Rubber composite used for bonding belt ply of tire and tire manufactured with the composite

A technology of rubber composition and belt layer, which is applied to special tires, tire parts, transportation and packaging, etc., and can solve problems such as weak bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0121] [Manufacturing example: Manufacture of rubber composition]

[0122] Rubber compositions for bonding tire belts in Examples and Comparative Examples were produced using the compositions in Table 1 below. The rubber composition is produced according to the usual method for producing rubber compositions.

[0123] 【Table 1】

[0124]

[0125] (1) First raw material rubber: solution-polymerized styrene-butadiene rubber.

[0126] (2) The second raw material rubber: butadiene rubber.

[0127] (3) Silica: nitrogen adsorption specific surface area is 150m 2 / g, CTAB adsorption specific surface area is 150m 2 / g.

[0128] (4) Oil: oil having anti-ozone properties.

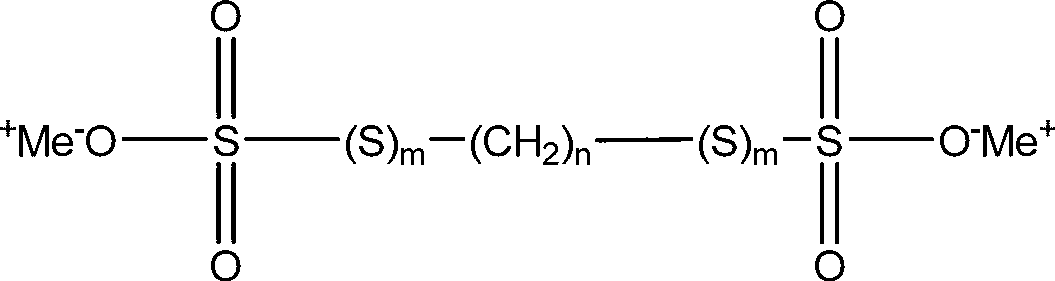

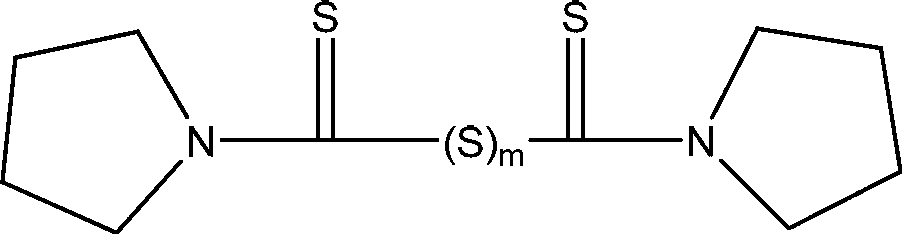

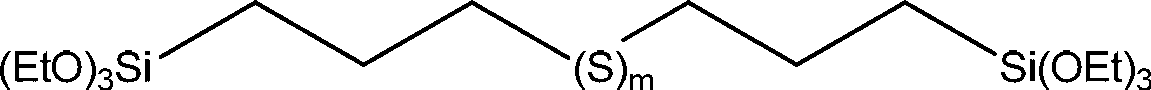

[0129] (5) Aramid short fiber particles: 3 strands of aramid short fibers (with an average length of 4 mm and an average diameter of 0.125 mm, expressed by the chemical formula 1 with respect to 100 parts by weight of aramid short fibers) 1.6 parts by weight of the dihydrate of the compound (Me is Na, m is 1,...

experiment example

[0130] [Experimental example: Measurement of physical properties of manufactured rubber composition]

[0131] Table 2 shows the physical properties of the rubber test pieces produced in the above Examples and Comparative Examples.

[0132] -Hardness is the result of measurement with a Shore A (Shore A) hardness tester. The hardness is a value indicating handling stability, and the higher the value, the better the handling stability is.

[0133] -100% and 300% modulus (kgf / m 2 ): Modulus is the tensile strength at 100% or 300% elongation, measured according to the ISO37 standard, and the higher the value, the better the strength.

[0134] - Abrasion loss (g): Abrasion loss is the Lambourn abrasion tester (Lambourn abrasion tester), which is a numerical value indicating the amount of rubber lost when it is rotated at room temperature, with a slip rate of 25% and a load of 1.5kg. The larger the value, the more excellent the wear performance.

[0135] -tanδ is measured by ARES...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com