Reliable opening can end for reclosing can

a can end and reliable technology, applied in the field of containers, can solve the problems of carbon dioxide escaping and spillage, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

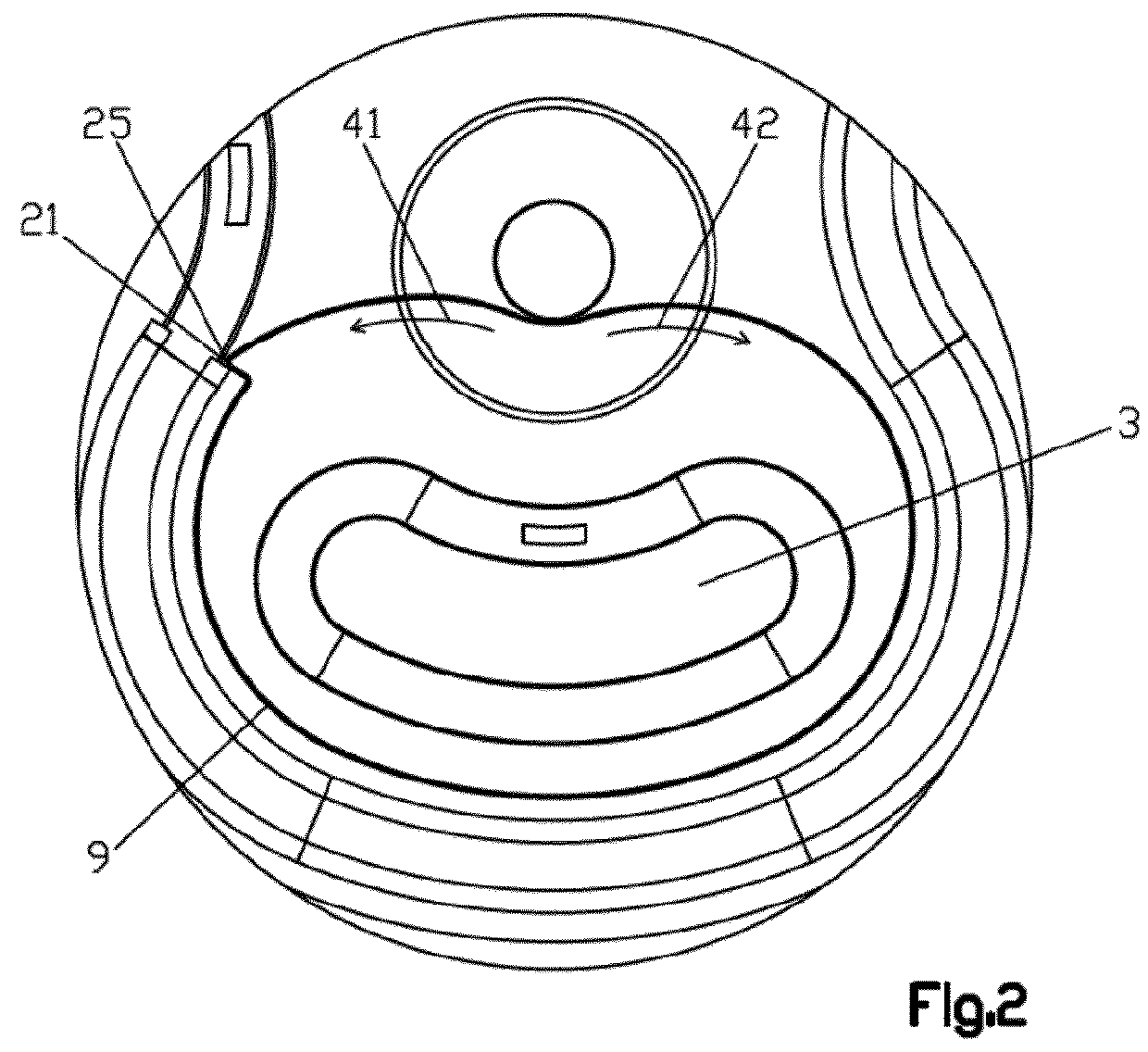

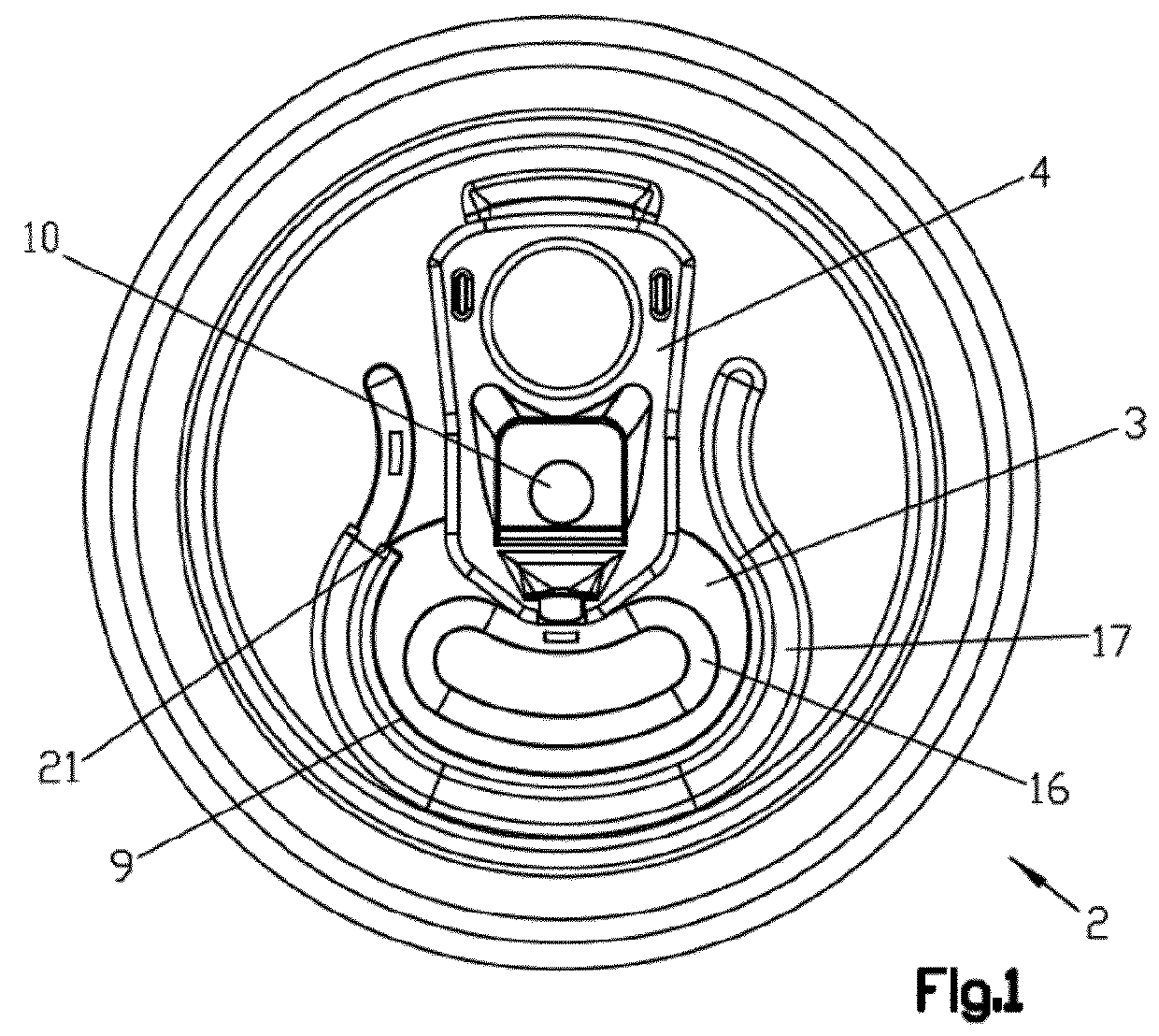

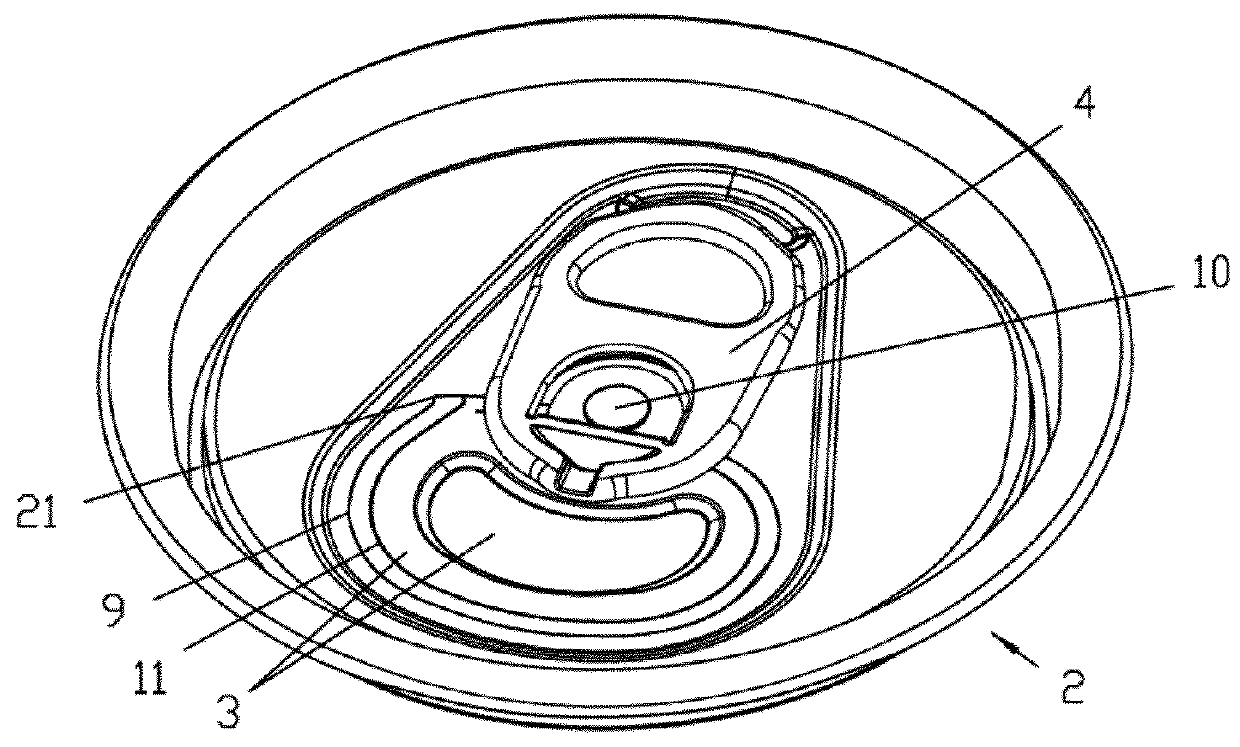

[0067]FIGS. 1 and 2 show a can end and FIGS. 3a and 3b illustrate another embodiment of a can end. Referring to FIG. 3a, the central part of the can end 2 has a tear panel or cap top 3, that can be torn off along a pre-formed shallow groove 9 or other form of mechanical weakness, by pulling at the pull tab 4, which works as a lever. Pull tab 4 is attached to can end 2 by a fixing device 10 such as a rivet. As disclosed in WO 2012 / 028694, “Reclosing can for food product” (mentioned hereinbefore), the cap top 3 is torn completely from the can end, i.e. removed from the can end, along the pre-defined groove 9, thus creating a drinking or pouring aperture. After tearing off the cap top 3, the cap top 3 remains located on top of a shut-off valve 6 (shown in FIG. 3b), which is configured to seal the drinking or pouring aperture after drinking or pouring. The embodiment of the can end illustrated in FIG. 3b further comprises an intermediate element 80 to which the shut-off valve 6 is attac...

second embodiment

[0088]FIG. 24 illustrates means for preventing propagation of the tear outside of the pre-defined groove 9. In this embodiment, the means for preventing propagation of the tear outside of the pre-defined groove comprise an additional groove 28. In FIG. 24, the additional groove 28 is oriented perpendicularly to the direction of the pre-defined groove 9 in its endpoint 24 which is the means 24 for arresting propagation of the tear.

third embodiment

[0089]FIG. 25 illustrates means for preventing propagation of the tear outside of the pre-defined groove 9, that is very similar to the one shown in FIG. 24. However, while in the embodiment of FIG. 24 the additional groove 28 passes through the endpoint 24 of the pre-defined groove, in the embodiment of FIG. 25 the additional groove 28 is positioned at a small distance, of e.g. 1 mm, from the abrupt change of direction 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com