Staircase Element and Method for Building a Staircase

a technology for building stairs and elements, which is applied in the direction of stairways, stair halls, building structures, etc., can solve the problems of laborious and time-consuming installation of heavy elements, difficult and slow coating of the different surfaces of the stairs, etc., to facilitate and accelerate the building of stairs, increase the strength and fire resistance, and facilitate the effect of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

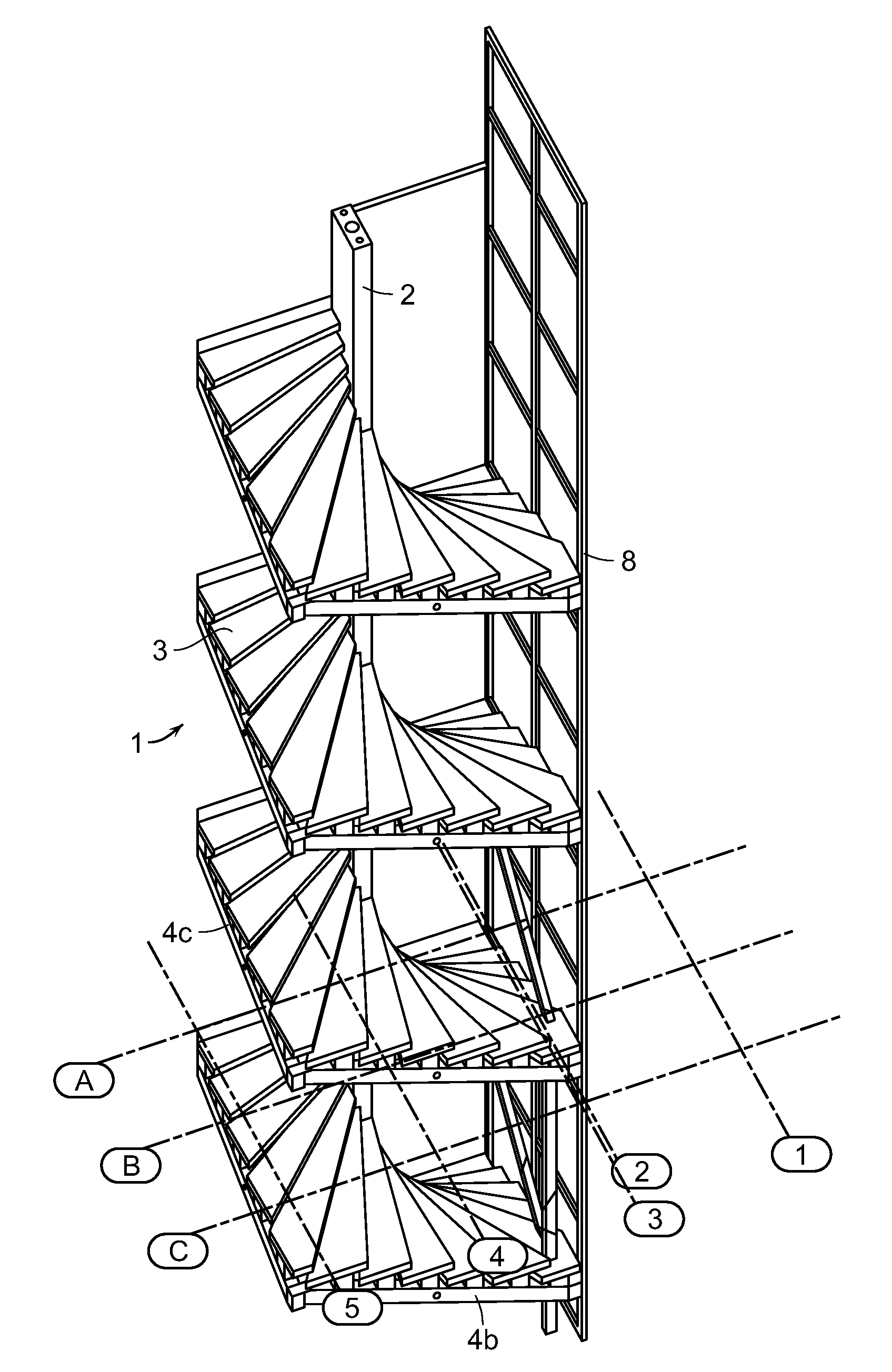

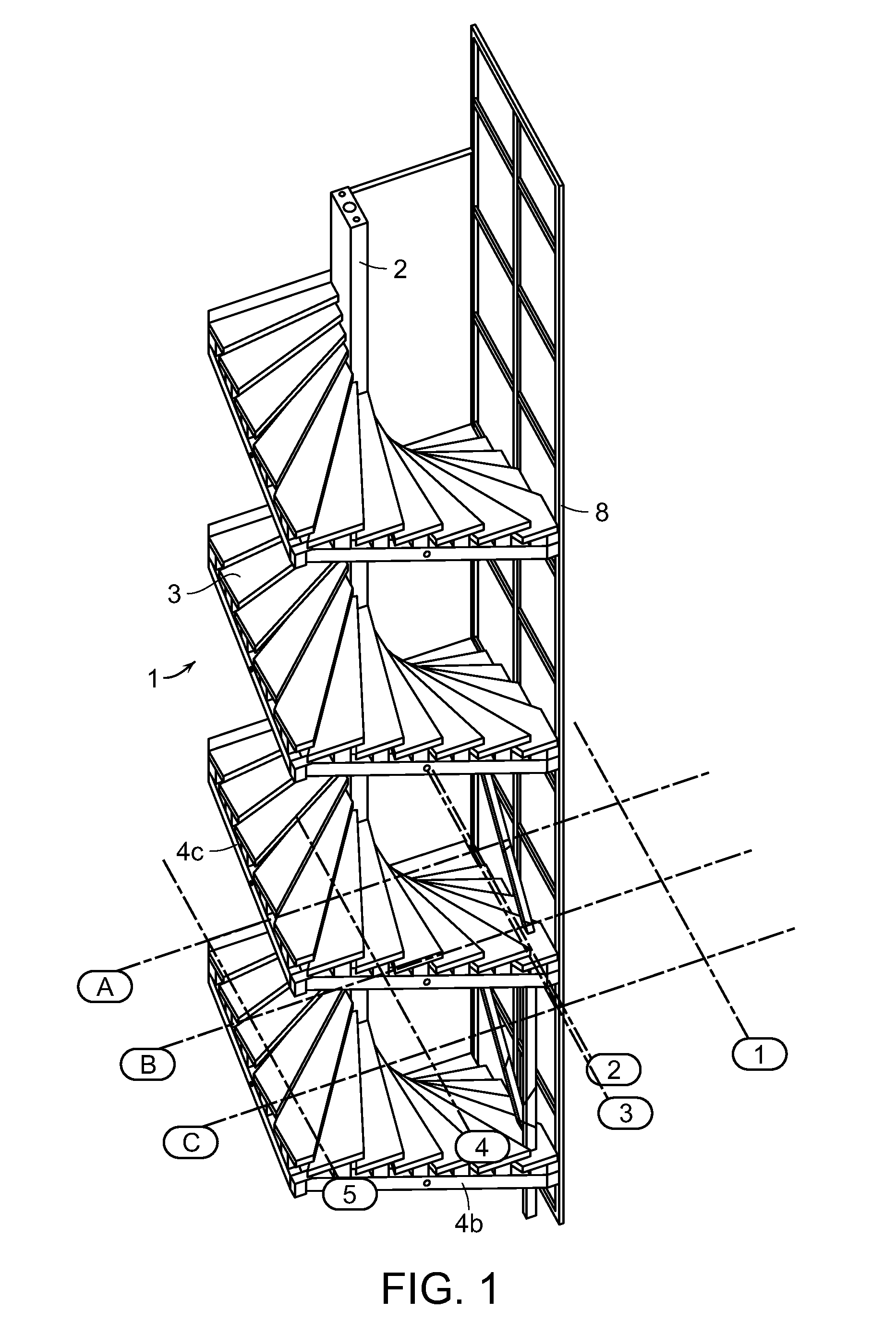

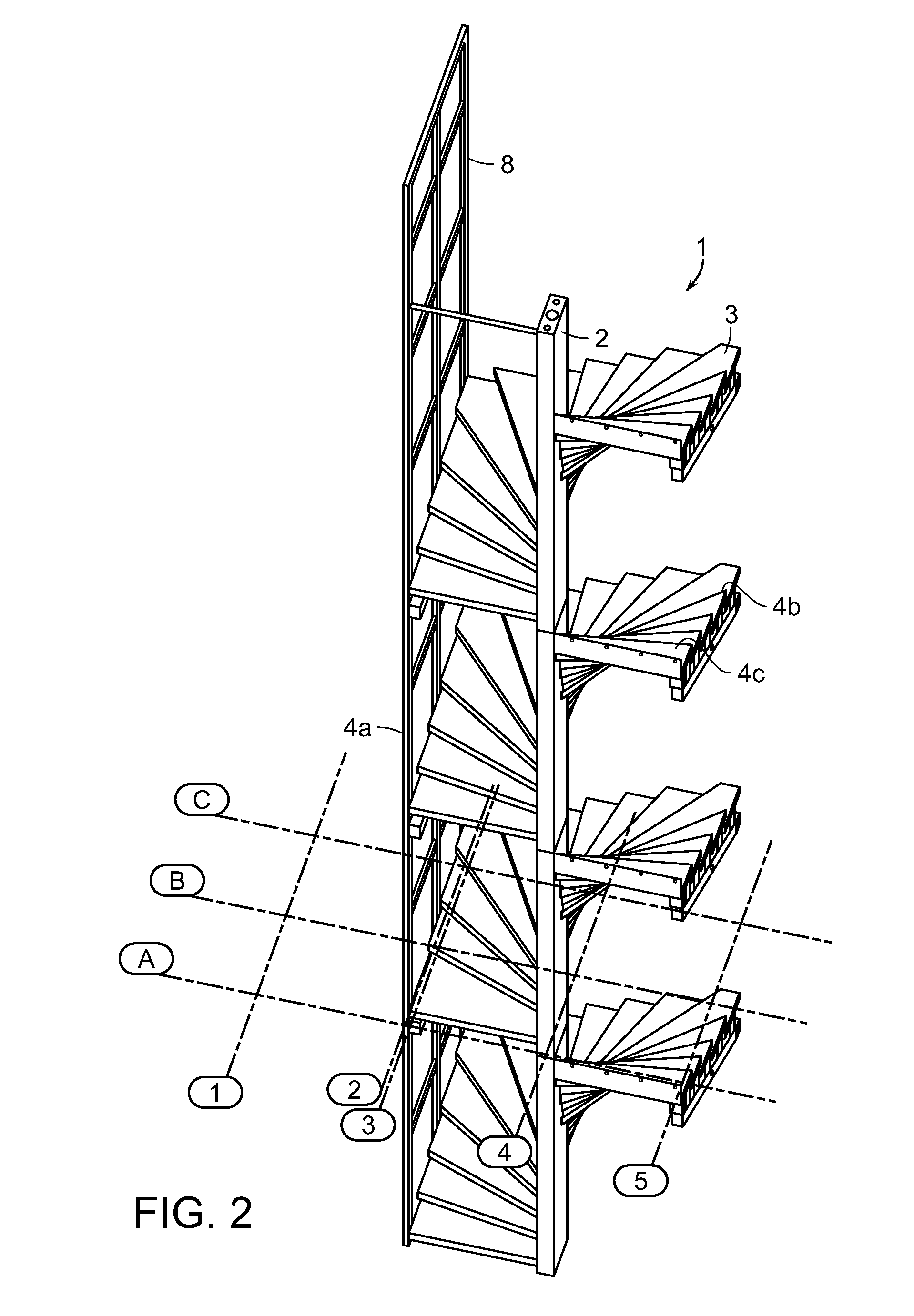

[0026]A staircase element (1), comprising:[0027]a tubular mast (2) erectable to a vertical position on the floor or a corresponding surface of a stair hall, and fillable with concrete;[0028]stair step elements (3) fixed at their first end stepwise to the mast (2) and branching off radially from the mast (2);[0029]at least one tubular stringer (4a to 4c) fastened to the second end of the stair step elements (3), fillable with concrete and connectable with fastening members (8) to at least one wall of the stair hall, for supporting the stair step elements (3) at their second end and for anchoring the staircase element (1) to a building.

example 2

[0030]The staircase element (1) according to example 1, comprising two or more stringers (4a to 4c) perpendicular to each other.

example 3

[0031]The staircase element according to example 2, wherein the lower end of the lowermost stringer (4a) is provided with at least one casting hole, and a connecting piece (7a, 7b) is provided between two successive stringers (4a to 4c), for guiding concrete through a casting hole in one stringer (4a) into all the stringers (4a to 4c) of at least one staircase element (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com