Low profile compliant latch assembly and electronic circuit card and chassis incorporating same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

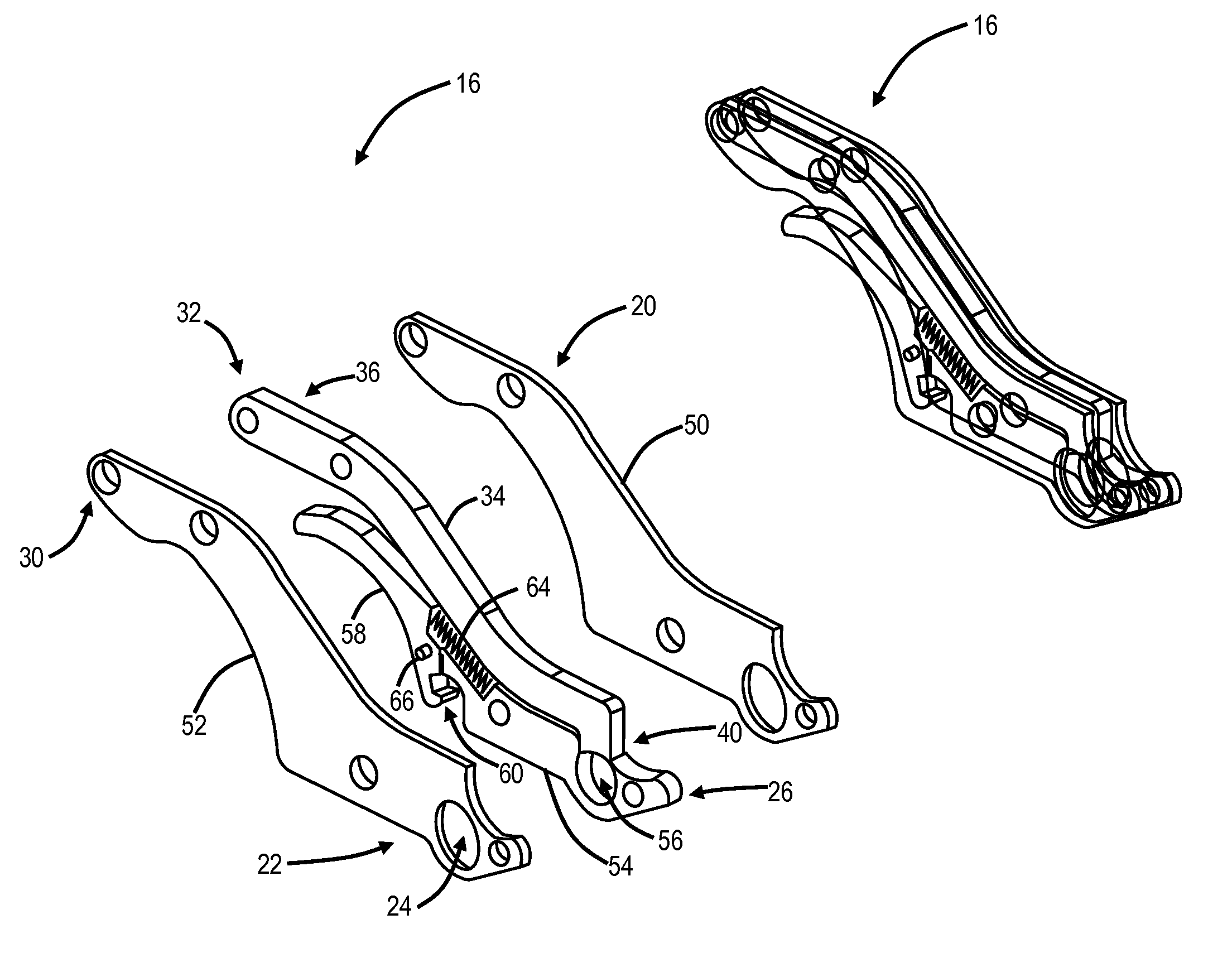

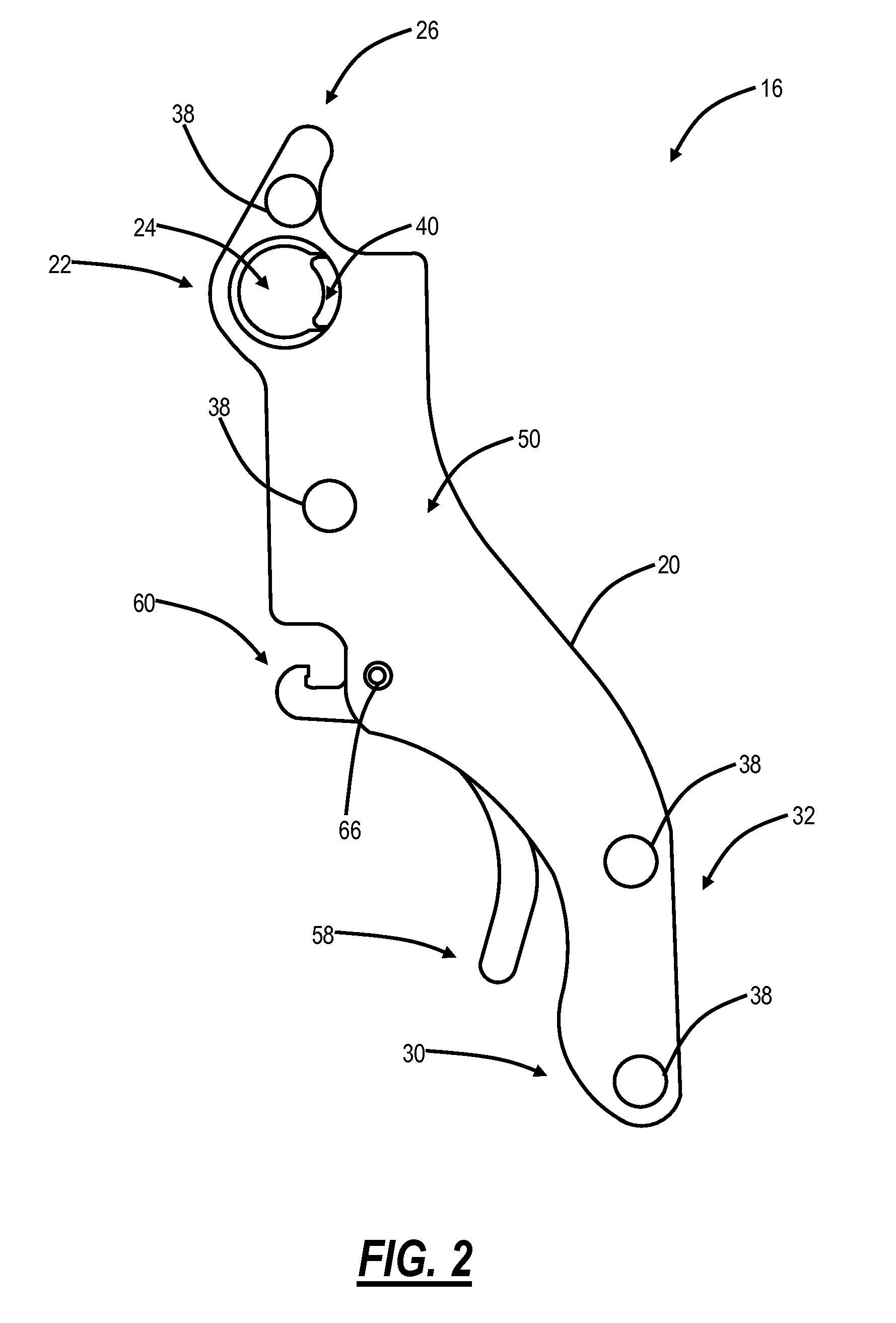

[0019]Again, in various exemplary embodiments, the present disclosure provides a low profile compliant latch assembly that incorporates an internal leaf spring, compliant portion, and / or compliant material that allows the latch assembly to properly and adequately secure an electronic circuit card in a chassis while accommodating varying manufacturing and assembly tolerances, both while maintaining a minimal footprint.

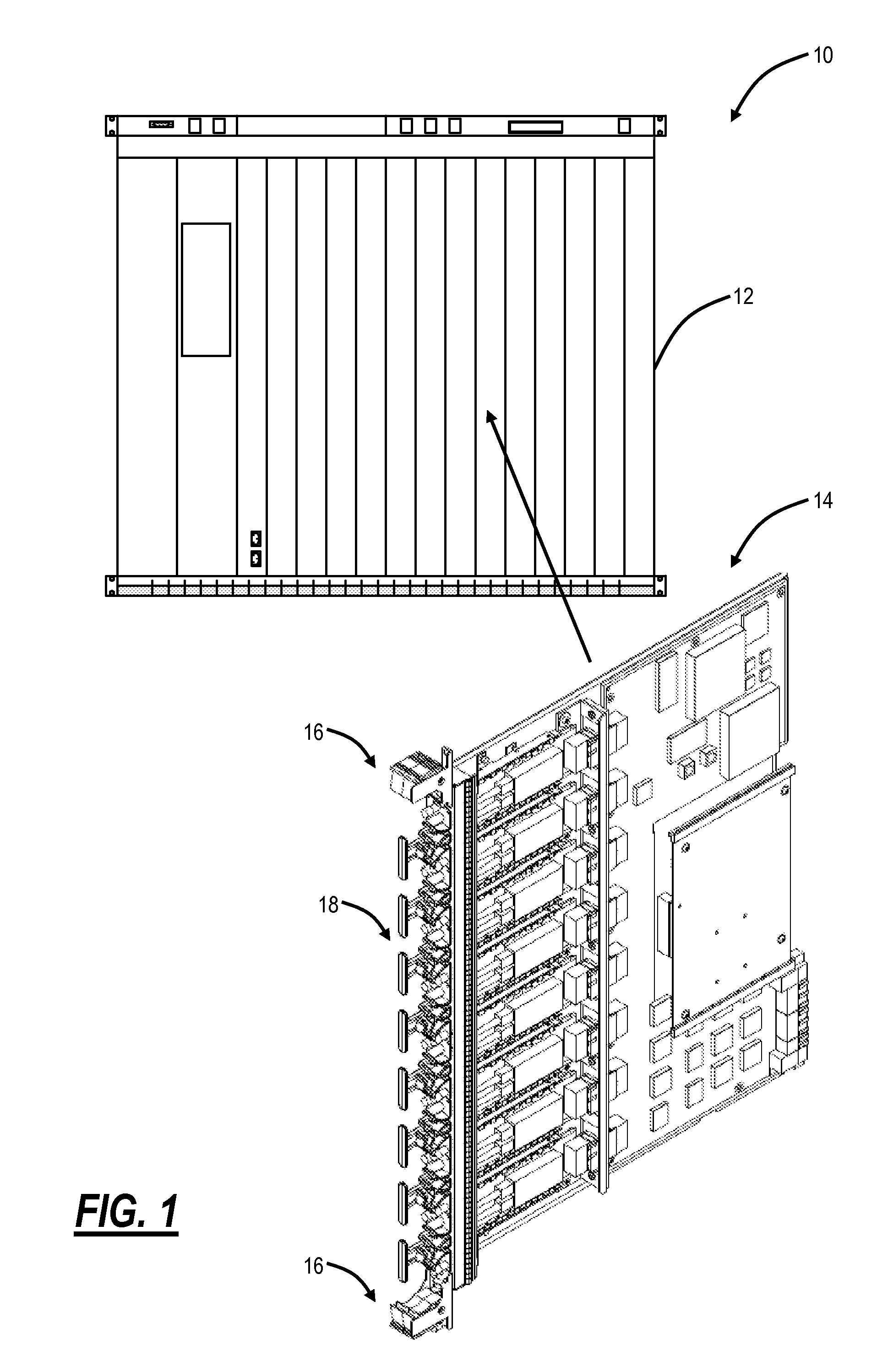

[0020]Referring specifically to FIG. 1, an electronic chassis 10, such as that used in an optical networking system, is illustrated. The chassis 10 includes a shelf structure 12 that houses a plurality of electronic circuit cards 14 in a side-by-side vertical orientation, for example. Each of the electronic circuit cards 14 is held in the shelf structure 12, in part, by a pair of latch assemblies 16, one latch assembly 16 disposed at the top of the faceplate 18 of the electronic circuit card 14 and one latch assembly 16 disposed at the bottom of the faceplate 18 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com