Power equipment

a technology of power equipment and stoppers, which is applied in the direction of mowers, agriculture tools and machines, etc., can solve the problems of deformation or increase the size of the operation lever and/or the stopper, and reduce the design freedom of the operating portion including the operation lever, so as to prevent deformation and damage of the operation lever and/or the stopper, and increase the strength of the component parts. the effect of the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

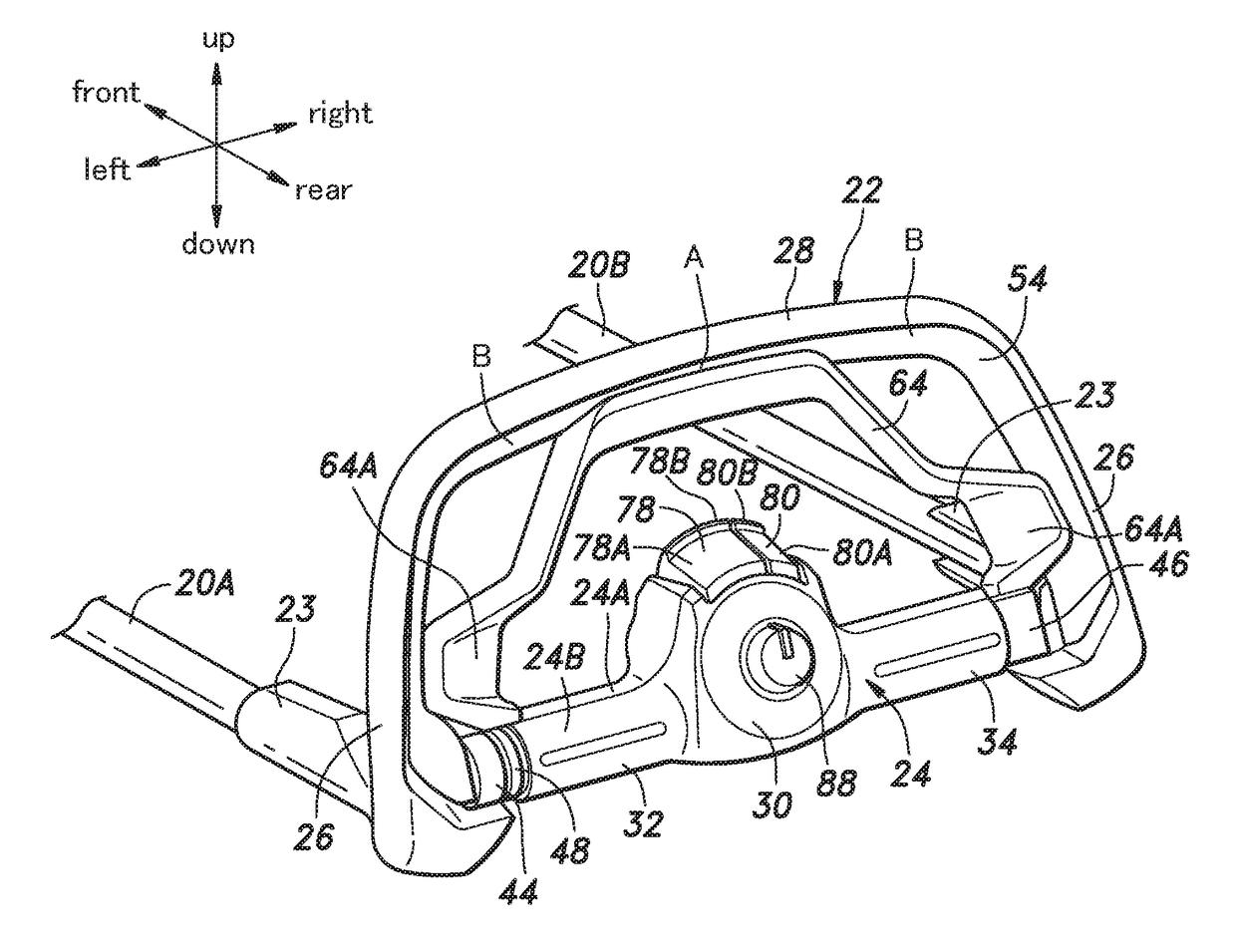

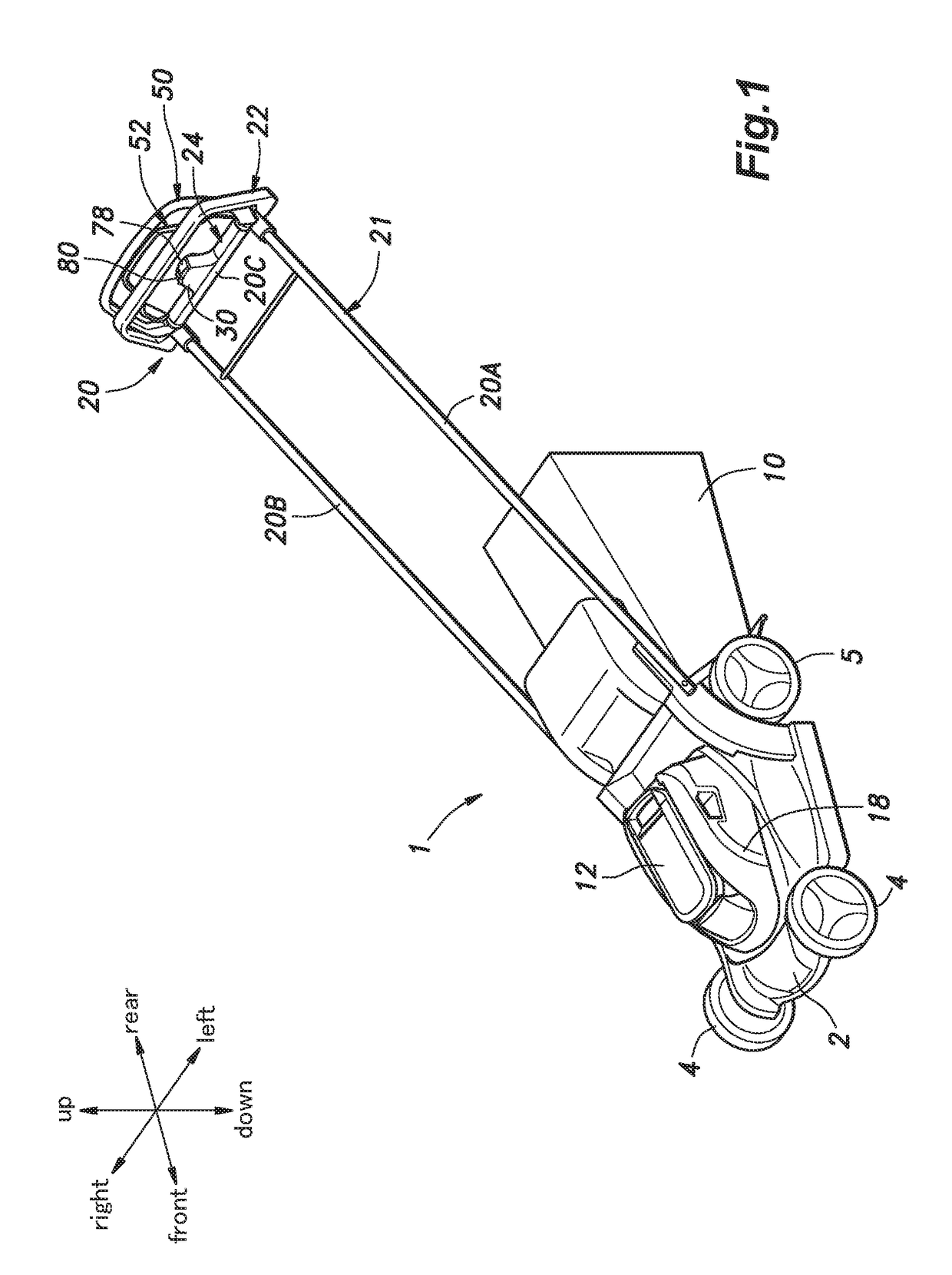

[0041]A walk behind electric lawn mower embodying power equipment according to the present invention will be described in the following with reference to FIGS. 1 to 14.

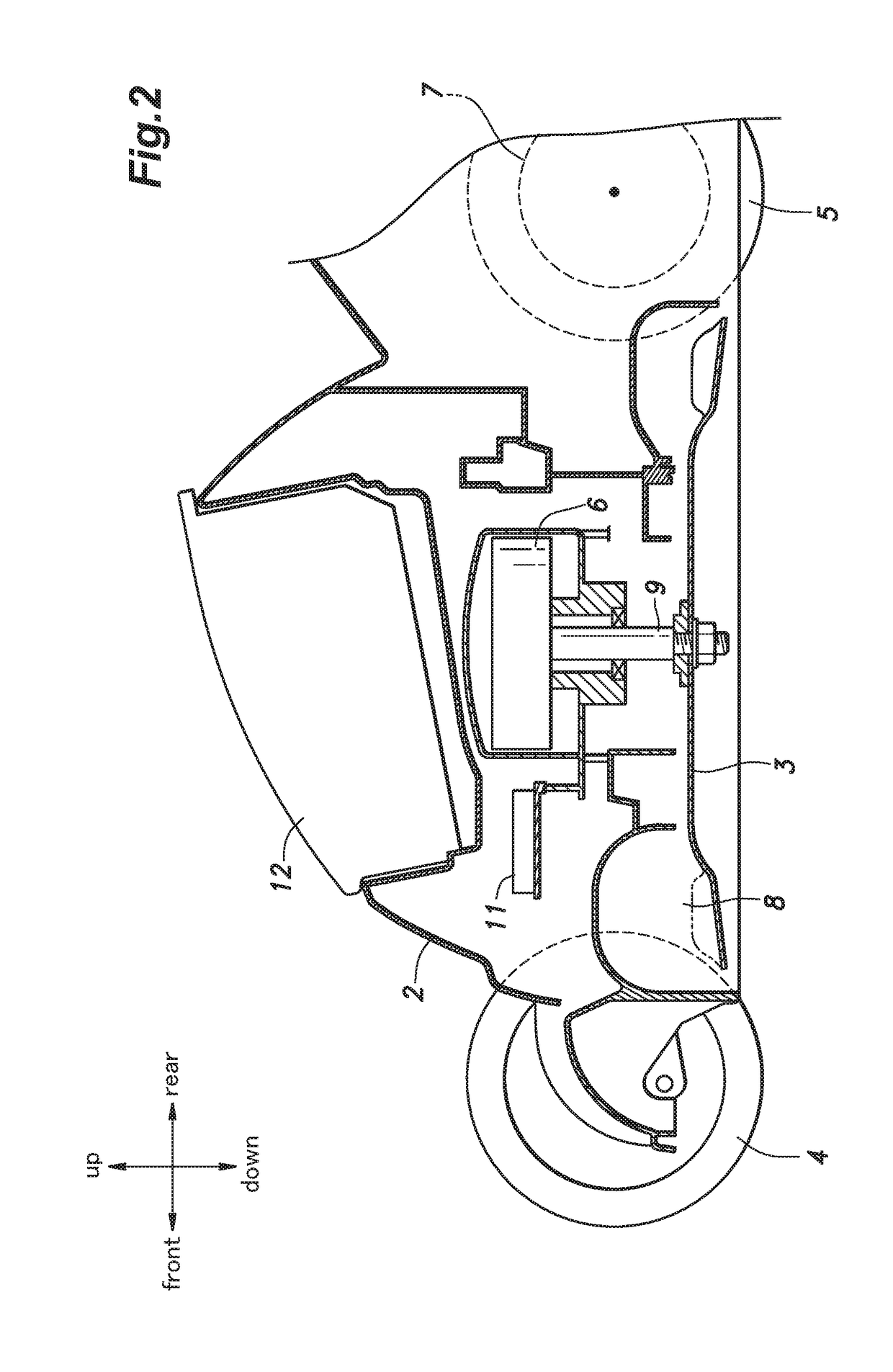

[0042]As shown in FIGS. 1 and 2, the electric lawn mower 1 includes a main body 2, a cutter blade 3 provided in the main body 2, a pair of front wheels 4 and a pair of rear wheels 5 each supported rotatably on the main body 2, a cutter blade electric motor (work unit electric motor) 6 provided in the main body 2 to drive the cutter blade 3, and a travel electric motor 7 for driving the rear wheels 5.

[0043]The cutter blade 3 is disposed in a cutter blade chamber 8 formed in a bottom of the main body 2 so as to open downward such that the cutter blade 3 is rotatable in a substantially horizontal plane. The cutter blade 3 is secured to a lower end of an output shaft 9 of the cutter blade electric motor 6 and is driven by the output shaft 9 to rotate about a vertical axis. A grass bag 10 is provided to a rear end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com