Handgun with Trigger Guard Attachment, and Holster

a trigger guard and handgun technology, applied in the field of semiautomatic pistols, can solve the problems of not much gripping force available to control the movement of the handgun, adversely affecting the accuracy and speed of additional shots, and the muzzle rising abruptly when the weapon is used, etc., to achieve strong clamping force, enhance control, and high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The drawings illustrate one embodiment of the invention. A handgun holster 10 (FIG. 5) has a body 12 defining a chamber 14 for receiving a handgun that is illustrated schematically at 20. The holster body 12 includes a first or top wall 16 (forward wall when the holster is secured on the shooter's belt), and, on the opposite side of the chamber 14, a second or bottom wall 18 (back wall when the holster is secured on the shooter's belt).

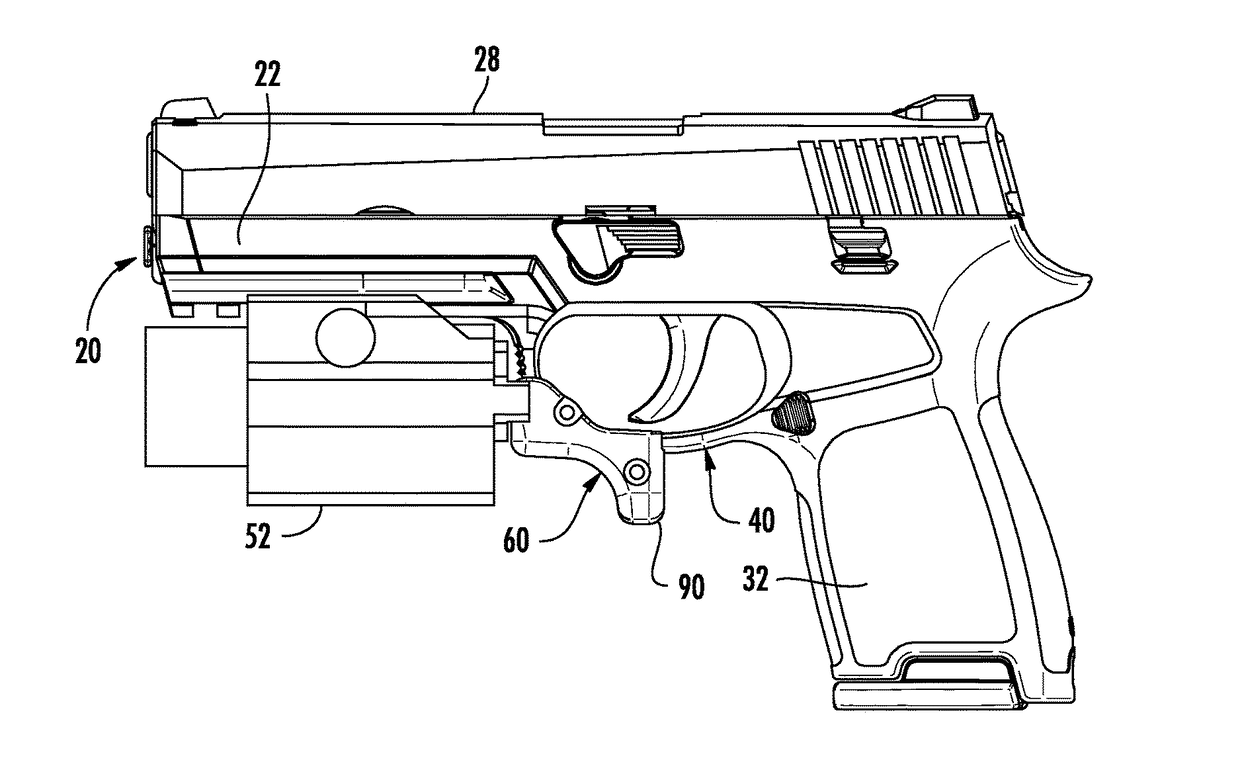

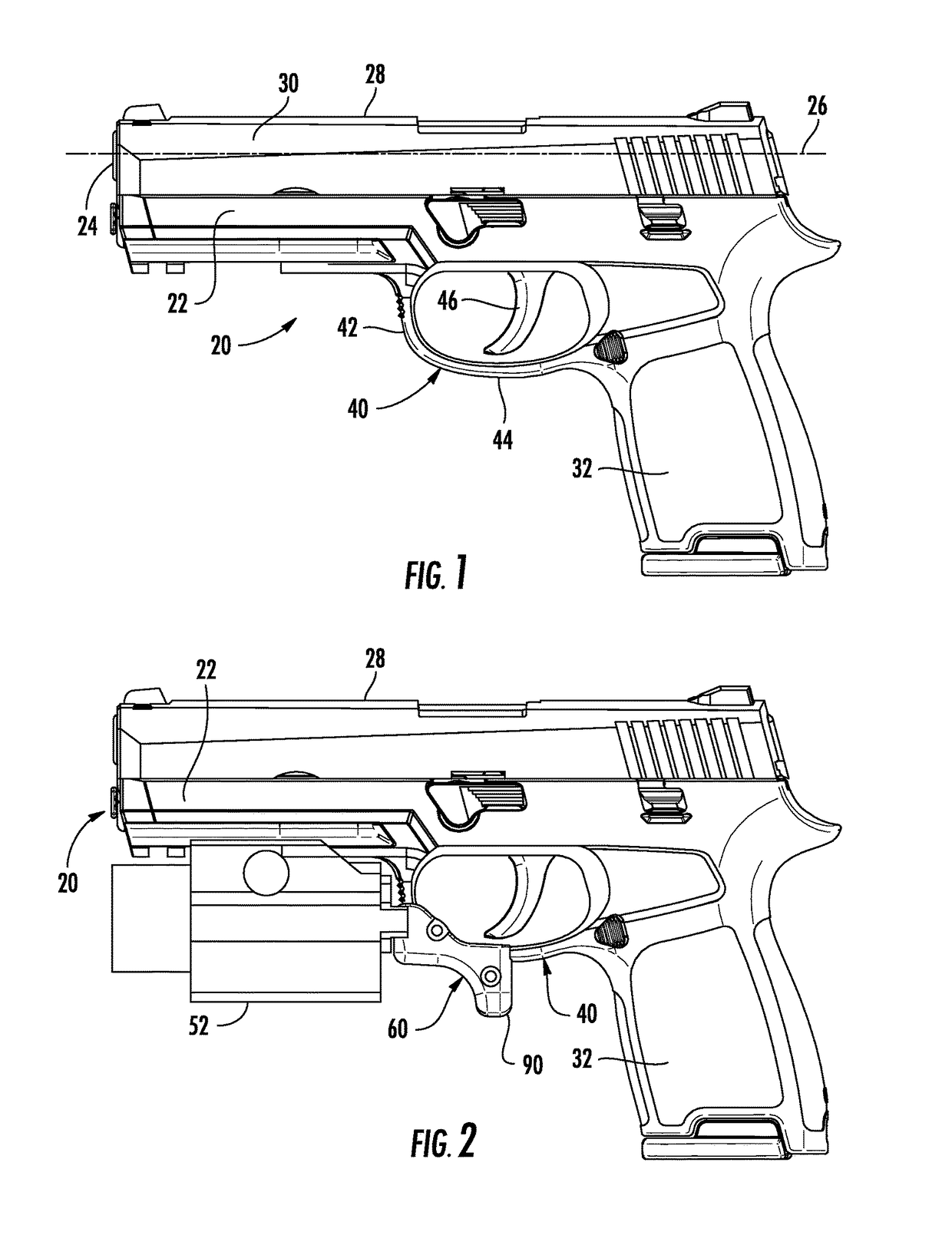

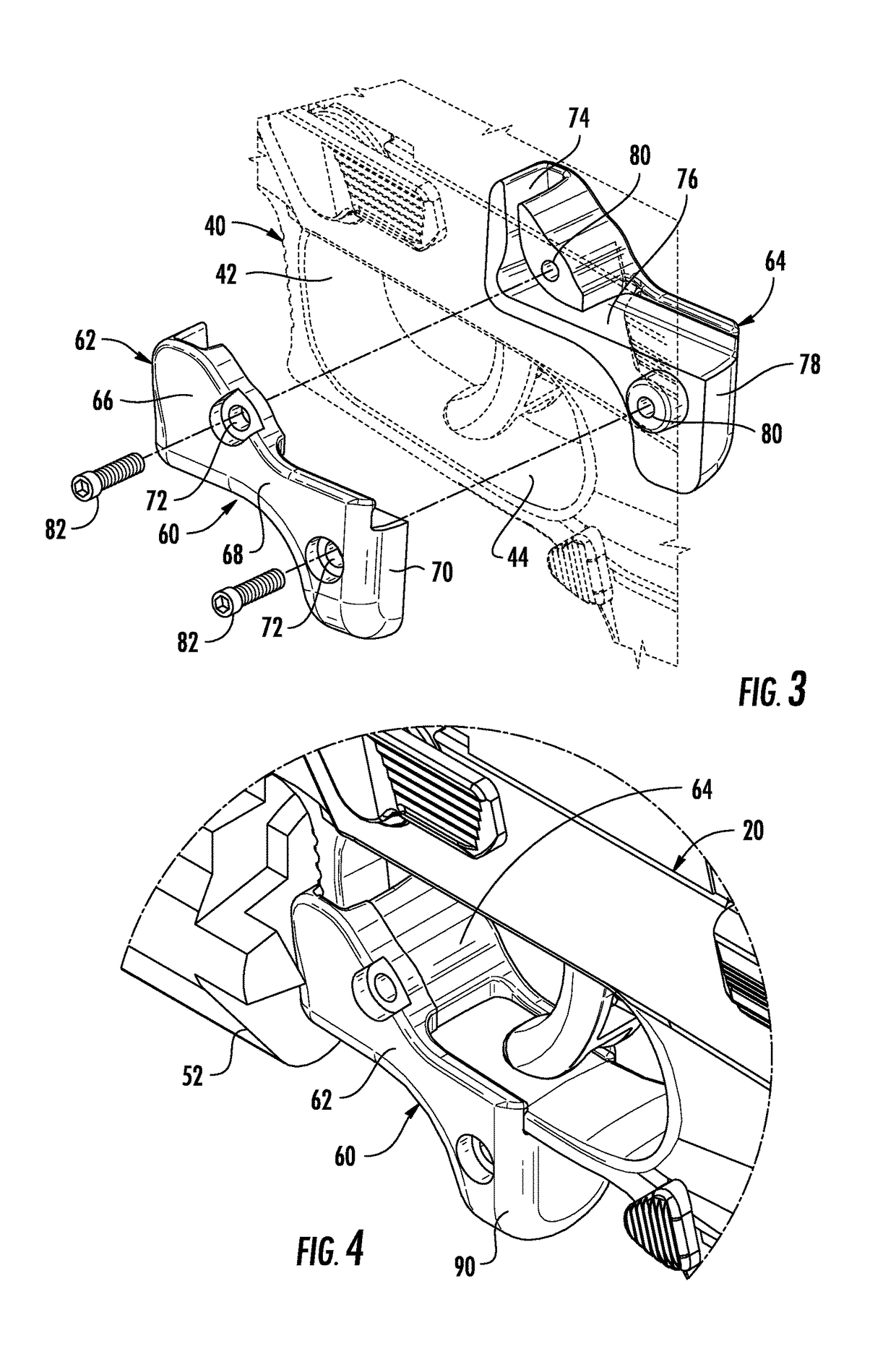

[0013]The handgun 20 (FIG. 1) in the illustrated embodiment is a semi-automatic handgun. The handgun 20 has a body 22 including a muzzle 24 defining a bore axis 26 near the top edge 28 of the handgun. A slide 30 at the top of the body 22 reciprocates relative to the body, in a direction parallel to the bore axis 26, when the handgun 20 is fired. The slide 30 forms the top edge 28 of the handgun 20. The handgun's grip 32 is part of the body 22 and is located at the back end of the handgun 20 at a location below the bore axis 26.

[0014]The handgun ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com