Linear tensioner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

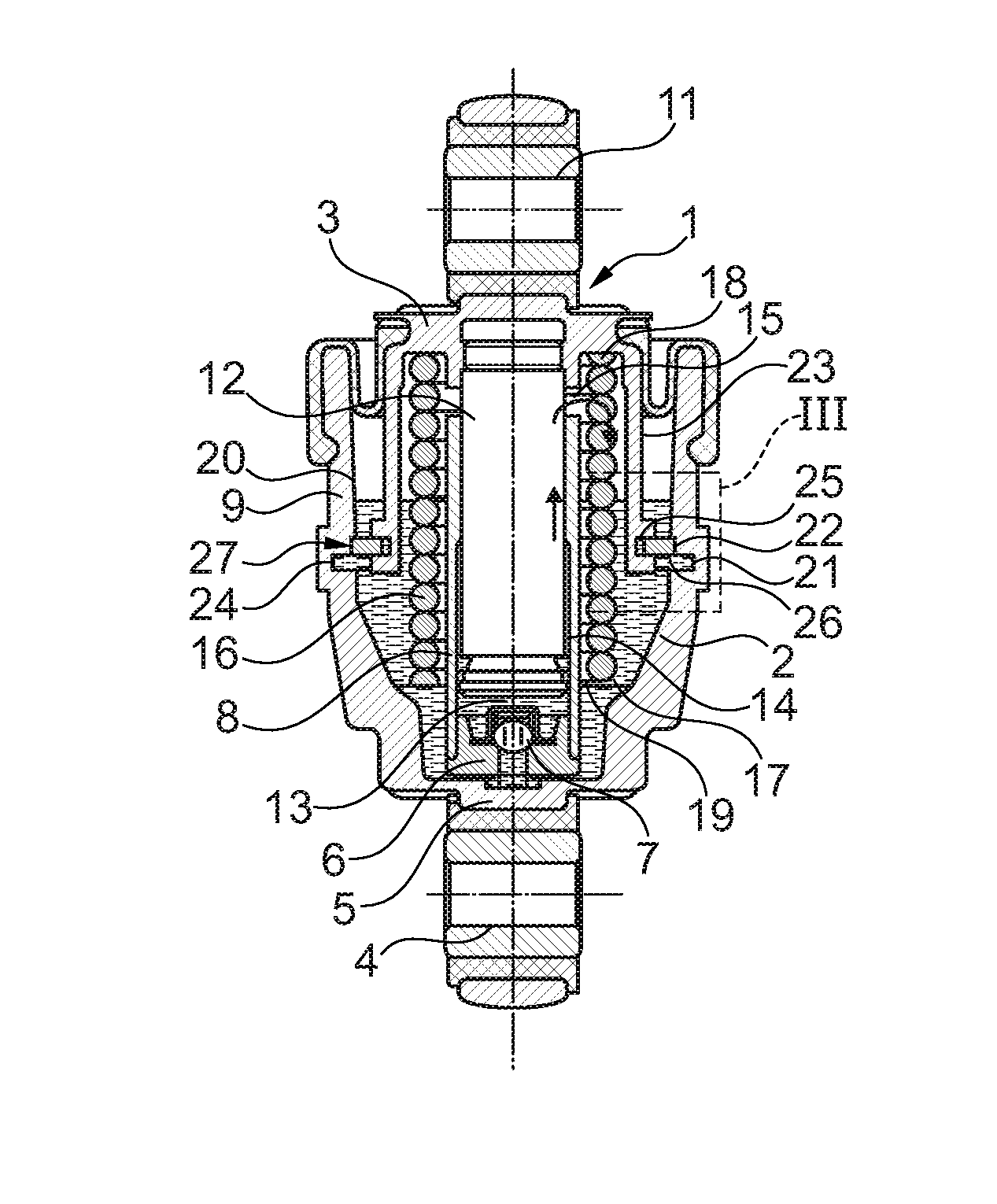

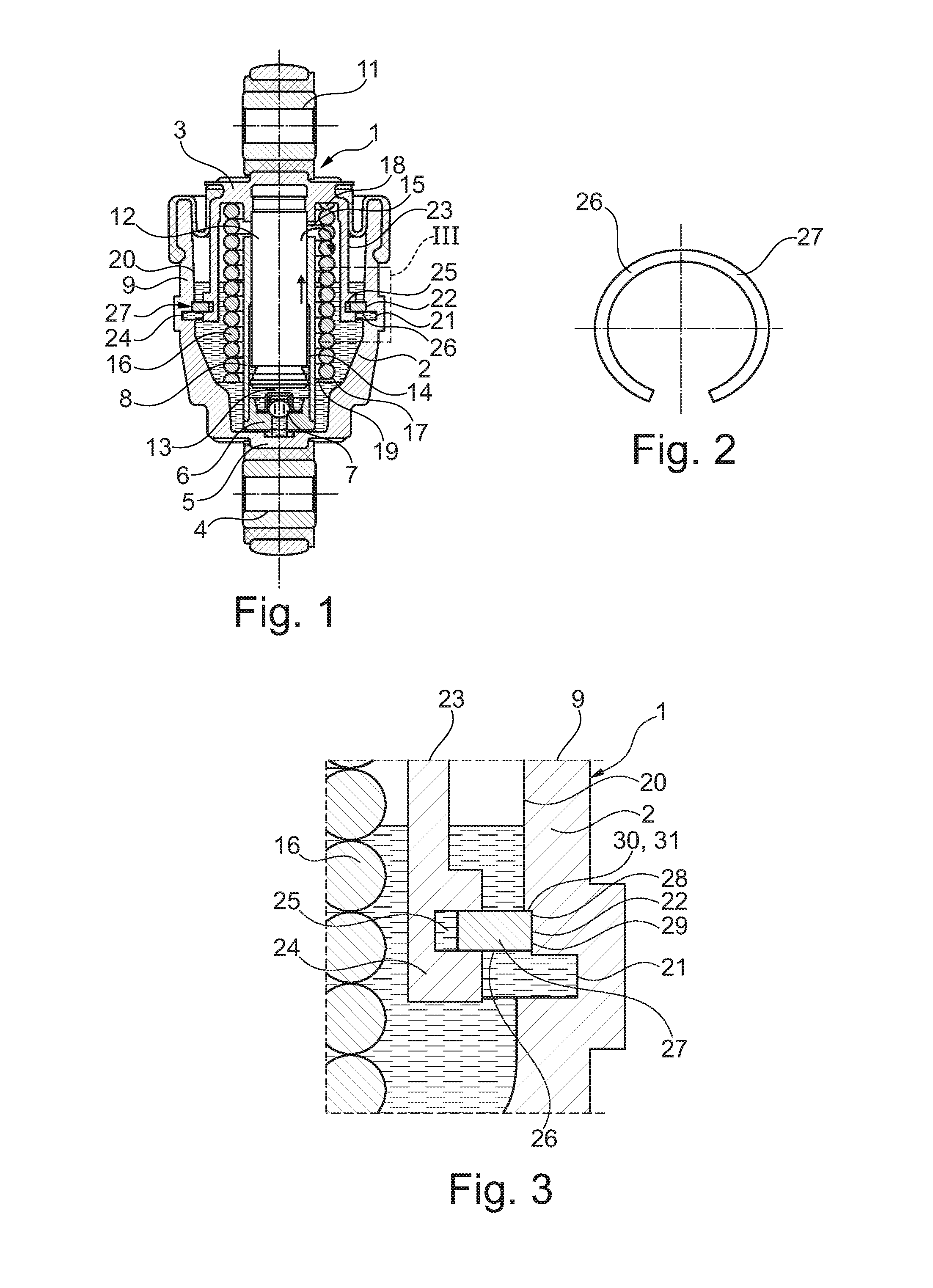

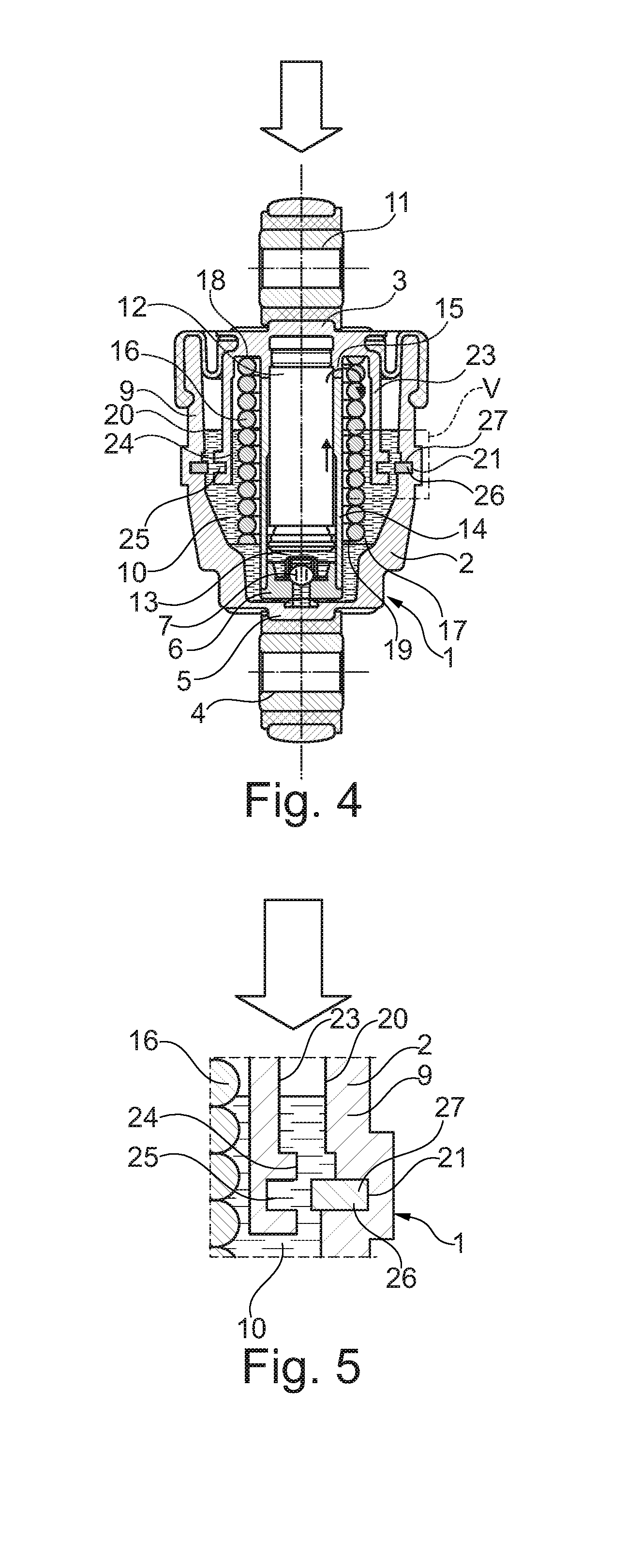

[0028]In FIG. 1, 1 designates a linear tensioner that has a first adjustment element 2 and a second adjustment element 3. The first adjustment element 2 has a fixing eyelet 4 by which the linear tensioner 1 can be mounted so that it is fixed in place and can pivot on a crankcase of a reciprocating-piston internal combustion engine. A base 5 of the first adjustment element 2 on which a valve housing 6 of a non-return valve 7 is fixed connects to the fixing eyelet 4.

[0029]A hydraulic cylinder 8 extends out from this valve housing 6 in the longitudinal direction of the linear tensioner 1, wherein this cylinder is connected to the valve housing 6 in a sealed manner. Extending from the base 5 is a hollow-cylindrical section 9 of the first adjustment element 2 that is constructed in multiple different steps and with inclined wall sections. This hollow-cylindrical section 9 surrounds the hydraulic cylinder 8 with a radial distance, which forms an oil reservoir 10.

[0030]The second adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com