Rubber composition for bonding tire belt and tire manufactured using same

A technology of rubber composition and belt layer, which is applied in the direction of special tires, tire parts, transportation and packaging, etc., and can solve problems such as weakening of the bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0121] [Production example: Production of rubber composition]

[0122] The rubber compositions for tire belt layer bonding of the Examples and Comparative Examples were produced using the composition of Table 1 below. The production of the rubber composition is based on a usual method of producing a rubber composition.

[0123] 【Table 1】

[0124]

[0125] (1) The first raw material rubber: solution polymerized styrene-butadiene rubber.

[0126] (2) The second raw material rubber: butadiene rubber.

[0127] (3) Silica: The nitrogen adsorption specific surface area is 150m 2 / g, CTAB adsorption specific surface area is 150m 2 / g.

[0128] (4) Oil: Oil with characteristics of ozone resistance.

[0129] (5) Aromatic polyamide short fiber particles: 3 strands of aromatic polyamide short fibers (average length of 4mm, average diameter of 0.125mm, relative to 100 parts by weight of aromatic polyamide short fibers, represented by the chemical formula 1 1.6 parts by weight of the dihydrate of th...

experiment example

[0130] [Experimental example: Measurement of physical properties of manufactured rubber composition]

[0131] The physical properties of the rubber test pieces manufactured in the above-mentioned Examples and Comparative Examples were measured, and the results are shown in Table 2.

[0132] -Hardness is measured by a Shore A (Shore A) hardness tester. The hardness is a value indicating operational stability, and the higher the value, the better the operational stability.

[0133] -100% and 300% modulus (kgf / m 2 ): Modulus is the tensile strength at 100% or 300% elongation, measured according to ISO37 standards. The higher the value, the better the strength.

[0134] -Abrasion loss (g): The abrasion loss is the Lambourn abrasion tester, which is a numerical value indicating the loss of abraded rubber when rotating at room temperature, a slip rate of 25%, and a load of 1.5 kg. The larger the abrasion performance, the better.

[0135] -tanδ is measured by ARES (10Hz, 0.5% stress). The lo...

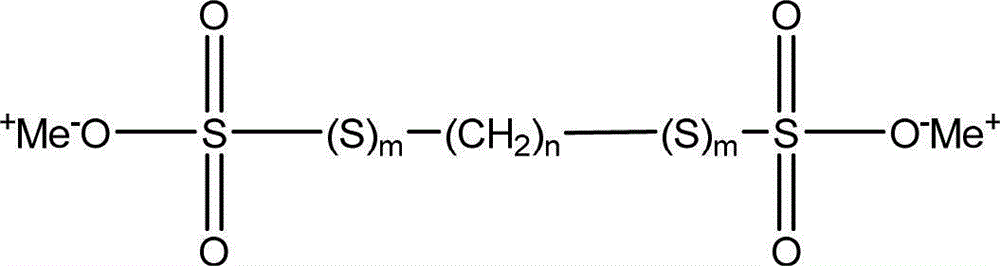

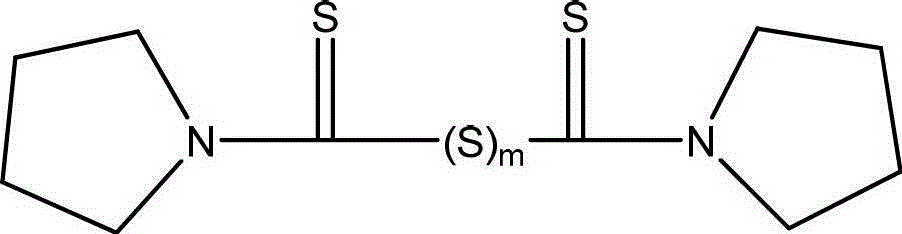

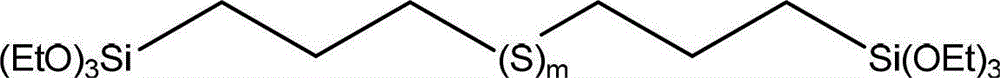

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com