Manufacturing apparatus for metal molded body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

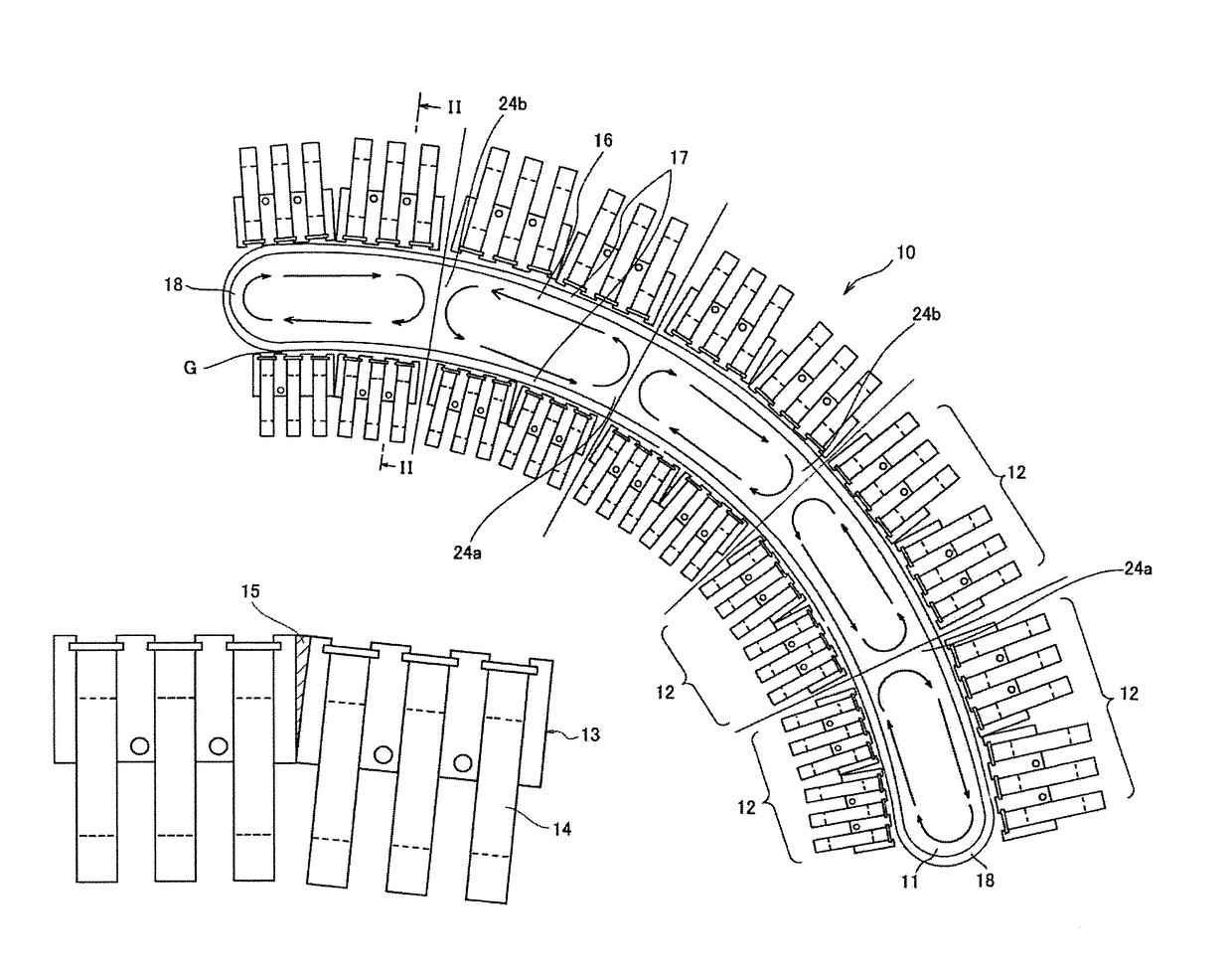

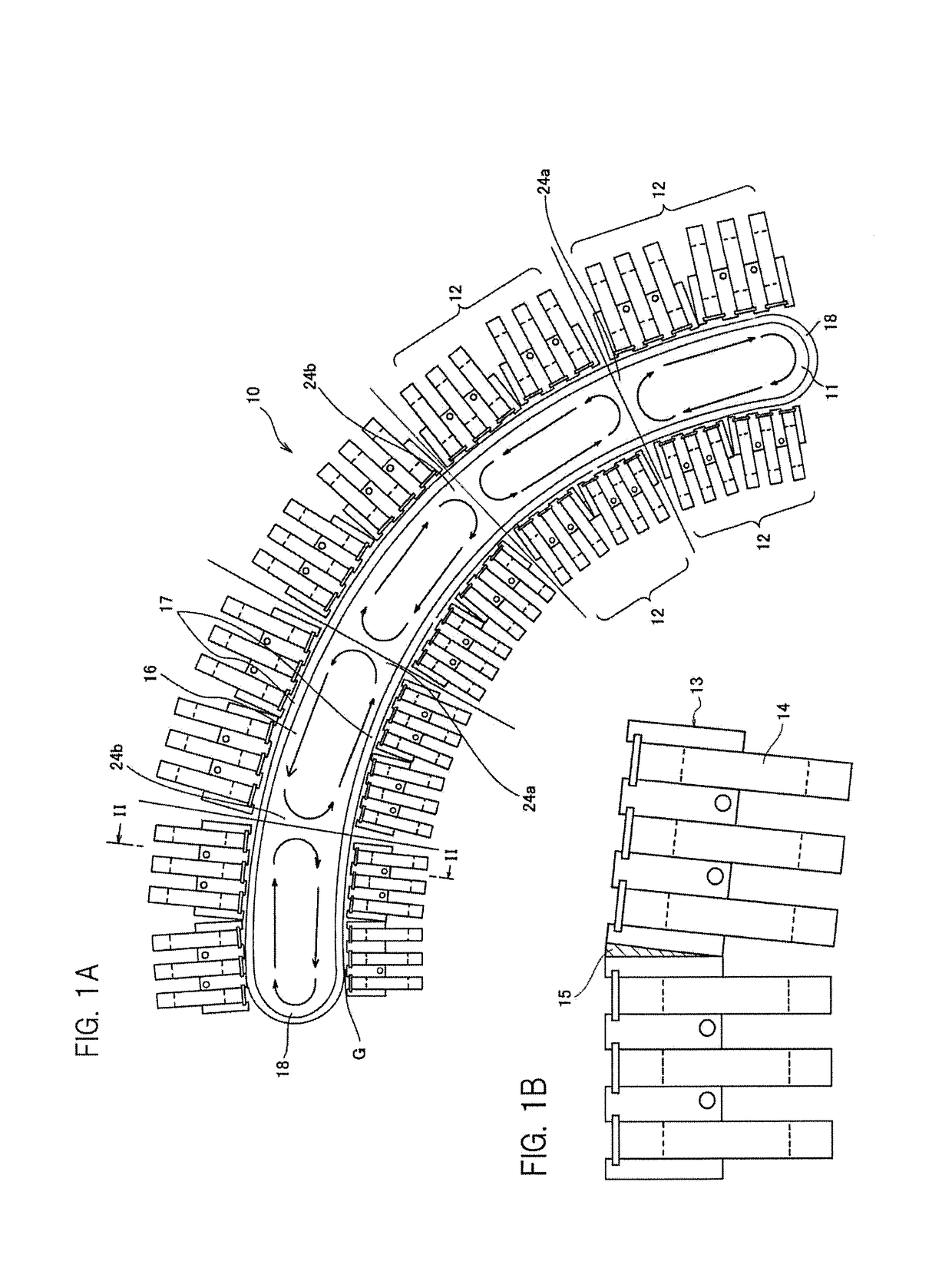

[0022]A manufacturing apparatus (electromagnetic stirring apparatus) 10 for a metal molded body illustrated in FIG. 1A includes an elongated die 11 that is curved in an arc shape in plan view, and a plurality of pairs of thrust units 12 that are disposed along a wall surface of the die with the die disposed therebetween. Each thrust unit 12 includes cores 13, and coils 14 that are wound around the cores 13, as illustrated in FIG. 1B. In this embodiment, two sets each obtained by winding the three coils 14 around the one core 13 are connected through a wedge shaped magnetic body 15 for curvature adjustment at an angle, and are made to be one unit. In FIG. 1A, the wedge shaped magnetic bodies are omitted.

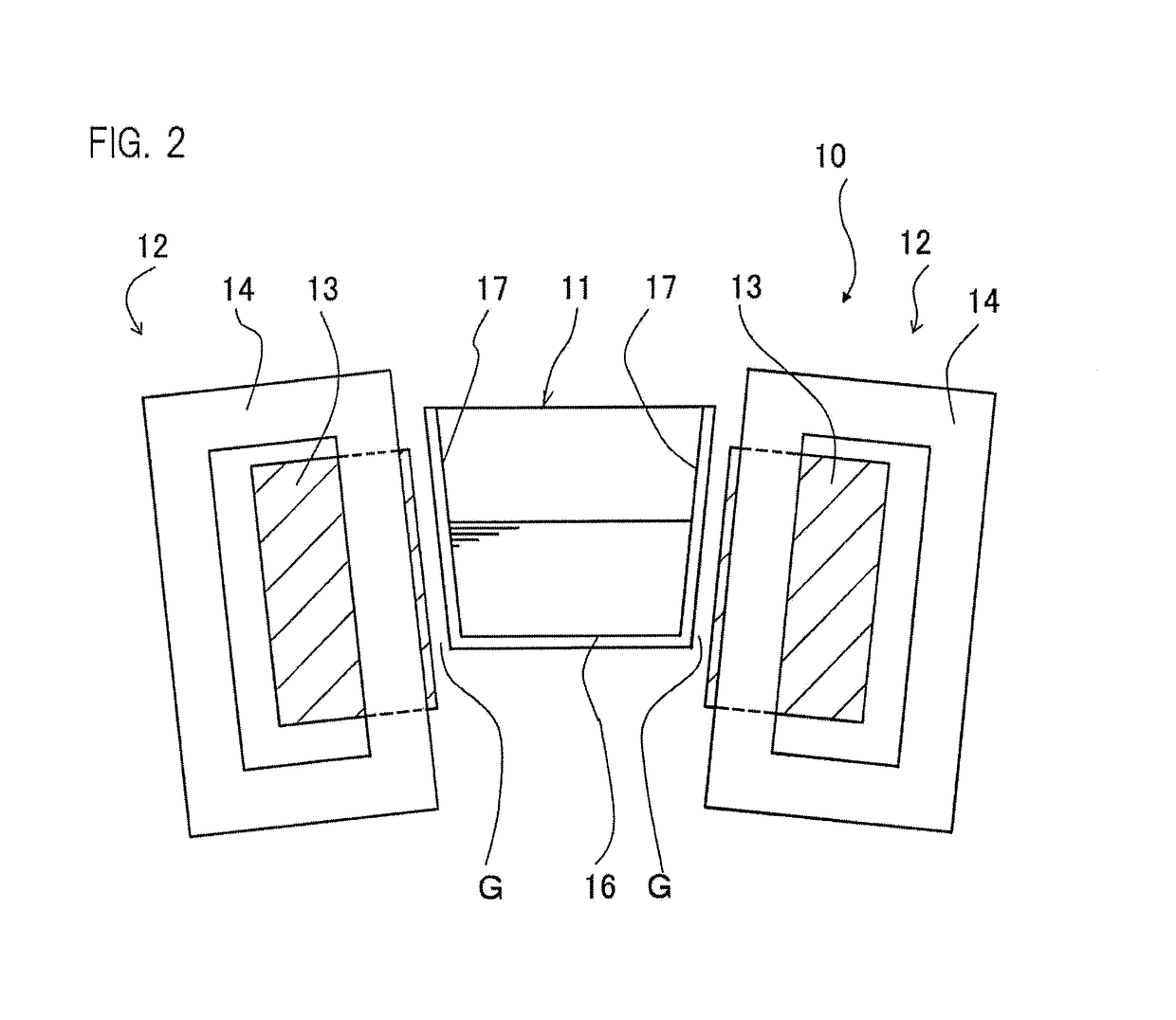

[0023]The die 11 has a substantially U-shaped cross-section including a bottom plate 16, and side walls 17 rising from both ends of the bottom plate, as illustrated in FIG. 2, for example. In general, the depth of the die 11 is deeper than the width. Additionally, the side walls 17 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com