Prefabricated modular rebar modules and methods of using the same

a technology of modular rebar and rebar cage, which is applied in the field of reinforced concrete, can solve the problems of time-consuming process of installing components on site, long and labor-intensive work, and long rods themselves, and achieves the effect of simple and efficient way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

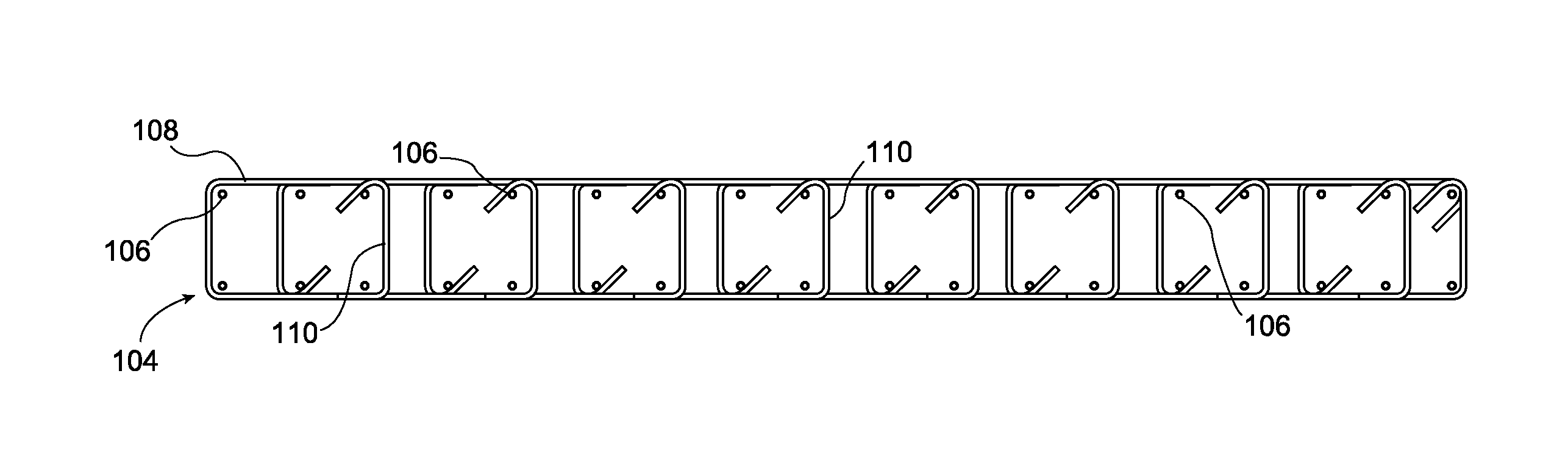

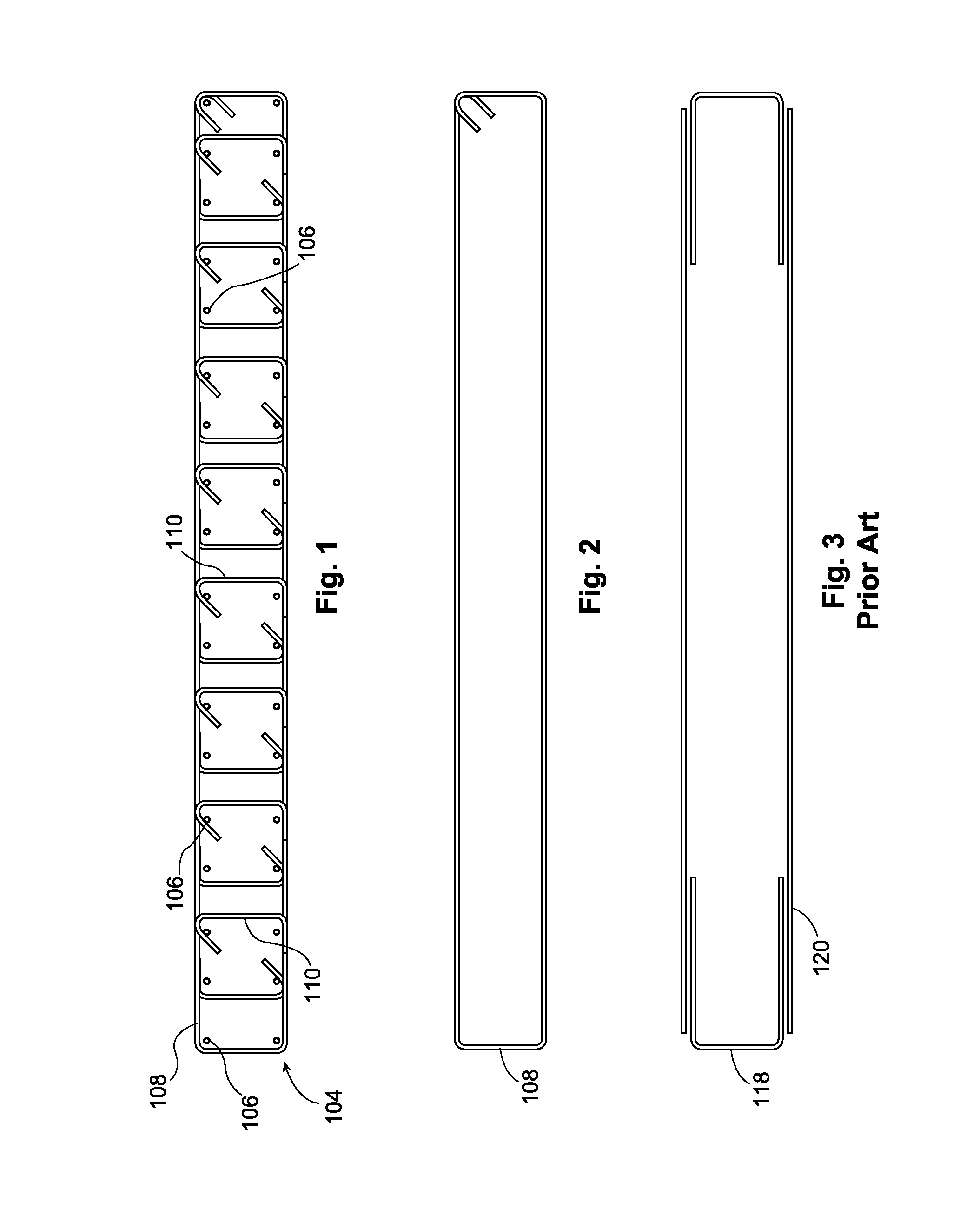

[0037]A prefabricated welded cage 104 is shown in FIG. 1. The prefabricated welded cage 104 includes a number of vertical reinforcing bars 106. A continuous tie 108 extends around the vertical reinforcing bars 106. Although only one continuous tie is shown in FIG. 1, it will be understood that the welded cage 104 includes a plurality of continuous ties 108 which are placed at vertical intervals around the vertical reinforcing bars 106. Preferably, the plurality of continuous ties 108 are spaced at even intervals along the height of the vertical reinforcing bars 106. A. plurality of shear ties 110 extend generally horizontally between the vertical reinforcing bars 106. The welded cage 104 is sized and shaped for shipping.

[0038]The structure of one of the plurality of continuous ties 108 is shown in FIG. 2. The continuous tie 108 shown in FIG. 2 is a single piece of reinforcing steel that forms a closed loop with, for example, ends that overlap.

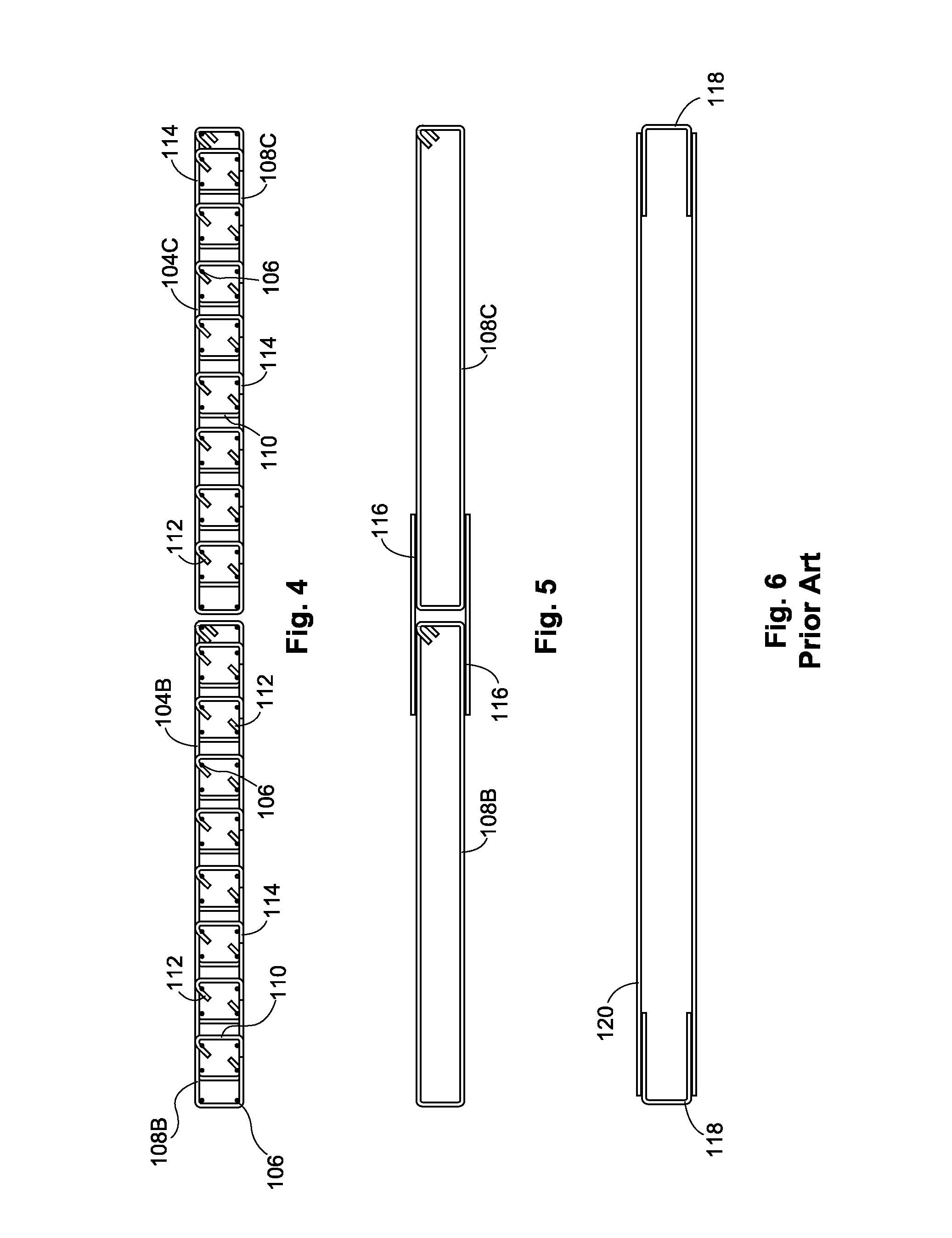

[0039]In FIG. 3, a prior art design for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com