Pile hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

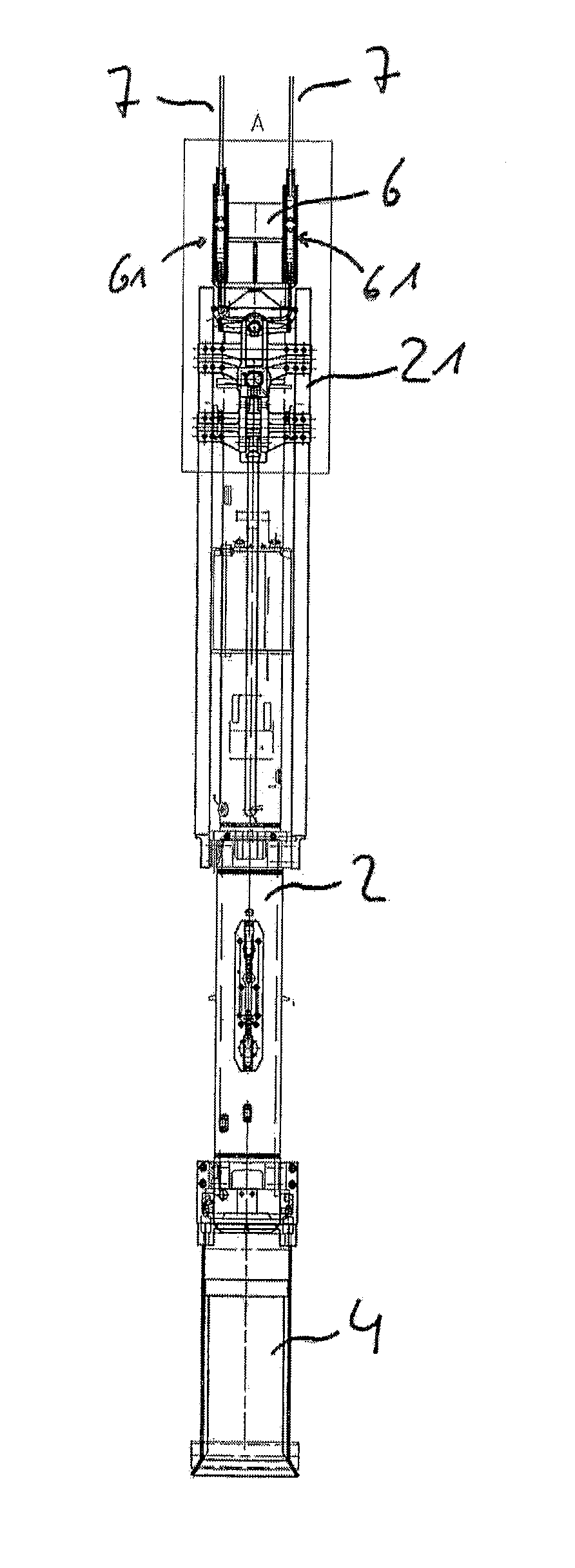

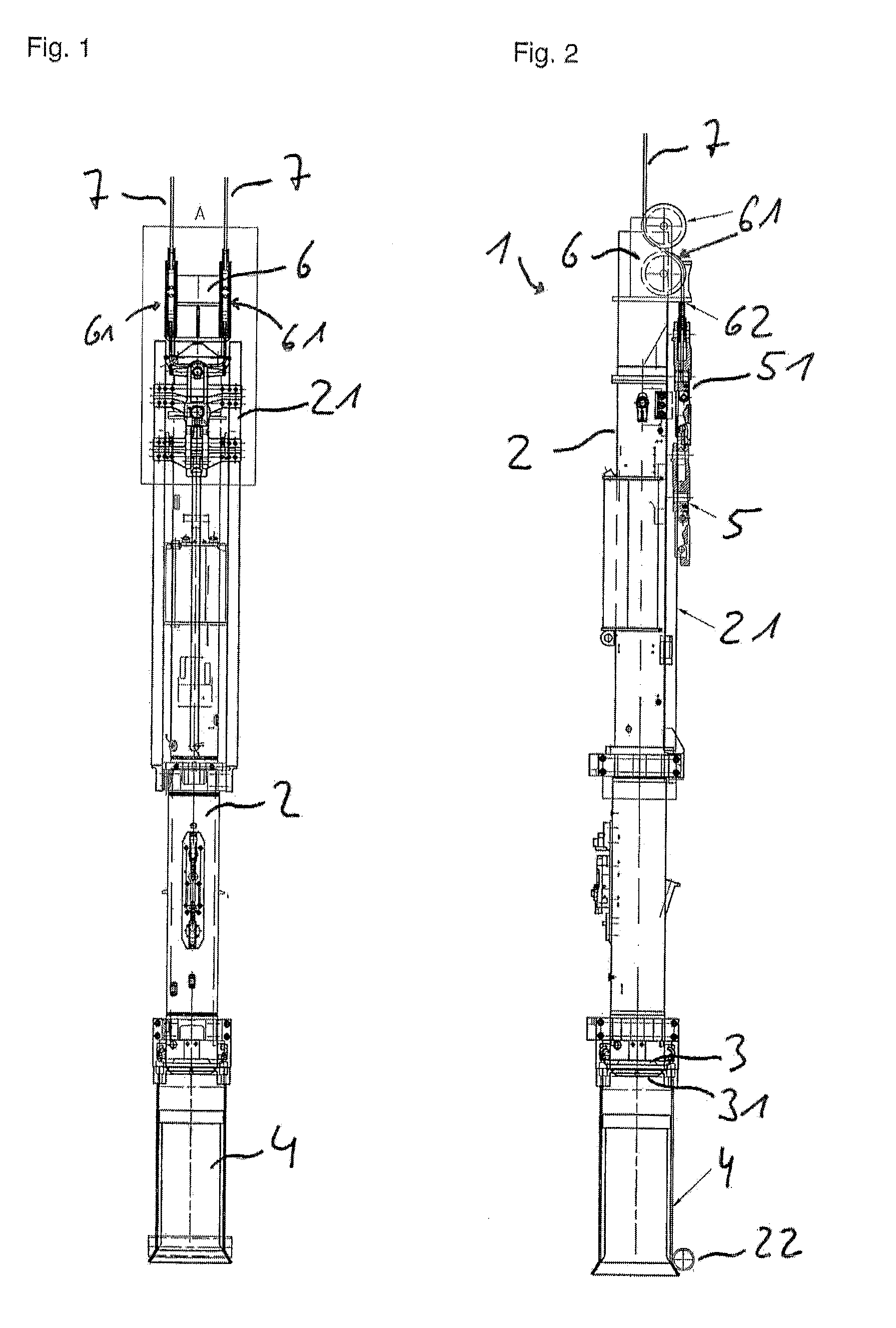

[0027]Referring now in detail to the drawings, the pile hammer shown in FIGS. 1 and 2 selected as an exemplary, embodiment is configured as a diesel hammer 1. The diesel hammer 1 has a cylinder 2 that is open on both sides, and regularly can have a length of 3 to 8 meters and a diameter of 0.2 to 1.5 meters. A piston—not shown—is displaceably disposed in the cylinder. A striker 3 coaxial to the piston engages into the open lower end of the cylinder 2, in displaceable manner. A striker plate 31 is formed onto the striker 3; its lower delimitation surface, directed outward, interacts with the upper end of a concrete pillar to be pile-driven during operation. In the exemplary embodiment, a pile ram chisel 4 for accommodating material to be pile-driven is disposed below the striker plate 31.

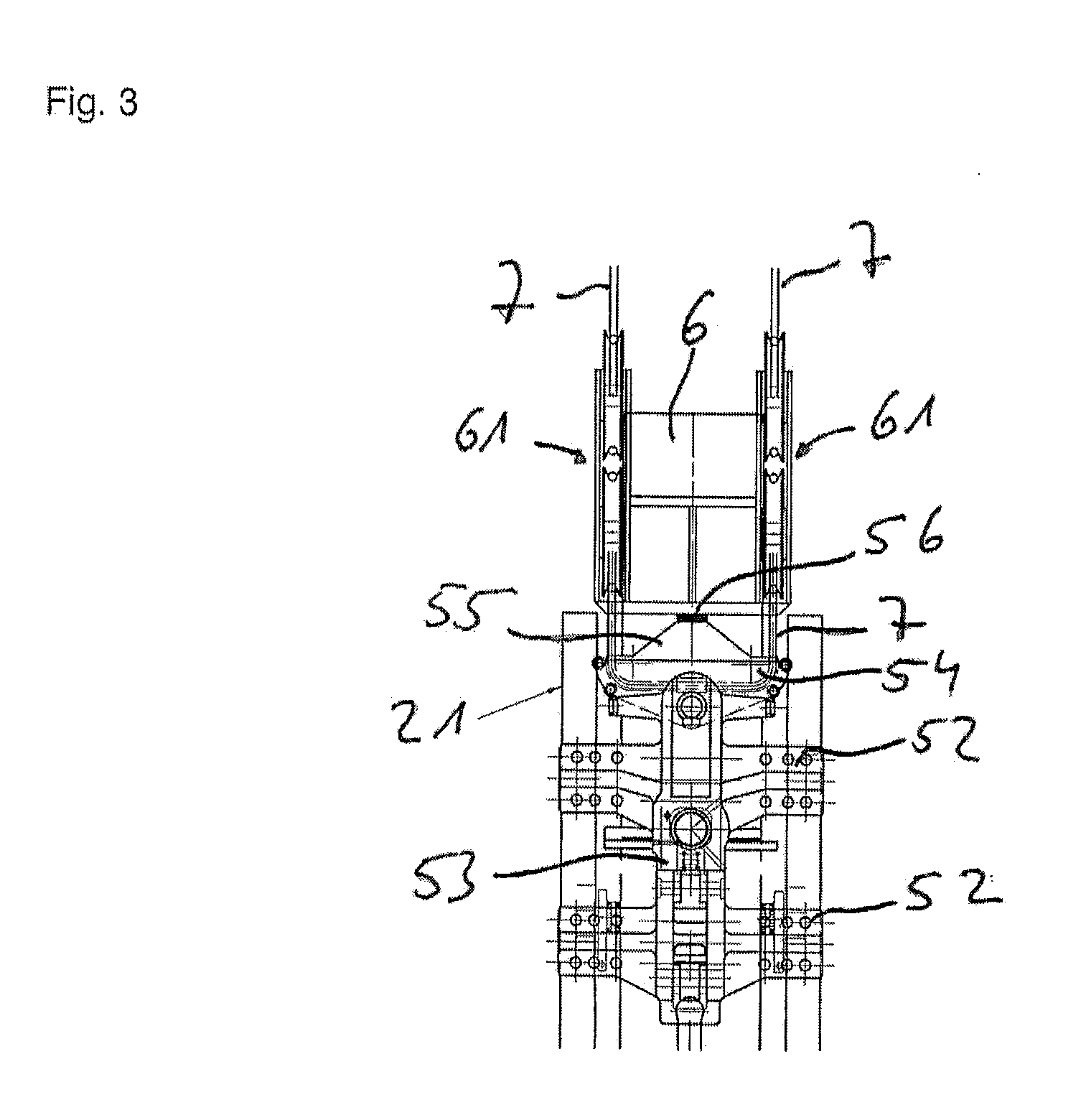

[0028]Two guide spars 21 are attached on the outside of the cylinder, parallel to one another, on which the carriage 51 of a disengagement apparatus 5 is guided so as to be displaceable.

[0029]The car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com