Preparation method of RE-Fe-B part hydrogen storage alloy

A technology for hydrogen storage alloys and alloys, applied in the field of hydrogen storage materials, can solve problems such as no raw materials involved in alloy preparation, no specific requirements for preparation processes, etc., and achieve good charge/discharge or hydrogen absorption/desorption cycle stability, excellent Effect of gas phase hydrogen absorption/desorption reversibility and small hydrogen absorption/desorption expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

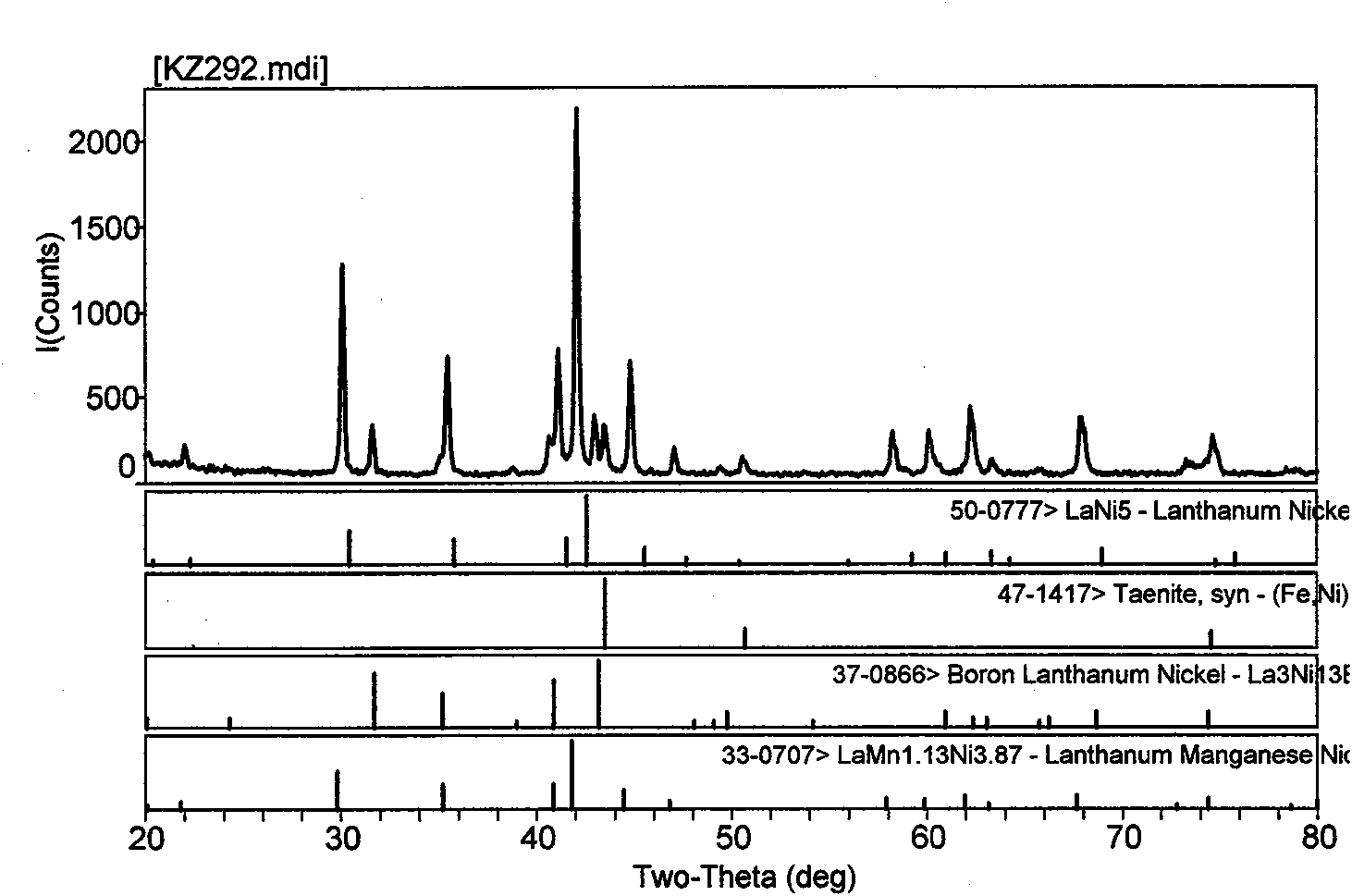

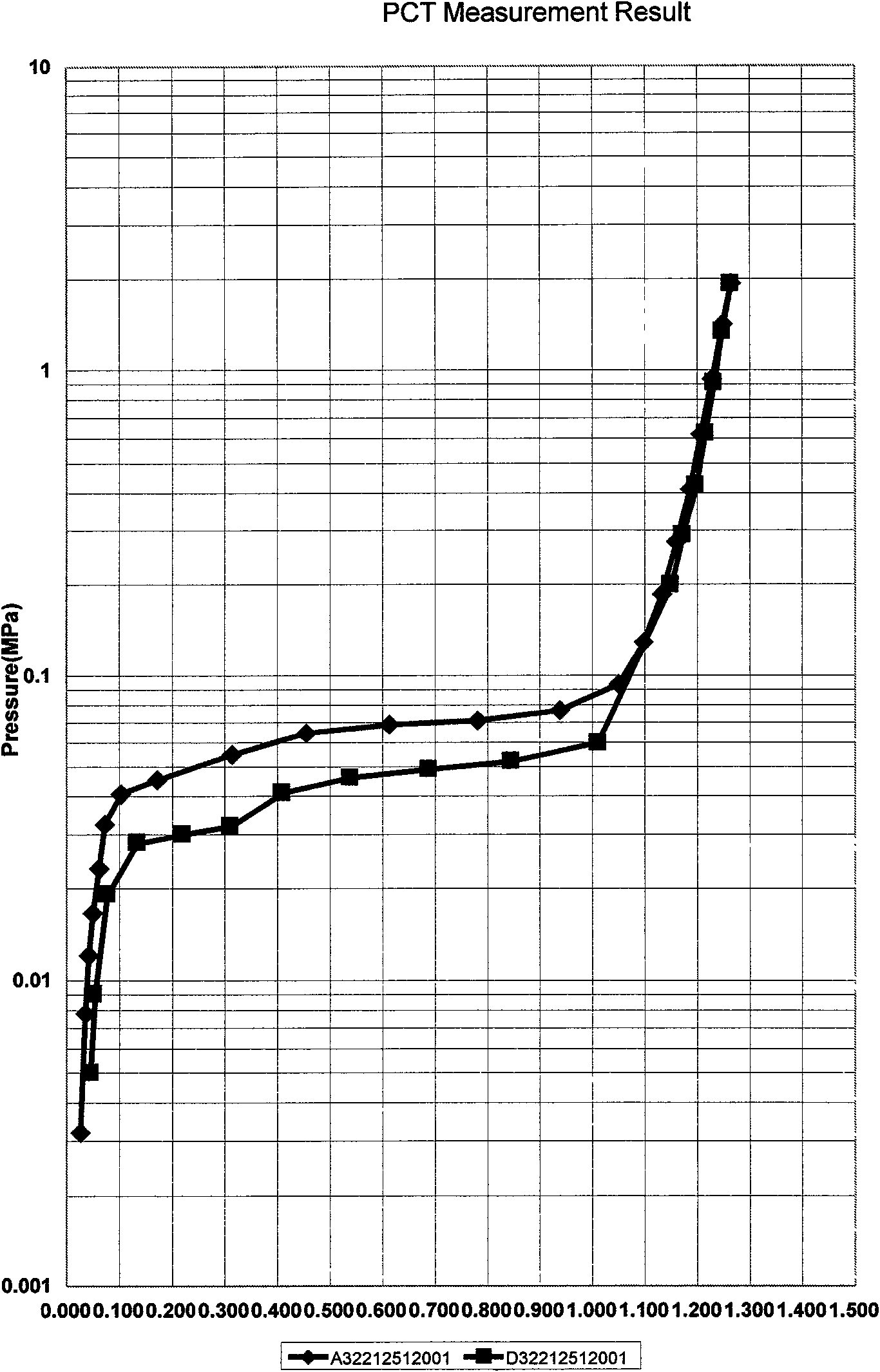

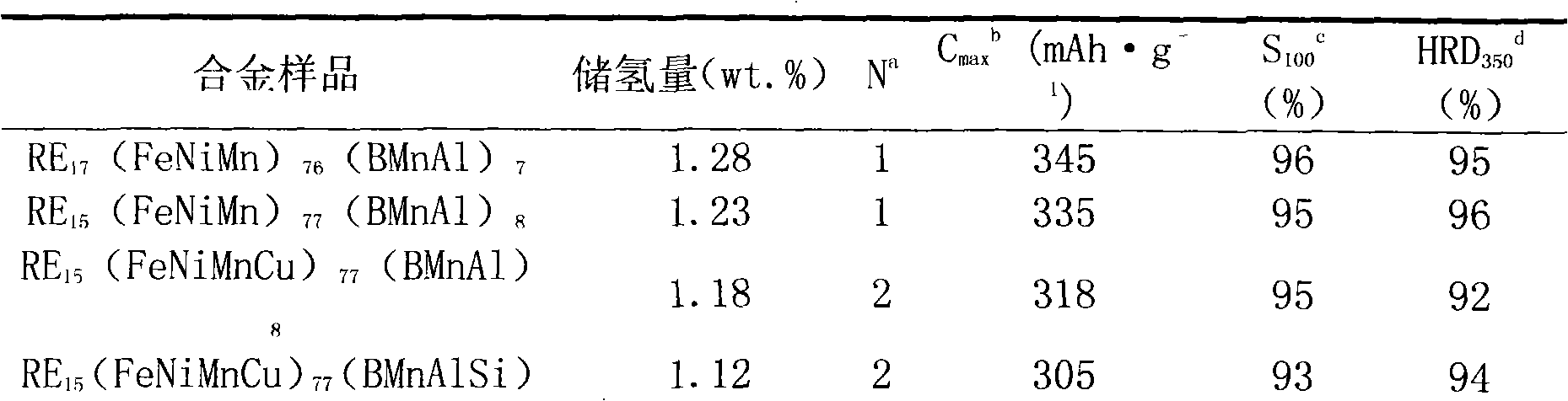

[0022] The prepared alloy composition is RE 19 (FeNiMn) 68 (BMnAl) 68 、RE 17 (FeNiMn) 76 (BMnAl) 7 、RE 15 (FeNiMn) 77 (BMnAl) 8 、RE 15 (FeNiMnCu) 77 (BMnAl) 8 、RE 15 (FeNiMnCu) 77 (BMnAlSi) 8 、RE 8 (FeNiMn) 86 (BMnAl) 6 、RE 8 (FeNiMn) 27 (BMnAl) 24 、RE 8 (FeNiMn) 28 (BMnAl) 24 、RE 5 (FeNiMn) 18 (BMnAl) 18 、RE 5 (FeNiMn) 2 (BMnAl) 6 、RE 2 (FeNiMn) 23 (BMnAl) 3 、RE 2 (FeNiMn)(BMnAl)3 、RE 2 (FeNiMn) 14 (BMnAl). According to the stoichiometric ratio of the prepared alloy, RE-Fe alloy, RE-Fe-B alloy, LaNi 5 type alloy, B-Fe alloy, B-Ni alloy as raw materials, and other elements in the alloy composition RE, Fe, Ni, Mn, Cu, Mn, Al, Si as raw materials for balance components, considering the La, Smelting and burning loss of Mn and Al elements. Various raw materials (purity greater than 99.0%) were calculated and weighed. The raw materials were made into RE-Fe-B alloy flakes under the protection of Ar gas by medium frequency induction melting-quick ...

Embodiment 2

[0028] The prepared alloy composition is RE 15 (FeNiMn) 77 (BMnAl) 8 . According to RE 15 (FeNiMn) 77 (BMnAl) 8 The stoichiometric ratio of the alloy is calculated and weighed by using elemental metal La, metal Ni, metal Mn, metal Al, and La-Fe, B-Fe alloys as raw materials, and considering the melting and burning loss of La, Mn, and Al elements. The amount of various raw materials (purity greater than 99.0%). The smelting preparation process, heat treatment method, powder making method and performance testing method are the same as in Example 1. The test results are shown in Table 2.

[0029] Table 2RE 15 (FeNiMn) 77 (BMnAl) 8 Properties of Hydrogen Storage Alloys

[0030]

Embodiment 3

[0032] The prepared alloy composition and raw materials are the same as in Example 2. The high-temperature melting and casting method, the high-temperature melting-gas atomization method and the powder sintering method are respectively used for preparation. The preparation process is carried out under the protection of Ar gas, and the heat treatment method, powder making method and performance testing method are the same as in Example 1. The test results are shown in Table 3.

[0033] Table 3RE 15 (FeNiMn) 77 (BMnAl) 8 Performance Comparison of Different Preparation Methods of Hydrogen Storage Alloys

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com