Optical strain gauge strips

A strain gauge and optical technology, applied in the field of optical strain gauges, to achieve the effect of saving distance, high repeatable manufacturing accuracy, and saving structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

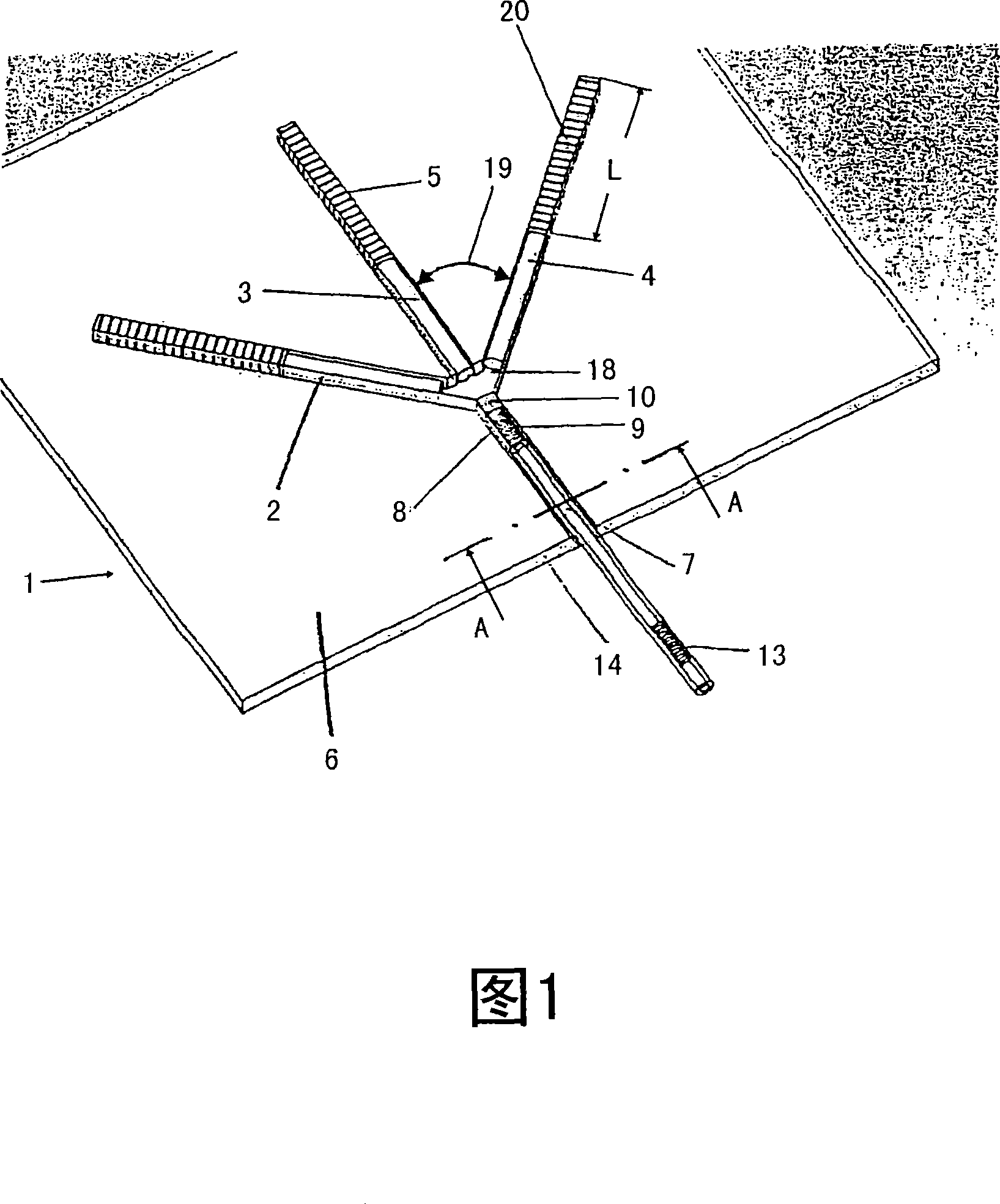

[0017] FIG. 1 shows an optical strain gauge 1 which is designed as a rosette for two-axis strain measurement and consists of three measuring waveguide sections 2 , 3 , 4 arranged next to each other with pressed Bragg gratings 5 . , they are fed by the feed waveguide 7, and the light wave signal of the feed waveguide is transmitted through the ray expansion element 8.

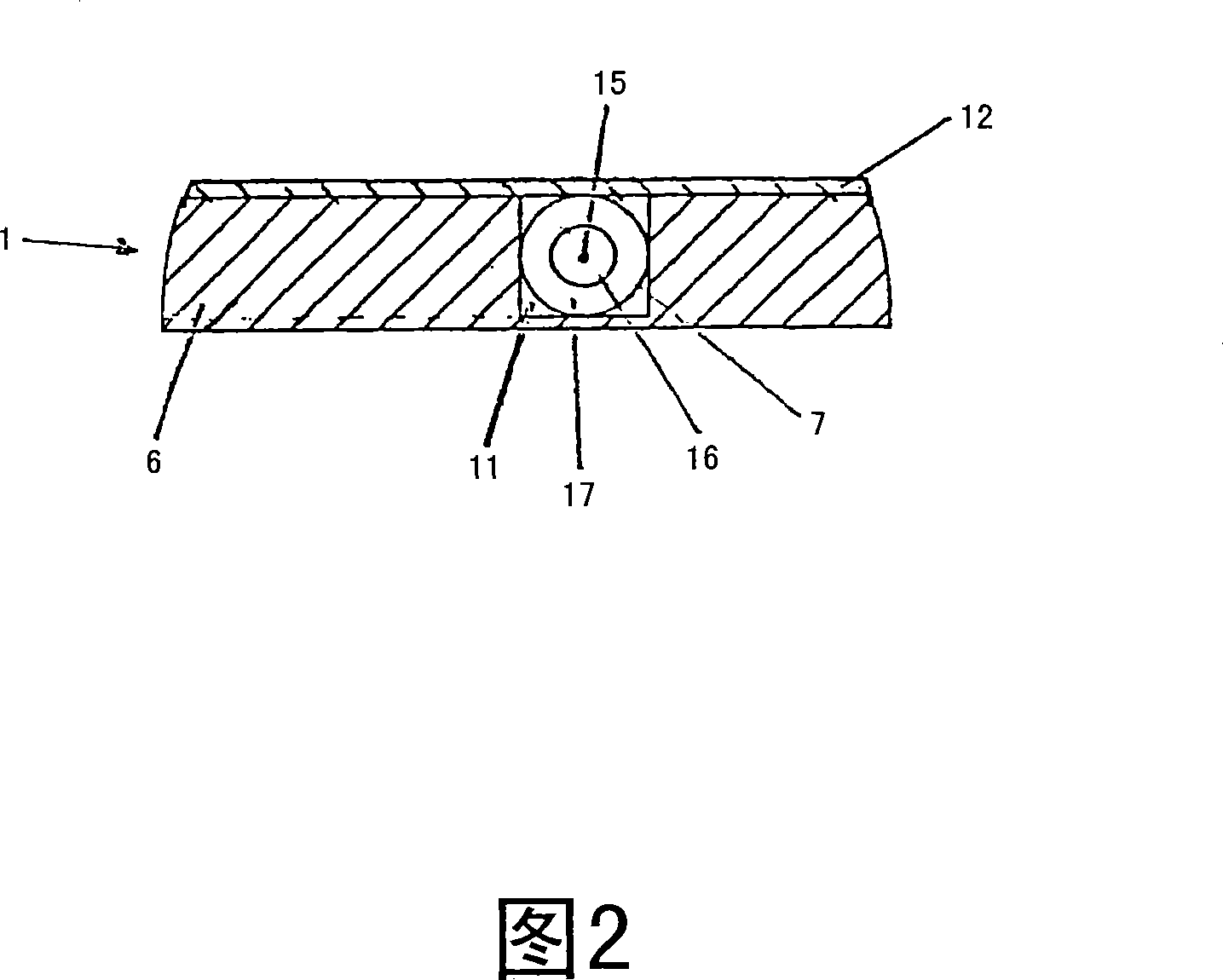

[0018] The optical waveguides 2 , 3 , 4 are all designed as straight sections and are embedded in a common carrier layer 6 , which is designed as a carrier film. In this case, the waveguide sections consist of a feed waveguide and three further sections of the measuring waveguide 2 , 3 , 4 with preferably pressed Bragg gratings 5 . For receiving the optical waveguides 2, 3, 4, a thin carrier film 6 is provided, which preferably consists of a hard and elastic plastic such as polyamide. However, the carrier film 6 can also be made of other hard elastic plastics, glass, ceramic or metal. In this case, the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com