; raw material with a purity more than 99.9at% is placed in an electric arc furnace according to mixture ratio of the Gd5Si1.4Ge2.6Cx and is melted in a turning over manner with the protection of high-purity argon, thus obtaining uniform alloy cast ingots; the melted cast ingots with tantalum sheets are packaged and encapsulated in a vacuumized tube for heat treatment; samples of the cast ingots which goes through the heat treatment is directly placed in liquid nitrogen for quenching from high temperature , thus obtaining the Gd5Si1.4Ge2.6Cx compound; the method also comprises the step of adding interstitial atom C. The material of the invention has lower temperature delay and magnetic lag, better thermal stability and large magnetothermal effect, good repetitiveness and uniformity and stable performance.

Owner:CENT IRON & STEEL RES INST

Rare-earth series hydrogen storage alloy

InactiveCN101532102BPrevent oxidationReduce microhardnessAlkaline accumulator electrodesRare earthCo element

Owner:HENAN UNIV OF SCI & TECH

Piezoelectric valve

ActiveCN101755157BLow reliabilitySmall flow powerOperating means/releasing devices for valvesThin material handlingEngineeringNozzle

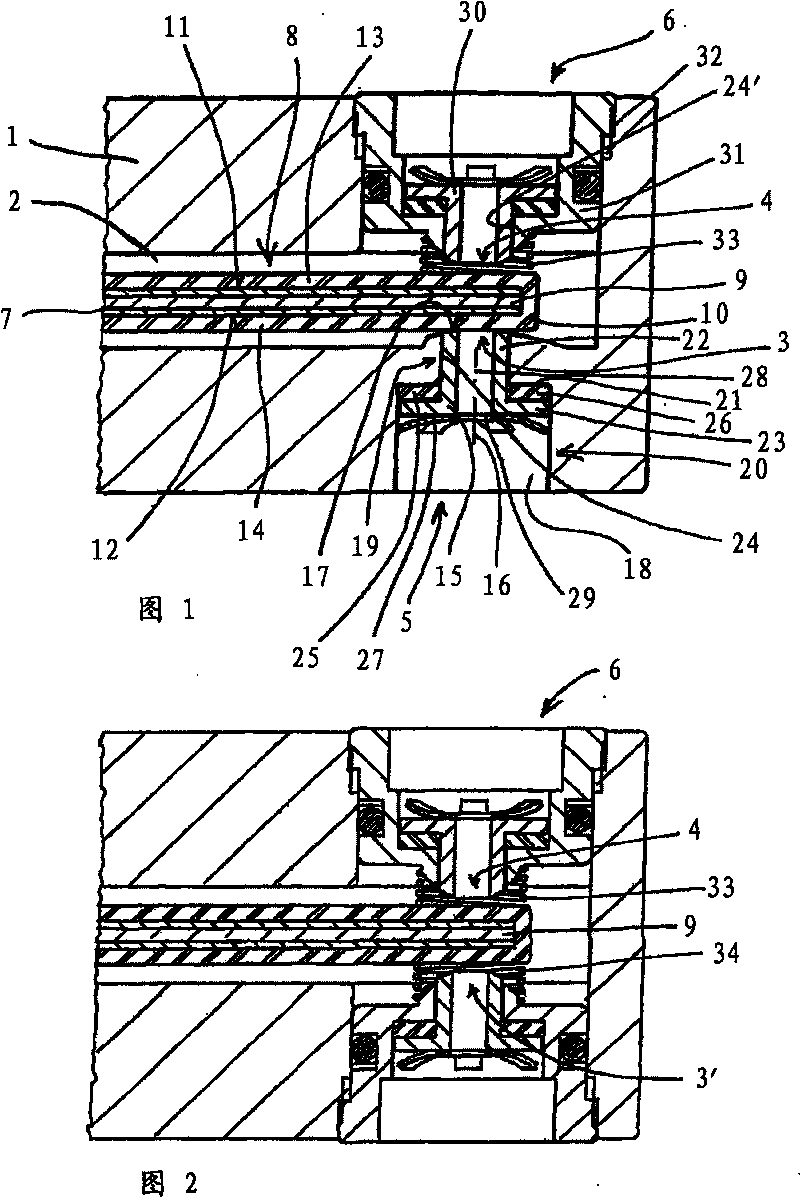

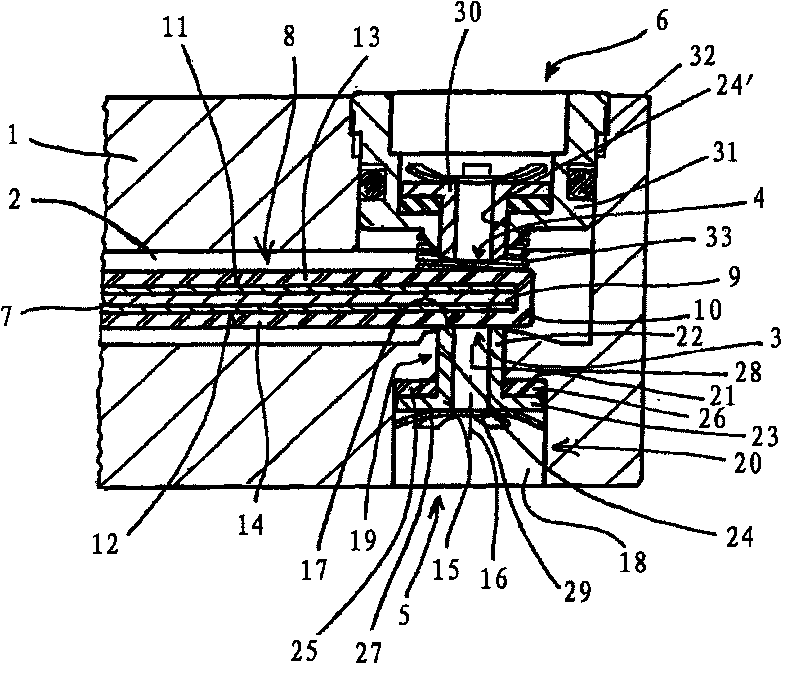

The invention relates to a piezoelectric valve having a housing (1), comprising an inner chamber (2) through which a medium can flow, wherein at least one nozzle (3, 3'; 4) that communicates with an associated connection (5; 6) for the flow medium and having a sealing seat with a seat surface ends in said chamber. The inner chamber of the housing receives a piezoelectric flexible element (7) deformable by electric energization such that the nozzle (3, 3'; 4) can be closed by a section (9) of the flexible element, the section being moveable relative to the nozzle due to the deformation of the flexible element (7). The flexible element comprises a support (13; 14) in the region opposite the nozzle, the support being made of an elastic resilient material. The sealing seat is arranged on a nozzle insert (15; 30) on the front side, said insert being movably arranged substantially perpendicular to the seat surface (17) in a receptacle (24; 24') on the housing, wherein between the receptacleand the associated nozzle insert, a thermally expandable compensation member (25) acts.

Owner:HOERBIGER FLOW CONTROL GMBH

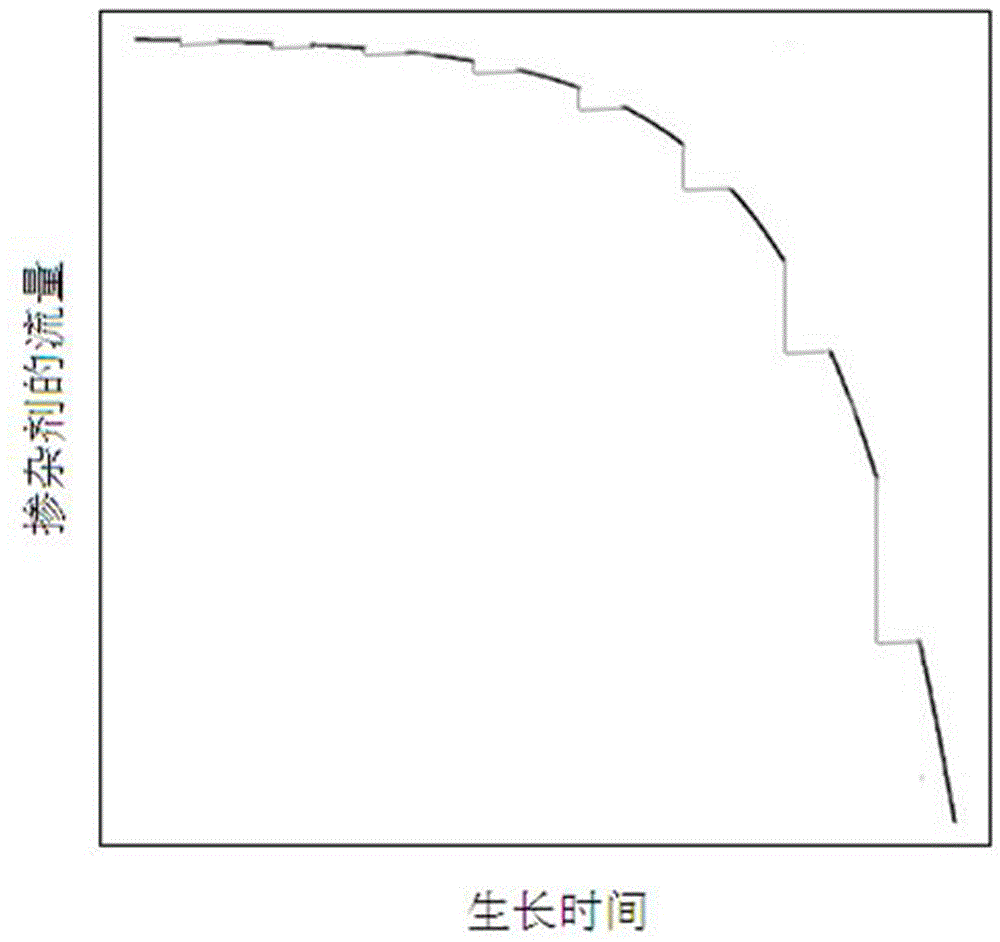

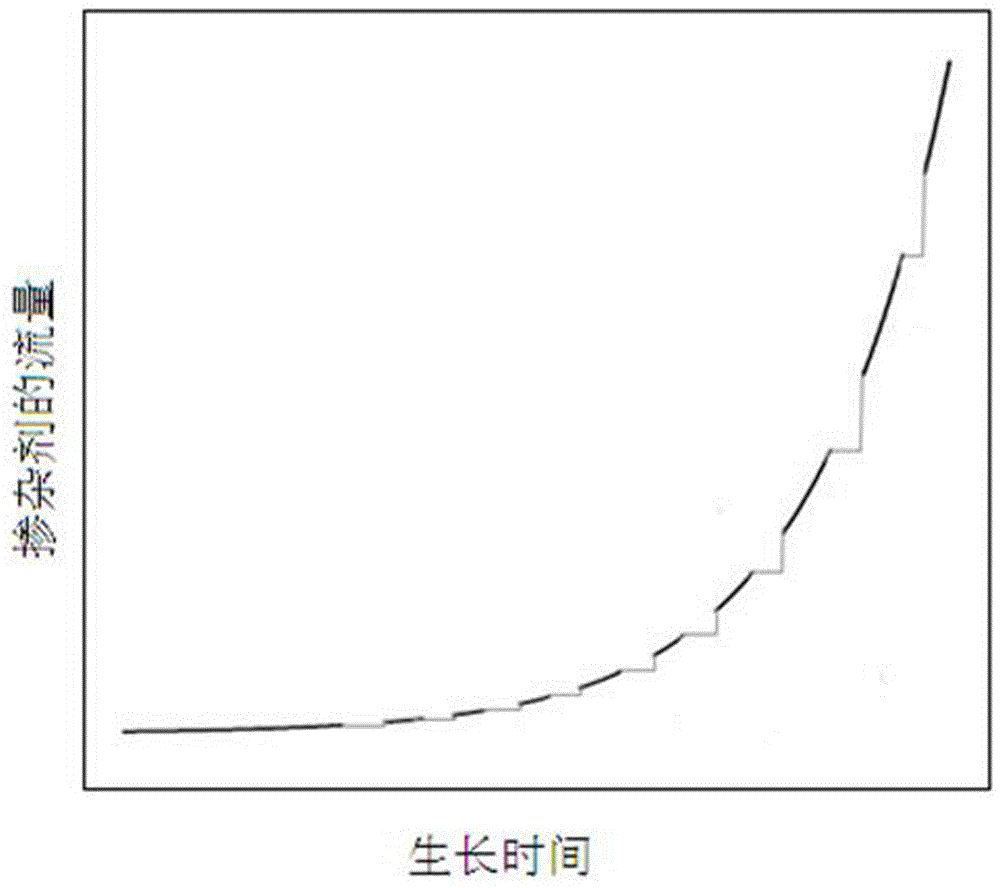

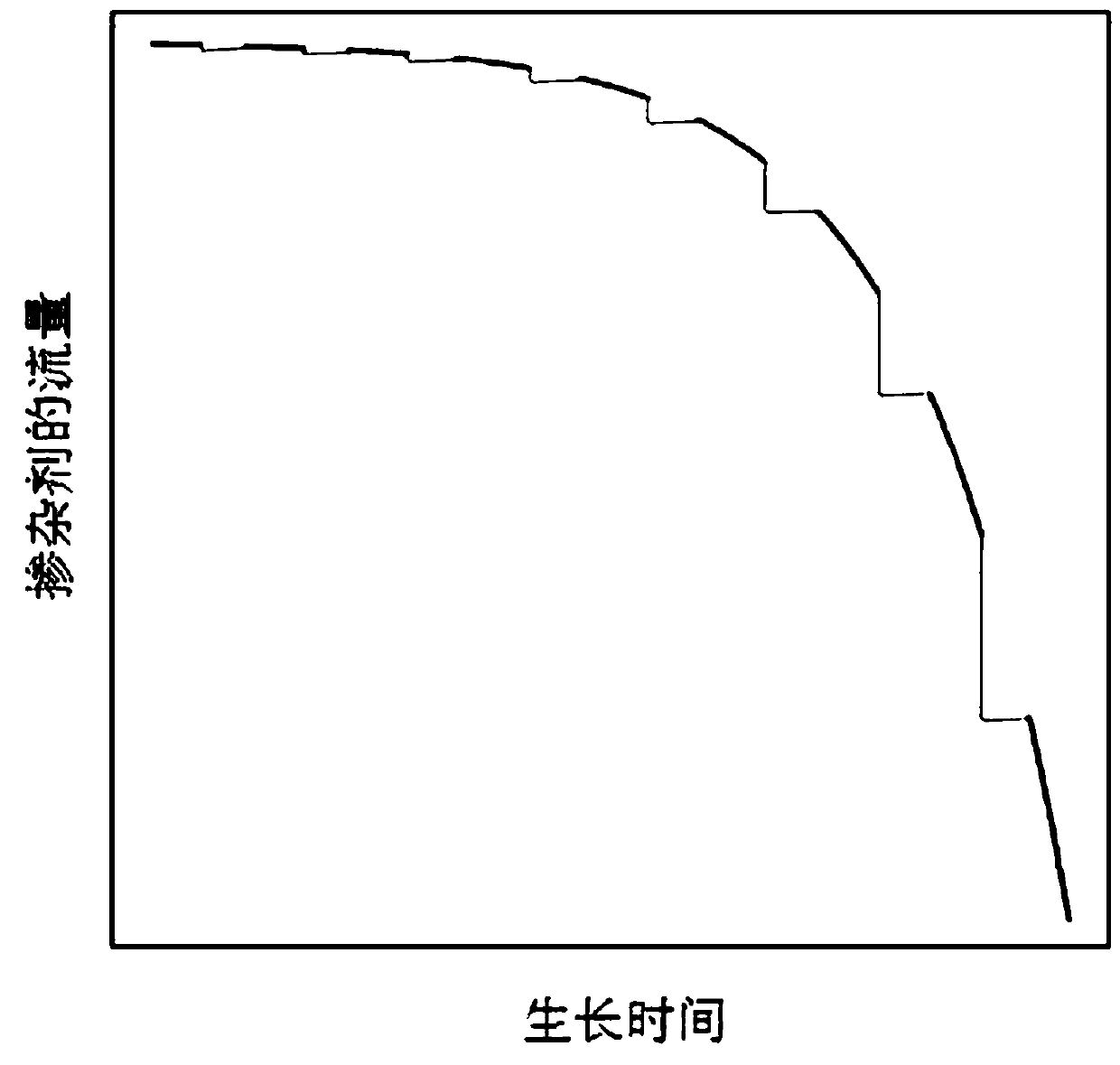

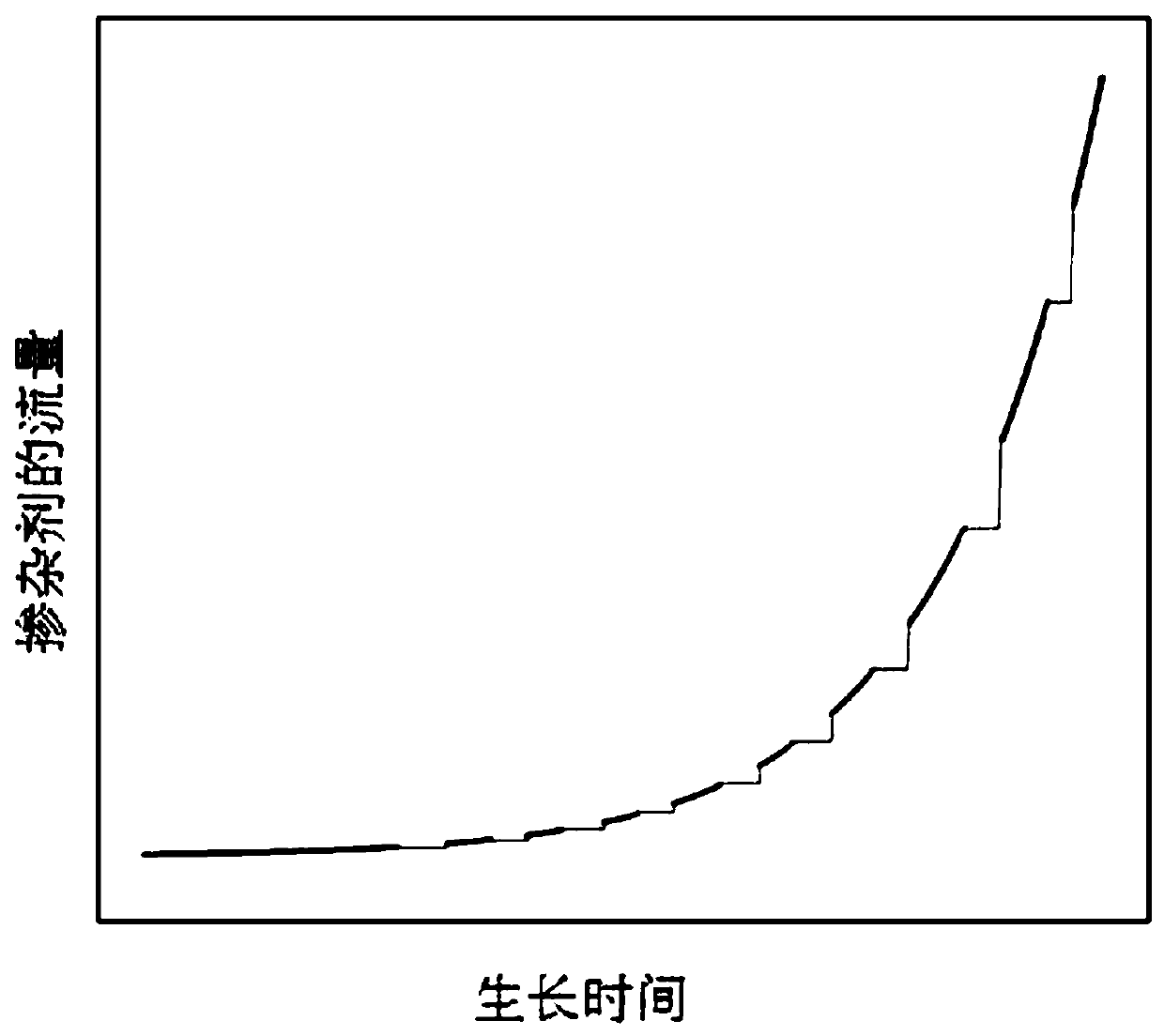

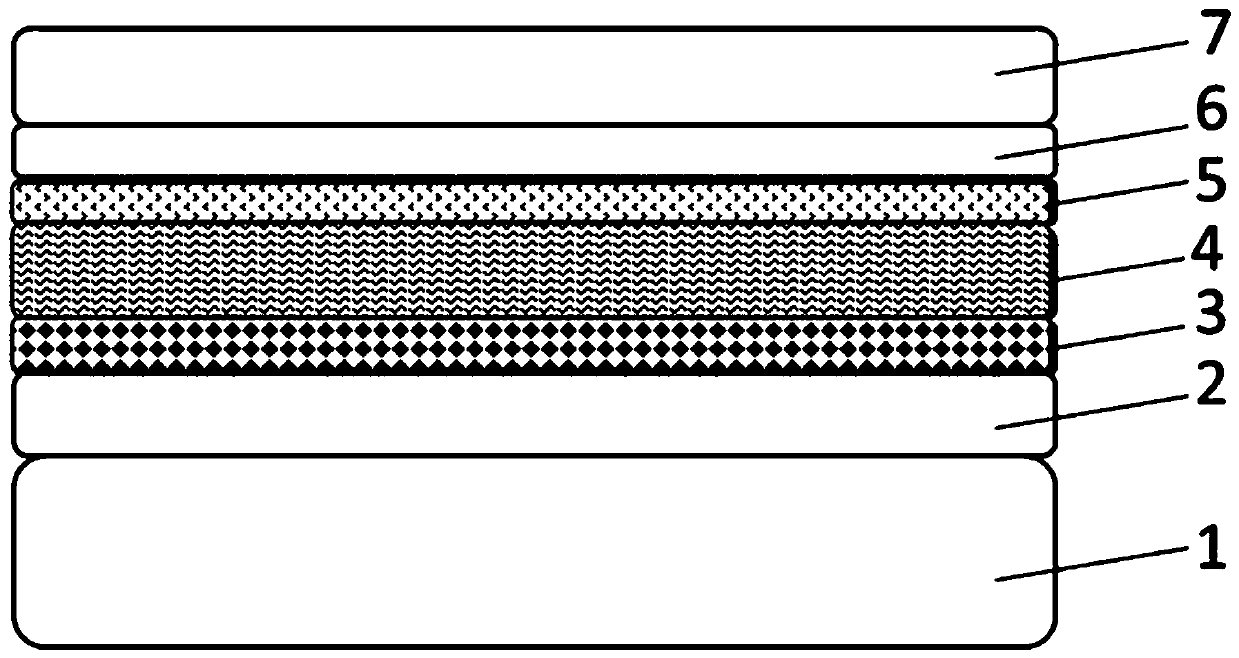

Solar battery with functional areas prepared by means of digital-exponential hybrid doping mode and preparation method of solar battery

ActiveCN106252463AEasy to separateReduce compound rateFinal product manufacturePhotovoltaic energy generationDopantTerra firma

The invention discloses a solar battery with functional areas prepared by means of a digital-exponential hybrid doping mode and a preparation method of the solar battery. According to the preparation method, the functional areas of the solar battery are prepared through a digital doping and exponential doping cooperated mode. According to the digital doping and exponential doping cooperated mode, digital doping is carried out on a doping area sectionally, and a dopant is doped into a reaction chamber, the flow rate of the dopant going through digital jump; and exponential change occurs between two adjacent doping concentrations. According to the solar battery using the digital-exponential hybrid doping mode, the digital-exponential hybrid doping mode is adopted to form the main functional layers of the solar battery, so that an enhanced built-in electric field can be formed, and more effective separation of photo-generated carriers can be prompted. With the solar battery adopted, the lifetime of the photo-generated carriers can be prolonged remarkably, so that the mobility of the carriers can be improved; and the open-circuit voltage of the battery can be improved significantly; and a solid foundation can be laid for the development of next-generation ultra-efficient solar batteries.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

A method and application for preparing gn@cellulose-based solid-solid phase change fibers in different phases

ActiveCN110629551BWith heat storage and temperature adjustment functionRealize secondary processingHeat-exchange elementsVegetal fibresPolymer scienceCellulose fiber

The invention discloses a method and application for preparing GN@cellulose-based solid-solid phase change fibers in different phases. The method includes: (1) cellulose fiber dispersion; (2) surface graft modification: reacting halogenated acid halide monomers with cellulose to obtain cellulose ester; (3) SI-ATRP method reaction: step 2) After the obtained cellulose ester, GN and solvent B are uniformly dispersed, a ligand, a catalyst and an alkyl acrylate are added to react to obtain a reaction mixture; (4) purification: after purifying the reaction mixture obtained in step 3), GN@cellulose- g-Polyalkylacrylate solid-solid phase change fiber. The fiber is pressed into a film to obtain a film. In this method, cellulose fibers are used as the matrix, halogen functional groups are grafted through an acylation reaction, and alkyl acrylates are directly grafted on the surface of the modified cellulose fibers through SI-ATRP without changing the structure of the cellulose fibers. For reinforcing materials, fibers with flexibility, high thermal conductivity and high enthalpy value are prepared without post-processing, which is conducive to secondary processing.

Owner:TIANJIN POLYTECHNIC UNIV

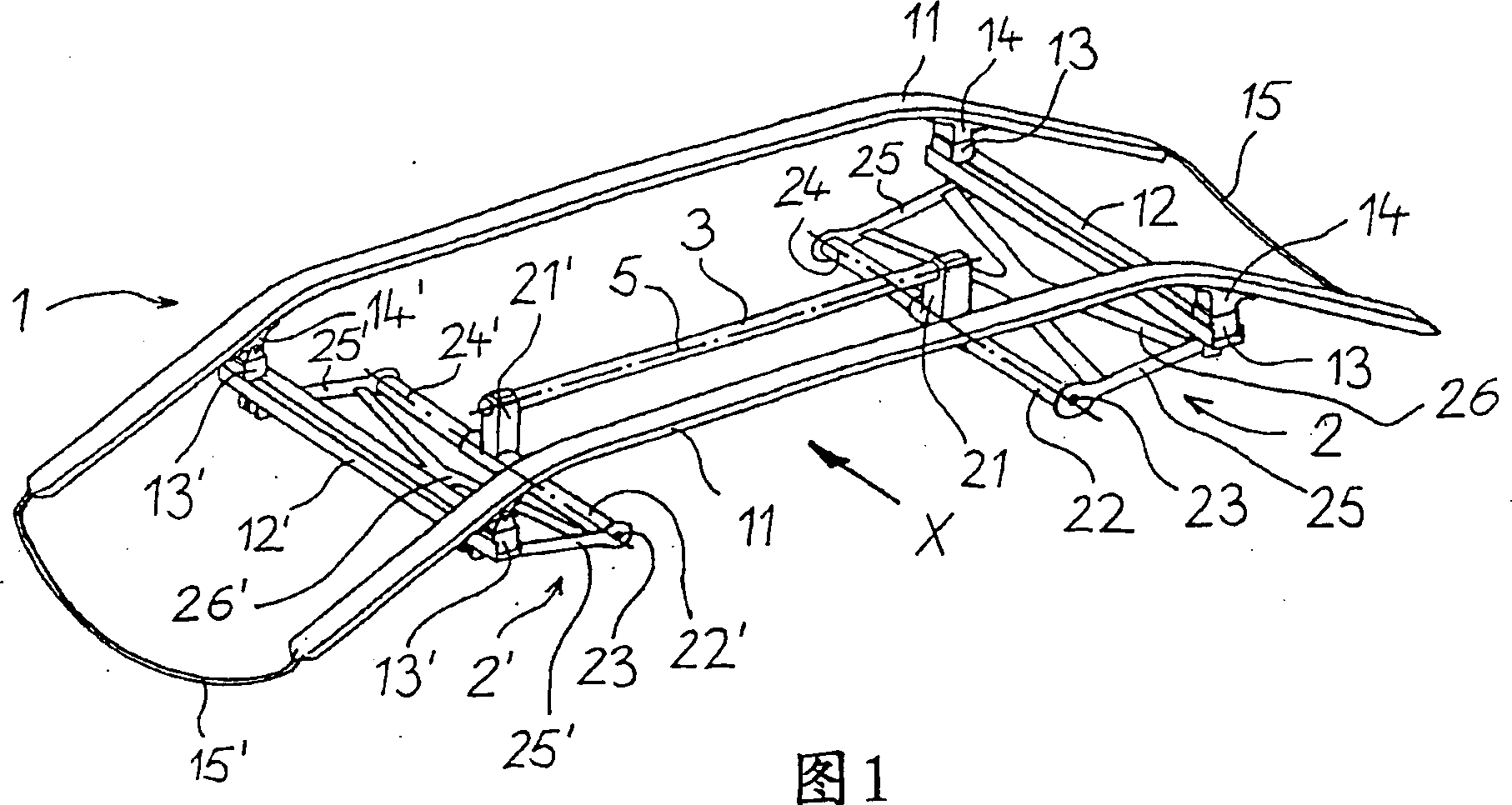

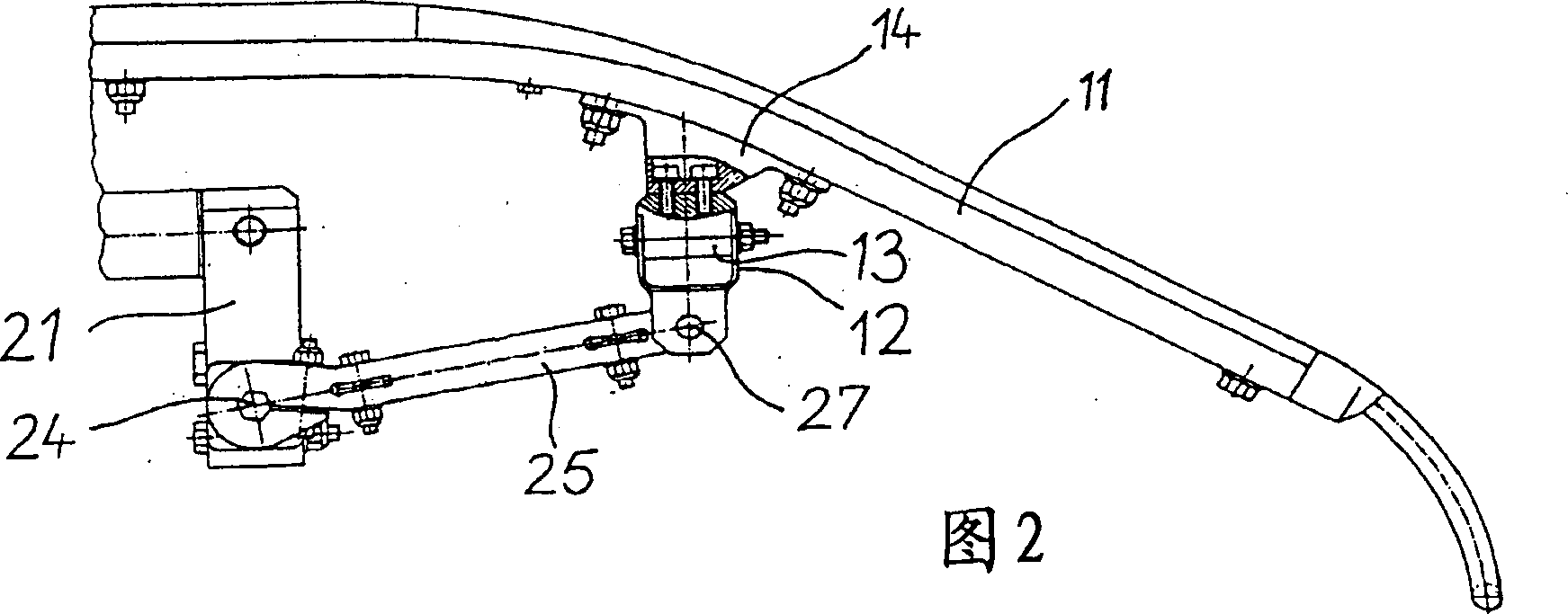

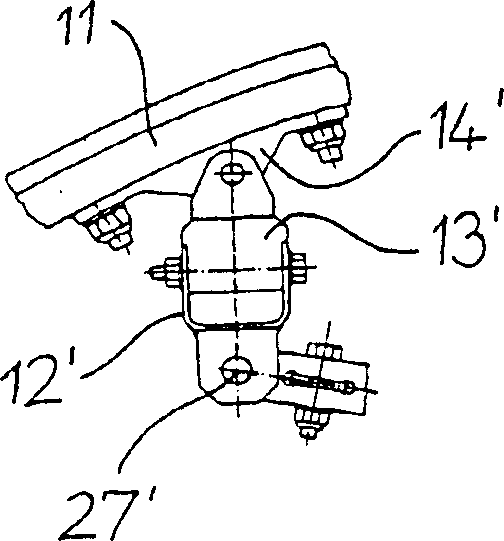

Suspension spring

InactiveCN1273323CReduce air resistanceReduce coefficient of frictionRailway vehiclesPower current collectorsEngineeringSlide plate

The invention relates to a bow suspension for a current collector of electrically driven vehicles, in particular rail vehicles. Said bow suspension comprises a frame (1) which has a pantograph contact strip (11) that is supported on an apex shaft (3) by a spring arrangement (2, 2'), said apex shaft (3) being rotatably mounted in an apex tube for connection to a chassis of the current collector. The spring arrangement (2, 2') of said bow suspension has a torsion spring (23, 23') and exhibits a defined rigidity that is independent of the airstream, even at high-speed operation, and a vertical spring displacement which is predetermined by the network operator.

Owner:BOMBARDIER TRANSPORTATION GMBH

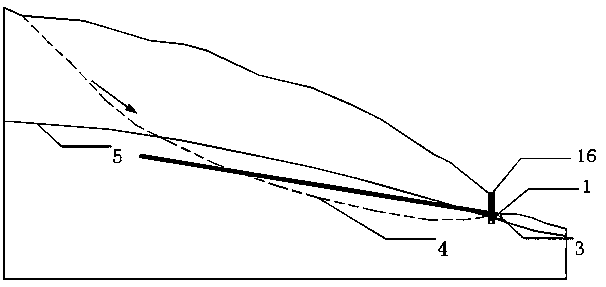

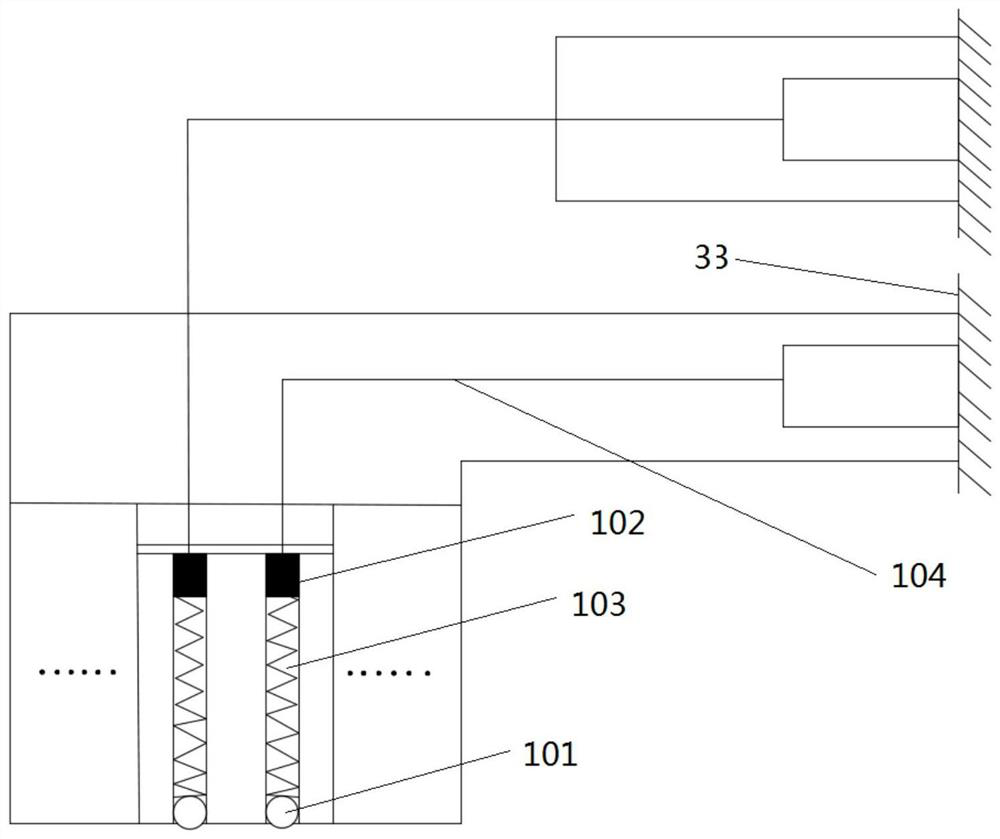

Core-pulling type horizontal sand well used for deep-seated landslide drainage

PendingCN109763501ADrain permanentlyReduce maintenance costsClimate change adaptationExcavationsGeotextileEnvironmental geology

The invention relates to a core-pulling type horizontal sand well used for deep-seated landslide drainage. The core-pulling type horizontal sand well comprises a sand well main body, wherein the sandwell main body has a slope, a retaining wall is arranged on the front edge of the slope, a drilling hole is formed in the slope, a core-pulling type horizontal sand well structure is embedded in the drilling hole, and the core-pulling type horizontal sand well structure at least comprises a PVC pipe, a geotechnical cloth bag, main reinforcements, dual-ring shaped hoopings, sand, a drainage pipe and a well lid; the geotechnical cloth bag is longitudinally provided with the two dual-ring shaped hoopings; every two adjacent dual-ring shaped hoopings are connected with each other in series by three main reinforcements; one end of the drainage pipe penetrates through the well lid and is exposed outside; a gap between two layers of geotechnical cloth is filled with the sand; a drainage hole is formed in the wall of the PVC pipe; the well lid is used for sealing the drilling hole and is flush with the retaining wall. In the core-pulling type horizontal sand well, the core-pulling type horizontal sand well structure can be connected with the drainage hole in the wall surface of the retaining wall, so as to form a complete drainage system, so that the deep-seated landslide drainage rate isincreased, and the affection on the landslide stability of underground water is reduced to the maximum extent.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI

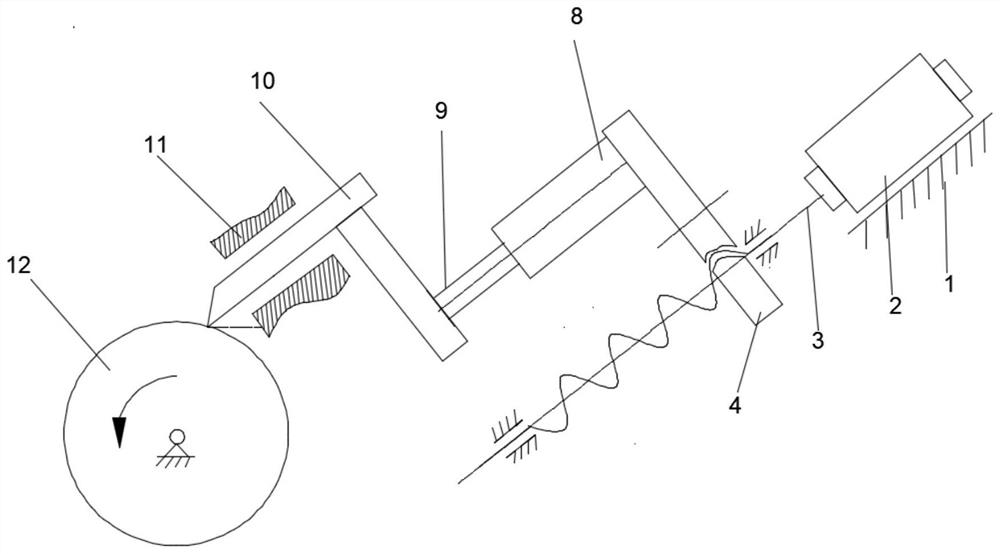

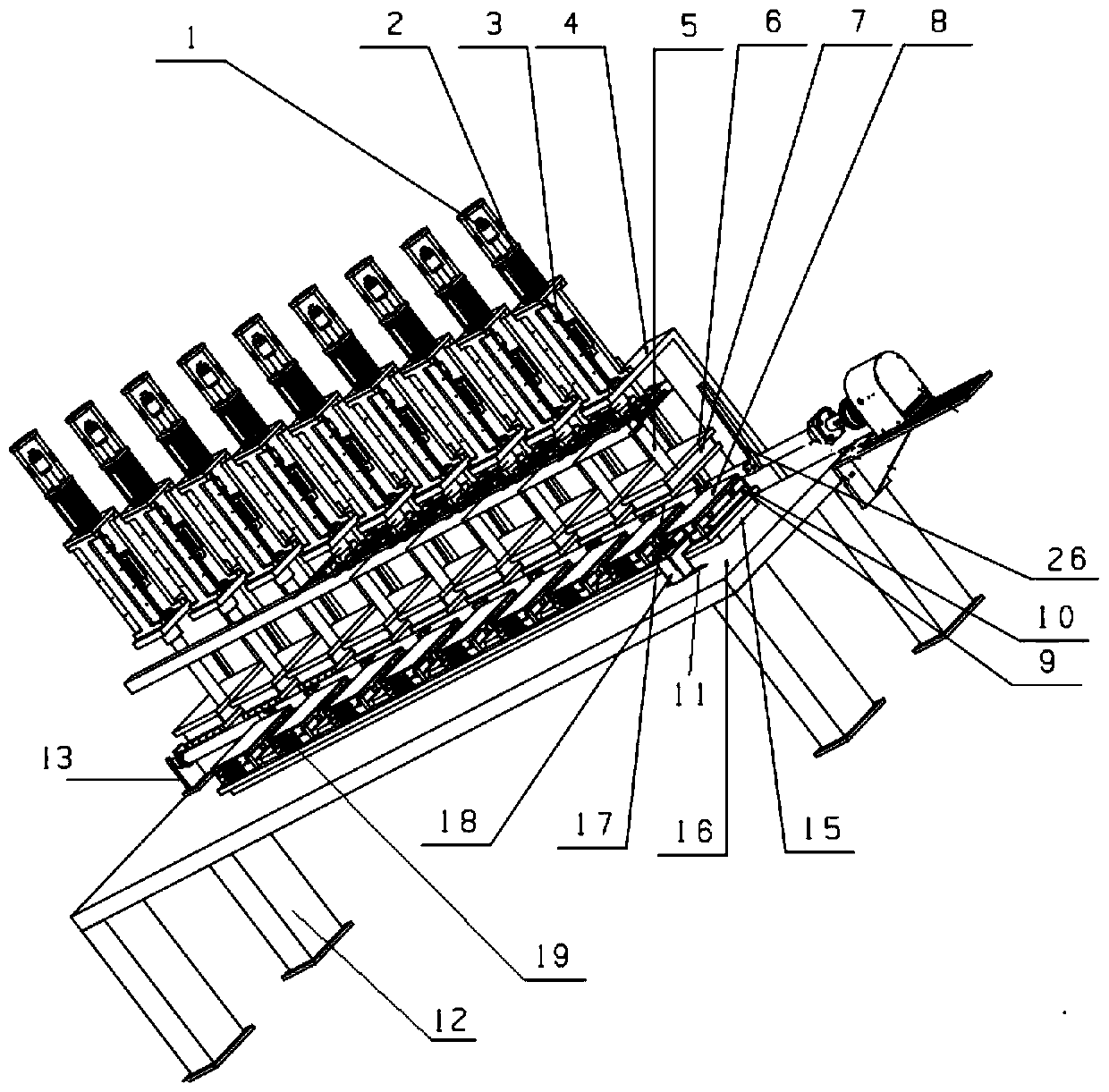

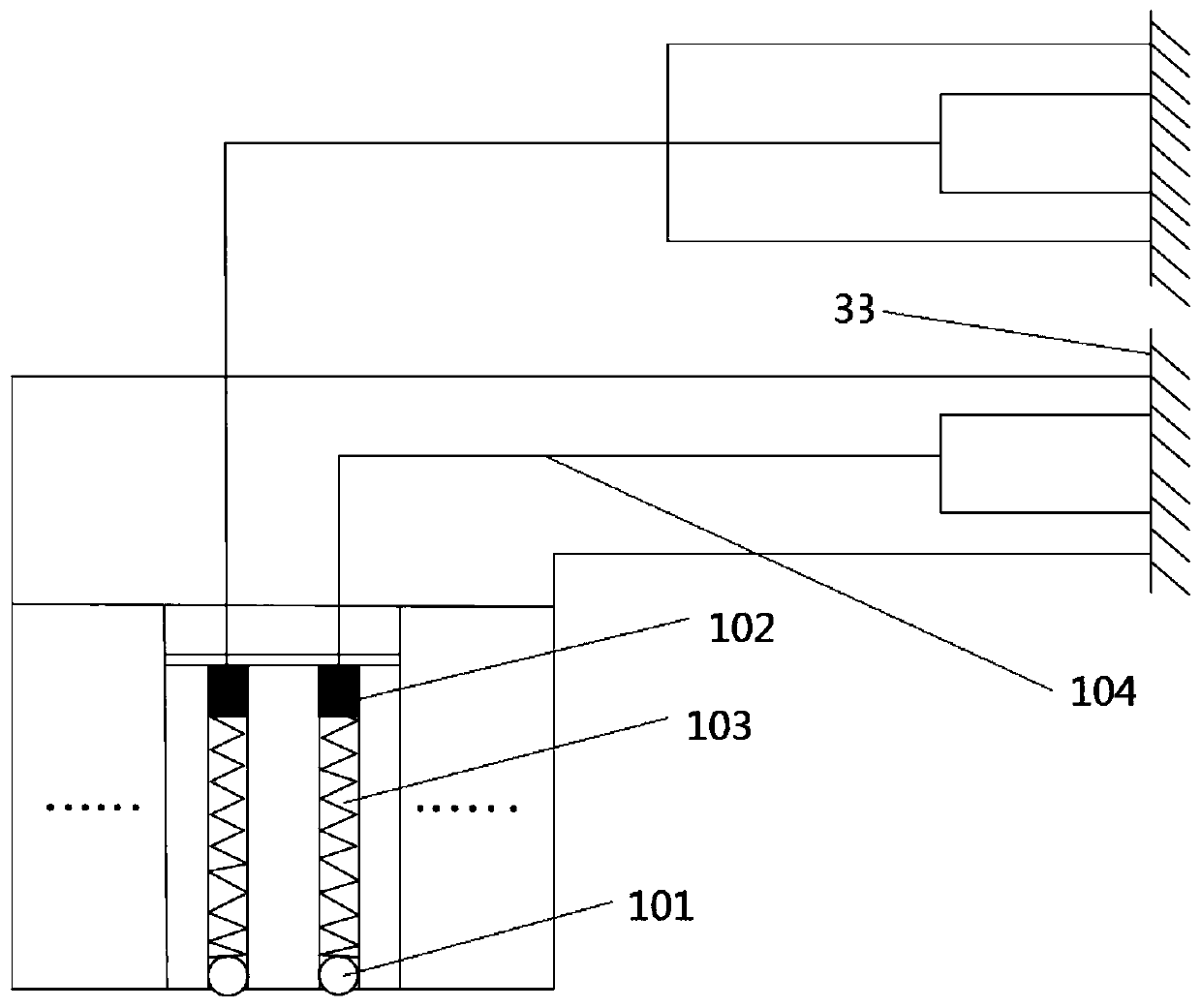

Super magnetostrictive material ink scraper feeding mechanism for flexo printing machine

PendingCN111823708AHigh magnetostriction coefficientLow saturation magnetic fieldPrinting press partsAgricultural engineeringElectric machinery

The invention provides a super magnetostrictive material ink scraper feeding mechanism for a flexo printing machine. The machine comprises a coarse feed mechanism and a micro feed mechanism. The coarse feed mechanism comprises a motor arranged on a frame and a linear feed component driven by the motor. The micro feeding mechanism comprises a shell arranged on the linear feed component, a driving coil arranged in the shell, a giant magnetostrictive sheet which can be deformed by the magnetic field of the driving coil, and a propulsion rod driven to realize micro feeding by the giant magnetostrictive sheet. The propulsion rod is provided with an ink scraper. Through the feeding movement of the ink scraper, the ink quantity of an anilox roller is controlled. The mechanism can solve the problems of low feed precision, large error and difficulty in accurately controlling the amount of supply ink for printing of traditional ink scraper feeding mechanisms.

Owner:静宁县恒达有限责任公司 +1

A kind of gn@cellulose-based solid-solid phase change material and its preparation method and application

ActiveCN110698597BImprove solubilityRealize secondary processingMonocomponent synthetic polymer artificial filamentHeat-exchange elementsPolymer scienceSpinning

The invention discloses a GN@cellulose-based solid-solid phase change material and a preparation method and application thereof. The method includes: (1) dissolving cellulose; (2) homogeneous graft modification: reacting halogenated acid halide monomers with cellulose to obtain cellulose ester; (3) ATRP reaction: reacting the obtained cellulose ester in step 2). After the cellulose ester, GN and solvent B are uniformly dispersed, add ligand, catalyst and alkyl acrylate to react to obtain a reaction mixture; (4) purification: after purifying the reaction mixture obtained in step 3), GN@cellulose-g- Polyalkylacrylate copolymer. The copolymer is melt extruded and spun to obtain solid-solid phase change fibers. The copolymer was electrospun to obtain a film. In this method, cellulose fiber is used as the matrix, halogen functional groups are grafted through acylation reaction, and alkyl acrylate is grafted on the cellulose skeleton through ATRP, and graphene is used as reinforcing material to prepare flexible and high thermal conductivity without post-processing. , Fiber with high enthalpy value, which is conducive to secondary processing.

Owner:TIANJIN POLYTECHNIC UNIV

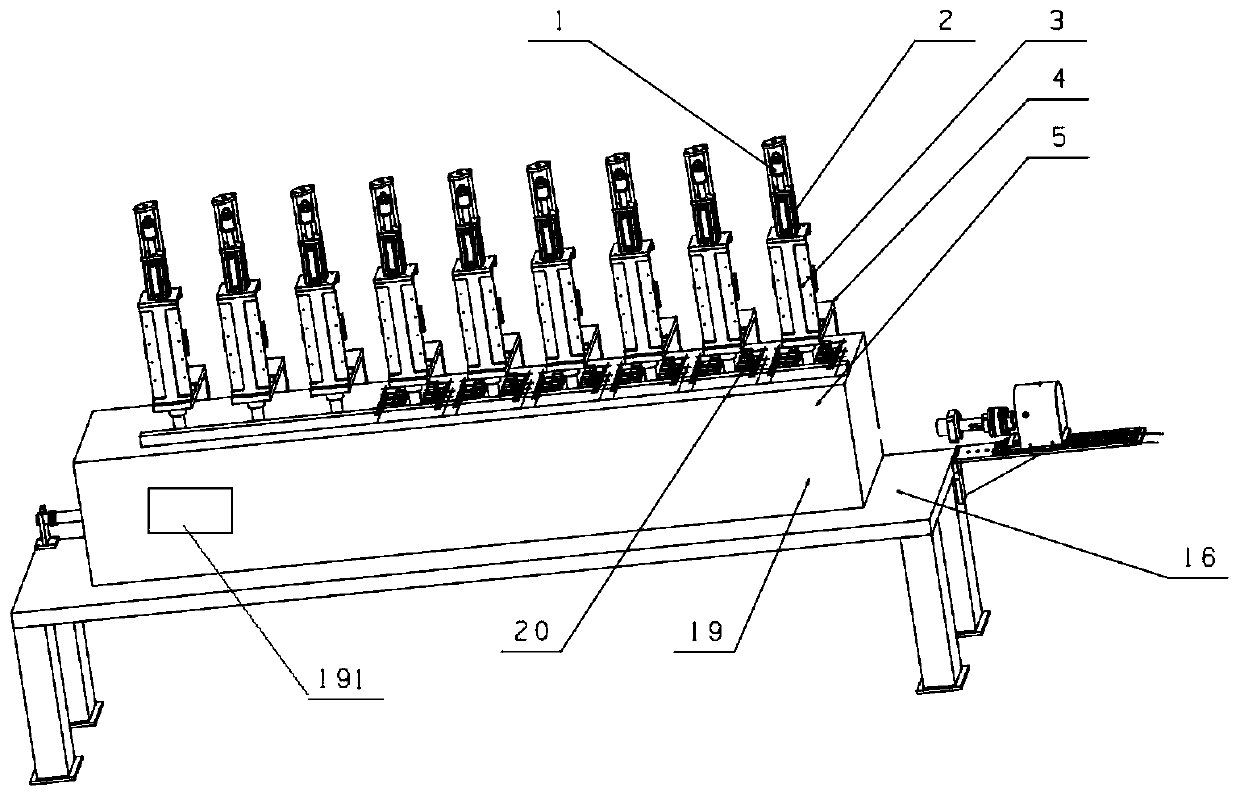

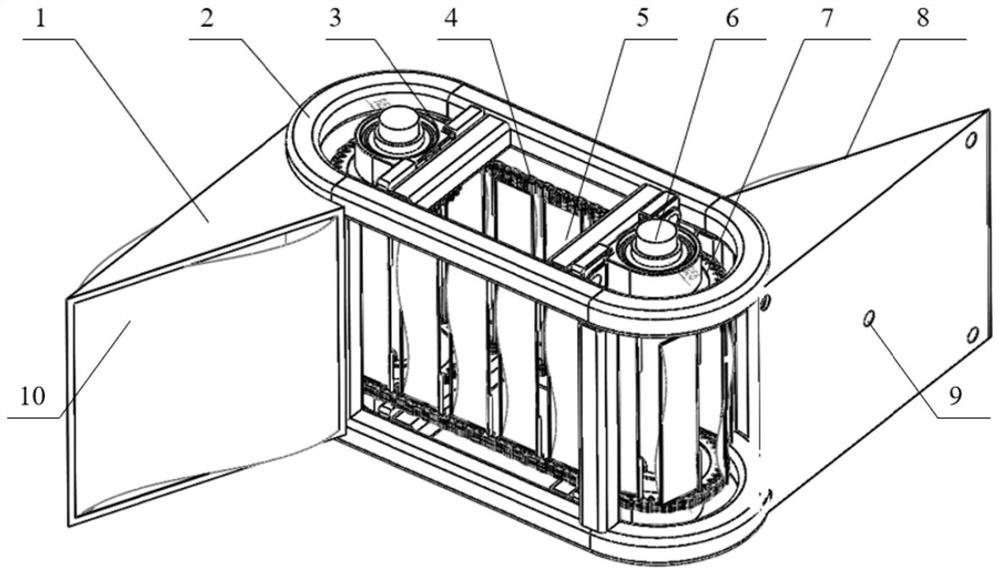

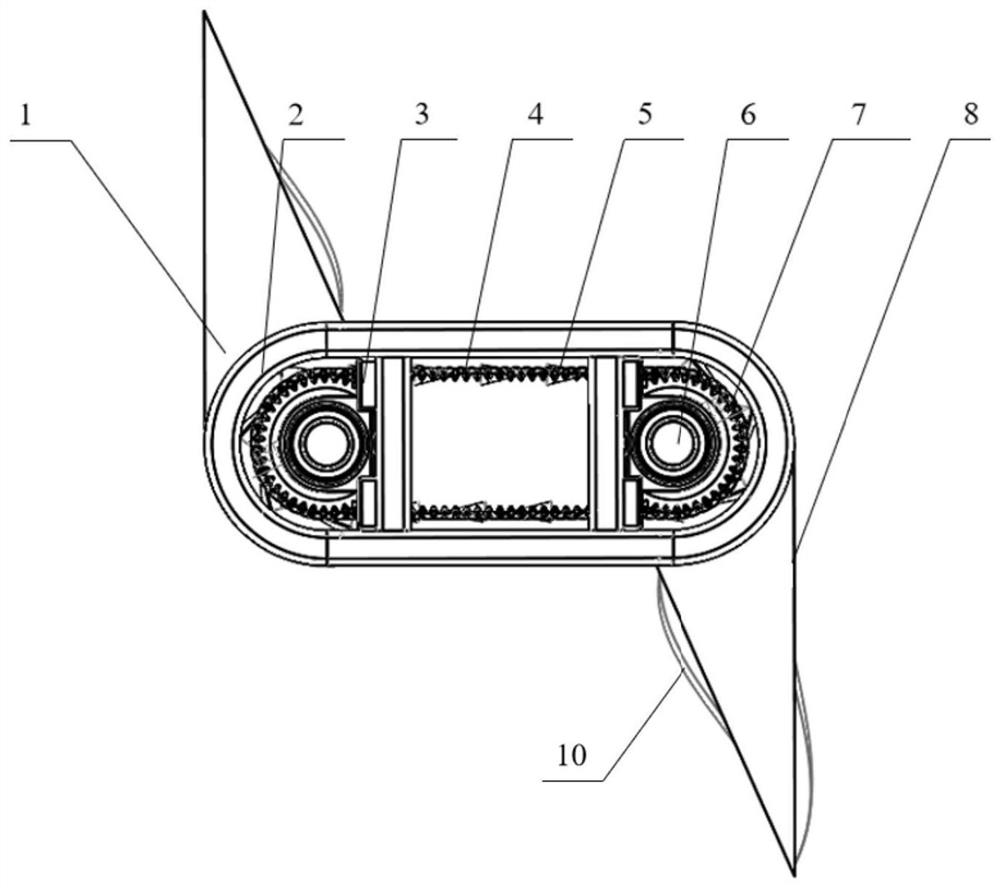

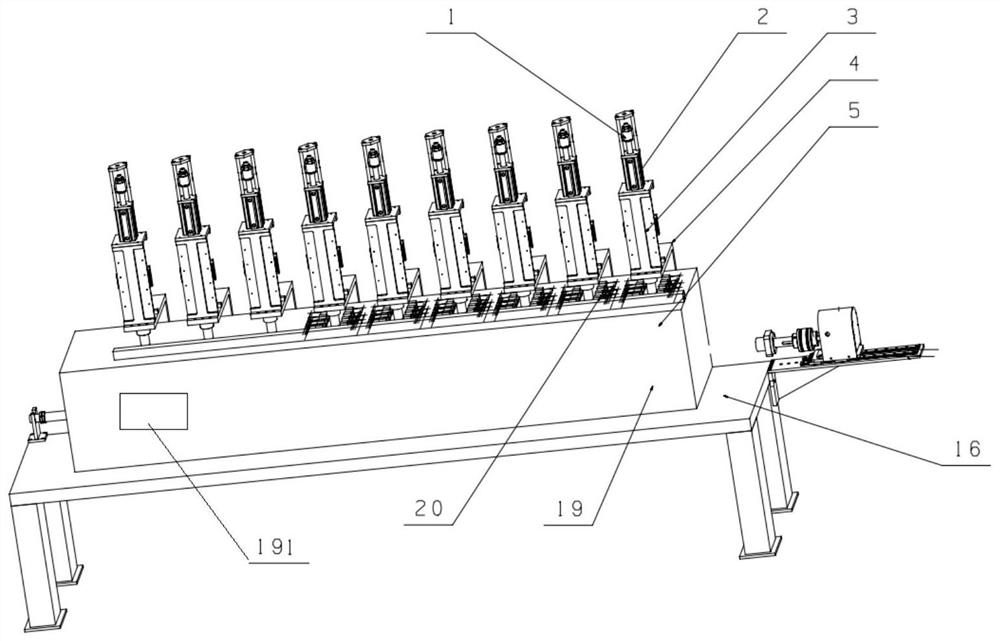

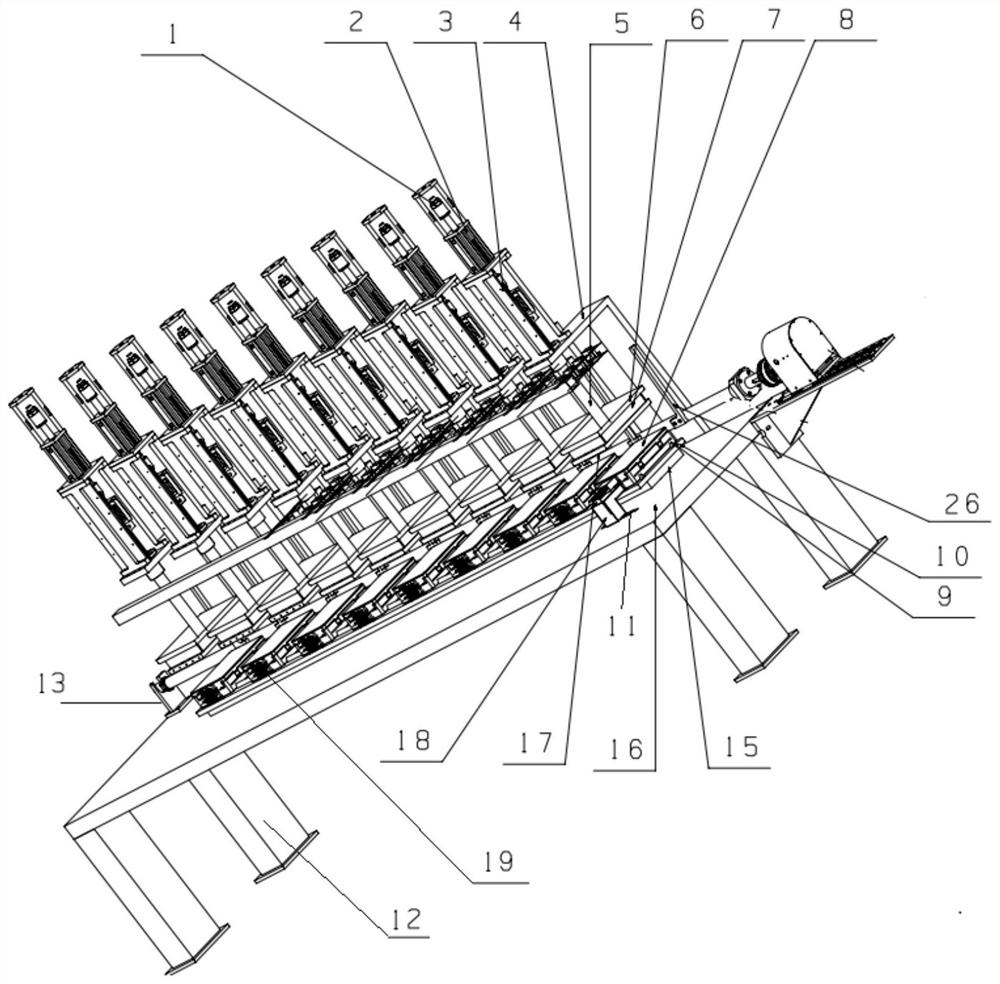

Measuring and controlling integrated electric eddy current type hot bending equipment for 3C members, and control method

ActiveCN110194583AFast temperature riseHysteresis effect is smallGlass reforming apparatusGlass productionHeating timeEngineering

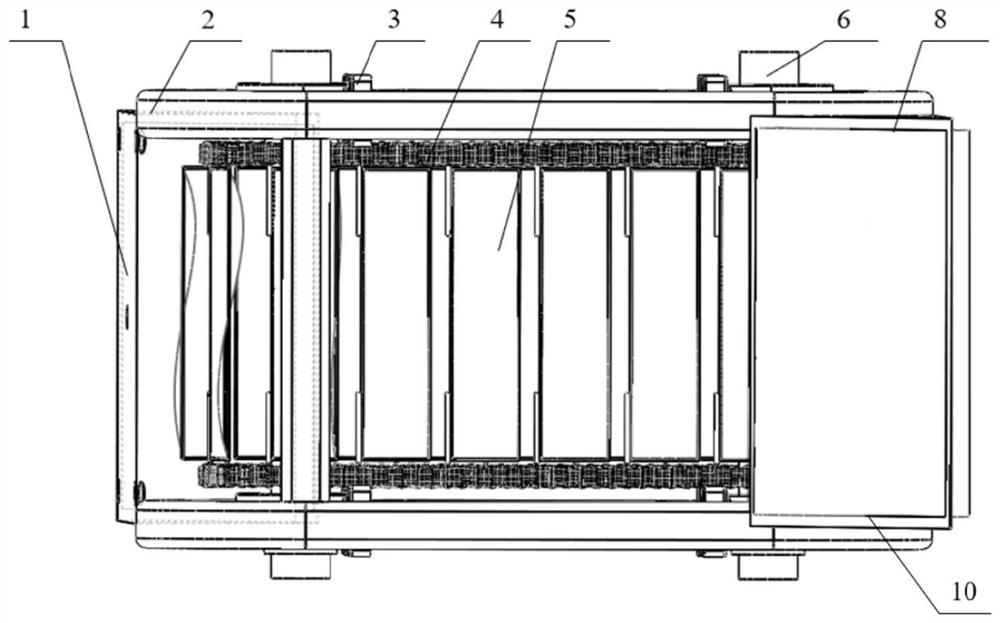

The invention relates to measuring and controlling integrated electric eddy current type hot bending equipment for 3C members, and a control method. The measuring and controlling integrated electric eddy current hot bending equipment comprises a furnace body mechanism and a control end, wherein measuring and controlling integrated electric eddy current type mechanisms are arranged in the furnace body mechanism, execution mechanisms are arranged on the furnace body mechanism, the measuring and controlling integrated electric eddy current type mechanisms and the execution mechanisms respectivelycommunicate with the control end, three types of workstations are sequentially arranged from front to rear on the furnace body mechanism, and respectively are a preheating and heating workstation, ahot bending molding workstation and a cooling workstation, the three workstations respectively comprise a measuring and controlling integrated electric eddy current type mechanism, the measuring and controlling integrated electric eddy current type mechanism has a mold for carrying out hot bending on a 3C member, and an auxiliary mechanism is arranged on the furnace body mechanism, and is used forpushing a translation mold, and the one workstation corresponds to the one execution mechanism. According to the present invention, with the equipment and the method, the heating time and the cycle time can be reduced, and the production efficiency can be improved.

Owner:GUANGDONG HUST IND TECH RES INST

A diversion type biaxial membrane swing type water turbine

ActiveCN112879198BImprove efficiencyReduce resistanceHydro energy generationReaction enginesWater turbineAcute angle

Owner:XI AN JIAOTONG UNIV

A new single-sided core-wound clamping brush seal structure

ActiveCN107559052BReduce gapReduce flutterLeakage preventionMachines/enginesHysteresisMetallic materials

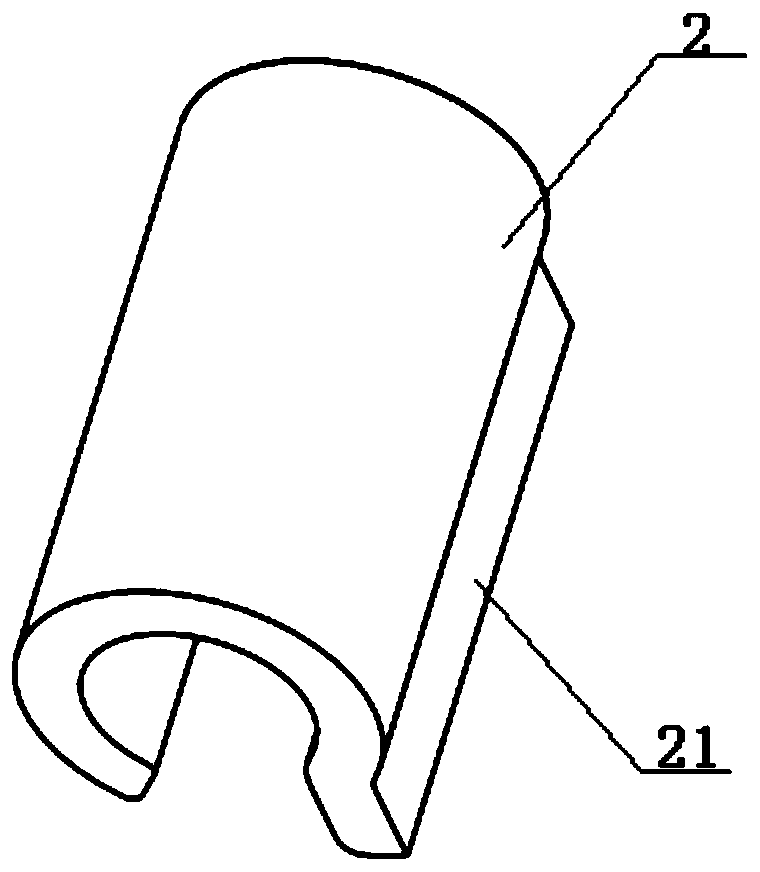

The invention discloses a unilateral core-winding clamping type brush sealing structure. The unilateral core-winding clamping type brush sealing structure comprises a front baffle plate, a C type clamp, a rear baffle plate, a core wire, a front end decompression plate, a rear end decompression plate and a brush wire, wherein the C type clamp is clamped and fixed between the front baffle plate andthe rear baffle plate, the front end decompression plate and the rear end decompression plate are connected to the lower ends of the front baffle plate and the rear baffle plate correspondingly, and the front end decompression plate and the rear end decompression plate raise inwards correspondingly to form a decompression chamber. The lower end of the C type clamp is connected with a vertical baffle plate, and the brush wire is wound on the core wire and arranged in a clamping hole of the C type clamp in a tightly clamped mode. In the initial mounting state, the free end of the brush wire is attached to the inner side of the vertical baffle plate and the inner side of the rear end decompression plate sequentially, and extends out of the decompression chamber and in contact with a rotor. The unilateral core-winding clamping type brush sealing structure is low in production cost, the material of the brush wire can select a metal or non-metal material, the brush wire is replaceable and simple to mount, the hysteresis effect is reduced greatly, the property of the brush wire is stable and reliable, the service life of the brush wire is long, and the brush sealing structure can be widely applied to various kinds of turbine mechanical equipment.

Owner:SHENYANG AEROSPACE UNIVERSITY

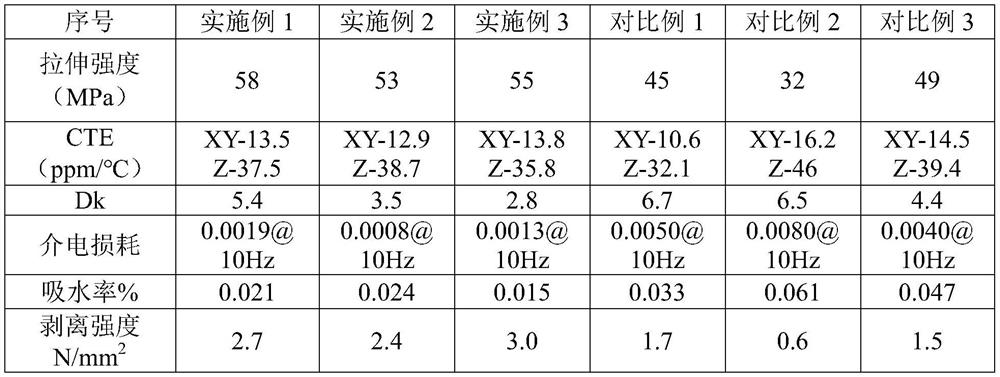

Technological method for processing high-frequency copper-clad plate by means of additive manufacturing of PTFE (polytetrafluoroethylene)

ActiveCN114474910ALow dielectric constantHigh-speed transmission capabilitySynthetic resin layered productsLaminationCopper foilEmulsion

The invention belongs to the technical field of preparation of high-frequency copper-clad plates, and particularly relates to a process method for processing a high-frequency copper-clad plate by adopting an additive manufacturing PTFE (Polytetrafluoroethylene) mode. The preparation method comprises the following steps: mixing and grinding aluminum oxide, titanium oxide and silicon oxide in proportion, sintering, and then grinding to prepare a ceramic filler; the preparation method comprises the following steps: mixing a ceramic filler with a KH560 aqueous solution to prepare a dispersion liquid; adding the dispersion liquid into a PTFE emulsion to prepare an emulsion; putting the emulsion into electrostatic spinning equipment, and adjusting the receiving distance between a spray head of the electrostatic spinning equipment and a copper foil to be 8-15cm; starting electrostatic spinning equipment and then directly jet-printing on the surface of the copper foil; putting the product into a high-temperature hot press for sintering and pressing; and taking out the product from the high-temperature hot press, and standing at room temperature to prepare the high-frequency copper-clad plate processed by adopting a PTFE additive manufacturing mode. According to the high-frequency copper-clad plate disclosed by the invention, the dielectric constant is obviously reduced, and the high-speed transmission capability of signals is ensured.

Owner:SHANDONG SENRONG PLASTIC IND TECH

A kind of solar cell and its preparation method adopting digital-exponential mixing method to dope functional region

ActiveCN106252463BEasy to separateReduce compound rateFinal product manufacturePhotovoltaic energy generationDopantTerra firma

A solar cell with functional areas prepared by a digital-exponential hybrid doping mode, and a method for preparing the solar cell. Functional areas of a solar cell are prepared by a digital doping and exponential doping cooperated mode. The digital doping and exponential doping cooperated mode refers to: digital doping is carried out sectionally in a doped region, the flow capacity of a dopant is doped into a reaction chamber in a digital transition, and an exponential change occurs between two adjacent doping concentrations. According to the solar cell prepared by a digital-exponential hybrid doping mode, the digital-exponential hybrid doping mode is used in the main functional layers of the solar cell, so that a built-in electric field can be enhanced, and photo-generated carriers can be separated more effectively, and the lifetime of the photo-generated carriers can be prolonged, thereby improving the mobility of the carriers, and increasing an open-circuit voltage of the cell.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Rubber composition for bonding tire belt and tire manufactured using same

The invention relates to rubber composite used for bonding a belt ply of a tire and the tire manufactured with the composite. The rubber includes 100 parts by weight of raw material rubber; 0.01 to 10 parts by weight of aromatic polyamide short fiber particles formed by more than two strands of aromatic polyamide short fiber and containing rubber penetrated between the twisted aromatic polyamide short fibers. The rubber composite used for bonding the belt ply of the tire can improves the rigidity of rubber used for bonding the belt ply of the tire, reducing bonding thickness and reducing hysteresis effect of the rubber used for bonding the belt ply of the tire, so that energy loss caused by the rotation of the tire can be reduced.

Owner:HANKOOK TIRE WORLDWIDE

Measurement and control integrated eddy current hot bending equipment and control method for 3c components

ActiveCN110194583BLifting speed is fastHysteresis effect is smallGlass reforming apparatusGlass productionProcess engineeringActuator

A measurement and control integrated eddy current type hot bending equipment and control method for 3C components, including a furnace body mechanism and a control end, a measurement and control integrated eddy current type mechanism is installed in the furnace body mechanism, an actuator is installed on the furnace body mechanism, measurement and control The integrated eddy current mechanism and the actuator are respectively connected to the control end by communication. Three kinds of workstations are set up on the furnace body mechanism in sequence, namely the preheating and heating workstation, the hot bending forming workstation and the cooling and cooling workstation, and the preheating and heating workstation, The hot bending forming workstation and the cooling and cooling workstation respectively include a measurement and control integrated eddy current mechanism. The measurement and control integrated eddy current mechanism has a mold for hot bending of 3C components, and an auxiliary mechanism is installed on the furnace body mechanism. The auxiliary mechanism is used to push the translation Mold, one workstation corresponds to one actuator. The invention reduces the heating time and the production beat, and improves the production efficiency.

Owner:GUANGDONG HUST IND TECH RES INST

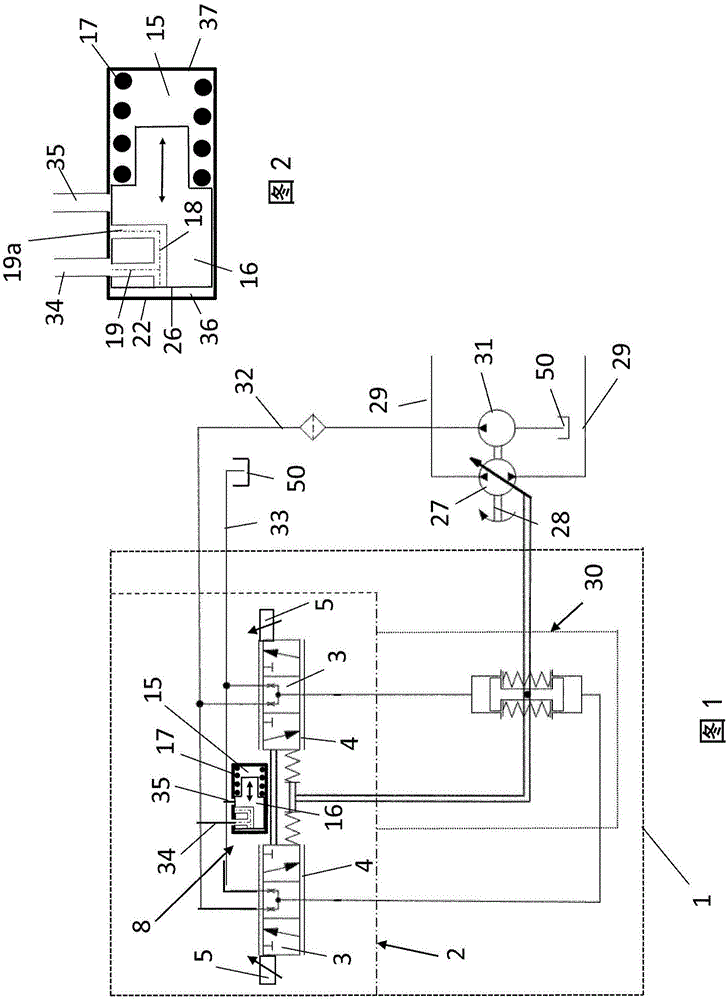

Hydrostatic displacement unit with reduced hysteresis

ActiveCN106884826AReduce static frictionReduce the amplitudeServomotor componentsCircuit elementsHysteresisSelf excited

The invention discloses a hydrostatic displacement unit with reduced hysteresis. The invention relates to a displacement unit (1) of a hydraulic machine, for which the hysteresis is reduced. For this purpose, in the control spool (3) and / or at the control spool (3) a mass body (16) and a spring (17) are arranged, which are excited to resonance vibrations. The vibrations are self-excited and sustained by a partial flow rate of the hydraulic fluid which is modulated periodically. The high frequent vibrations are transmitted over the spring (17) onto the associated control spool (3), thereby reducing the friction and hence the hysteresis.

Owner:DANFOSS POWER SOLUTIONS GMBH & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com