Electrode-rigidifying device and rigidifying system using said device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

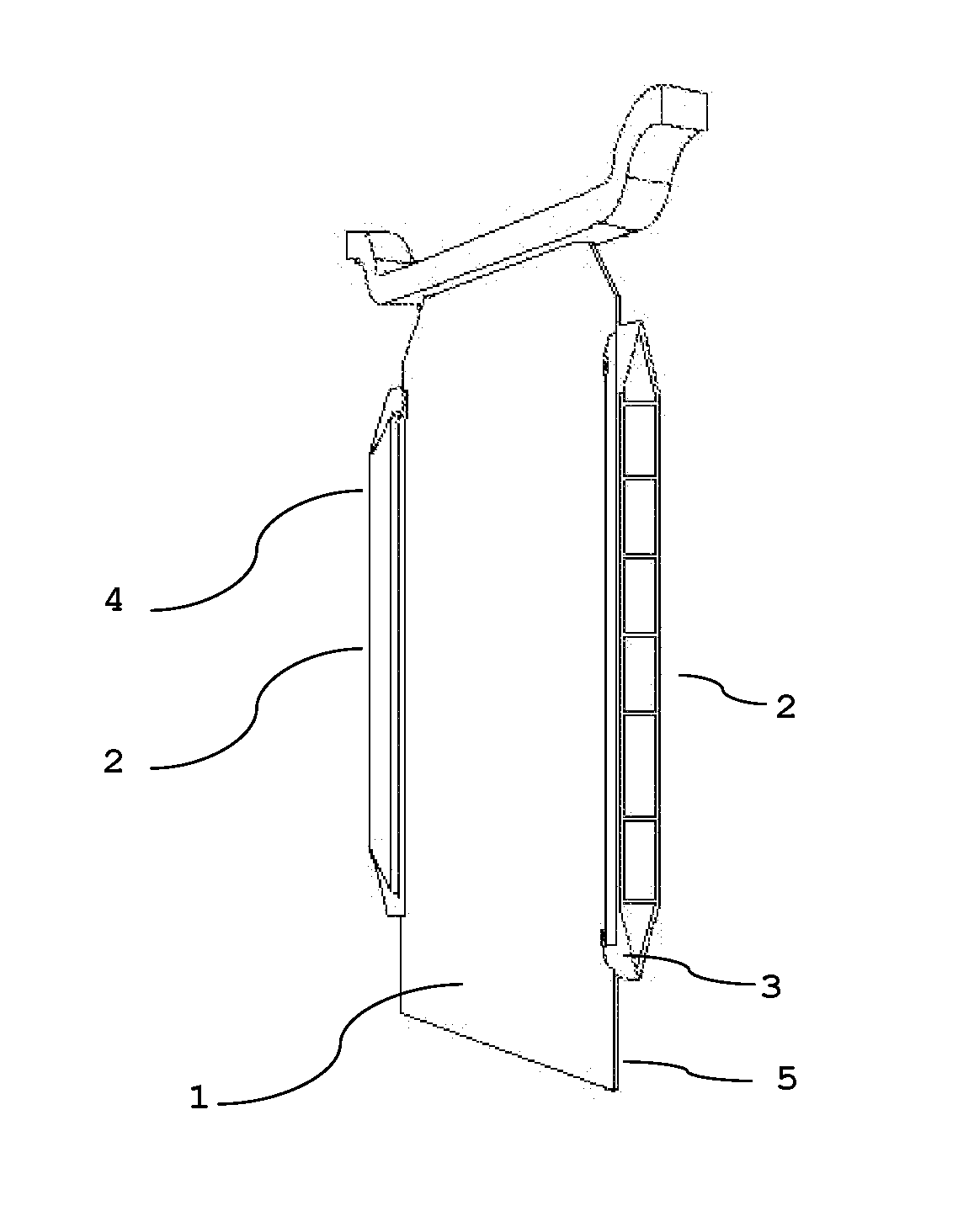

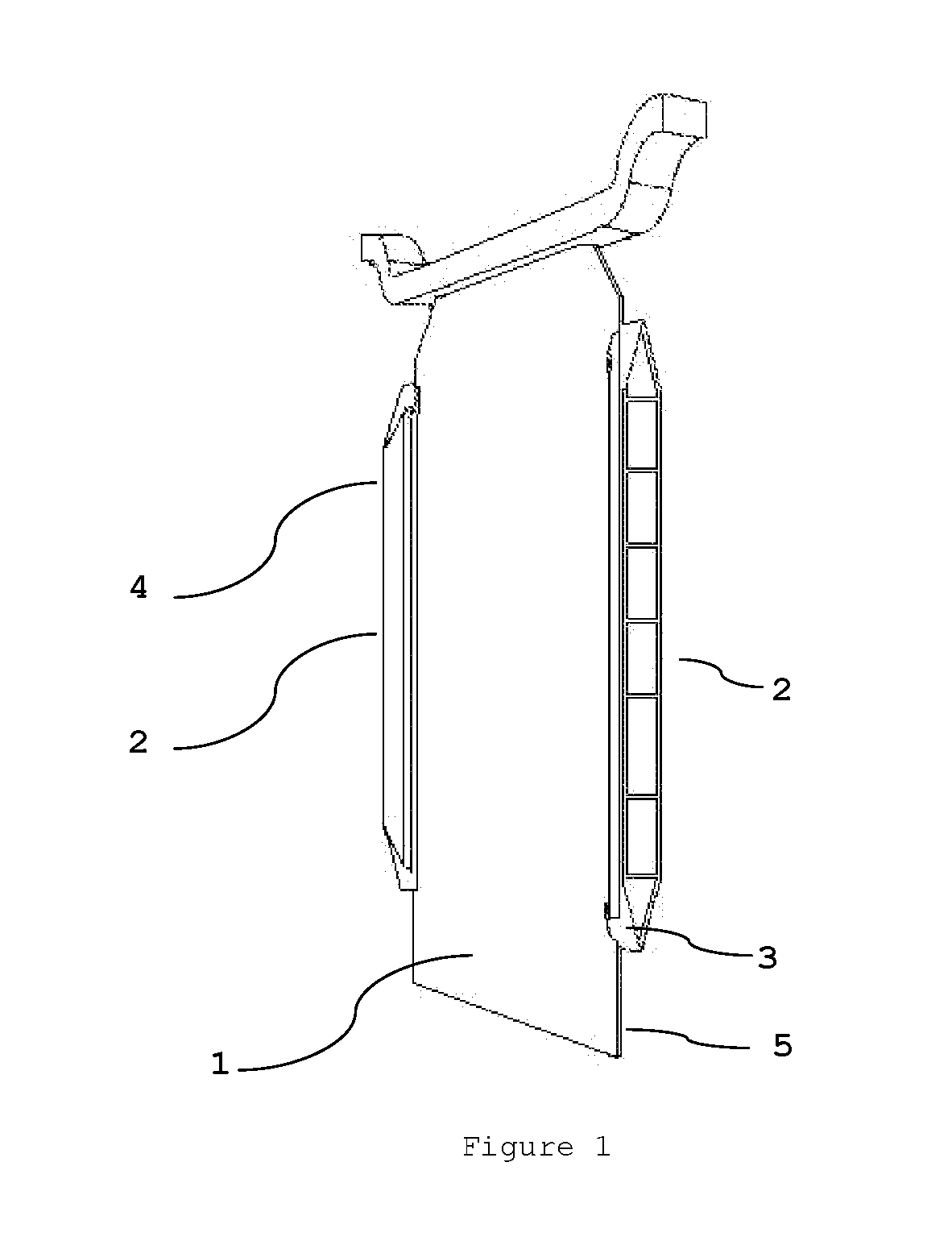

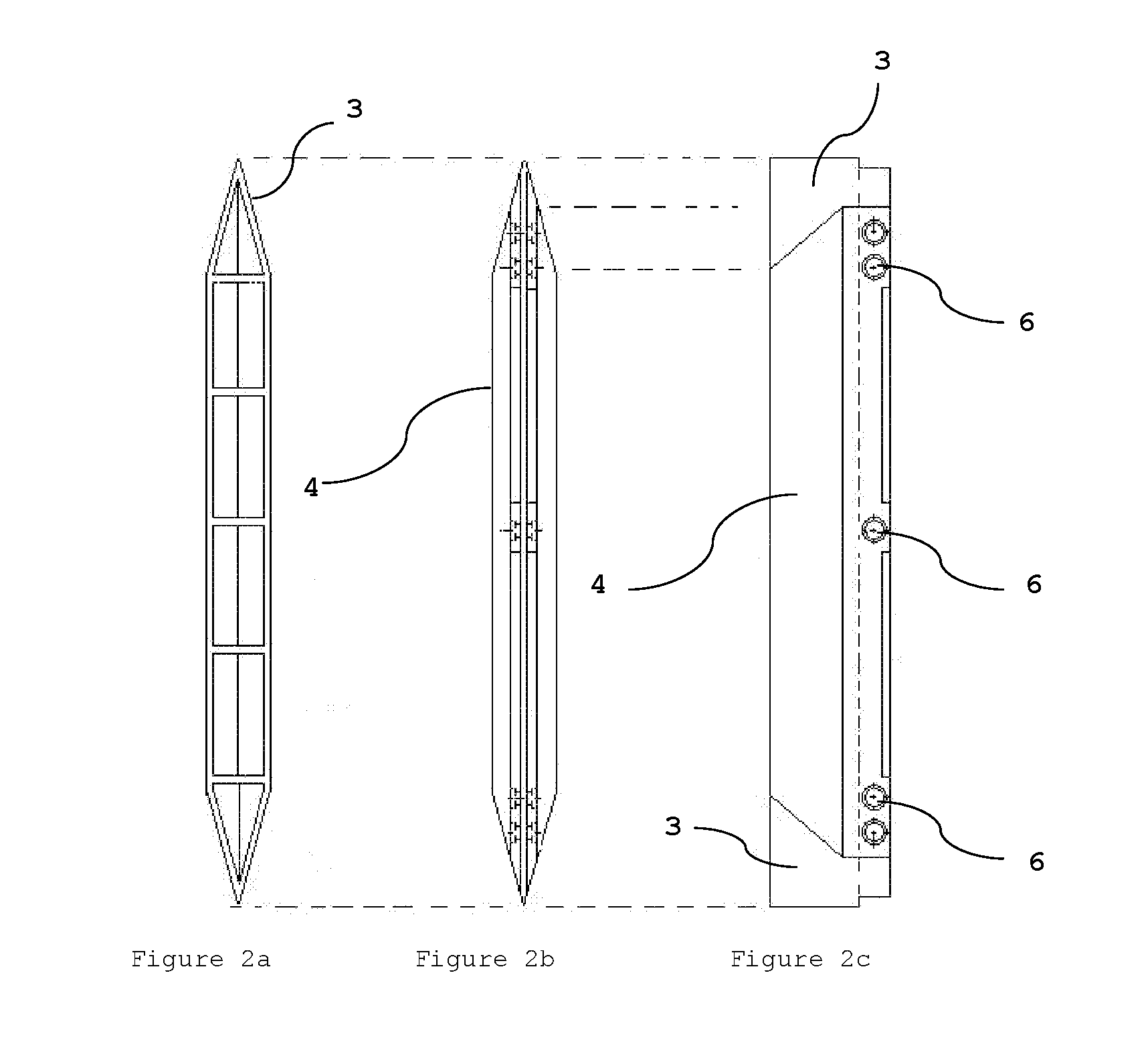

[0029]The present invention consists in a stiffening device and its incorporation to a stiffening system allowing to stiffening and keeping an anodic plate straight in its whole extension, while allowing keeping equidistant separation along the whole anode with respect to adjacent cathodes. Said system and device allows to reducing the formation of nodulations in the electric cathodes deposited by avoiding the formation of short-circuits originating in the reduces separation between anode and cathode, in addition to increasing the useful life of anodes by preventing their strain from the on-going degradation they are subject to during the operation in the electrolytic means.

[0030]FIG. 1 shows an embodiment of the stiffening system incorporating stiffening devices 2, two in particular, installed on the side 5 of an anodic plate 1 along most of the extension of said sides 5, covering at least 50% of the extension of said side or preferably between 50 and 100% of said sides, where in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com