Suspension spring

A hanger and spring device technology, which is applied to electric vehicles, power collectors, collectors, etc., can solve problems such as uncertain spring characteristics, wear, and limit the movement margin of the hanger, and achieve the effect of small air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

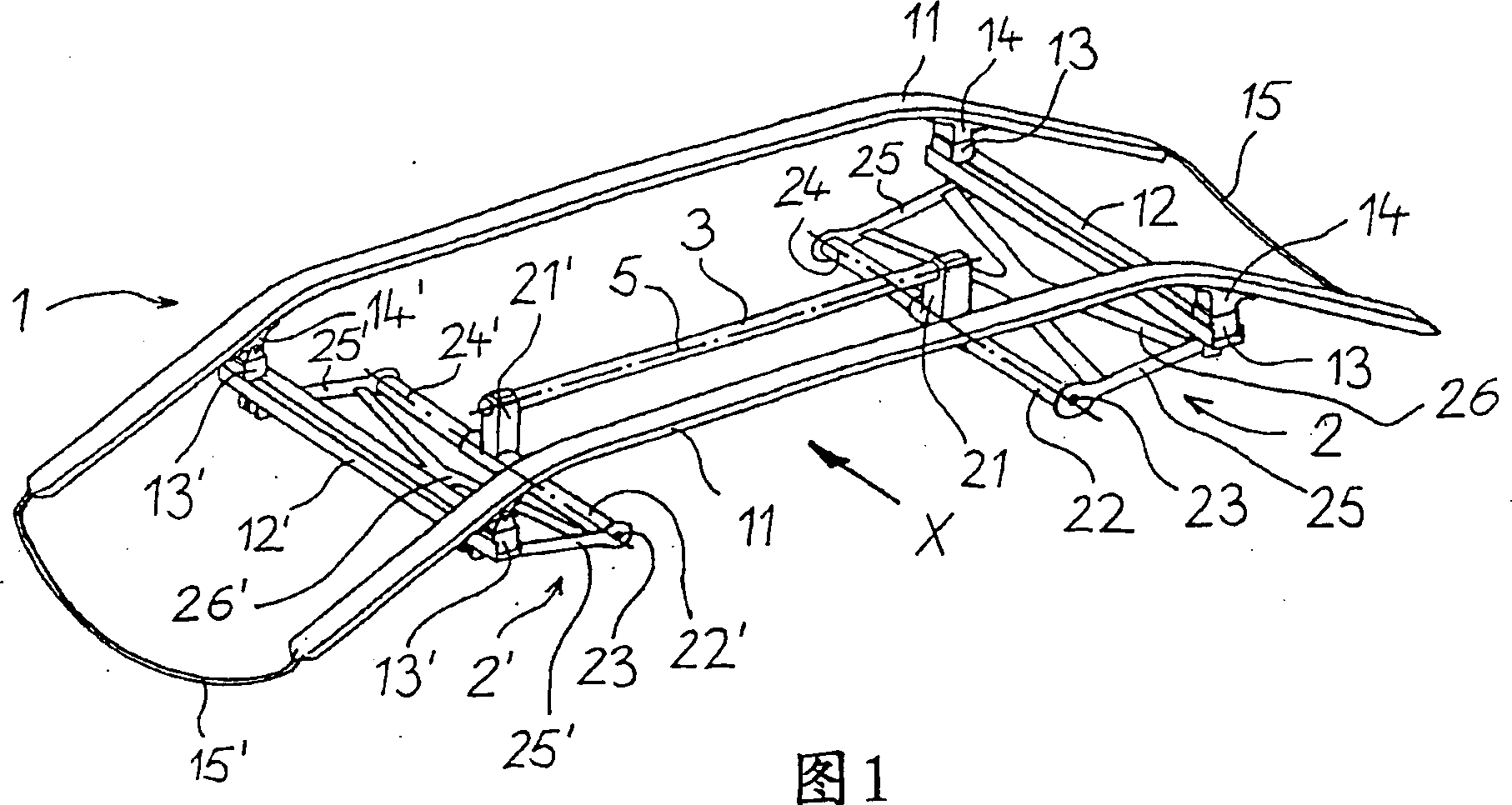

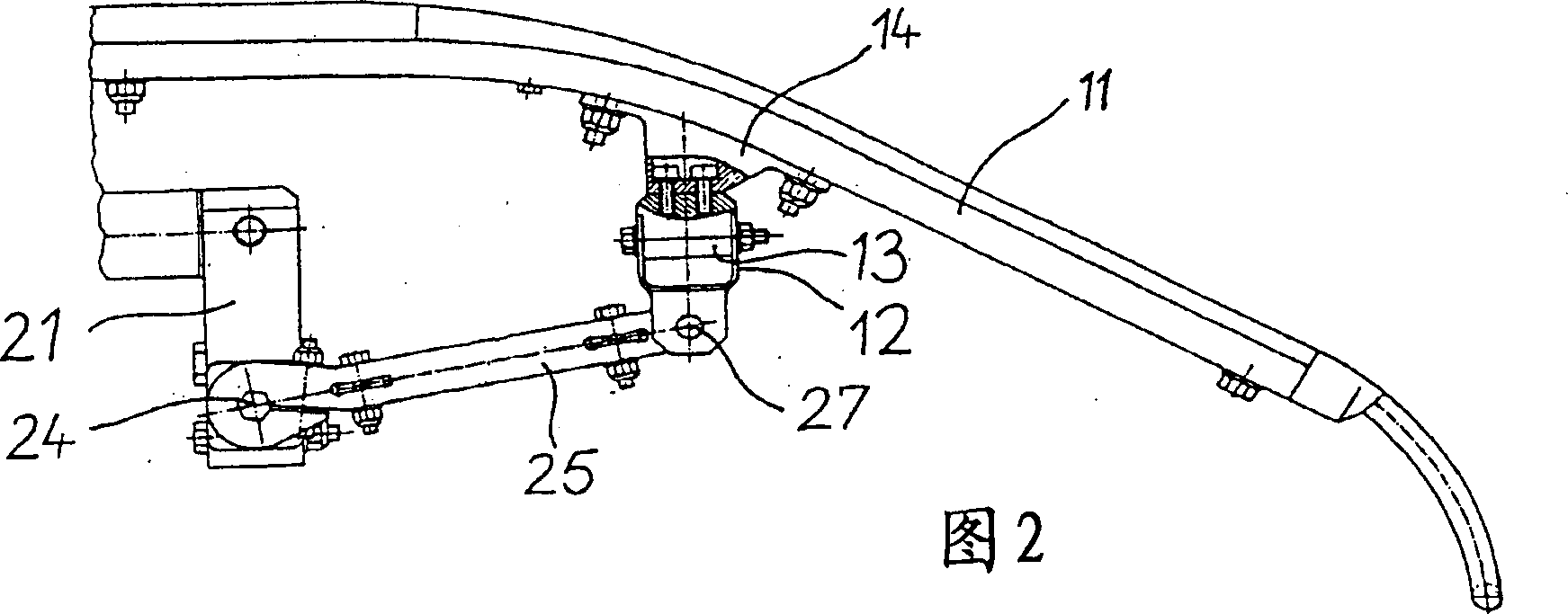

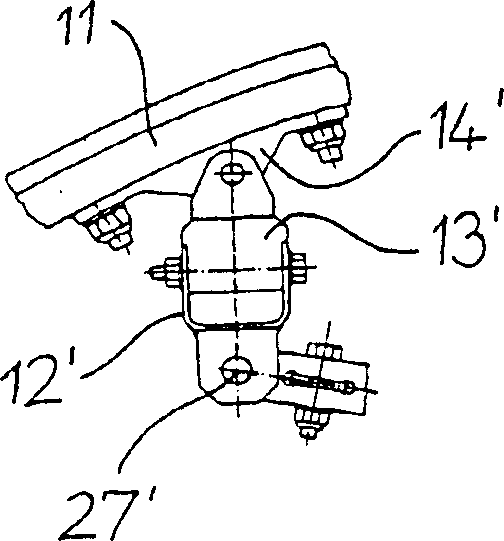

[0028] According to FIG. 1, a hanger for a current collector of an electric vehicle, such as a high-speed rail vehicle, has a frame 1 which is supported on a top shaft 3 via two spring devices 2, 2'. The frame 1 comprises two parallel sliding plates 11 extending perpendicularly to the traveling direction X for collecting electricity from trolley wires not shown in the figure and two supporting members 12, 12' extending parallelly along the traveling direction X. The supports 12, 12' are designed as upwardly open U-profiles, wherein a clamping section 13, 13' is inserted for each sliding plate 11, which can be inserted along the U-profile and screwed in the desired position. Mounts 14, 14' are attached to the underside of the slide 11, which are connected to the clamping sections 13, 13'. On each side of the vehicle, the ends of the sliding plate 11 are connected by sliding upper bows 15 , 15 ′, whereby the sliding wires sliding sideways can be redirected onto the carbon blocks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com