Washing machine with steam washing function and control method

a technology of washing machine and function, applied in the field of washing machines, can solve the problems of small quantity of generated steam, unsatisfactory effect, slow heating efficiency, etc., and achieve the effect of rapid heat and vaporization, rapid generating a large amount of steam, and reducing the cost of the washing machin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

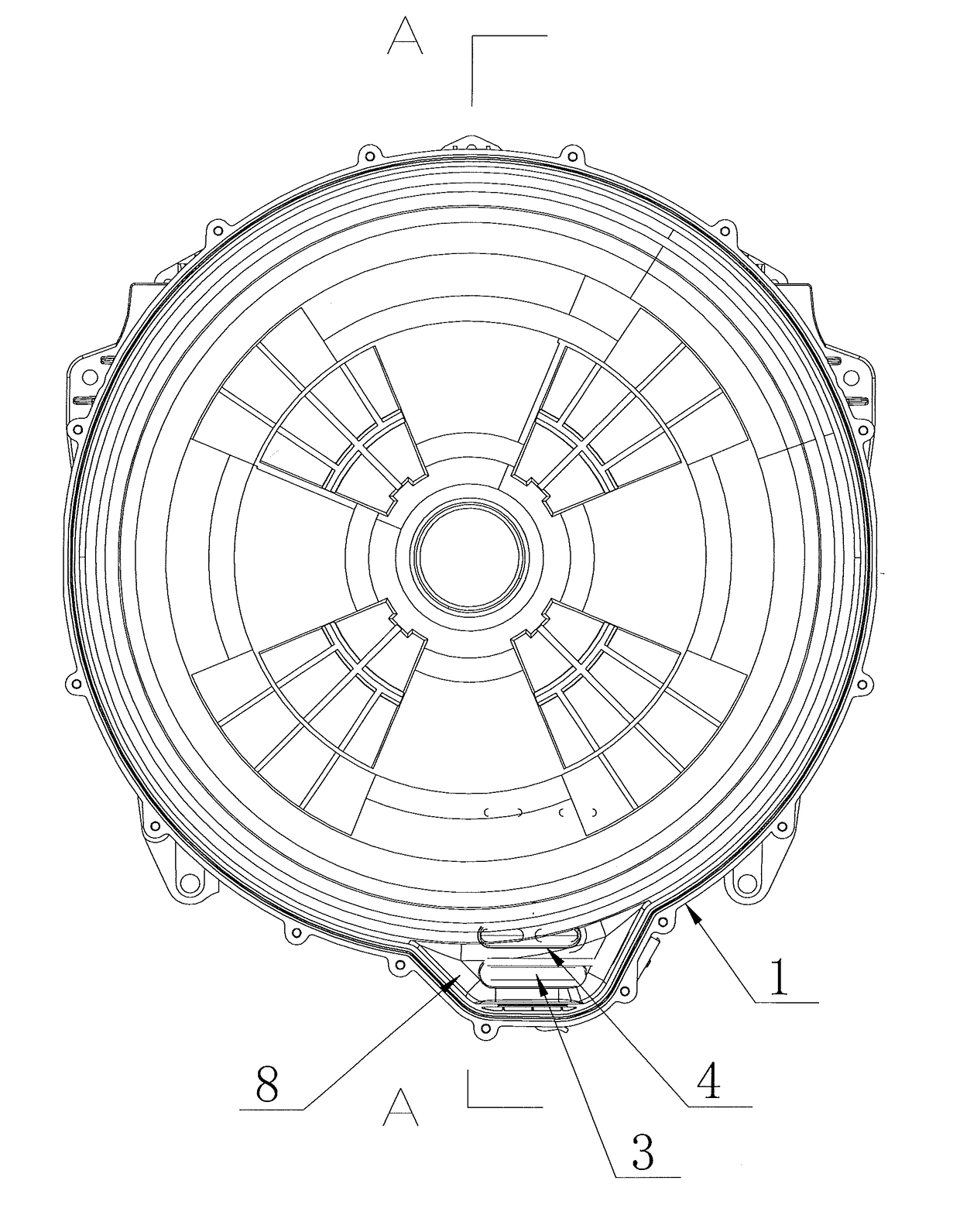

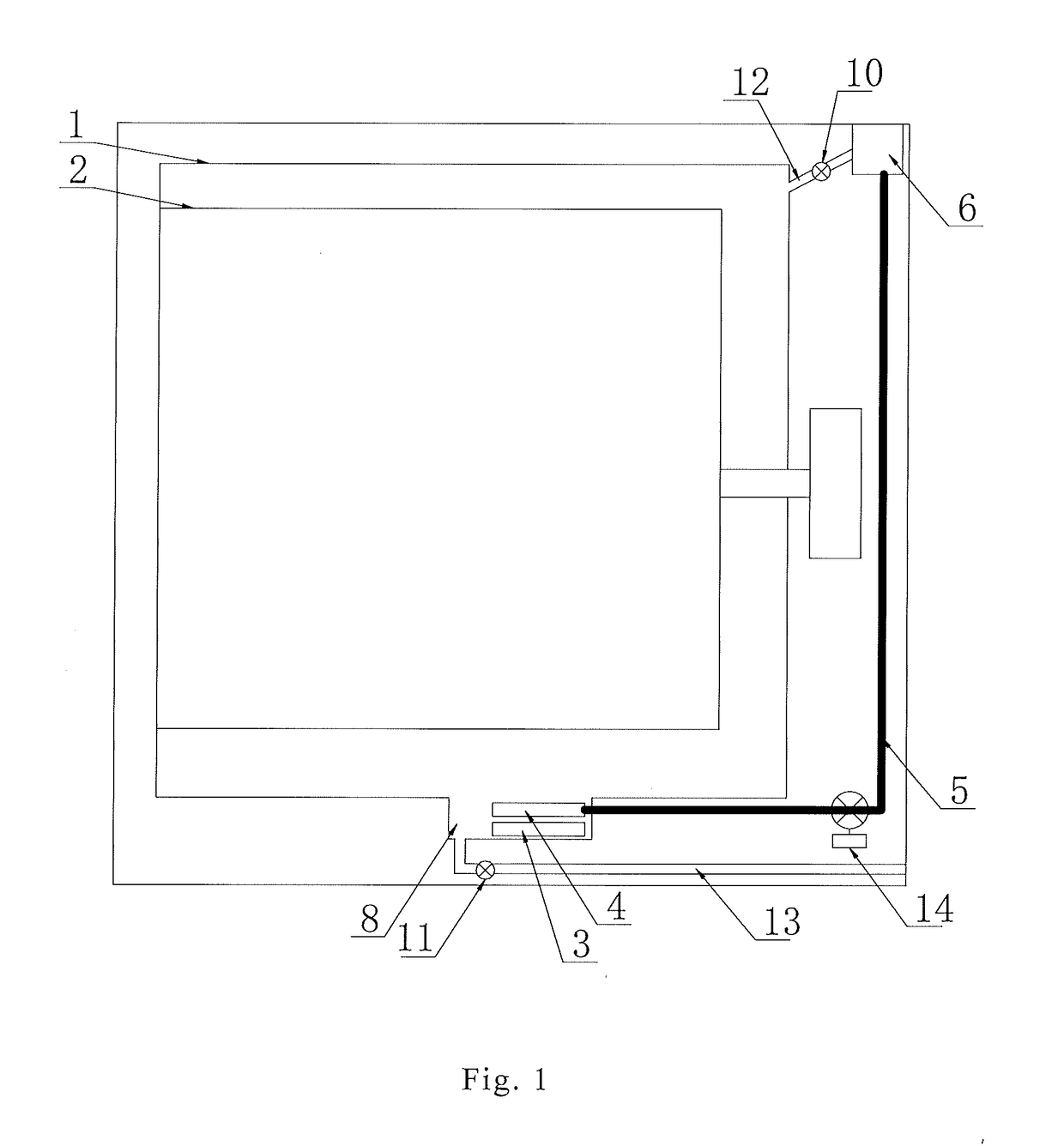

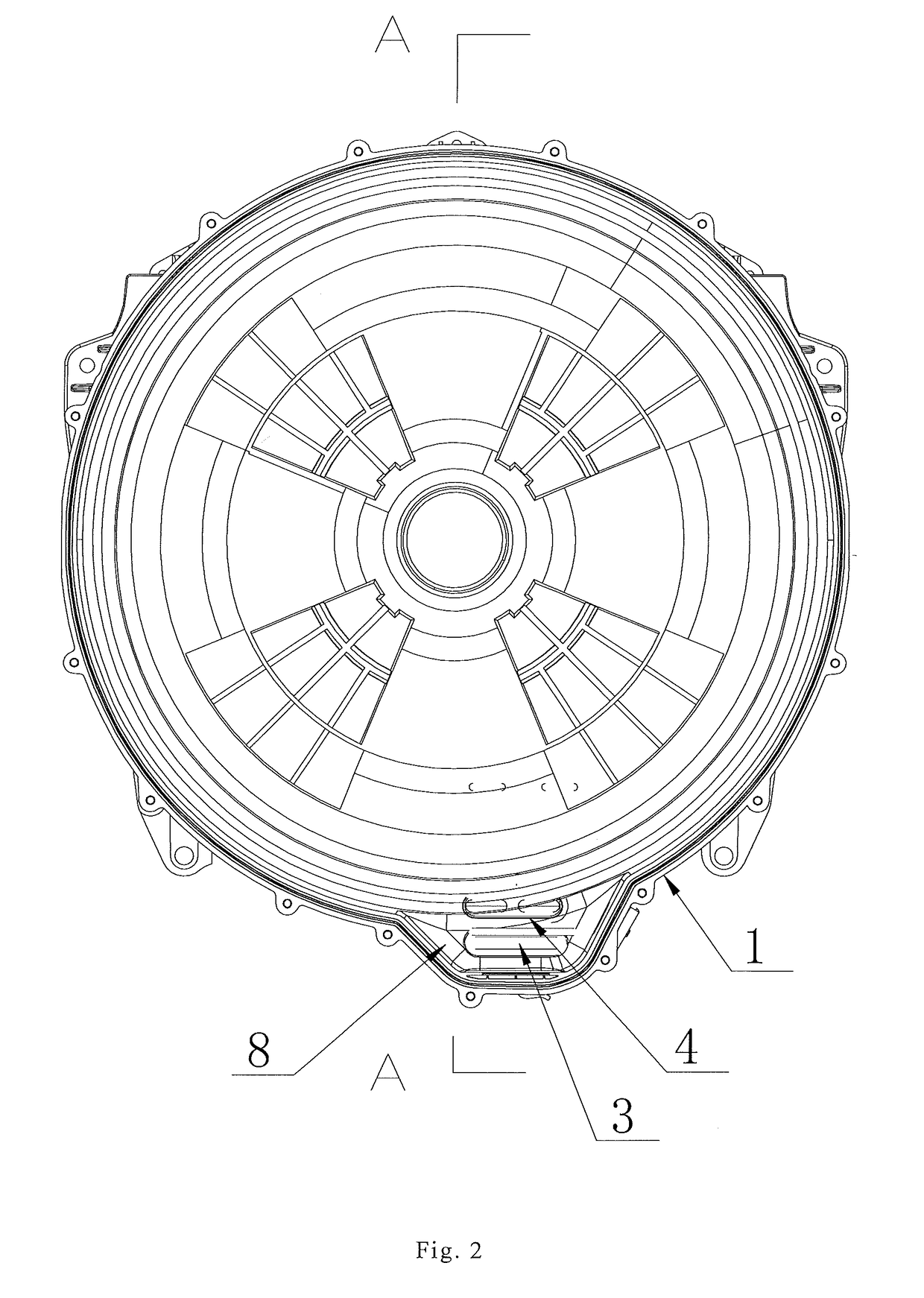

[0037]As shown in FIG. 1 to FIG. 4, in the present embodiment, the spray thrower (4) and the heater (3) are correspondingly arranged jointly or at a distance, the corresponding side of the spray thrower (4) is distributed with multiple spray holes (7) used for spraying water to the heater (3). Preferably, the spray thrower (4) and the heater (3) are spaced by a certain distance in order to improve the cover area of the spray holes (7). Meanwhile, the distance between adjacent spray holes (7) is made to be smaller than the diameter of the area covered by the sprayed water, such that each part of the heater (3) can be in contact with the sprayed water, so as to improve the generation efficiency of steam.

[0038]As shown in FIG. 4 and FIG. 5, in the present embodiment, the heater (3) is constituted by multiple heating pipes which are spirally arranged in an S shape; the spray thrower (4) is constituted by the pipeline (40) which is of the same shape as the heater (3), and multiple spray ...

embodiment 2

[0041]As shown in FIG. 1, in the present embodiment, the heater (3) and the spray thrower (4) are both arranged between the outer drum (1) and the inner drum (2), the steam generated at the heater (3) can flow into the space inside the inner drum (2) via a dehydration hole arranged on the inner drum (2), so as to perform steam washing, sterilization and disinfection, deodorization and the like on the clothes in the inner drum (2).

[0042]As shown in FIG. 2 and FIG. 3, in the present embodiment, the heater (3) is arranged at the bottom of the outer drum (1), the spray thrower (4) is arranged at the corresponding upper side of the heater (3), and the spray holes (7) are arranged on the lower surface of the spray thrower (4). The steam will move upwards in the outer drum (1) due to its low density, and the heater (3) is arranged at the bottom of the outer drum (1), such that the steam generated in the outer drum (1) is uniformly distributed inside the outer drum (1), and the clothes can ...

embodiment 3

[0044]In the present embodiment, the washing machine has a corresponding process of generating high-temperature steam, and the process specifically includes the following steps:

[0045]1) the water inlet pipe and the water outlet pipe of the outer drum are disconnected, so that the inner space of the outer drum is arranged to be airtight;

[0046]2) the washing machine fills water to the spray thrower, the spray thrower sprays water to the heater, and the heater begins to work to generate high-temperature steam, so as to enable the steam to be filled in the airtight inner space of the outer drum;

[0047]3) when step 2) is executed, the inner drum rotates at a certain rotation halt ratio.

[0048]Through the above method, the inner space of the outer drum can be rapidly and uniformly filled with steam, and steam can be utilized to heat and wet the clothes, such that the washing machine has the functions of steam washing, clothes drying, sterilization and disinfection, deodorization and ironing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com