Measuring and controlling integrated electric eddy current type hot bending equipment for 3C members, and control method

An eddy current and integrated technology, applied in the manufacture of tools, glass forming, glass reshaping, etc., can solve the problems of slow production cycle, rising production cost, large consumption of protective gas, etc., achieve fast temperature rise and reduce parts Quantity, the effect of easy temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

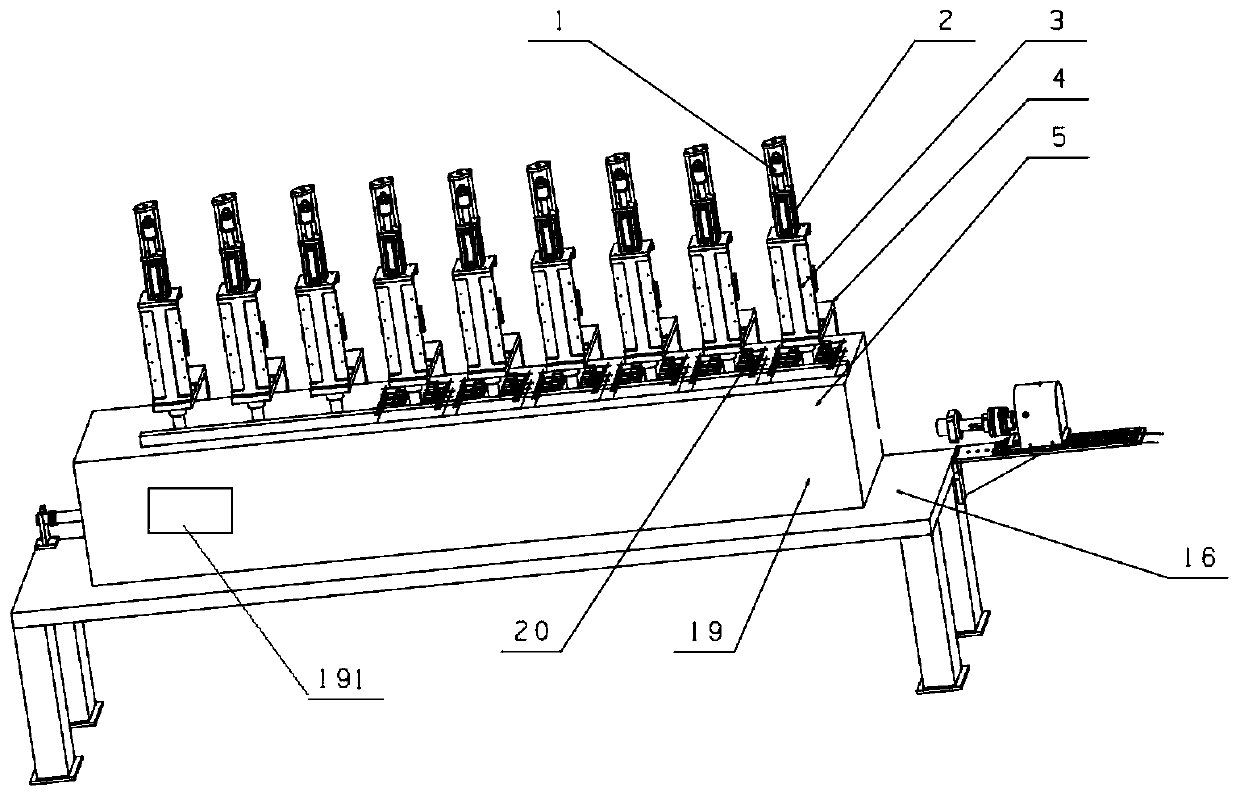

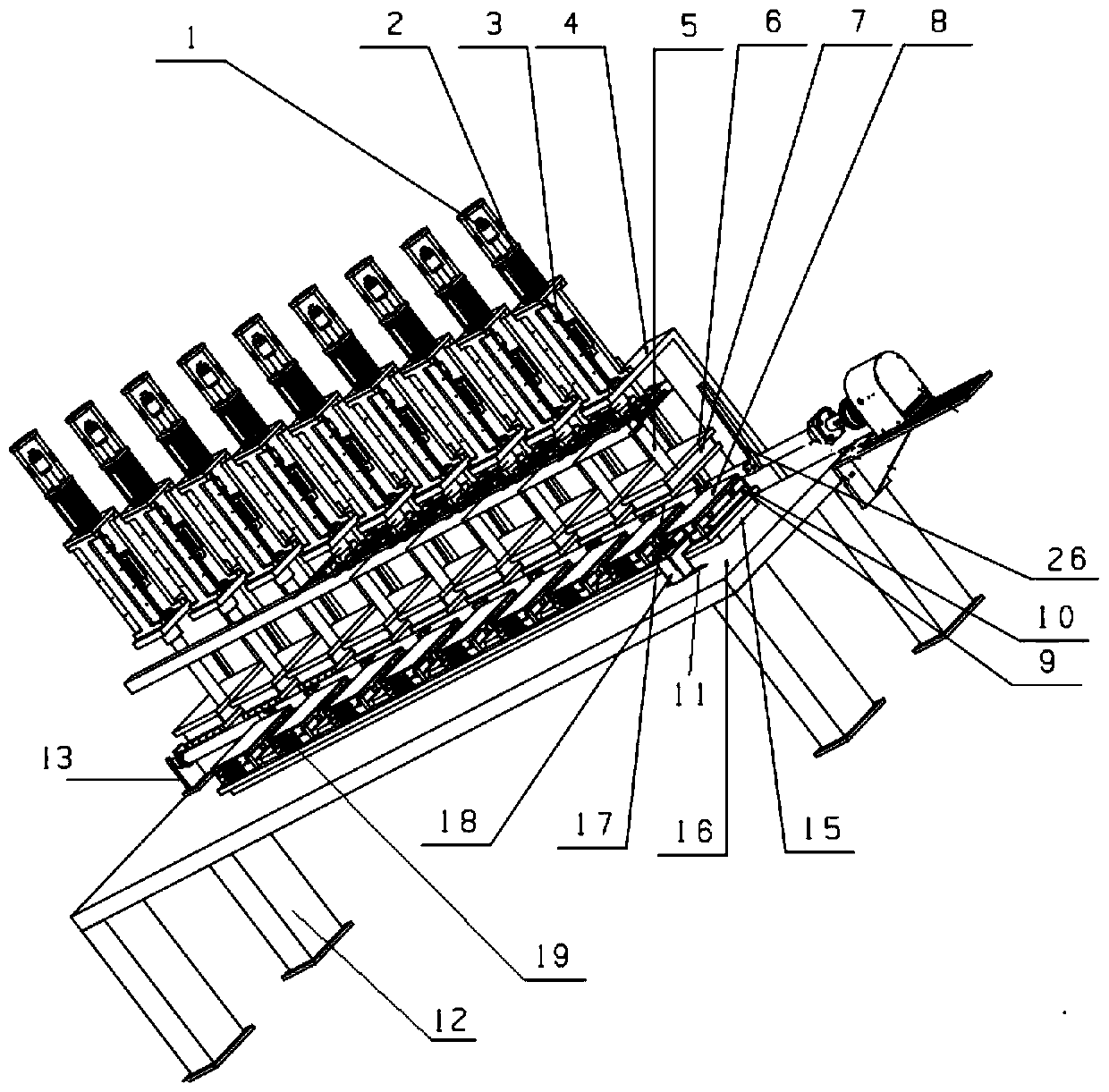

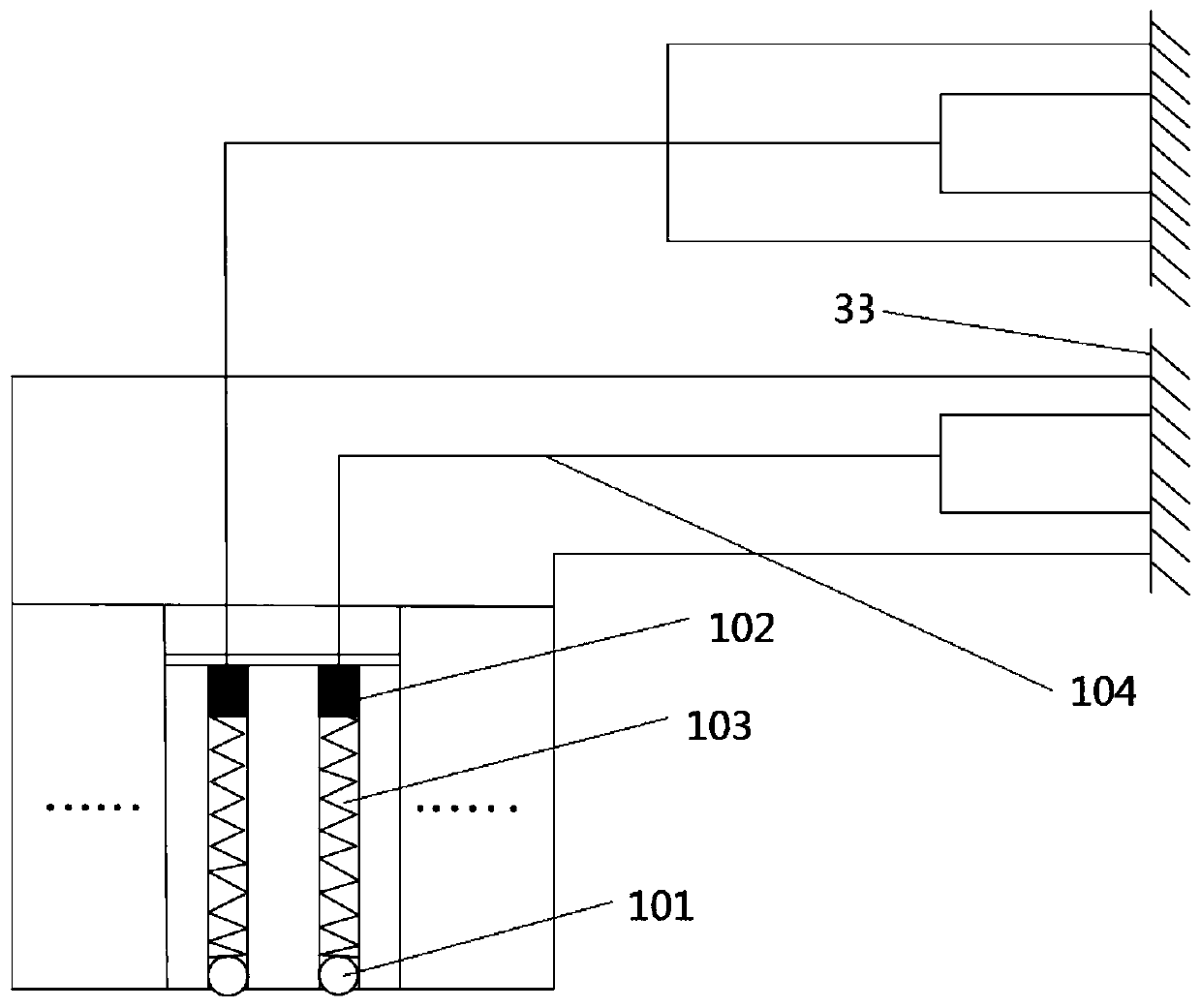

[0038] As shown in Figures 1-6, a measurement and control integrated eddy current type hot bending equipment for 3C components includes a furnace body mechanism and a control terminal. The furnace body mechanism is equipped with a measurement and control integrated eddy current type mechanism. An actuator is installed on the mechanism, and the measurement and control integrated eddy current mechanism and the actuator are respectively connected to the control terminal through industrial Ethernet communication. The furnace body mechanism is equipped with three workstations in sequence, namely, the preheating and heating workstation, and the hot bending forming Workstation and cooling and cooling workstatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com