Dry Goods Bulk Trailer with Uninterrupted Slope Sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

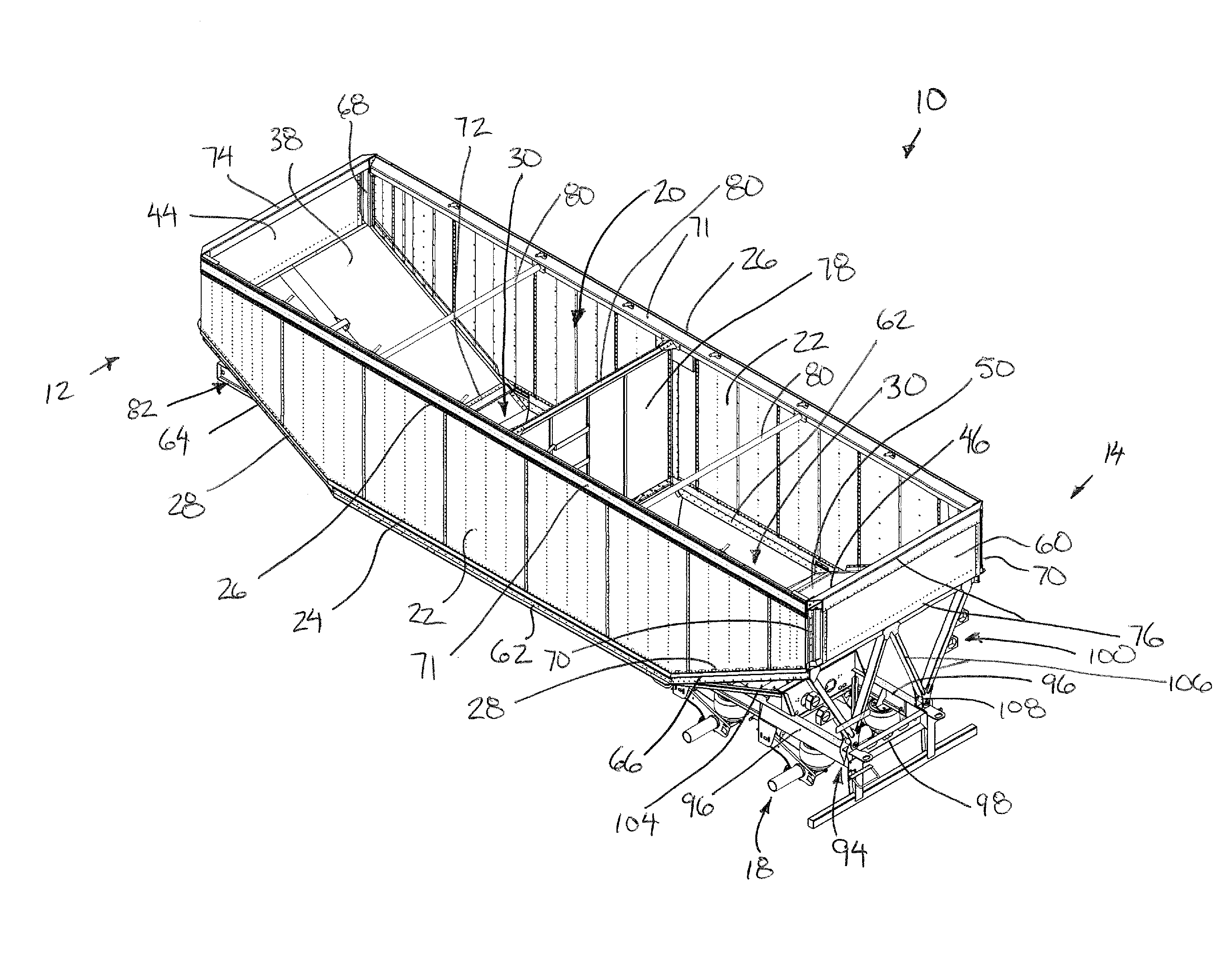

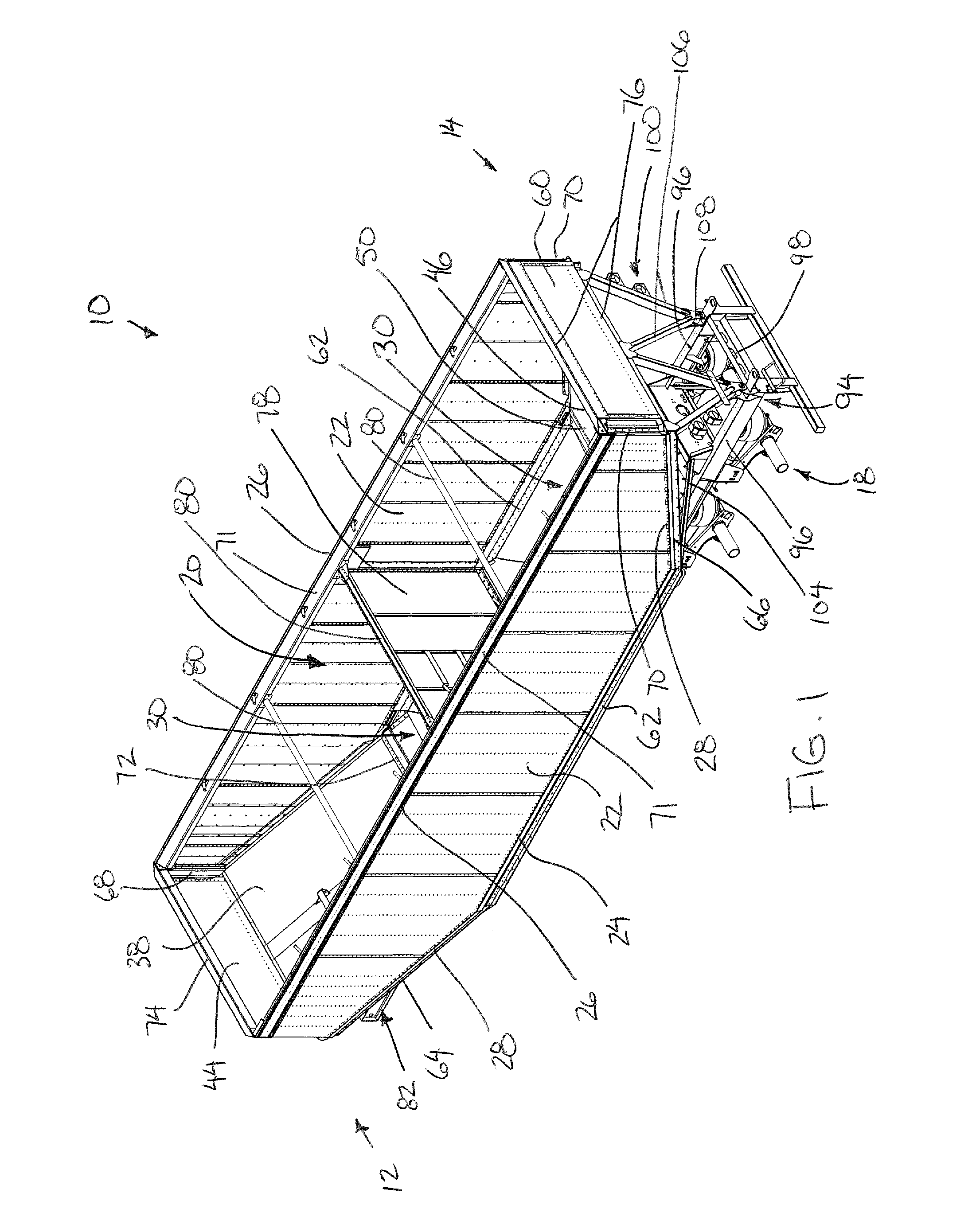

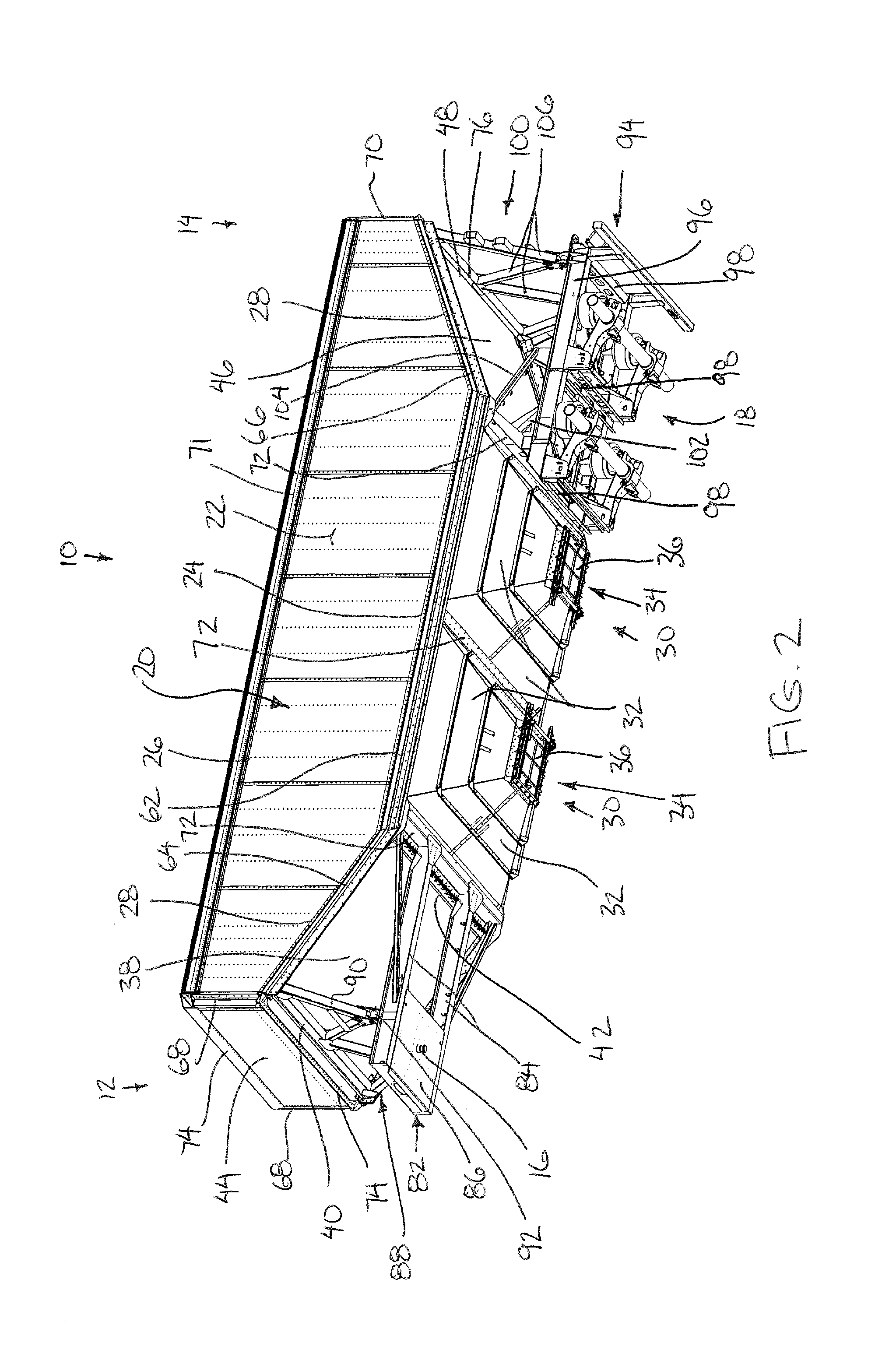

[0070]Referring to the accompanying figures, there is illustrated a dry goods bulk trailer generally indicated by reference numeral 10. The trailer 10 is particularly suited for use with a towing vehicle for movement across the ground in a forward transport direction with the vehicle. The trailer 10 includes a frame assembly which is elongate in a longitudinal direction corresponding to the forward transport direction in use from a front end 12 to a rear end 14 of the frame assembly.

[0071]A hitching element 16 is provided at the front end of the frame assembly for connection to a towing vehicle. Typically, the hitching element comprises a king pin for being received within a fifth wheel hitch plate commonly found on highway tractors.

[0072]The rear end of the frame assembly is supported on a rear wheel assembly 18 comprising a plurality of rear wheel axles supporting laterally opposed pairs of rear wheels thereon for rolling movement in the forward transport direction. A suitable rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com