Rare-earth series hydrogen storage alloy

A hydrogen storage alloy and rare earth technology, which is applied in the direction of electrical components, alkaline battery electrodes, battery electrodes, etc., can solve the problems of great difficulty in selecting alternative elements, and the synergy has a great influence on the performance of the alloy, so as to improve the cycle Stability and fast charge and discharge performance, improvement of discharge capacity and cycle stability, and the effect of improving discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

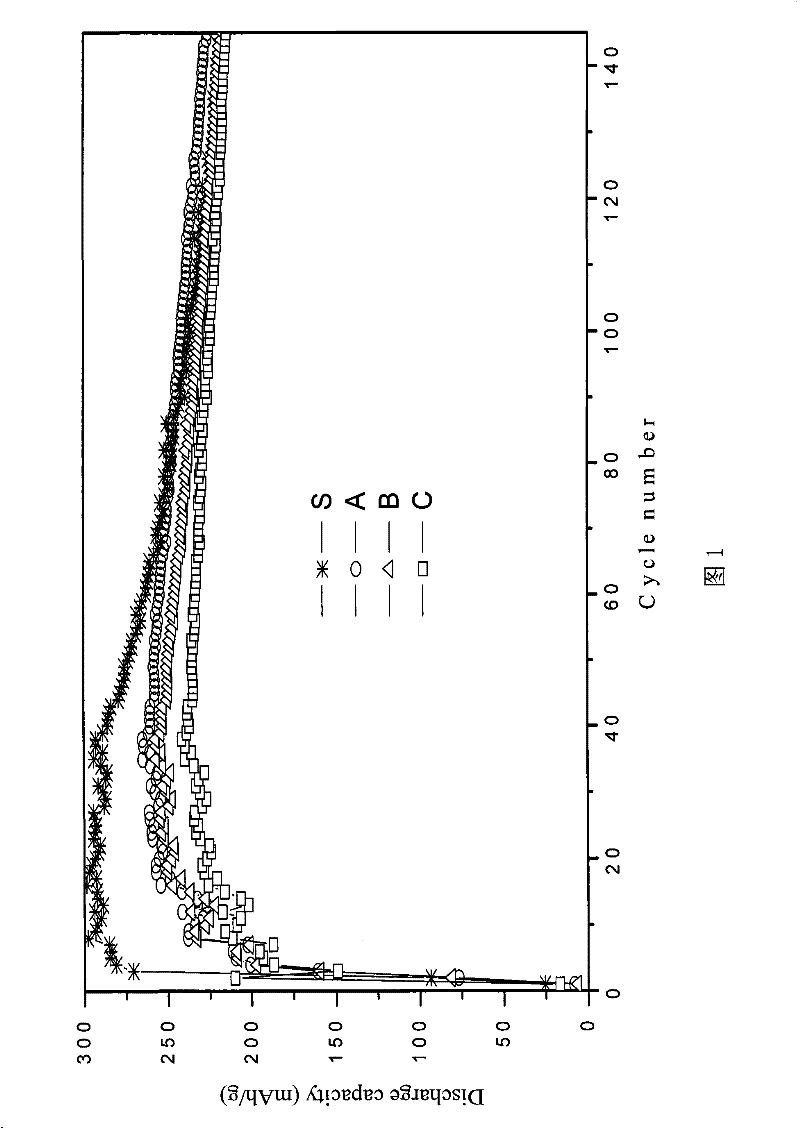

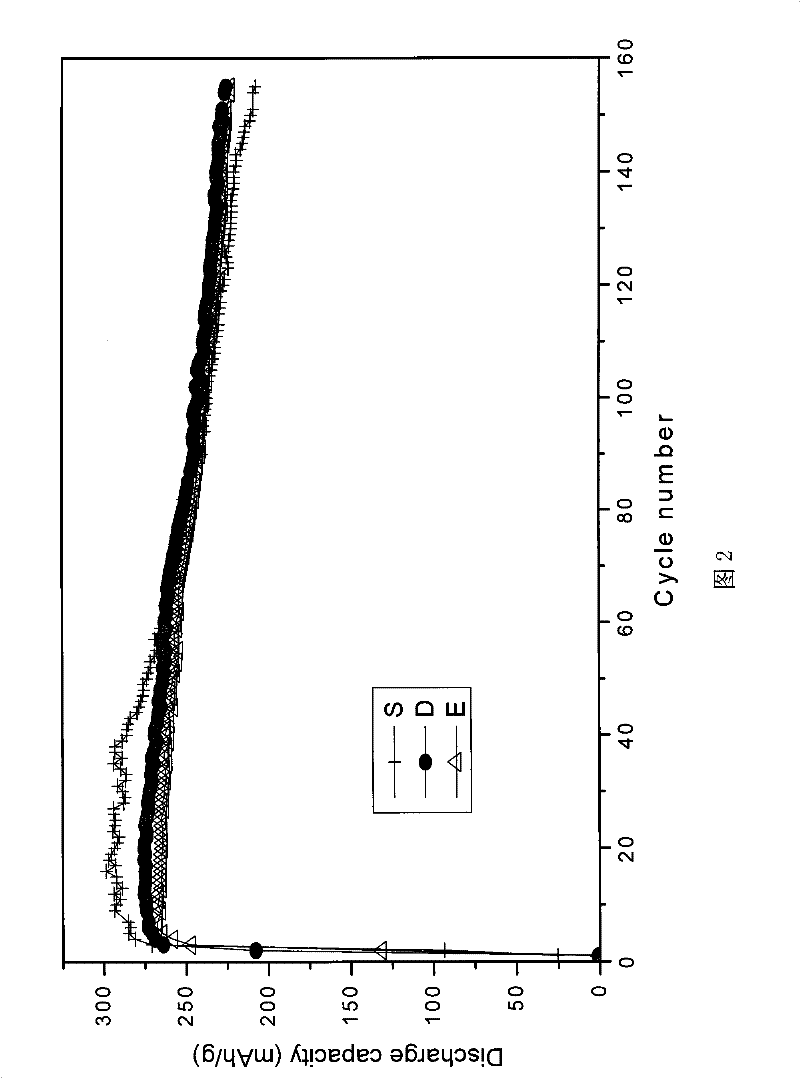

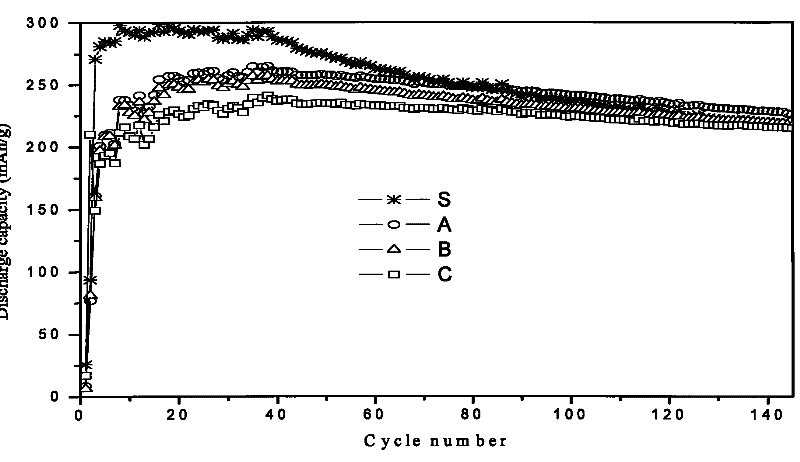

Embodiment 1

[0017] The chemical formula of the rare earth hydrogen storage alloy of the present embodiment is:

[0018] Ml 0.98 Dy 0.02 Ni 3.6 co 0.25 Al 0.25 mn 0.4 Cu 0.1 Fe 0.1 sn 0.1 Cr 0.1 Zn 0.1 (Alloy A).

[0019] The mixed rare earth Ml used therein includes the following components in mass percentage: La 80%, Pr 7%, Ce 8%, Nd 5%.

[0020] The preparation method of the rare earth hydrogen storage alloy of the present embodiment is as follows:

[0021] Dysprosium (Dy), mixed rare earth Ml and nickel (Ni), cobalt (Co), aluminum (Al), manganese (Mn), copper (Cu), iron (Fe), zinc (Zn), chromium (Cr) and tin (Sn) were placed in a vacuum non-consumable electric arc furnace, smelted under the protection of argon, and smelted repeatedly for 5 times, and finally cooled by a water-cooled copper ingot mold to make a hydrogen storage alloy ingot.

[0022] The preparation of the hydrogen storage alloy electrode of this embodiment:

[0023] The prepared alloy ingot is mechanically...

Embodiment 2

[0027] The chemical formula of the rare earth hydrogen storage alloy of the present embodiment is:

[0028] Ml 0.95 Dy 0.05 Ni 3.8 co 0.15 Al 0.35 mn 0.45 Cu 0.05 Fe 0.05 sn 0.05 Cr 0.05 Zn 0.05 (Alloy B).

[0029] The mixed rare earth Ml used therein includes the following components in mass percentage: La 90%, Pr 4%, Ce 4%, Nd 2%.

[0030] The preparation method and electrochemical performance detection method of the rare earth hydrogen storage alloy and electrode in this example are the same as in Example 1, and the hydrogen storage alloy electrode obtained in this example is marked as electrode B.

Embodiment 3

[0032] The chemical formula of the rare earth hydrogen storage alloy of the present embodiment is:

[0033] Ml 0.88 Dy 0.12 Ni 3.6 co 0.1 Al 0.3 mn 0.25 Cu 0.15 Fe 0.15 sn 0.15 Cr 0.15 Zn 0.15 (Alloy C).

[0034] The mixed rare earth Ml used therein includes the following components in mass percentage: La 84%, Pr 10%, Ce 4%, Nd 2%.

[0035] The preparation method and electrochemical performance detection method of the rare earth hydrogen storage alloy and electrode in this example are the same as in Example 1, and the hydrogen storage alloy electrode obtained in this example is marked as electrode C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com