Molded package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

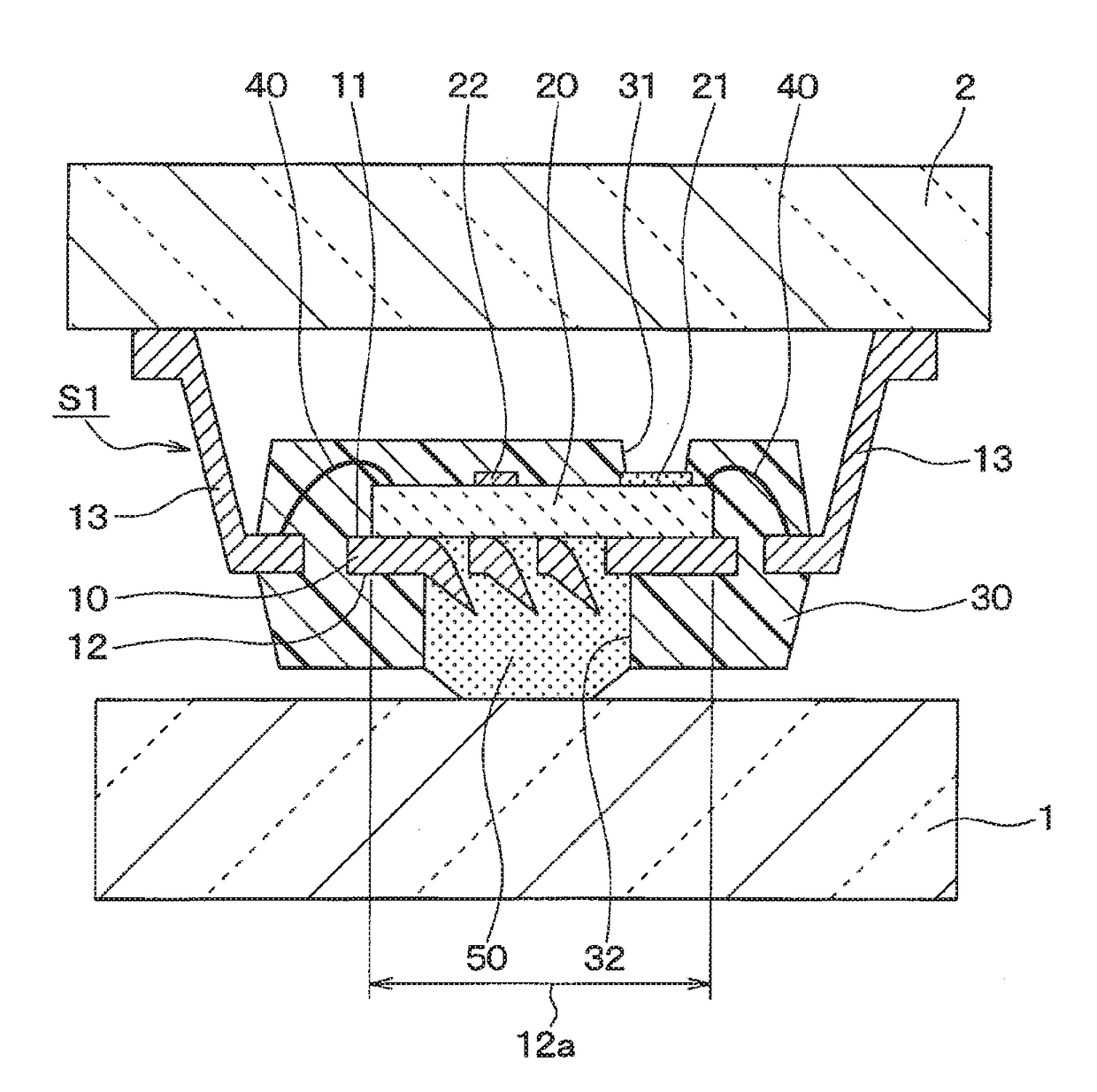

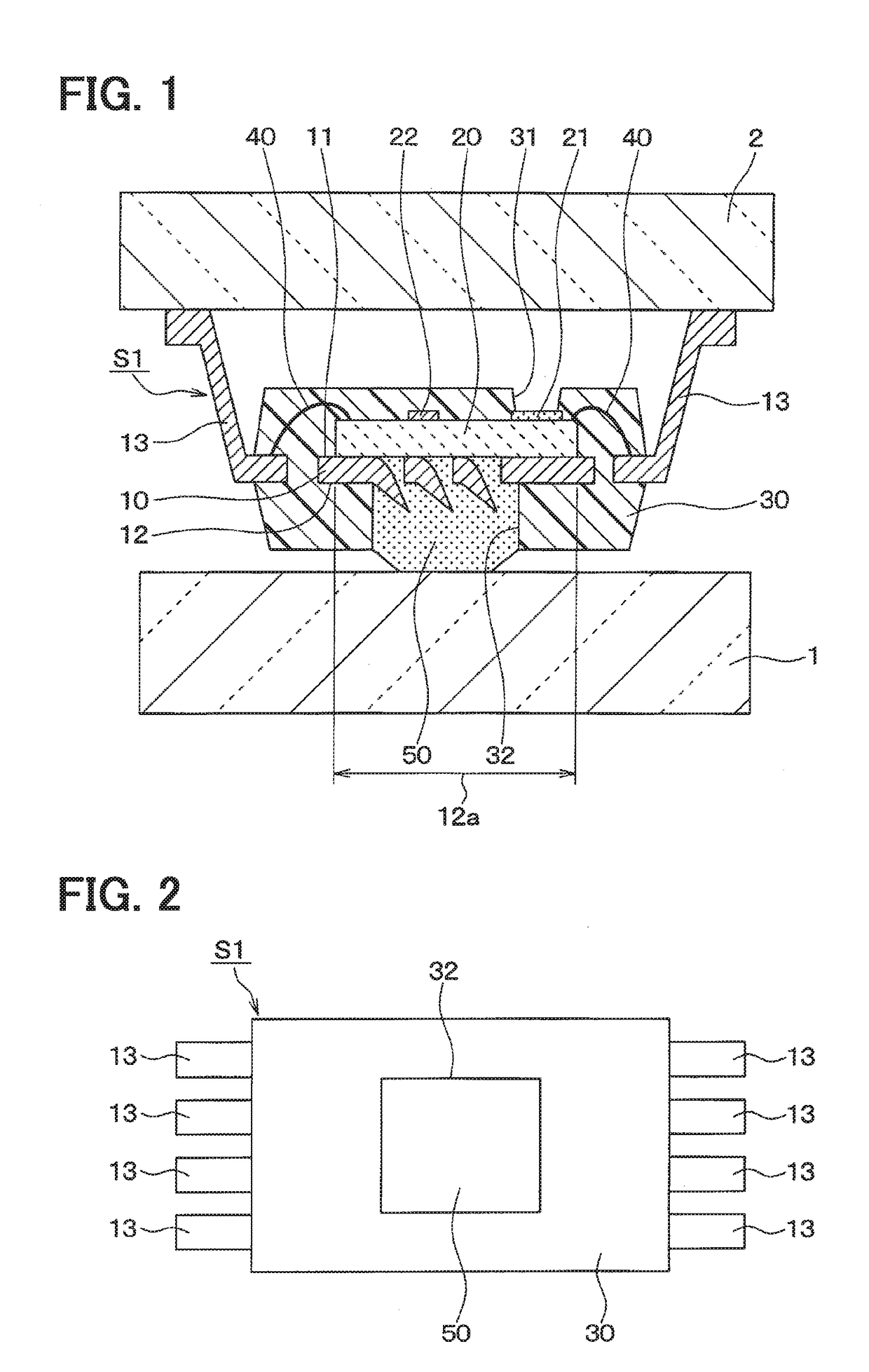

[0022]A molded package S1 according to the first embodiment of the present disclosure will be described with reference to FIGS. 1 and 2. The molded package S1 of the present embodiment is, for example, used as a humidity sensor of a vehicle air conditioning apparatus.

[0023]Specifically, an external member 1 located outside of the molded package S1 is glass, such as a windshield of a vehicle. The molded package S1 is attached to the external member 1 and detects the humidity inside of the passenger compartment and the temperature of the external member 1.

[0024]The molded package S1 of the present embodiment includes, as main components, a metal lead frame 10, an IC chip 20, and a molded resin 30. The lead frame 10 has a first surface 11 and a second surface 12 opposite to the first surface 11. The IC chip 20 is mounted on the first surface 11 of the lead frame 10. The molded resin 30 encapsulates the first surface 11 and the second surface 12 of the lead frame 10 with the IC chip 20....

second embodiment

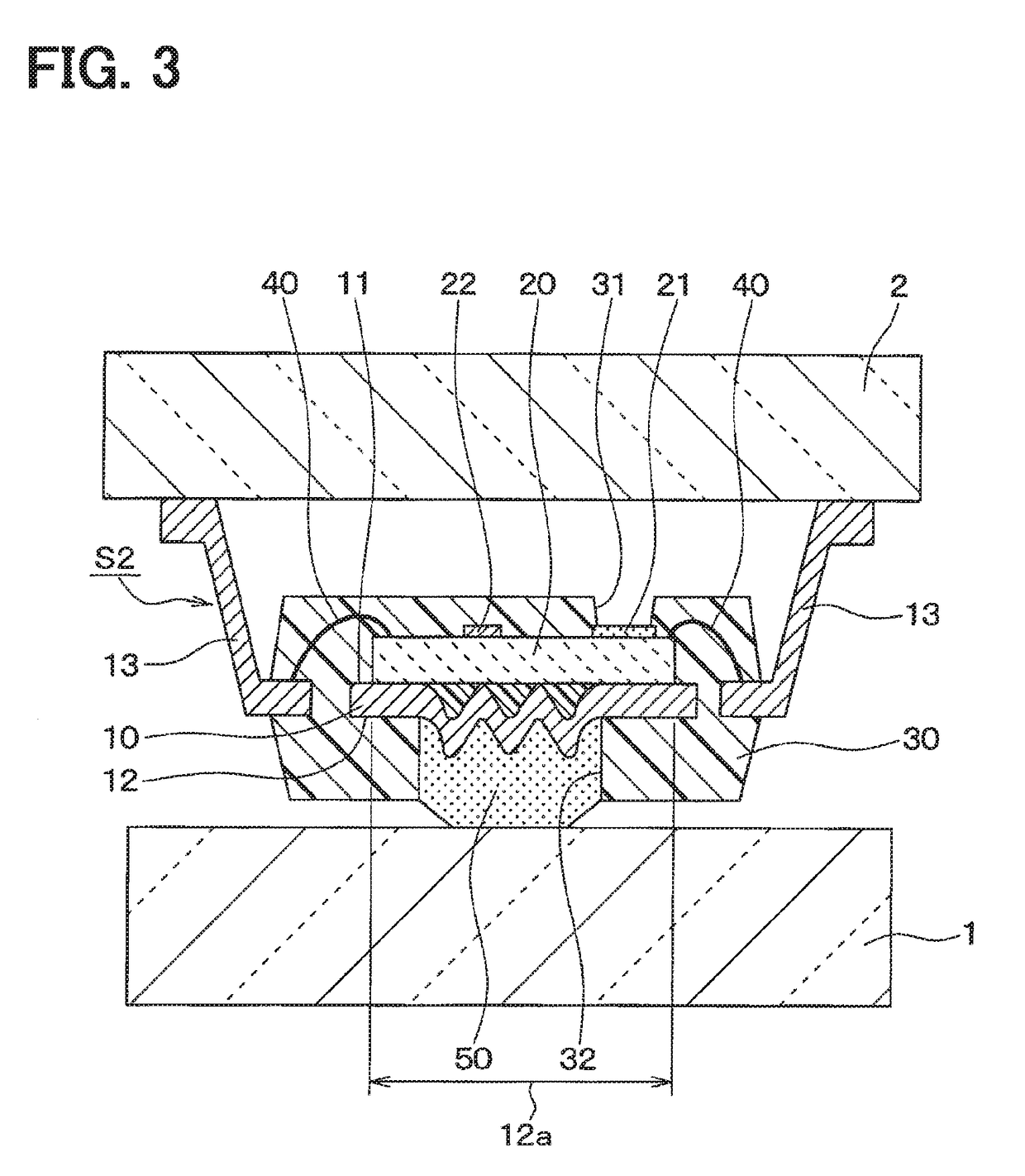

[0058]A molded package S2 according to a second embodiment of the present disclosure will be described with reference to FIG. 3. In the present embodiment, the molded package S2 is different from the molded package S1 of the first embodiment as the surface shape of the chip correspondence portion 12a is modified, and thus the difference will be mainly described hereinafter.

[0059]Also in the present embodiment, the chip correspondence portion 12a has a rough surface that is provided by forming the portion of the lead frame 10 corresponding to the chip correspondence portion 12a into a plate shape having projections and recesses in cross section, as the surface shape that can increase the contact area with the filler material 50.

[0060]In the first embodiment, the rough surface is formed as the surface with the fine splits. In the present embodiment, on the other hand, the rough surface is provided by a waved plate shape having substantially a uniform plate thickness.

[0061]In the prese...

third embodiment

[0062]A molded package S3 according to a third embodiment of the present disclosure will be described with reference to FIG. 4. In the present embodiment, the molded package S3 is different from the molded package S2 of the second embodiment as the surface shape of the chip correspondence portion 12a is modified, and thus the difference will be mainly described hereinafter.

[0063]The chip correspondence portion 12a of the second embodiment described above has the rough surface having substantially the uniform thickness, which is made by the pressing. In the present embodiment, on the other hand, the rough surface of the chip correspondence portion 12a is formed by partially differentiating the thickness of the chip correspondence portion 12a by a mold processing. Also in the present embodiment, the similar effects to the second embodiment can be expected.

[0064]Also in the second embodiment and the third embodiment described above, the projections of the rough surface of the chip corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com