Multi-sectional composite tooling

a composite tooling and multi-section technology, applied in the field of multi-sectional composite tooling, can solve the problems of increasing the cycle time of composite molding, increasing the cost of steel alloy tooling, and unsuitable unidirectional tape for composite tooling use, so as to eliminate any surface imperfections and ensure the same durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

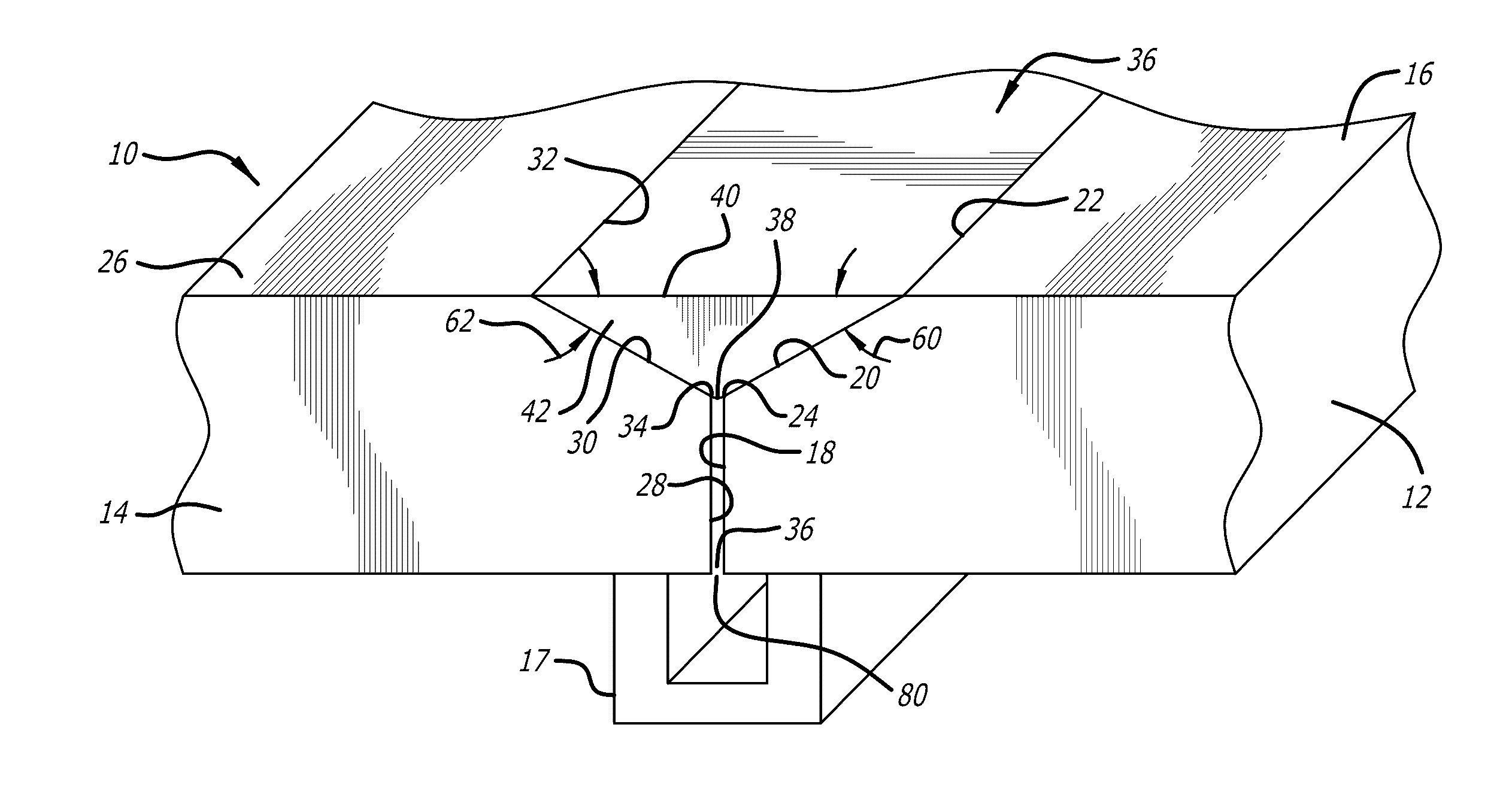

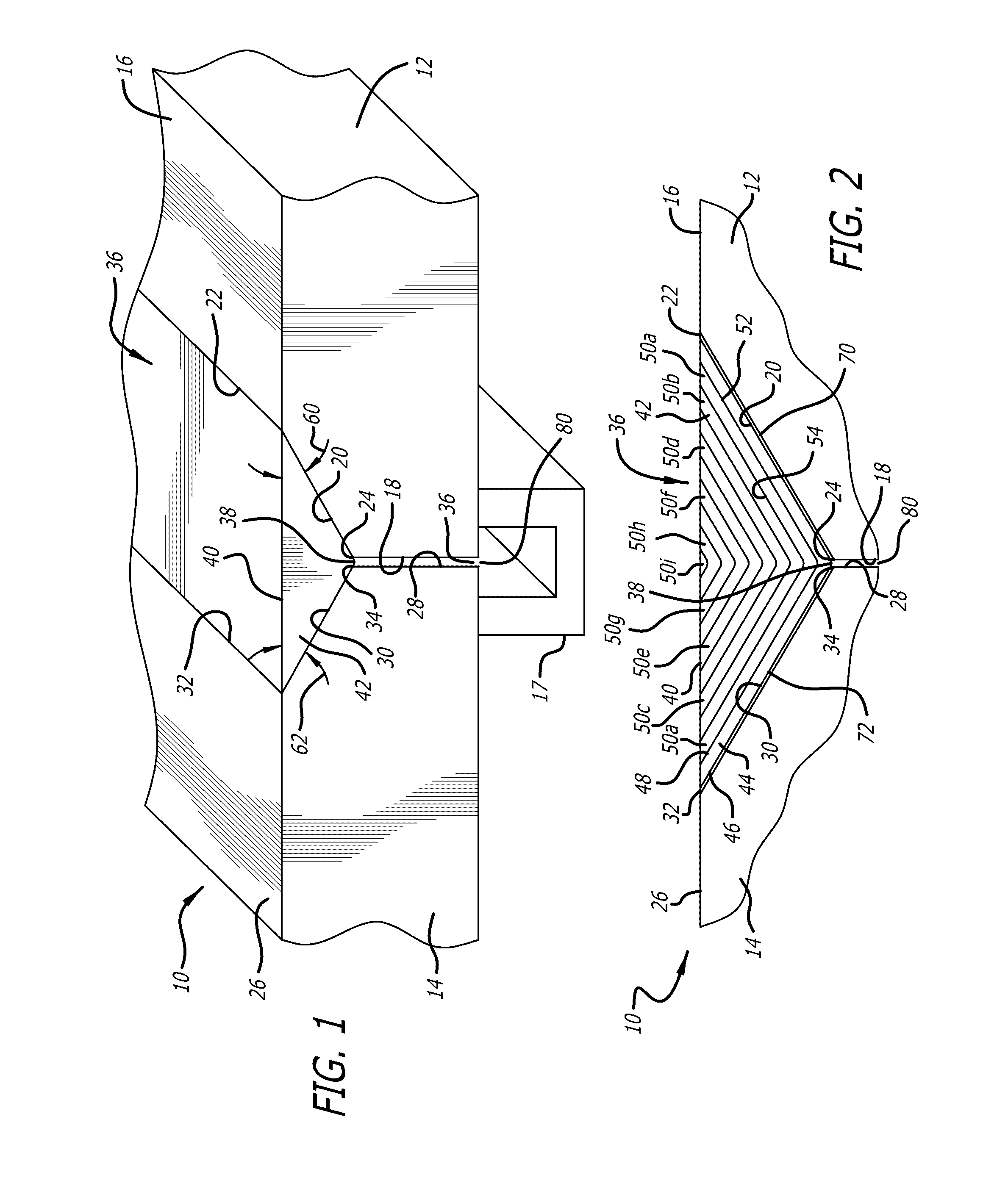

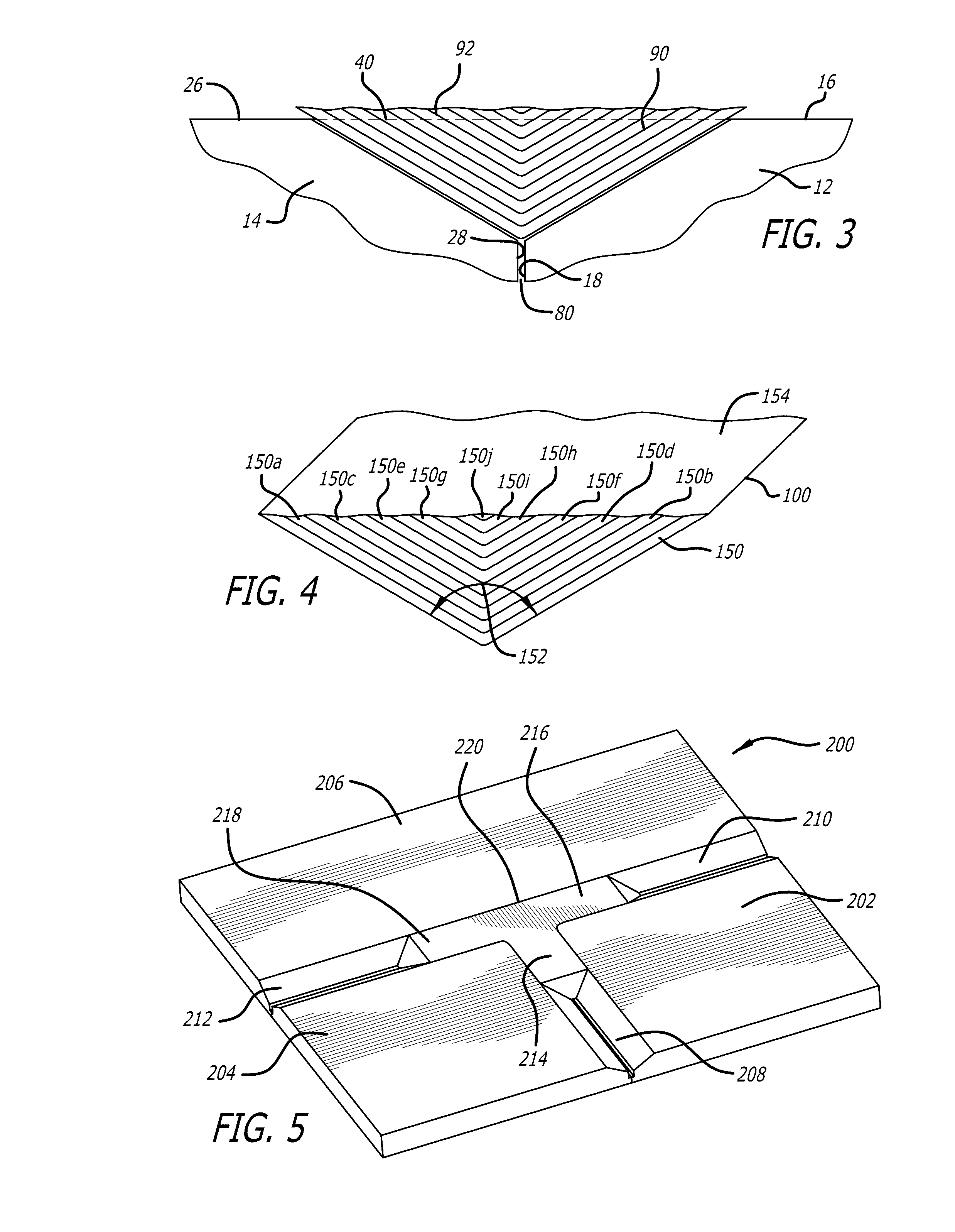

[0033]A portion of an exemplary multi-sectional composite tooling in accordance with the present invention is shown at 10 in FIGS. 1 and 2. The multi-sectional tooling is intended for use in fabricating large composite parts or structures in accordance with known autoclave curing processes where service temperatures are typically between 170° C. and 260° C. and where the tooling surfaces are exposed to pressures of between 45 psi and 125 psi. However, if desired, the tooling may be used in other molding processes where it is not necessary to heat the material being molded to such high temperatures and / or where high pressure is not used in the molding process.

[0034]Exemplary large composite parts or structures that can be molded using the multi-sectional tooling includes aircraft wings, fuselages, horizontal stabilizer spar tools, wing spar tools and empennage tools. The overall size of the molding surface provided by the multi-sectional tooling can range from a few square meters to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com