Sole member of footwear

a technology of sole member and shoe, which is applied in the direction of sole, footwear, apparel, etc., can solve the problems of leakage of liquid from the joint between the base plate and the cover, and achieve the effect of avoiding the confinement of liquid in the gap and reducing the increase in the pressure resulting from the confinemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

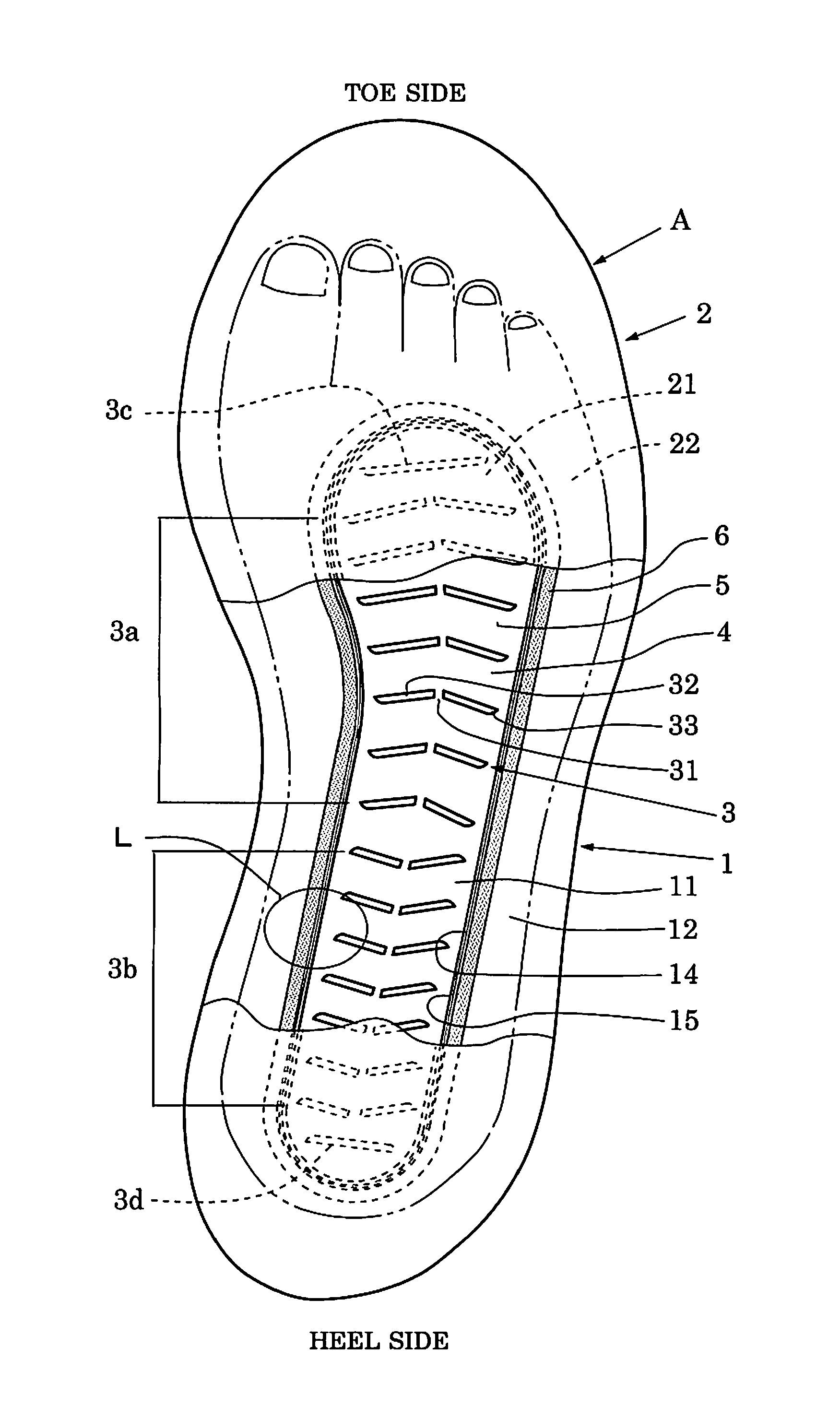

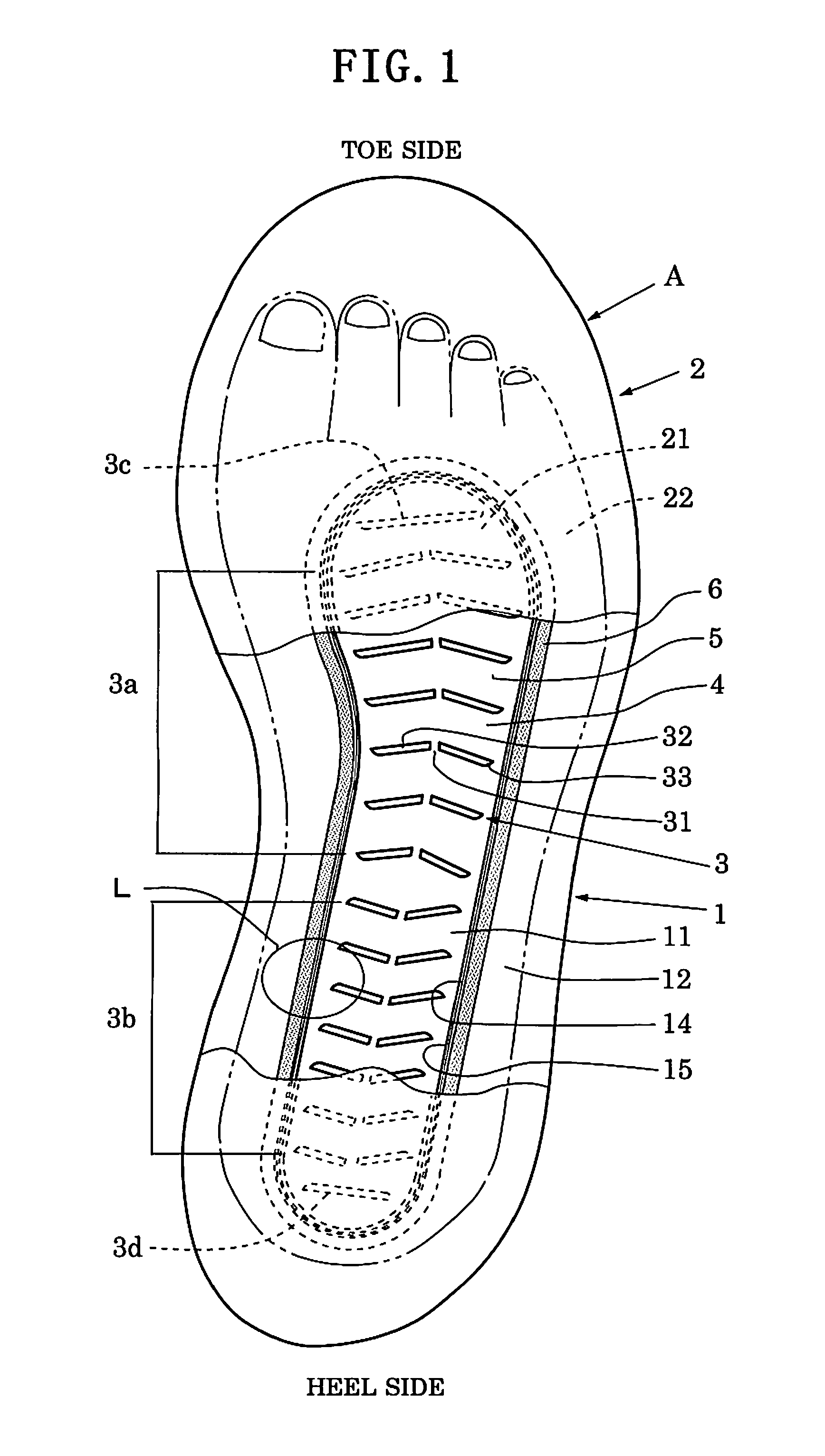

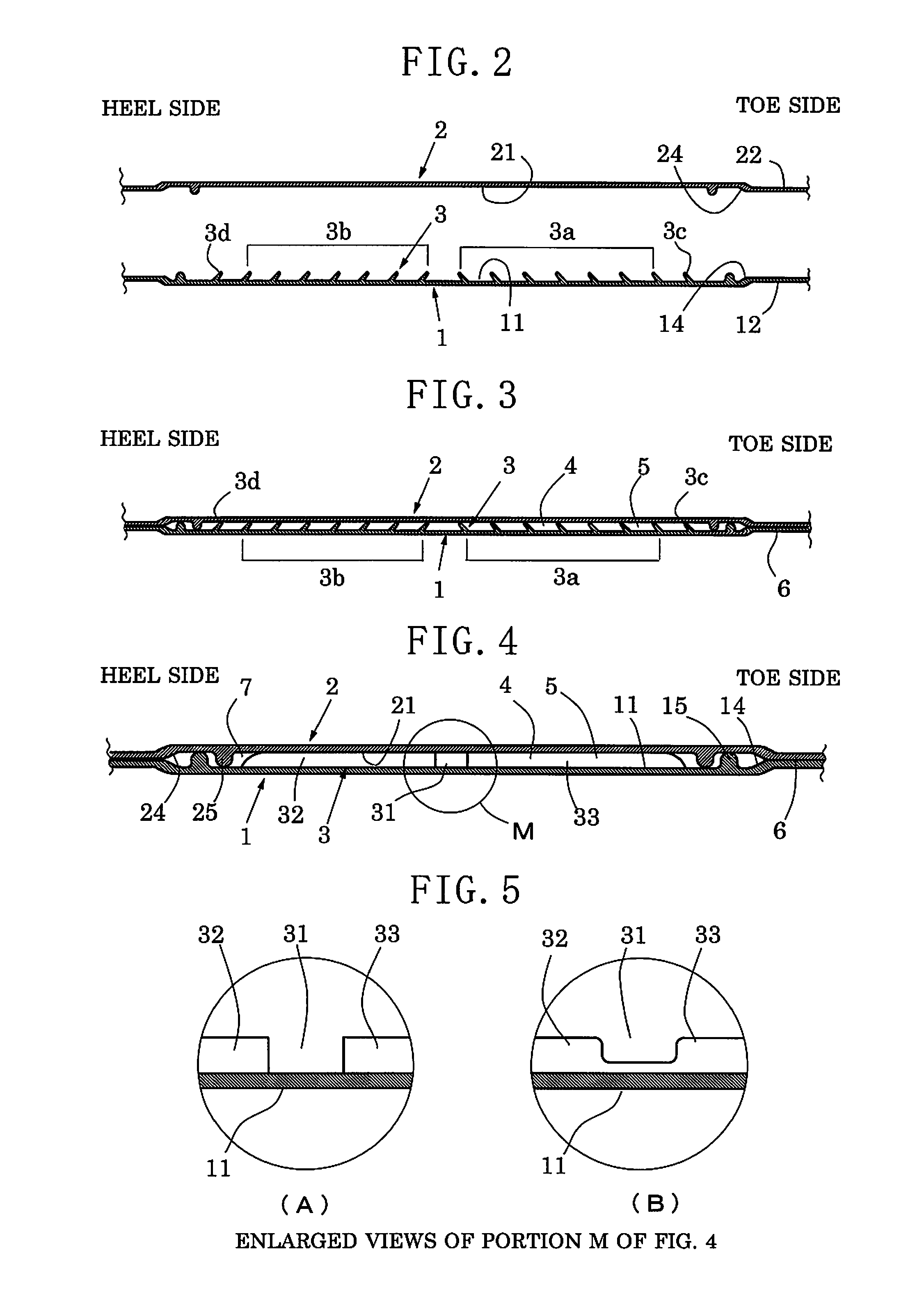

[0097]A sole member of footwear according to the present invention will next be described while referring to a shoe midsole, with reference to FIGS. 1 to 7. As shown in FIG. 1, the shoe midsole A according to the present invention includes a base plate 1, a cover 2, a plurality of blades 3, and liquid 4.

[0098]The base plate 1 has a first region 11 having a shape equivalent to a foot sole, and a first horizontal flange portion 12 surrounding the entire periphery of the first region. The cover 2 has a second region 21 which faces the first region 11 of the base plate 1, and a second horizontal flange portion 22 which faces the first horizontal flange portion 12. As is apparent from FIG. 1, the first region 11 of the base plate 1 has a length extending from the heel to the portion near to the roots of the toes, and a width of the portion where foot sole contacts with, when foot sole touches down on the ground.

[0099]As shown in FIGS. 2 to 4, the first region 11 has a concave shape which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com