A new single-sided core-wound clamping brush seal structure

A technology of clamping brush type and sealing structure, which is applied in the direction of machines/engines, leakage prevention, mechanical equipment, etc., can solve the problems of short brush life, large leakage of brush seal, poor sealing performance, etc. Long service life, stable and reliable sealing performance, and the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with specific embodiments, but the present invention is not limited thereto.

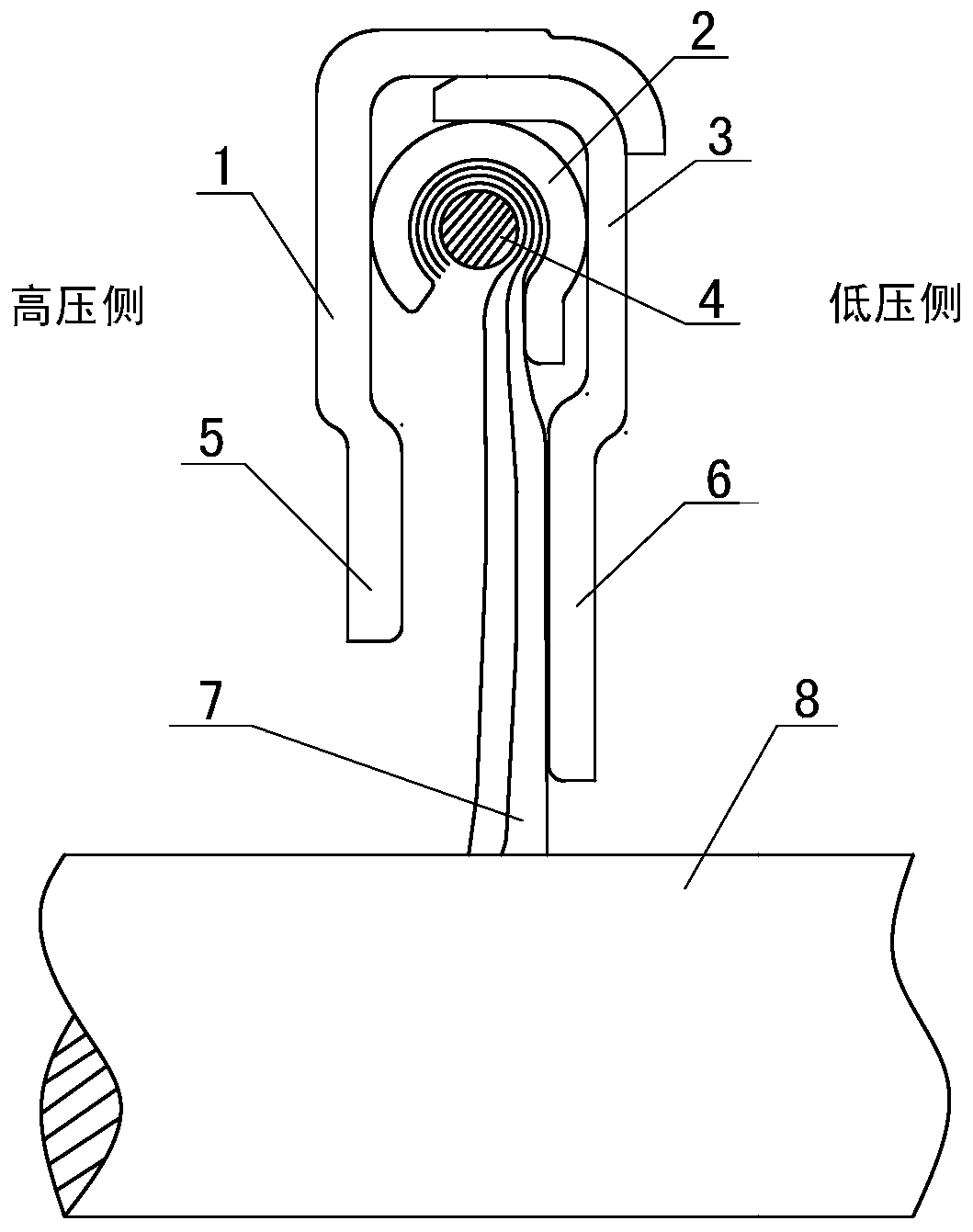

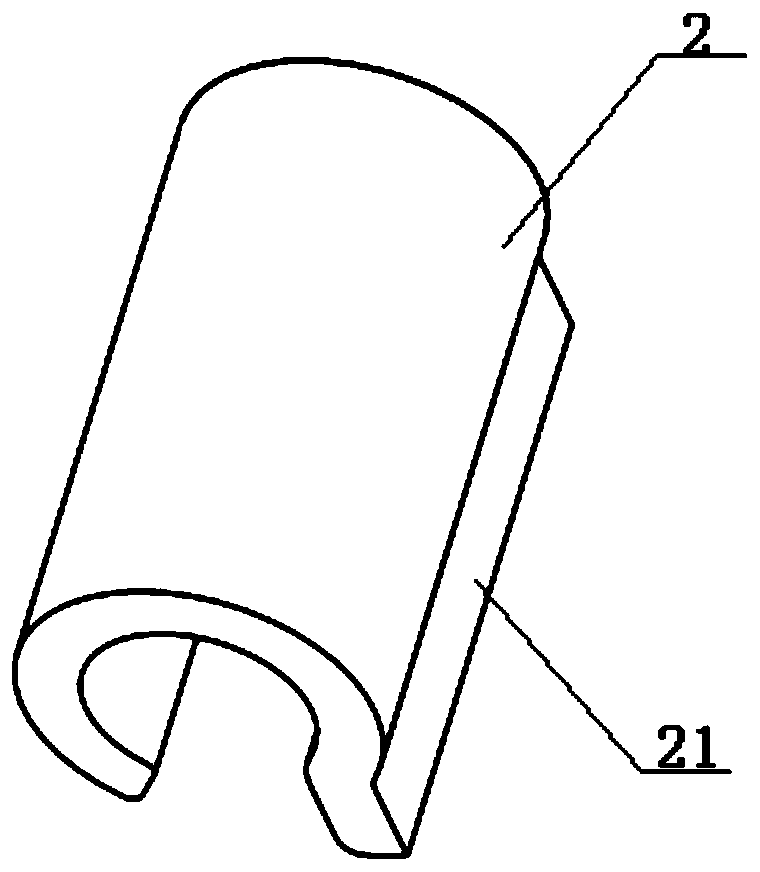

[0018] like figure 1 As shown, the present invention provides a novel one-sided core-wound clamping brush seal structure, including: front baffle 1, C-shaped clamp 2, rear baffle 3, core wire 4, front decompression plate 5, rear baffle The end decompression plate 6 and the brush wire 7, wherein the C-shaped clamp 2 is clamped and fixed between the front baffle 1 and the rear baffle 3, and the front end decompression plate 5 and the rear end decompression plate 6 are respectively connected to the front baffle 1 and the lower end of the rear baffle plate 3, the front end decompression plate 5 and the rear end decompression plate 6 protrude inwardly respectively to form a decompression chamber, and the lower end of the C-shaped clip 2 is connected with a vertical baffle plate 21 (such as figure 2 As shown), the brush filament...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com