Fan assembly for centrifugal blower and air conditioning apparatus including the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

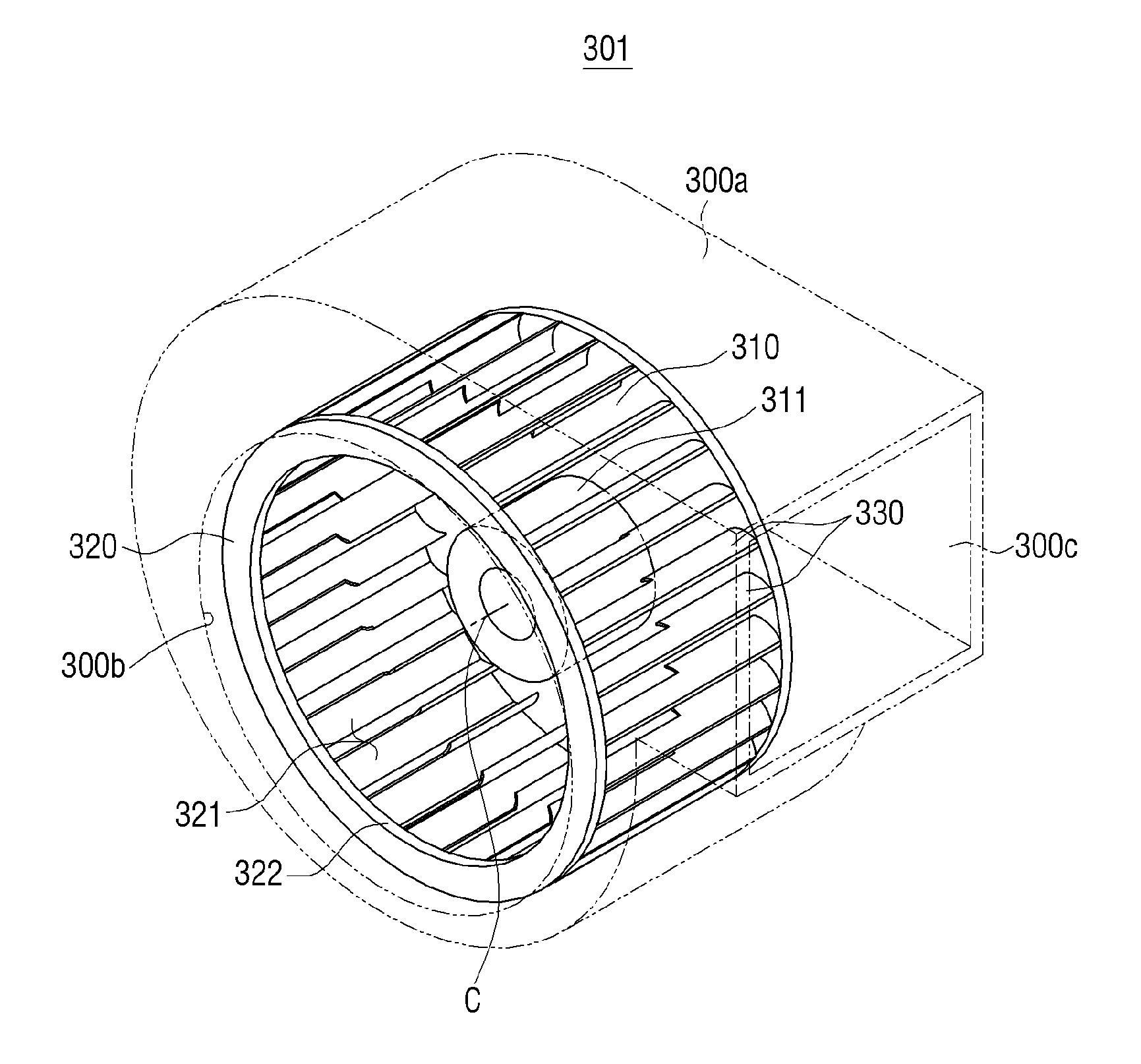

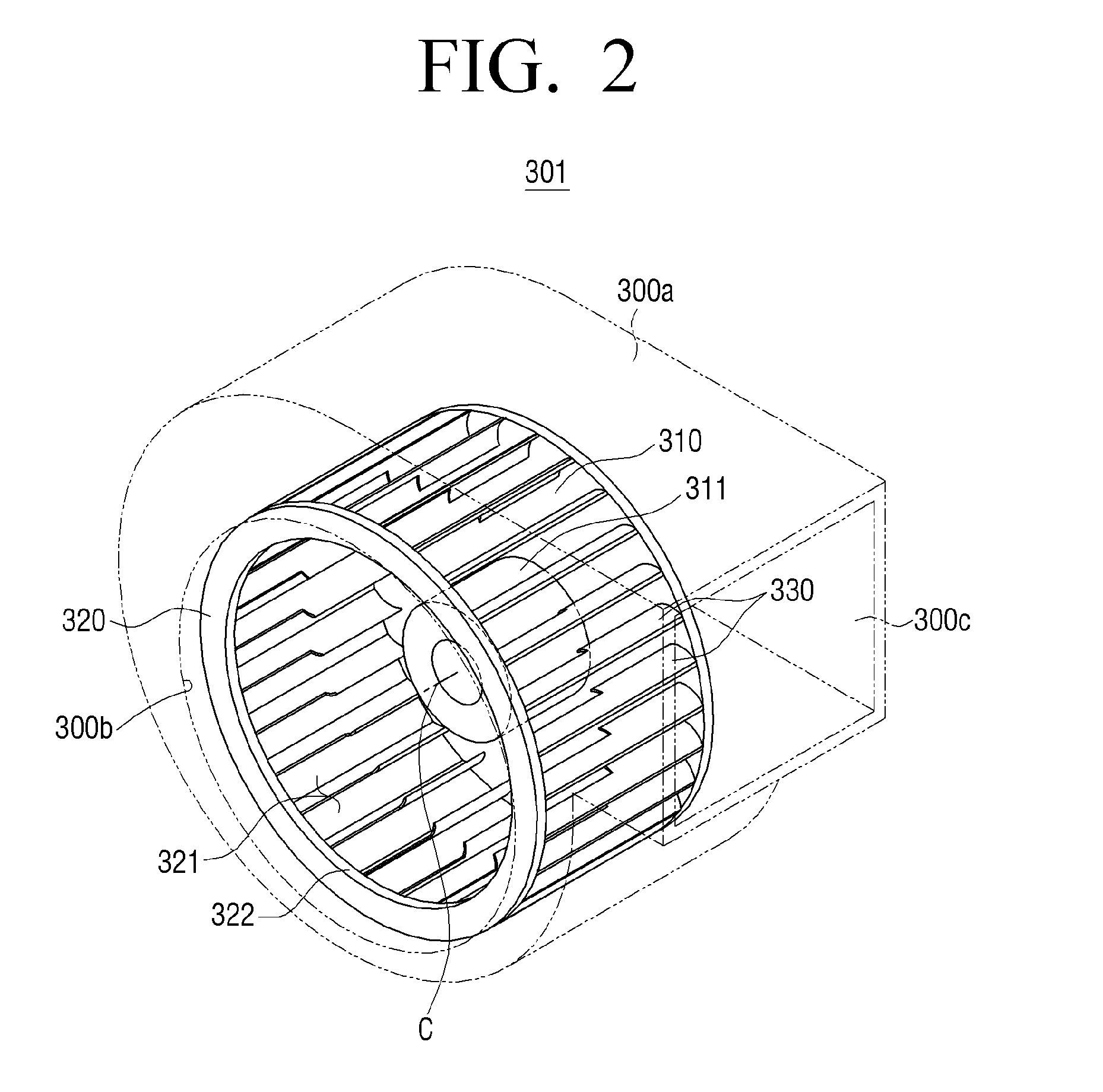

[0055]Referring to FIG. 3, a blade 330 according to the present disclosure is divided into a first portion 331 and a second portion 332 which have different widths according to the amount of air that is introduced through the inlet 321 and discharged in a radial direction of the fan assembly 301.

[0056]The first portion 331 is disposed adjacent to the inlet 321 and formed with a narrow and fixed or constant width W1 compared with a width W2 of the second portion 332, which in the embodiment also has a fixed or constant width W2.

[0057]In detail, in order to discharge the air introduced through the inlet 321, through the first portion 331 in the radial direction, a flow path of the air needs to be steeply changed to the radial direction immediately after the air passes through the inlet 321, and thus the amount of air discharged through the first portion 331 is smaller than the amount of air discharged through the second portion 332. Accordingly, the first portion 331 need not necessar...

second embodiment

[0067]Referring to FIG. 4, the blade 340 is formed in such a way that a portion 343 of an internally protruding portion of a second portion 342, adjacent to a first portion 341, is rounded. That is, the blade 340 is formed such that a width between the first portion 341 and the second portion 342 is not steeply changed, that is, the width is changed gradually.

[0068]Although not illustrated, a portion of an internally protruding portion of the first portion 341, adjacent to the second portion 342, may also be rounded.

[0069]Like in the first embodiment, the length of the first portion 341 is smaller than the length of the second portion 342.

[0070]When the blade 340 according to the second embodiment of the present disclosure is applied to the fan assembly 301, a flow direction of air introduced into the inlet 321 is changed towards the plurality of blades 340 with a predetermined curvature, like the blade 330 according to the first embodiment. In this case, as described above, the am...

third embodiment

[0072]With reference to FIG. 5, the blade 350 will be described.

[0073]The blade 350 according to the third embodiment is formed in such a way that the width of a first portion 351 is tapered towards the inlet 321. However, although the width of the first portion 351 is gradually tapered in FIG. 5, embodiments of the present disclosure are limited thereto, and the width of the first portion 351 may be non-gradually tapered. In addition, the first portion 351 may have a constant width, but a second portion 352 may have a width that is gradually or non-gradually tapered towards the inlet 321.

[0074]In addition, like the aforementioned blade 330 according to the first embodiment, the length of the first portion 351 may be smaller than the length of the second portion 352.

[0075]When the blade 350 according to the third embodiment is applied to the fan assembly 301, a flow direction of air introduced to the inlet 321 is changed towards the plurality of blades 350 with a predetermined curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com