Heat exchanging device and method therefor

a technology of heat exchange and heat exchanger, which is applied in the direction of heat exchangers, indirect heat exchangers, heat pumps, etc., can solve the problems of requiring a substantial amount of energy for heating up water, and achieve the effects of reducing the risk of rust or water stains, and improving the life of the devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

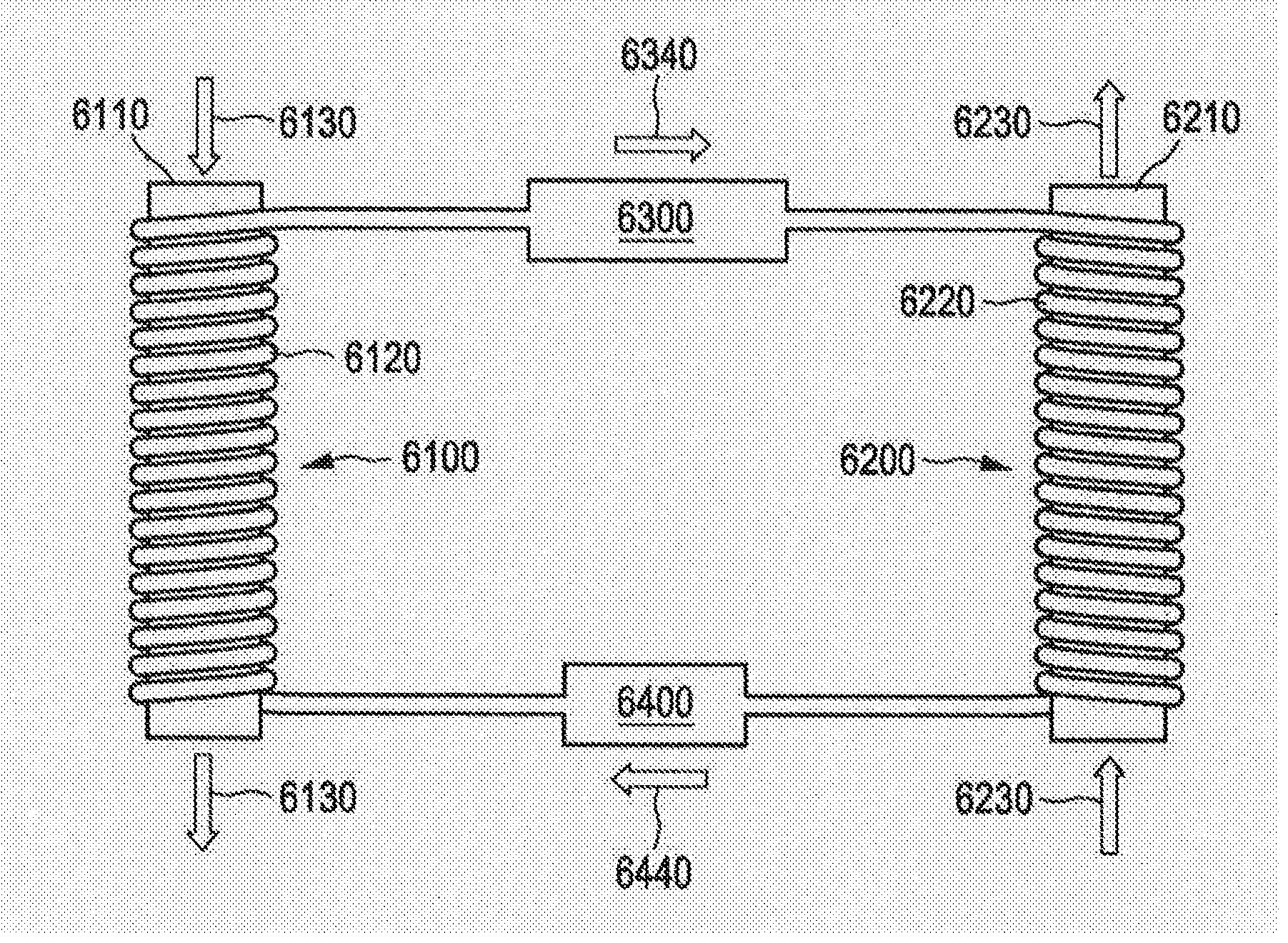

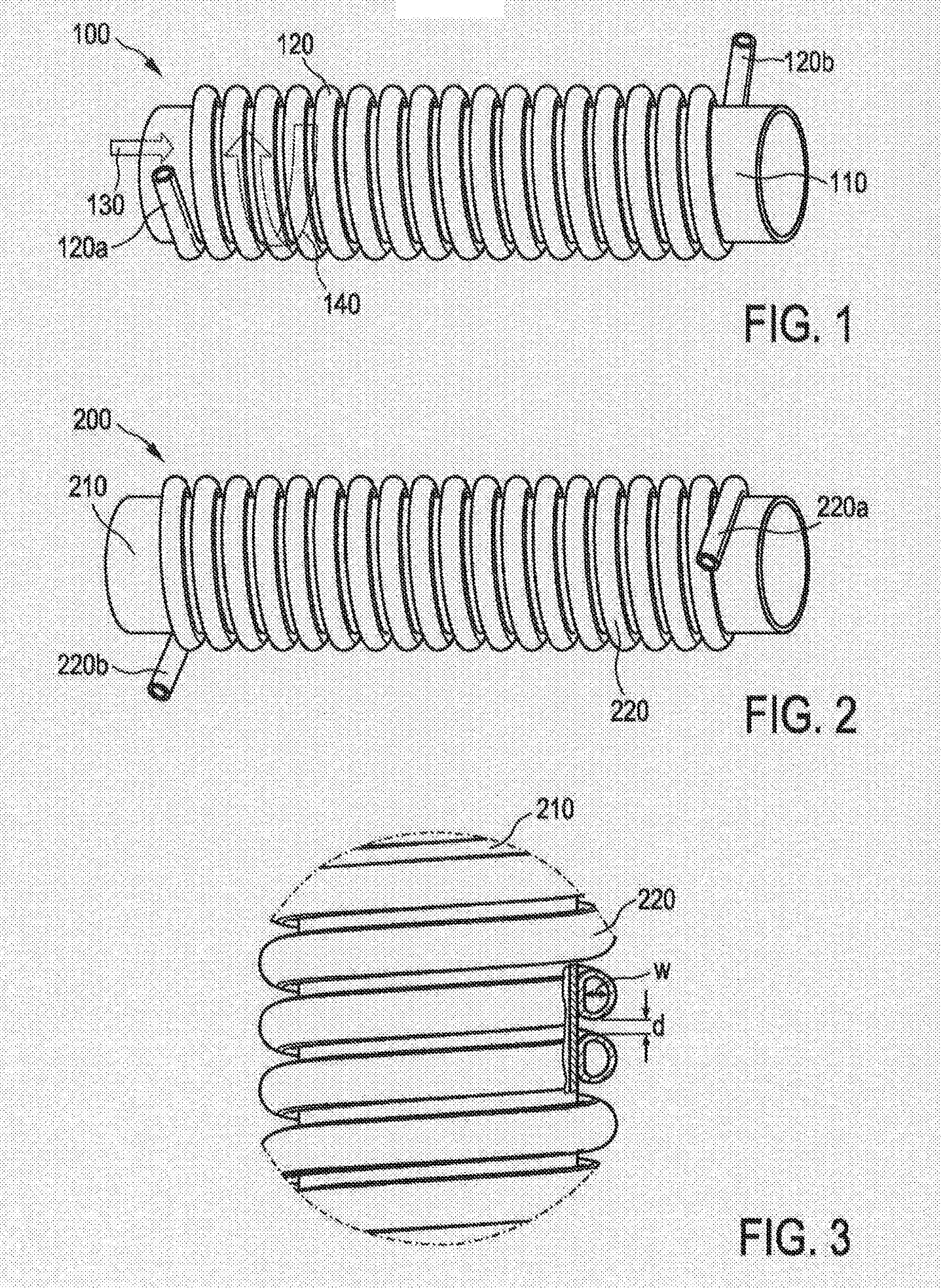

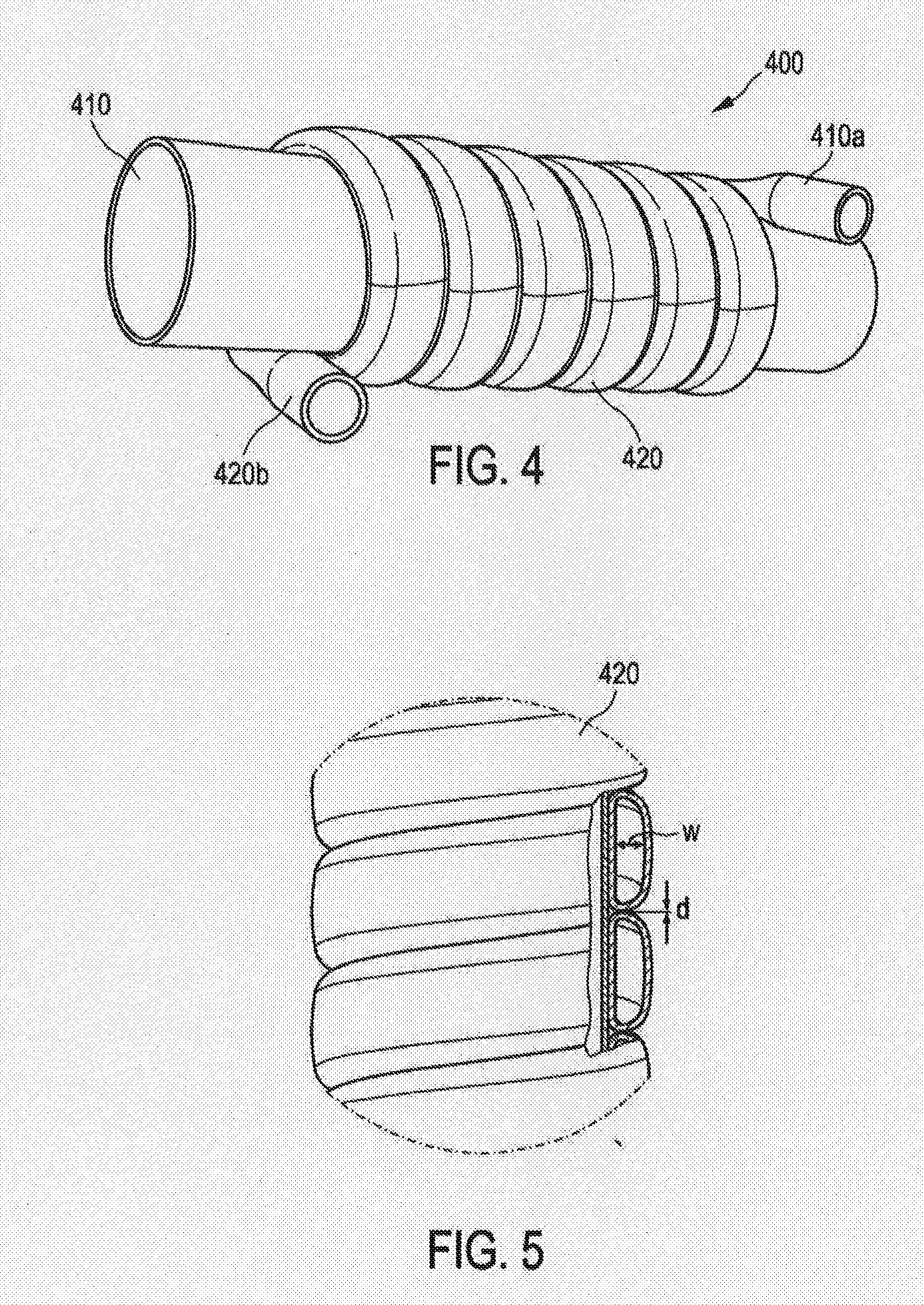

[0037]FIG. 1 shows schematically and exemplarily an embodiment of a heat exchanging device 100 in accordance with the present invention. Heat exchanging device 100 comprises a first hollow profile 110 configured to conduct a first medium. In an example, the first medium may be water, in particular wastewater from a dishwasher, a washing machine, or other domestic appliance. The flow direction of the first medium is indicated by arrow 130. Heat exchanging device 100 further comprises a second hollow profile 120 configured to conduct a second medium. In an example, the second medium may be a refrigerant. The flow direction of the second medium is indicated by arrow 140. As illustrated in FIG. 1, at least a part of second hollow profile 120 is wound around at least a part of first hollow profile 110. The present invention proposes to select a nominal width of second hollow profile 120 to be smaller than a nominal width of first hollow profile 110. The nominal width of second hollow pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com