Technological method for processing high-frequency copper-clad plate by means of additive manufacturing of PTFE (polytetrafluoroethylene)

A PTFE and additive manufacturing technology, used in the field of high-frequency copper clad laminates, can solve the problems of poor size control, poor dielectric properties of the plate, low product stability, etc., and reduce the hysteresis effect of dielectric conductance and polarization. , high-speed transmission capability, the effect of fast signal transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

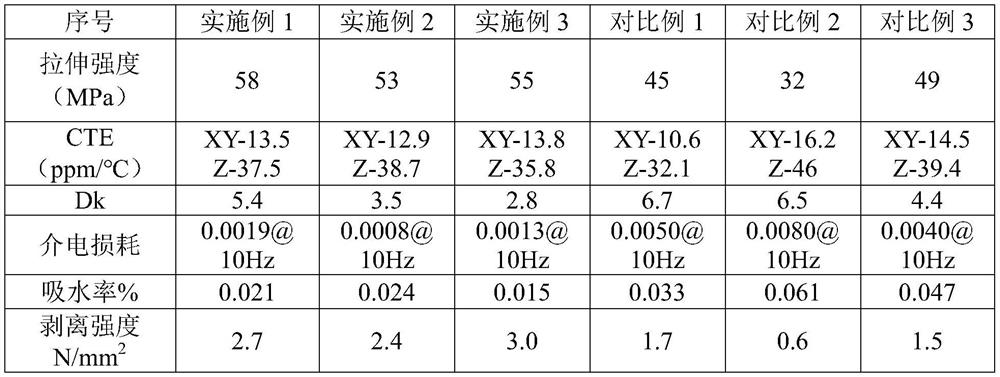

Examples

Embodiment 1

[0032] The process for processing high-frequency copper-clad laminates in the manner of additively manufacturing PTFE described in Example 1 consists of the following steps:

[0033] (1) After mixing and grinding alumina, titanium oxide and silicon oxide in a certain proportion, sintering at 1150°C, and then grinding the sintered product to prepare ceramic filler;

[0034] (2) mixing the ceramic filler prepared in step (1) with the silane coupling agent KH560 aqueous solution to prepare a dispersion;

[0035] (3) add the dispersion liquid that step (2) prepares in PTFE emulsion, stir and prepare to obtain emulsion;

[0036] (4) In a certain working environment, put the emulsion prepared in step (3) into the electrospinning equipment, and adjust the receiving distance between the nozzle of the electrospinning equipment and the copper foil to be 11cm;

[0037] (5) After the electrospinning equipment is turned on, it is directly spray printed on the surface of the copper foil, a...

Embodiment 2

[0051] The process method for processing high-frequency copper-clad laminates in the manner of additively manufacturing PTFE described in Example 2 consists of the following steps:

[0052] (1) After mixing and grinding alumina, titanium oxide and silicon oxide in a certain proportion, sintering at 1100°C, and then grinding the sintered product to prepare ceramic filler;

[0053] (2) mixing the ceramic filler prepared in step (1) with the silane coupling agent KH560 aqueous solution to prepare a dispersion;

[0054] (3) add the dispersion liquid that step (2) prepares in PTFE emulsion, stir and prepare to obtain emulsion;

[0055] (4) In a certain working environment, put the emulsion prepared in step (3) into the electrospinning equipment, and adjust the receiving distance between the nozzle of the electrospinning equipment and the copper foil to be 8cm;

[0056] (5) After the electrospinning equipment is turned on, it is directly spray printed on the surface of the copper foi...

Embodiment 3

[0070] The process for processing high-frequency copper-clad laminates in the manner of additively manufacturing PTFE described in Example 3 consists of the following steps:

[0071] (1) After mixing and grinding alumina, titanium oxide and silicon oxide uniformly according to a certain ratio, sintering at 1130°C, and then grinding the sintered product to prepare a ceramic filler;

[0072] (2) mixing the ceramic filler prepared in step (1) with the silane coupling agent KH560 aqueous solution to prepare a dispersion;

[0073] (3) add the dispersion liquid that step (2) prepares in PTFE emulsion, stir and prepare to obtain emulsion;

[0074] (4) In a certain working environment, put the emulsion prepared in step (3) into the electrospinning equipment, and adjust the receiving distance between the nozzle of the electrospinning equipment and the copper foil to be 15cm;

[0075] (5) After the electrospinning equipment is turned on, it is directly spray printed on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com