Clearance type Gd-Si-Ge magnetic cooling material and manufacturing method thereof

A magnetic refrigeration material and gap-type technology, applied in the direction of electrical components, circuits, thermoelectric devices, etc., can solve the problems of not being able to be used as a room temperature magnetic refrigeration material, large thermal hysteresis and magnetic hysteresis, disadvantages, etc., to maintain a large magnetocaloric effect , the effect of reducing the hysteresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Embodiment: preparation Gd 5 Si 1.4 Ge 2.6 C 0.1

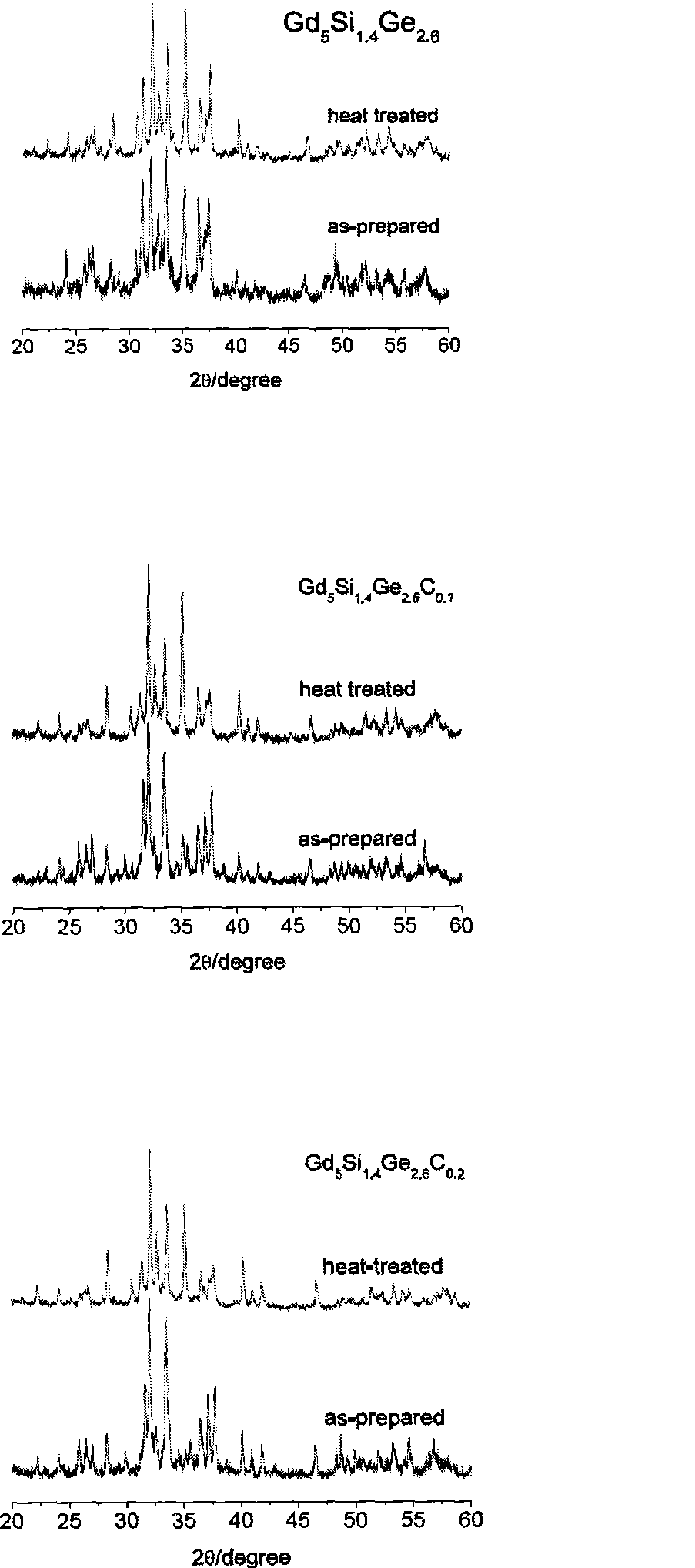

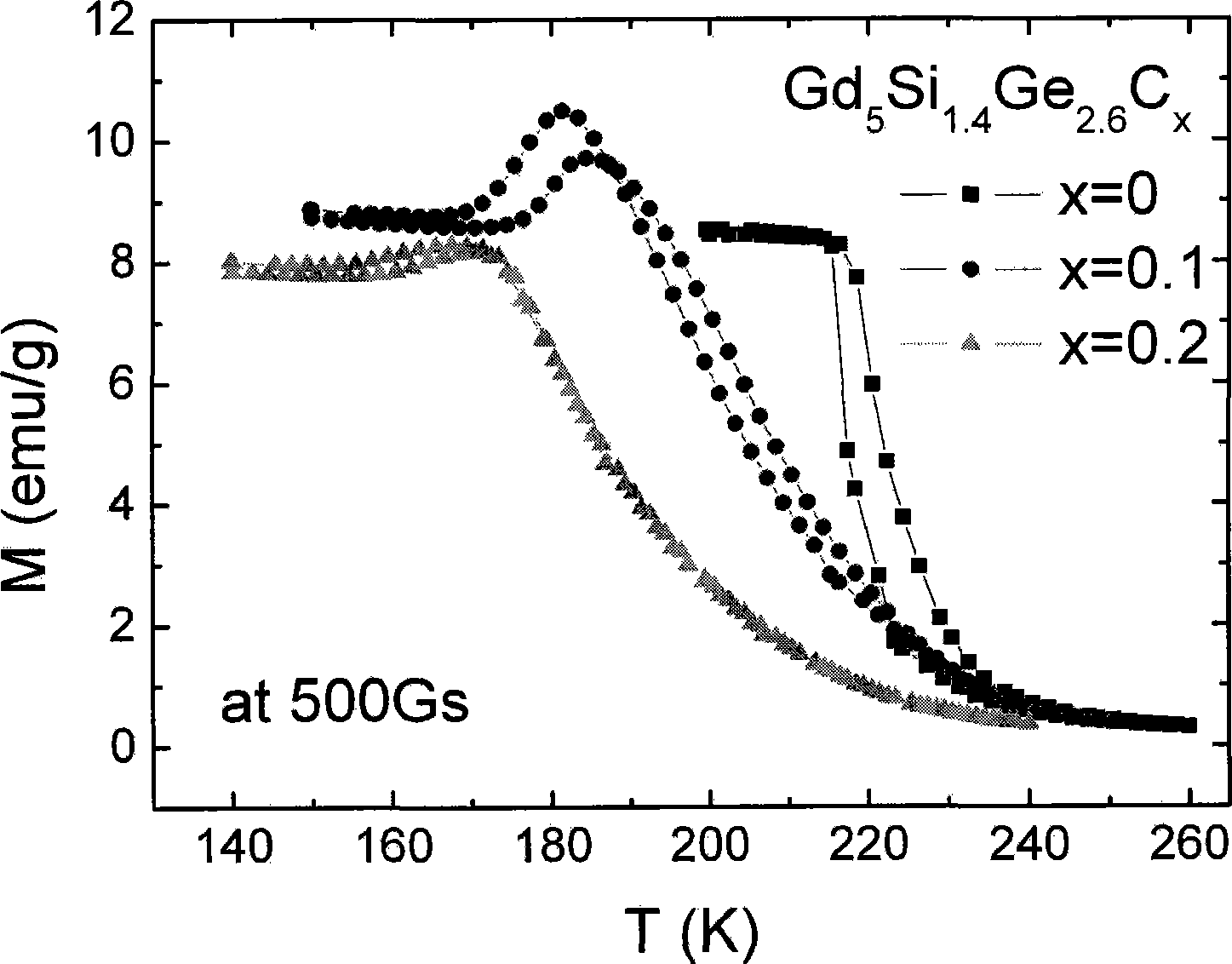

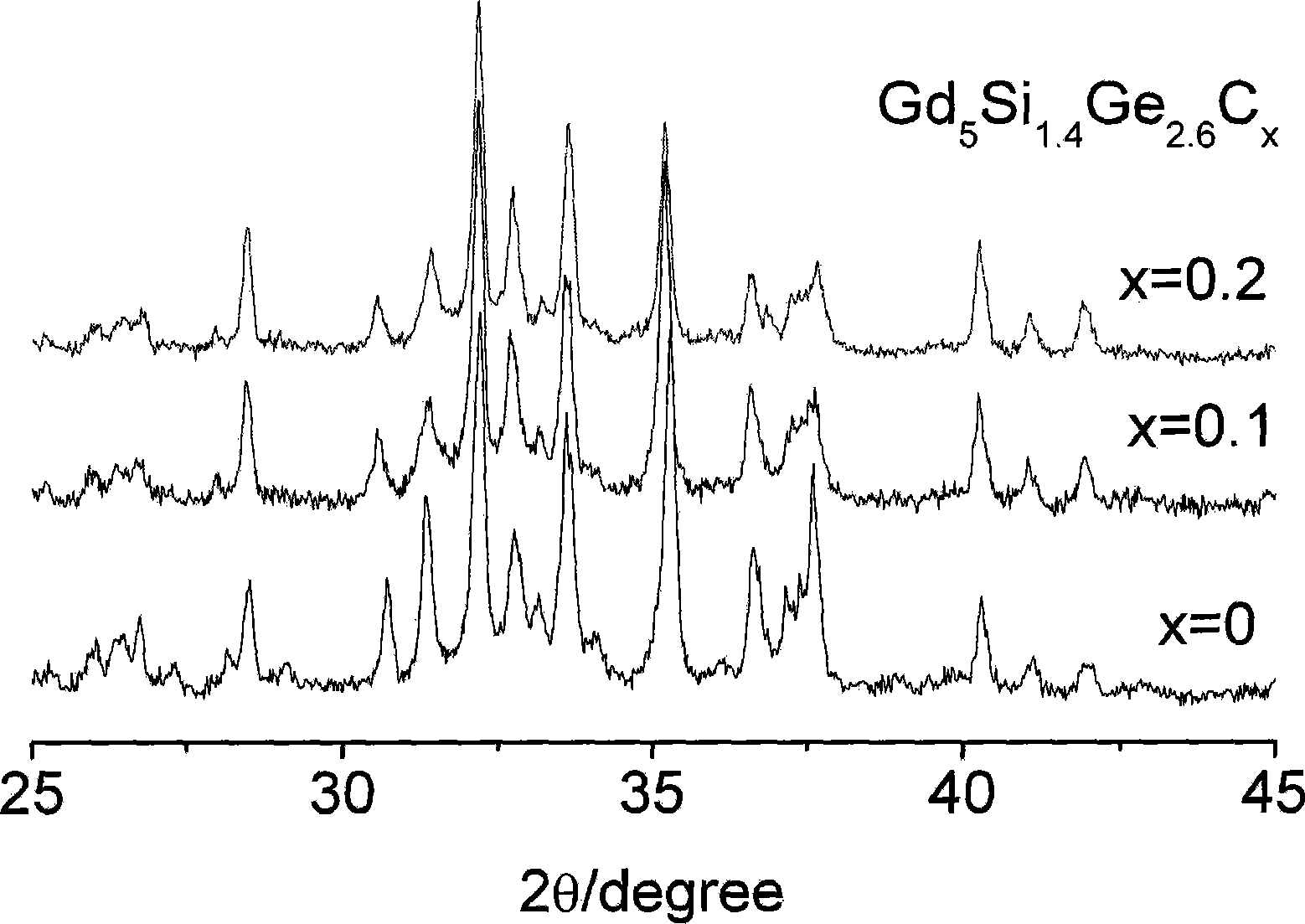

[0039] Gd, Si, Ge, and SiC with a purity of 99.9 at% are prepared in a molar ratio of 5:1.3:2.6:0.1 and then melted in an electric arc furnace to make an alloy ingot. Wrap the alloy ingot with tantalum sheets and seal it in a vacuum of 2.2×10 -4 In the quartz tube of Pa, it was heat-treated at 1120°C for 21 days, and the quartz tube was taken out at high temperature and quenched directly in liquid nitrogen. The X-ray diffraction of the sample was measured at room temperature, and the comparison before and after heat treatment was as figure 1 As shown, the X-ray diffraction results of samples with different C contents after heat treatment are as follows figure 2 As shown, all the heat-treated samples were confirmed to obtain single-phase monoclinic Gd 5 Si 2 Ge 2 type structure, and the peak position of the spectral line moves to a lower angle with the increase of C content, which is due to the expansion of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com