Dirt removing device and dirt removing unit

a dirt removal device and dirt removal technology, applied in road cleaning, cleaning equipment, carpet cleaners, etc., can solve the problems of unstable beating force and beating speed, inability to use detergents, and different degree of decontamination, so as to improve the effect of removing dirt, easy replacement, and easy removal of incrustation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment i

[0030]Hereinafter, embodiment I of the present disclosure will be described with reference to accompanying drawings.

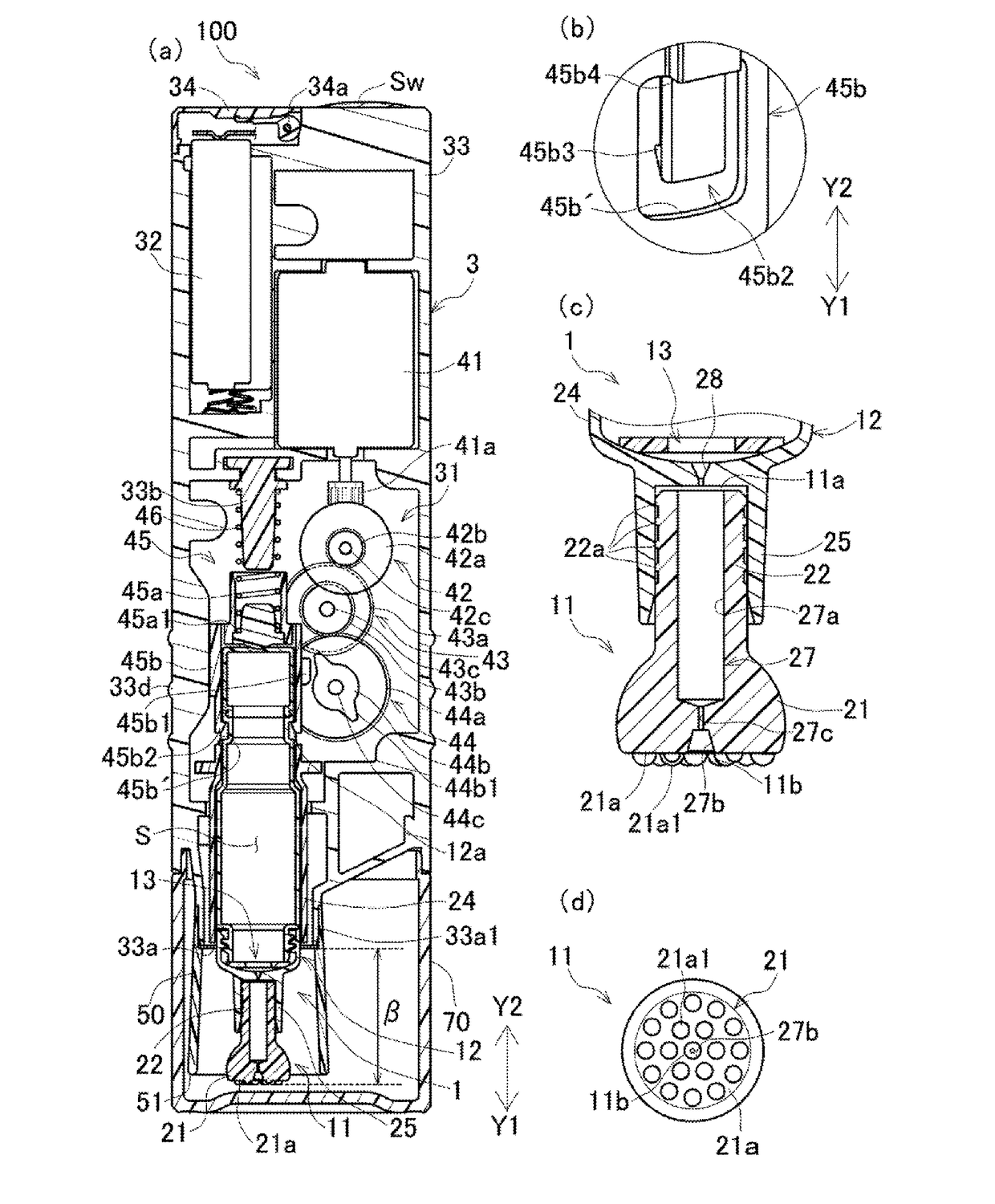

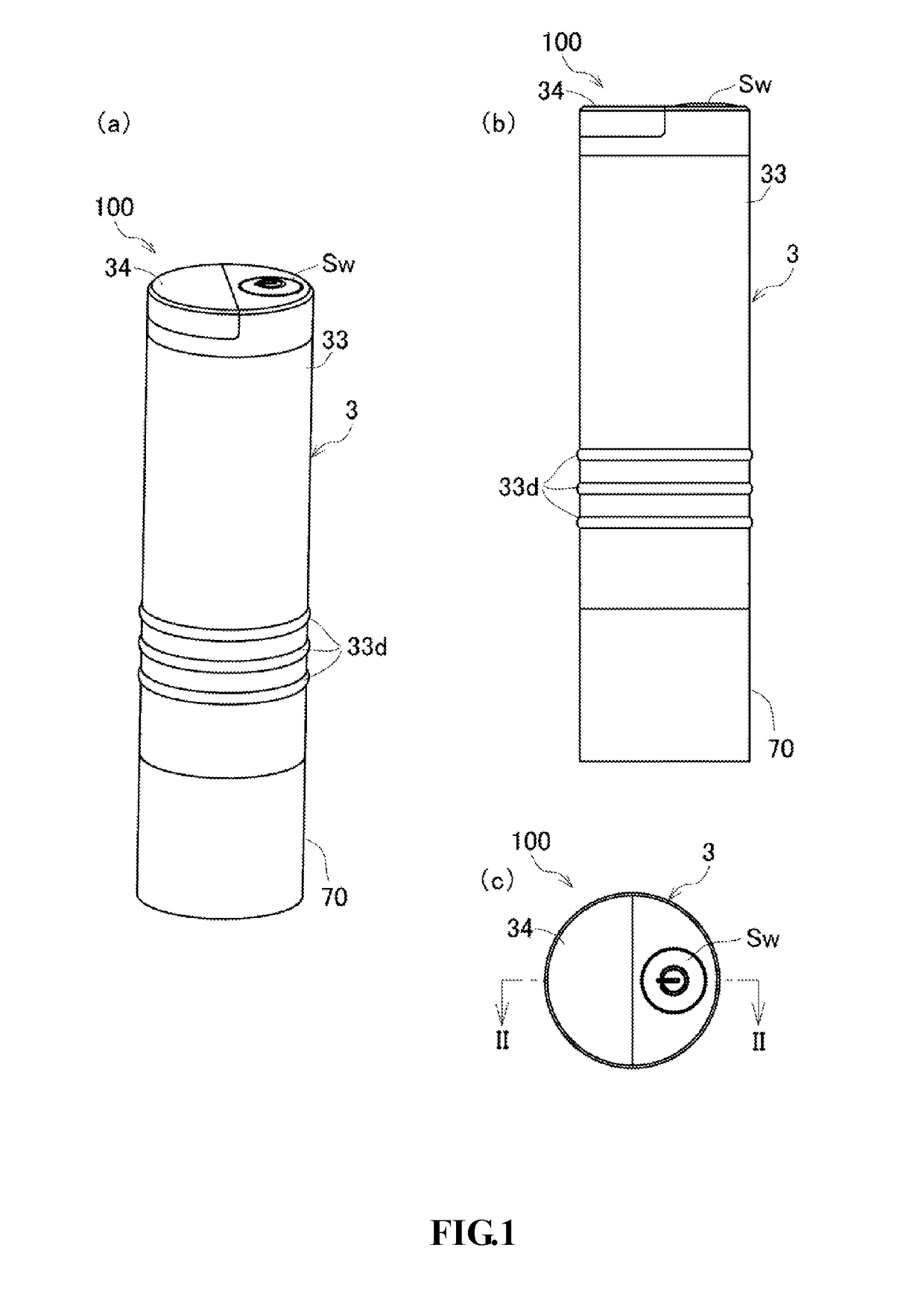

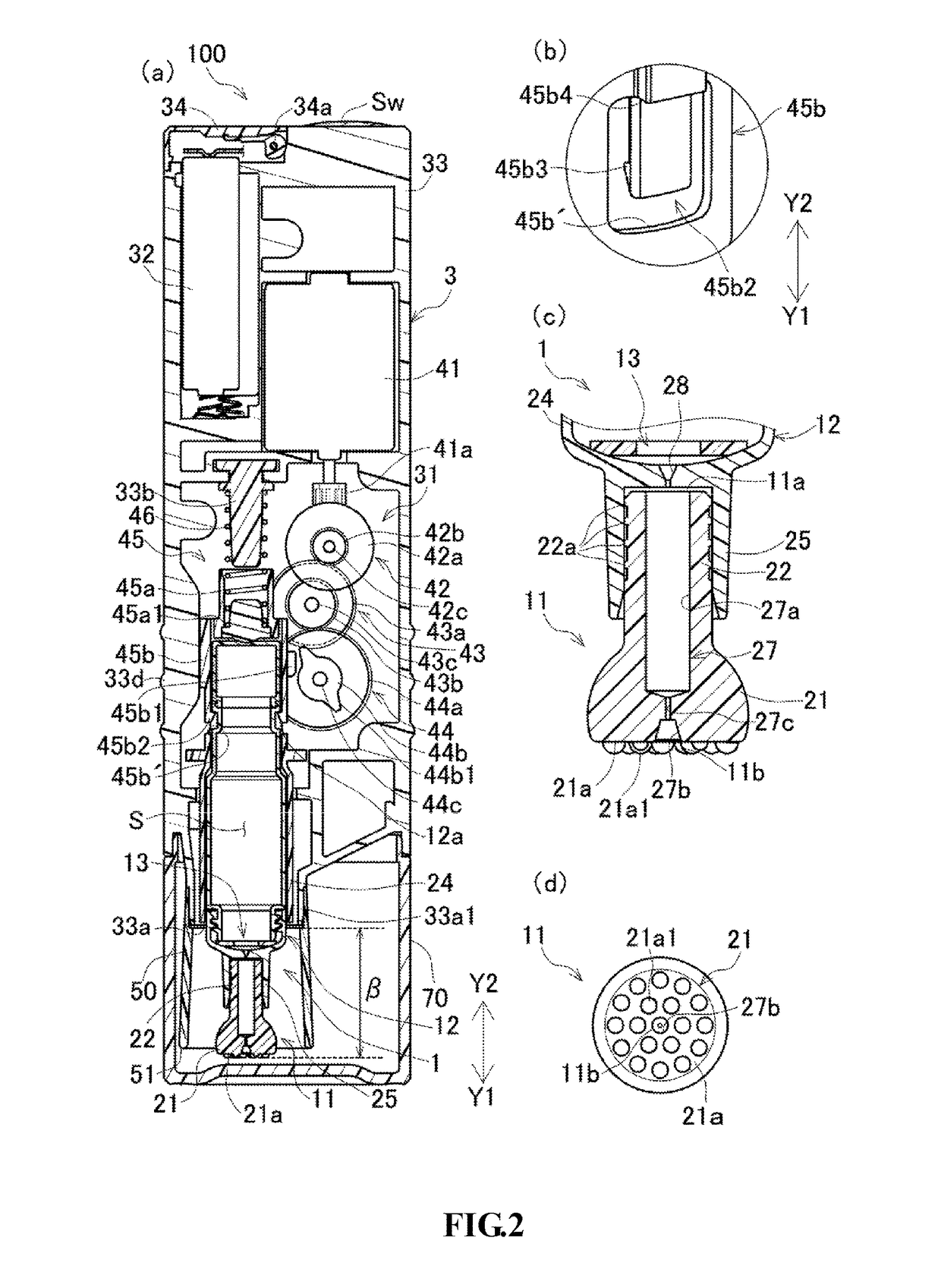

[0031]FIGS. 1 and 2 are views showing a dirt removing device 100 according to embodiment I of the present disclosure. Specifically, FIG. 1(A) is a perspective view showing the dirt removing device 100 according to the present embodiment. FIG. 1(B) is a side view showing the dirt removing device 100. FIG. 1(C) is a top view showing the dirt removing device 100. In addition, FIG. 2(A) is a longitudinal section view of the dirt removing device 100 along a section line II-II in FIG. 1(C). FIG. 2(B) is a perspective view showing a part of the dirt removing device 100, that is, a part in the vicinity of an engaging claw 45b2. FIG. 2(C) is an enlarged longitudinal section view showing a part of a liquid accommodating portion 12 and a head 11 shown in FIG. 2(A). FIG. 2(D) is a bottom view of the head 11.

[0032]As shown in FIG. 2(A), the dirt removing device 100 includes: a devi...

embodiment ii

[0086]FIG. 7 shows a part of a cassette mechanism 20 that constitutes embodiment II (that is, a dirt removing device 120) of the present disclosure. Specifically, FIG. 7 is a perspective view showing a part of a liquid accommodating portion 7 and a head 8. FIG. 7(A) shows the cassette mechanism 20 before the head 8 is inserted into the liquid accommodating portion 7. FIG. 7(B) shows the cassette mechanism 20 after the head 8 is inserted into the liquid accommodating portion 7. The dirt removing device 120 of the present embodiment is different from embodiment I in that the dirt removing device 120 has a liquid amount adjustment portion 9 for adjusting the drop amount of the liquid. Hereinafter, embodiment II is the same as embodiment I except for the structure described later, and the description of the same structure will be omitted. In addition, for easy description, although it is not shown in the drawings that the liquid storage portion 71 of the liquid accommodating portion 7 h...

embodiment iii

[0092]FIG. 9 is a longitudinal section view showing a dirt removing unit 130 according to embodiment III of the present invention. FIG. 10 is an exploded view showing a heating device 101 constituting the dirt removing unit 130 shown in FIG. 9. The dirt removing unit 130 of the present embodiment shown in FIG. 9 is composed of the dirt removing device 100 of embodiment I and the heating device 101.

[0093]As shown in FIG. 10, the heating device 101 includes a member 103 for arranging an absorbing pad (a cover for arranging an absorbing pad), a device body cover 105, a decorative panel 107, a heating plate 109, a first heat insulating material 111, a heater 113, a second heat insulating material 115 and a heating device body 117.

[0094]The member 103 for arranging an absorbing pad and the device body cover 105 are circular members in which opening portions 103a and 105a are formed at the centers, respectively. The member 103 for arranging an absorbing pad rotates in a state in which an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com