Weight secured by expansion element in golf club shaft

a golf club shaft and expansion element technology, applied in the field of golf club counterweighting, to achieve the effect of easy installation and easy incorporation into golf clubs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

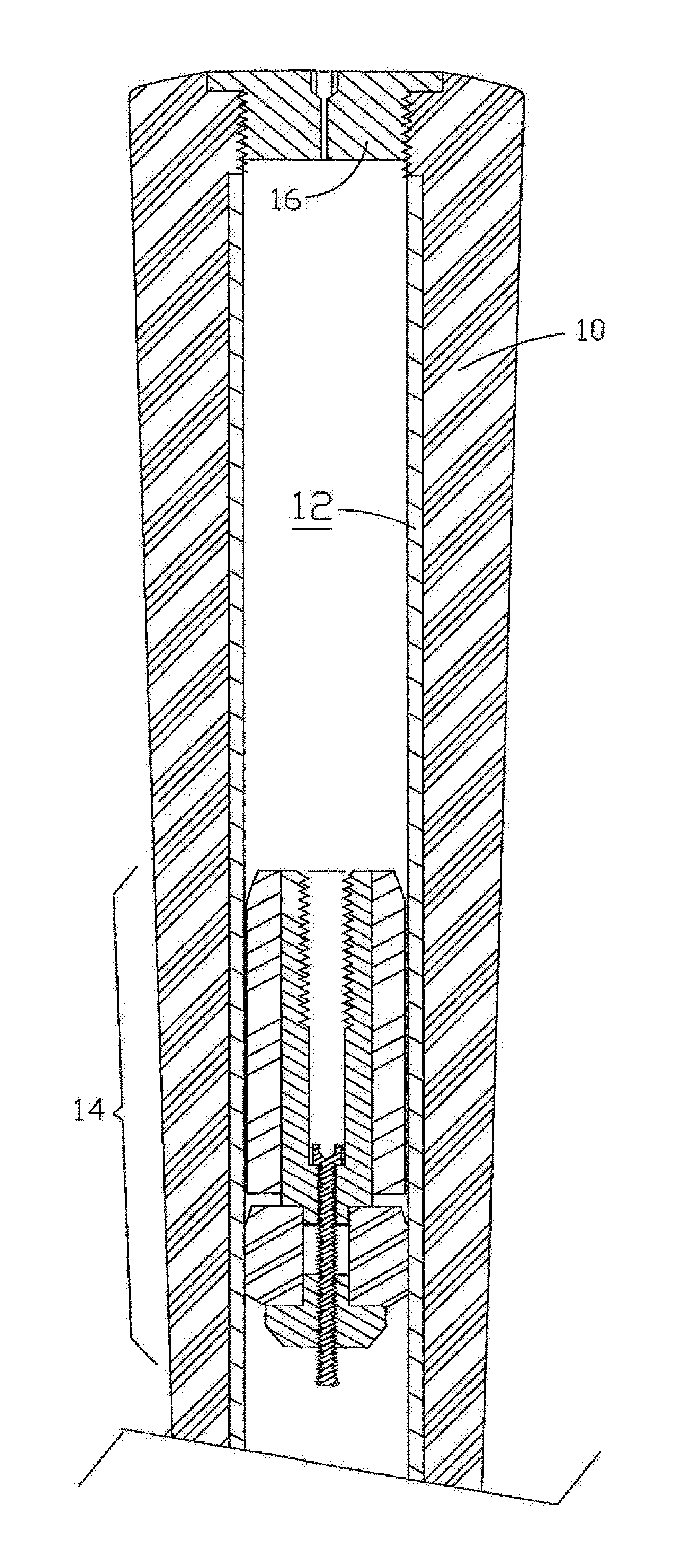

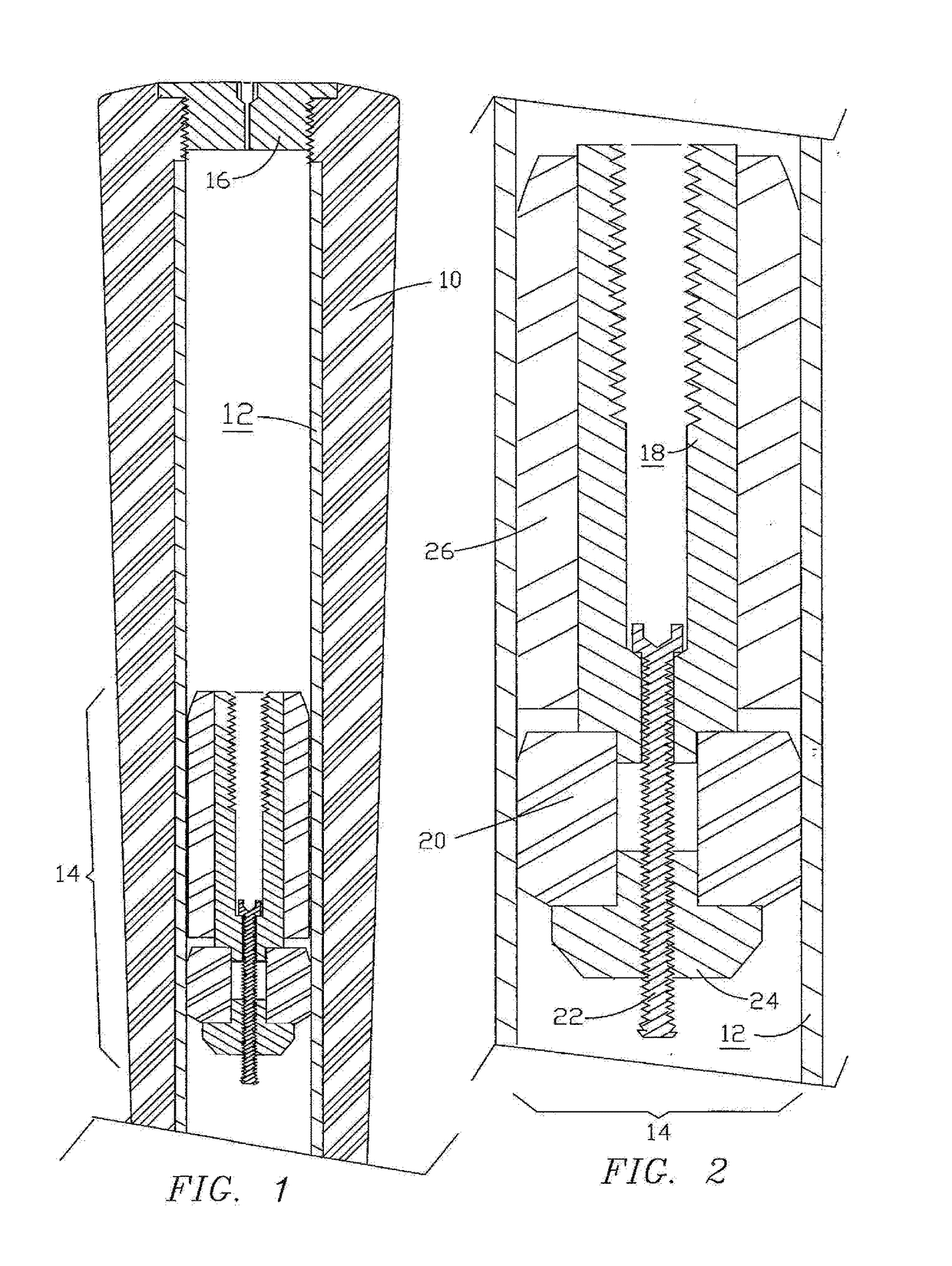

[0026]FIG. 1 is a cross-sectional elevation of an upper portion of a golf club having a grip 10 fitted onto a shaft 12 within which a weight assembly 14 of the present invention has been installed and secured at the selected axial location shown. A removable cap 16 in the top of grip 10 is fitted into a central opening in grip 10 sized to allow insertion and installation of weight assembly 14. Typically cap 16 is configured at top center with a driving recess and traversed there by a small vent passageway as shown.

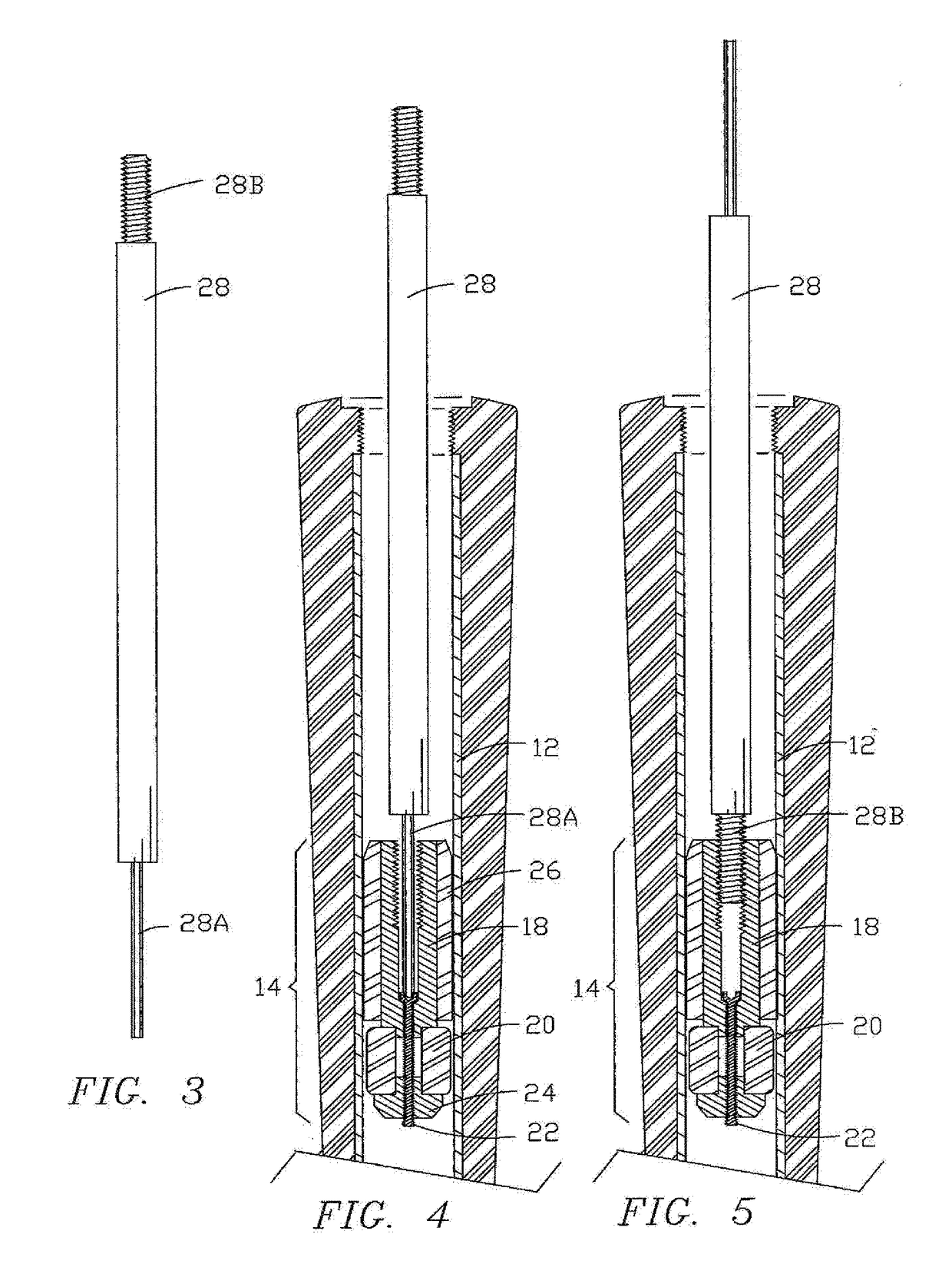

[0027]FIG. 2 is an enlargement of a portion of FIG. 1 showing a resilient expansion element 20 expanded and thus frictionally securing the weight assembly 14 to the surrounding portion of shaft 12. In weight assembly 14, a metal weight element 18 is coupled onto and drawn against expansion element 20 by a machine screw 22 threadedly engaging an annular pressure plate 24, in the form of an inverted T-nut, bearing against the bottom side of expansion element 20. As shown, sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com