Shielded module having compression overmold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The headings provided herein, if any, are for convenience only and do not necessarily affect the scope or meaning of the claimed invention.

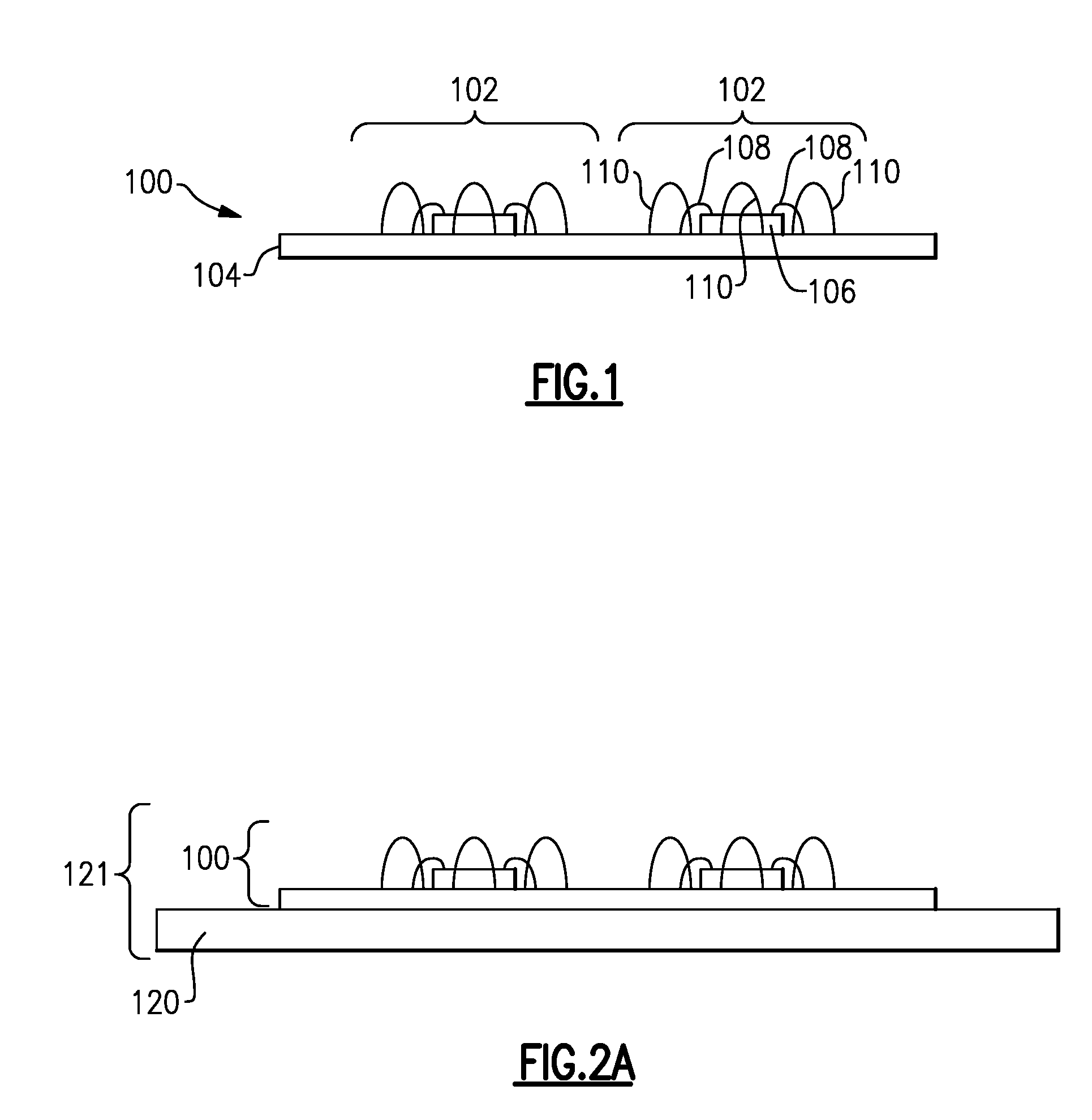

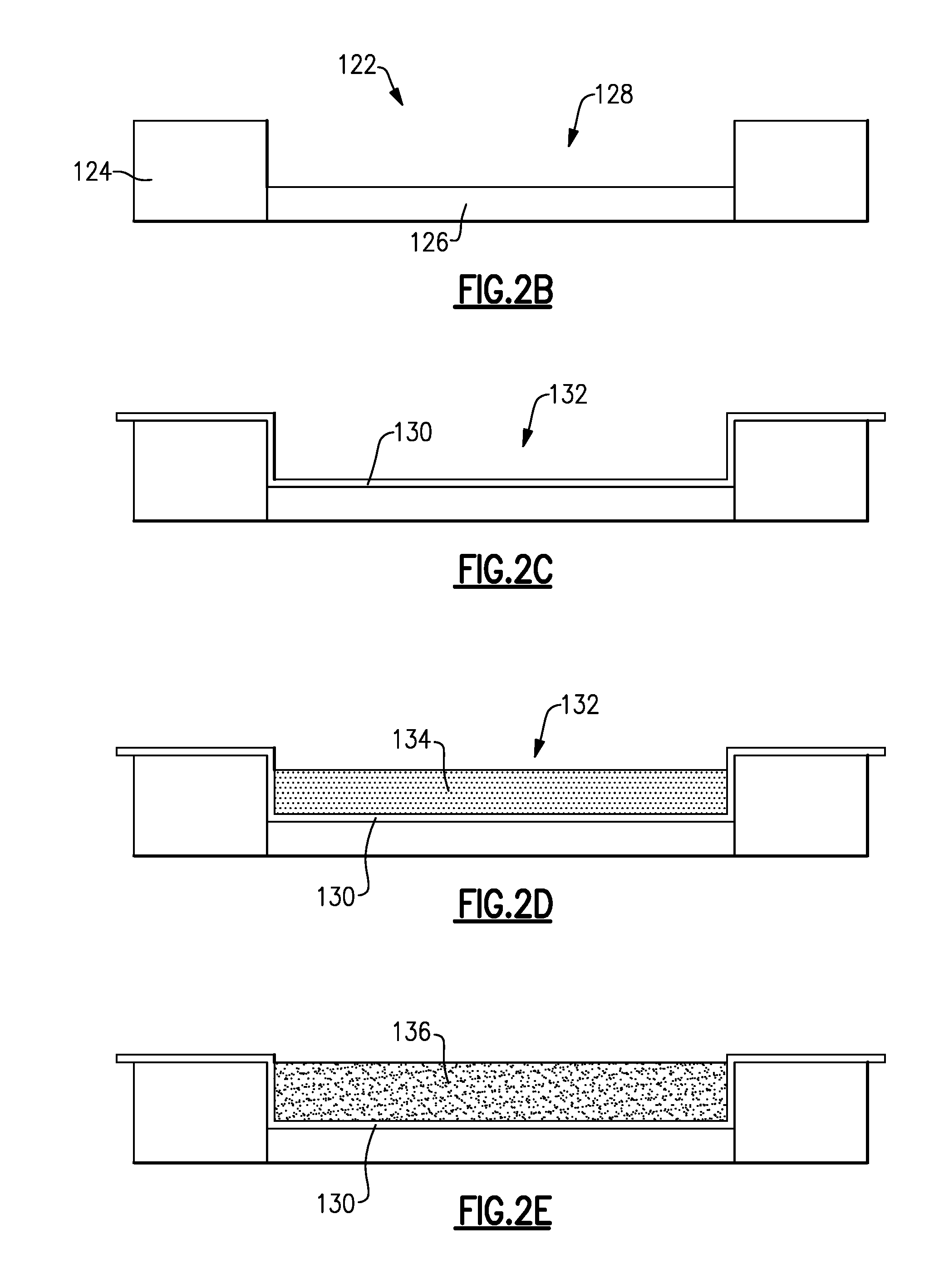

[0032]Described herein are examples of devices and methods related to a shielded module having a compression-molded structure such as an overmold. Such a module can include radio-frequency (RF) shielding facilitated by, for example, shielding-wirebonds. Additional details concerning such shielding-wirebonds can be found, for example, in Appendix A of U.S. Provisional Application No. 62 / 168,872 filed May 31, 2015, entitled SHIELDED MODULE HAVING COMPRESSION OVERMOLD, which is expressly incorporated by reference in its entirely, and which is to be considered part of the specification of the present application.

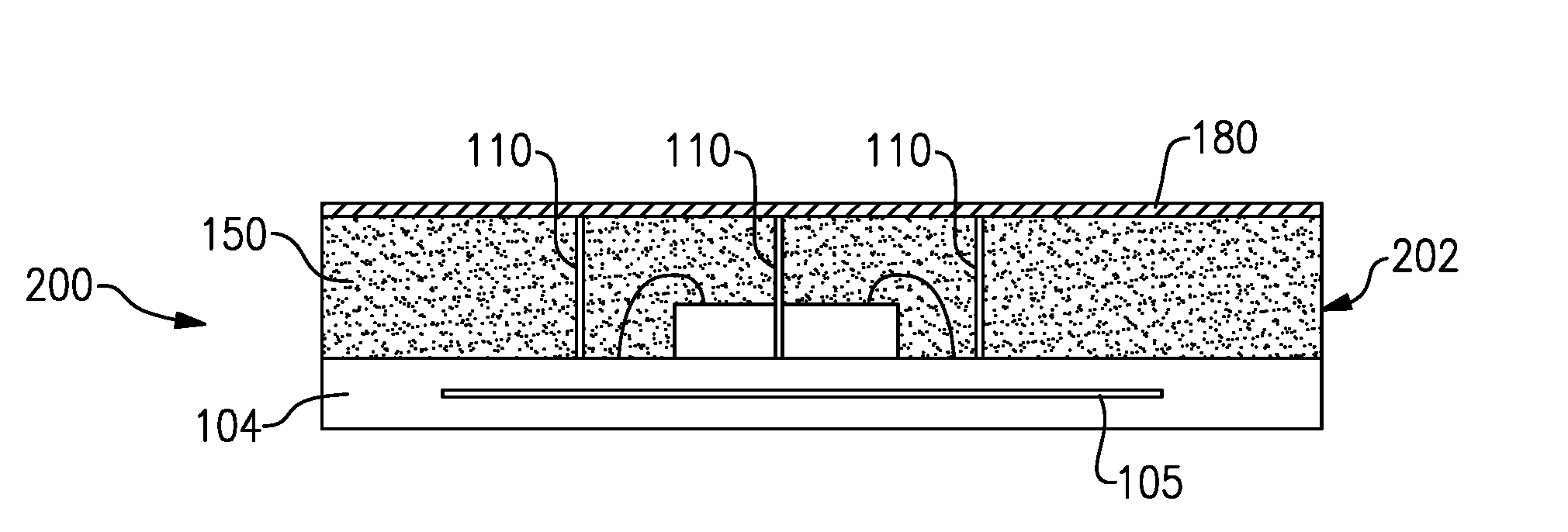

[0033]FIG. 1 shows a side view of a partially completed panel 100 having a packaging substrate 104. Such a packaging substrate 104 can include, for example, a laminate substrate. Formed or mounted on such a packaging substrate 104 are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com