Sweetener with imbedded high potency ingredients

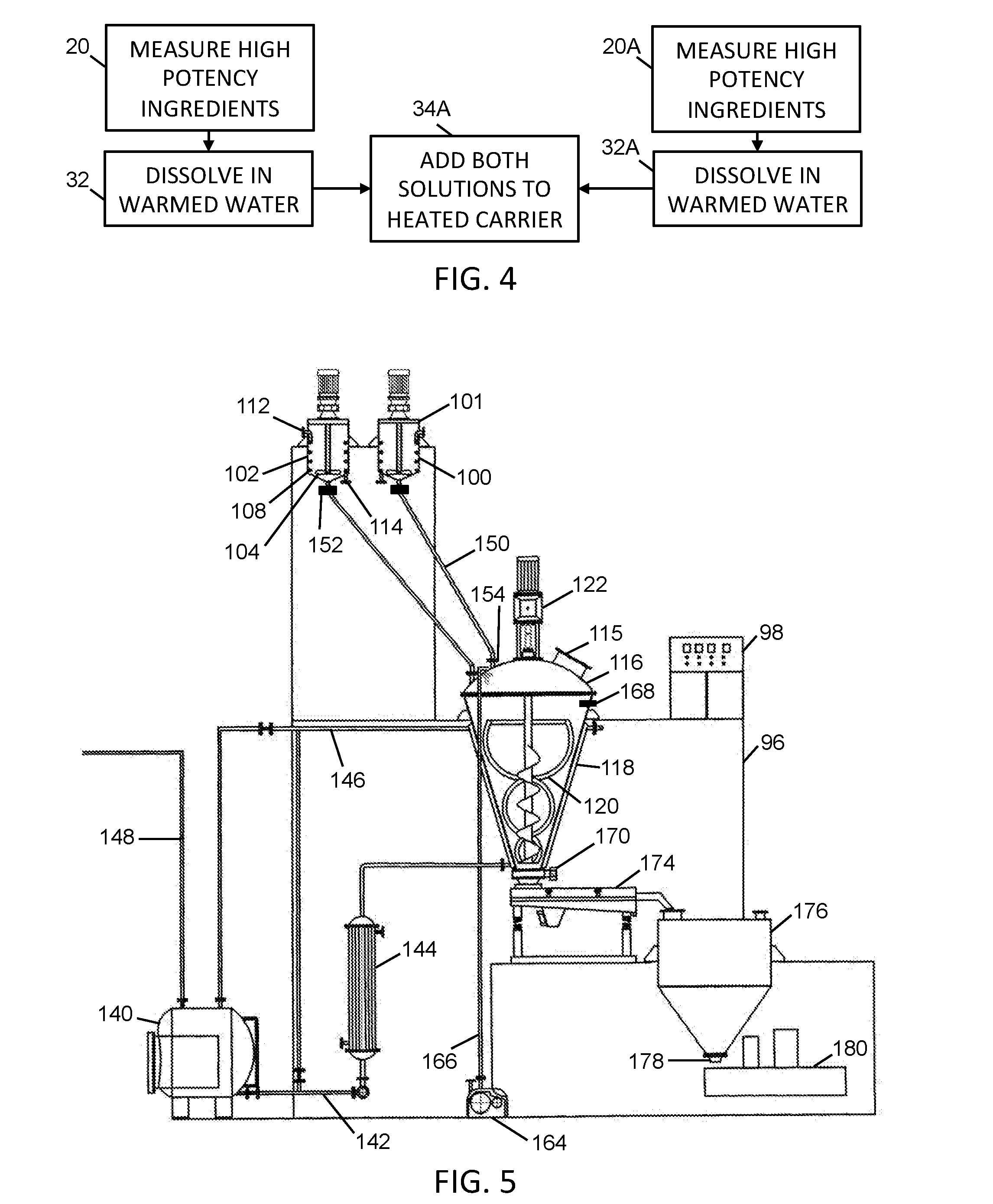

a technology of imbedded ingredients and sweeteners, which is applied in the field of granular, enhanced sweeteners with imbedded, high potency ingredients, can solve the problems of reducing the functionality of sugar that is essential for many recipes, requiring expensive ingredients, and replacing sugar with a non-nutritive sweetener and carrier requires many times more expensive ingredients. , to achieve the effect of enhancing sweeteners, less sugar, and high potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A. Glossary

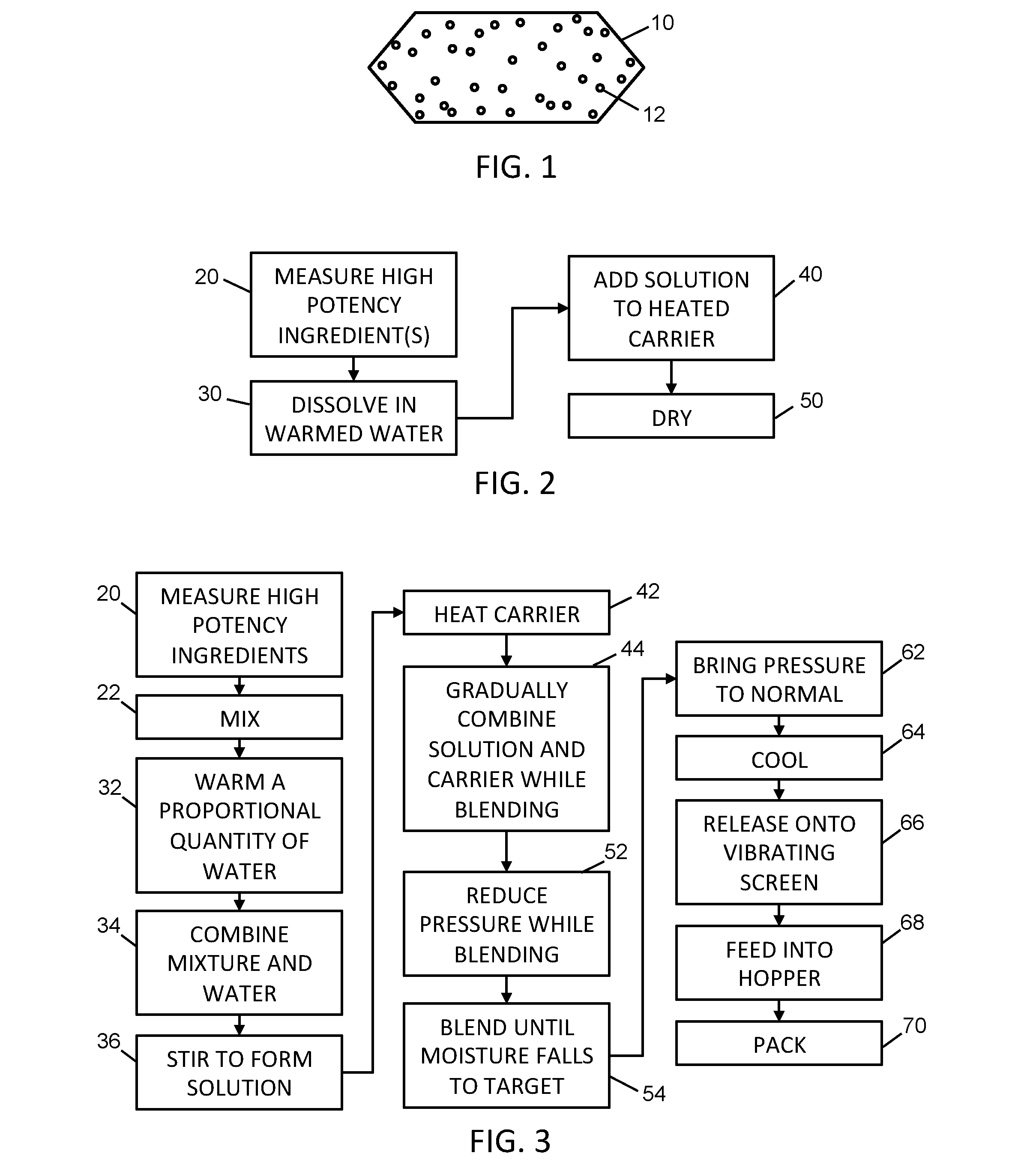

[0019]Carrier—As used here, a carrier is an edible substance that is capable of holding, supporting or otherwise bearing one or more edible, high potency ingredients within it. The edible carrier may be sweet or non-sweet. Herein, an example of a carrier is sucrose.

[0020]Granule—A small particle or grain having the form of a single crystal, multiple crystals stuck together or an agglomeration of smaller, constituent particles that are not readily separable.

[0021]High potency ingredient—An ingredient that only needs to be minimally present in a food product in order to have a significant effect on it. Examples of high potency ingredients include high potency sweeteners, vitamins, minerals, food coloring and flavoring. They may be natural or artificial.

[0022]High potency sweetener—A high potency ingredient that is many times sweeter than sugar. Such high potency sweeteners may be 50-400 times sweeter than sugar. Examples include stevia extract, monk fruit (Luo Han) extract,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com