A kind of solar cell and its preparation method adopting digital-exponential mixing method to dope functional region

A solar cell and exponential doping technology, applied in the field of solar cells, can solve the problems of limited effective electric field strength, low separation efficiency, restricting cell performance, etc., and achieve the effects of reducing hysteresis effect, improving mobility, and reducing recombination rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

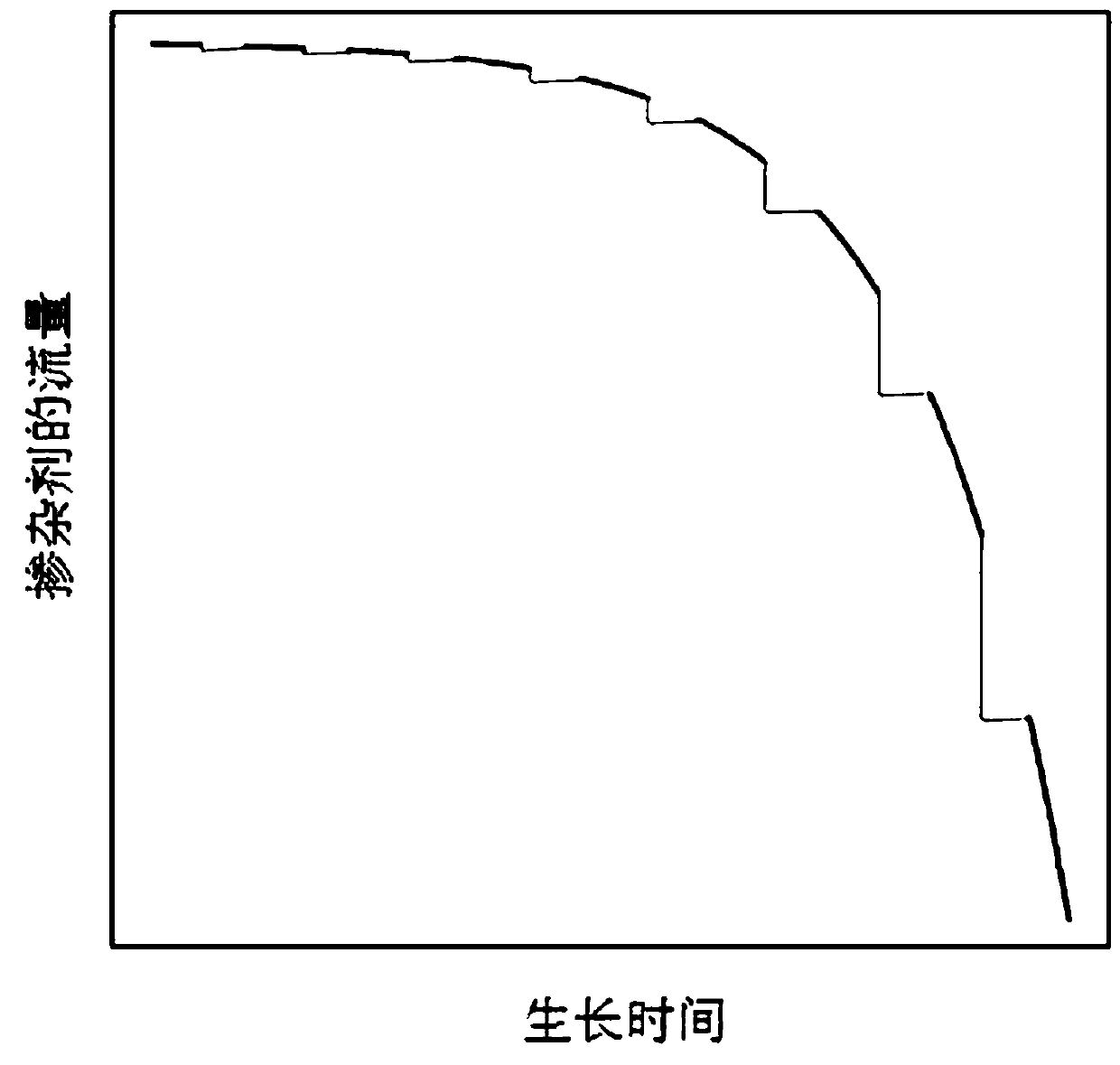

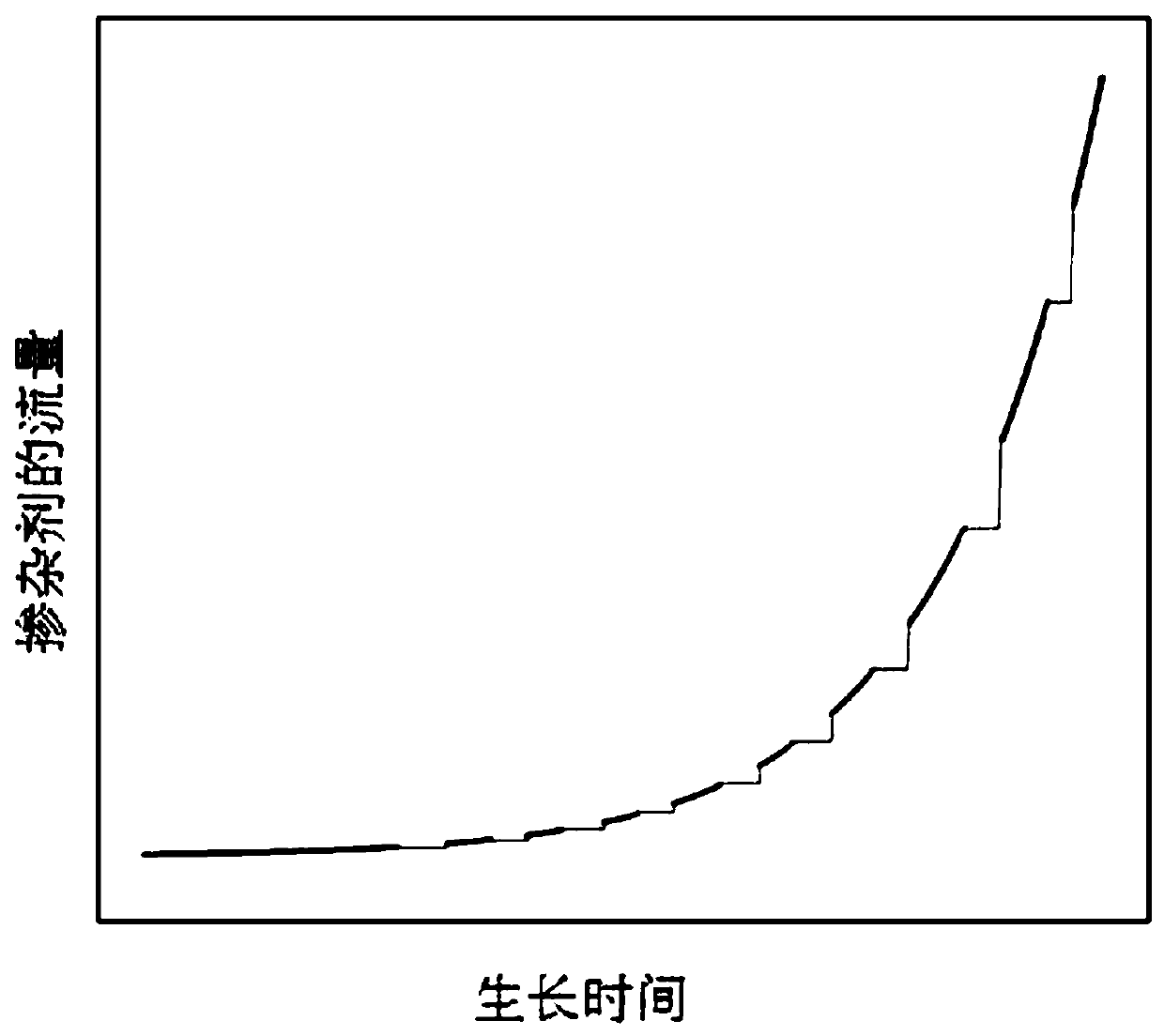

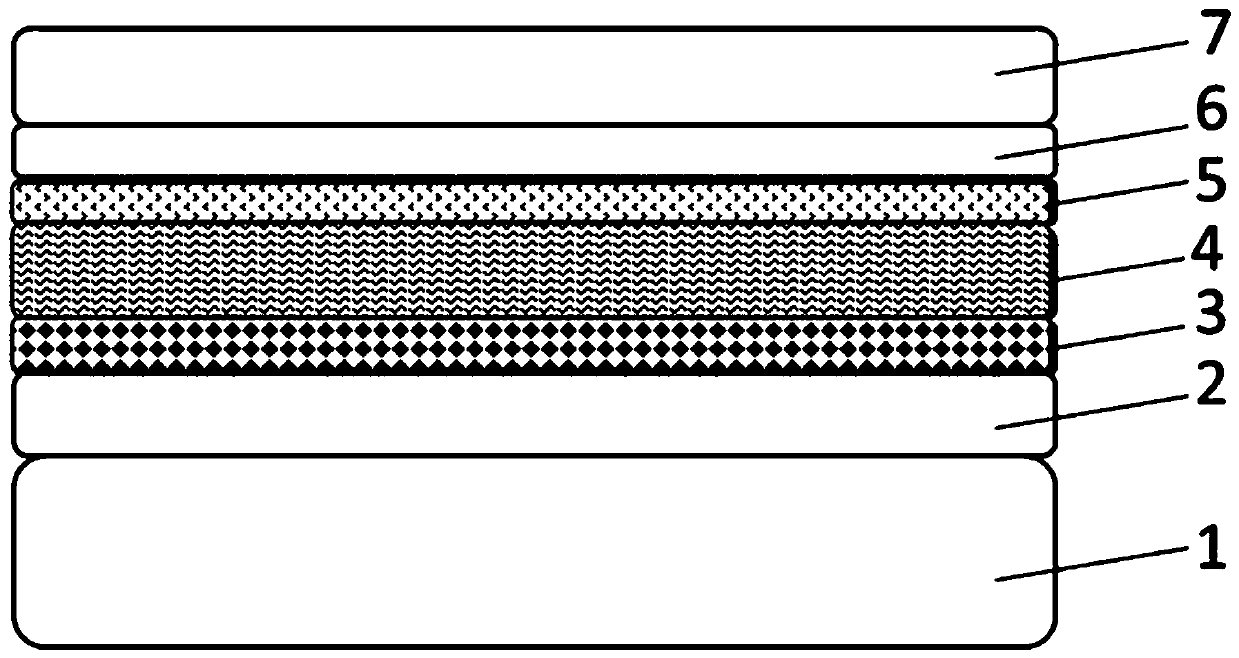

[0023] Such as image 3 As shown, taking the GaInP single-junction solar cell grown in the forward direction as an example, the GaAs buffer layer 2 is epitaxially grown on the GaAs (gallium arsenide) substrate 1 first, and then the AlGaInP (aluminum gallium indium phosphide) back field 3 is grown sequentially, and the GaInP Base region 4, GaInP emitter region 5, AlInP (aluminum indium phosphorus) window layer 6, GaAs cap layer 7. The structure was grown using low-pressure metal-organic chemical vapor deposition (LP-MOCVD) equipment. In the back field, base area and emitter area of the battery structure, digital-exponential doping is used for doping, in which the back field adopts such as figure 1 The negative exponential doping, that is, the doping concentration is decreasing; the base area adopts such as figure 2 The positive exponential doping, that is, the doping concentration increases; the emitter adopts such as figure 2 The positive exponential doping, that is, th...

Embodiment 2

[0025] Such as Figure 4 As shown, taking the reverse grown GaInP single-junction solar cell as an example, the GaAs buffer layer 20 is epitaxially grown on the GaAs (gallium arsenide) substrate 10 first, and then the AlInP (aluminum indium phosphide) window layer 30 is grown sequentially, and the GaInP emitter region 40 , GaInP base region 50 , AlGaInP (aluminum gallium indium phosphide) back field 60 , and GaAs contact layer 70 . The structure was grown using low-pressure metal-organic chemical vapor deposition (LP-MOCVD) equipment. The emitter region, the base region and the back field of the cell structure are doped by digital-exponential doping, wherein the emitter region is doped as figure 1 The negative exponential doping, that is, the doping concentration is decreasing; the base area adopts such as figure 1 Negative exponential doping, that is, the doping concentration decreases; the back field adopts such as figure 2 The positive exponential doping, that is, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com