Subsea centrifugal compressor with horizontal shaft and with only one axial thrust bearing

a centrifugal compressor and horizontal shaft technology, applied in the direction of pump installation, non-positive displacement fluid engine, liquid fuel engine components, etc., can solve the problems of increasing the number of compression stages, and affecting the efficiency of the motor compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

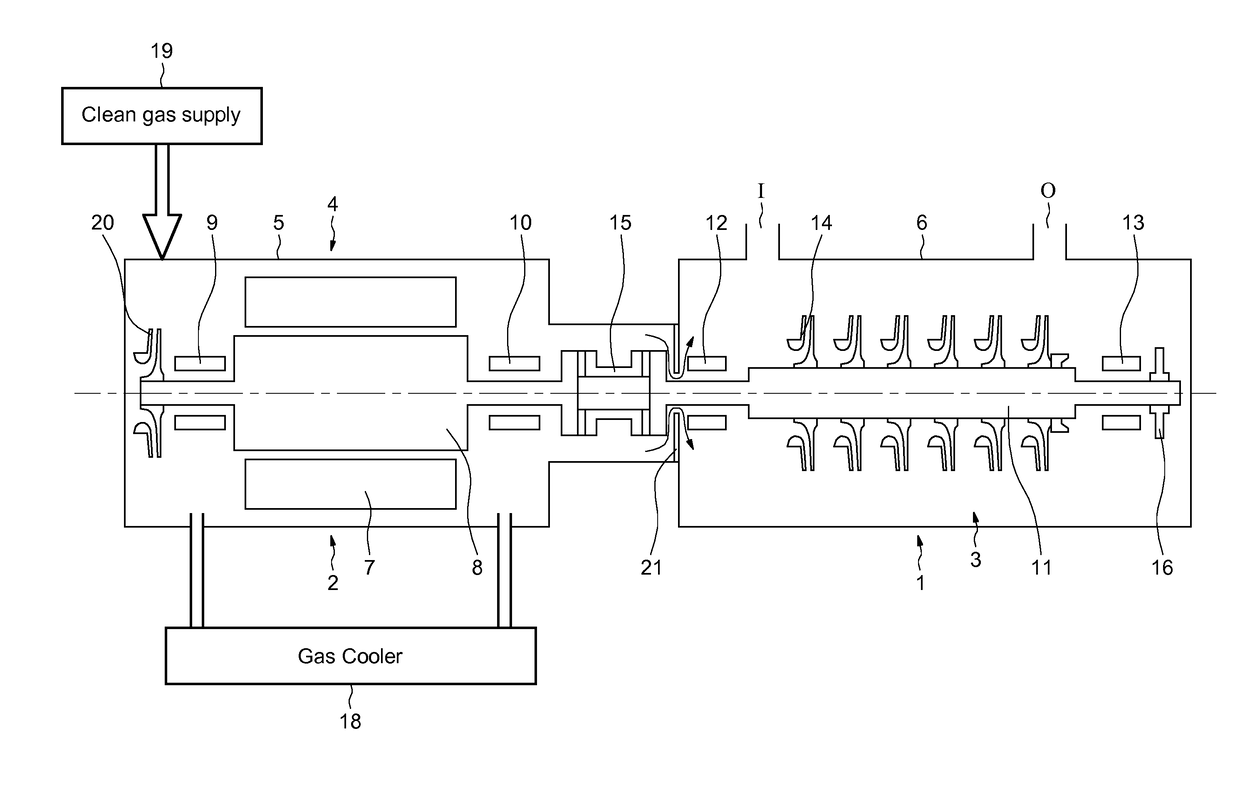

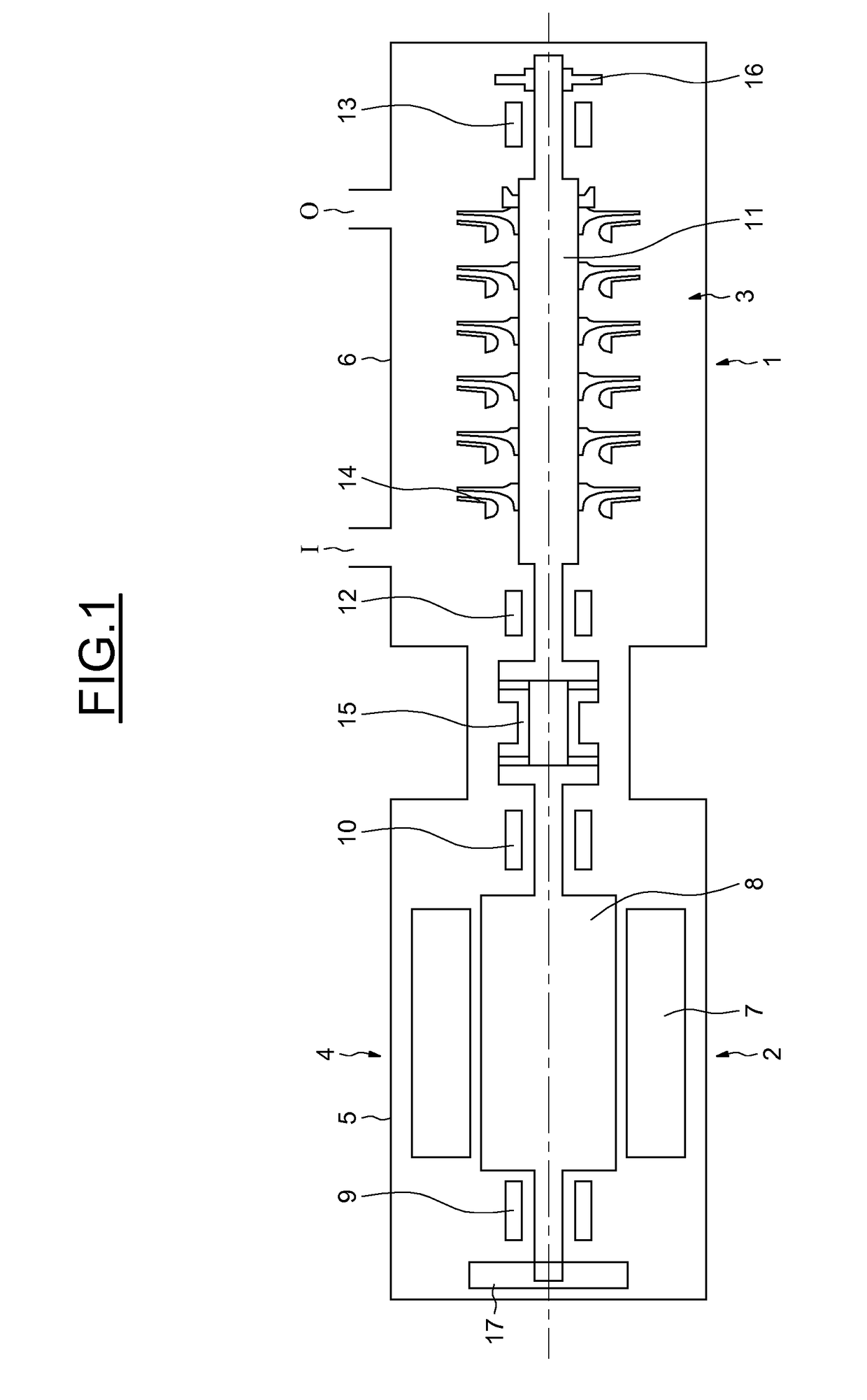

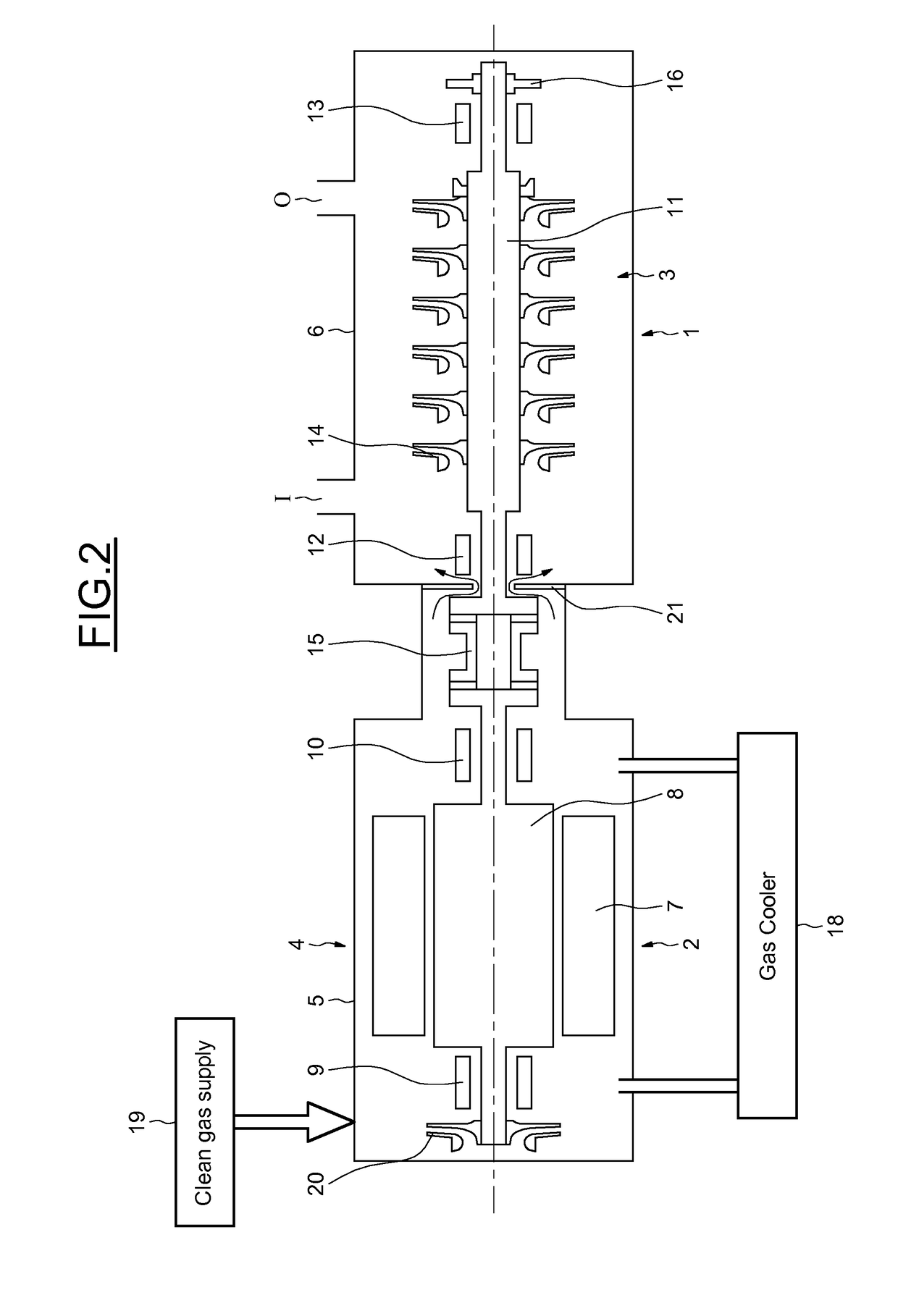

[0029]FIG. 1 shows a centrifugal compressor unit 1 according to embodiments of the invention, for subsea applications, having a motor 2 and one or more compressor(s) 3 mounted in a common casing 4 leak tight to the gas manipulated by the compressor 3.

[0030]The casing 4 comprises two casing elements fixed together by appropriate attachment means, the one, denoted by numeral reference 5, accommodating the motor 2 and the other, denoted by reference 6, accommodating the compressor.

[0031]The casing elements are intended to provide support and protection for the motor and the compressor, respectively. As illustrated, the casing 2 is provided with a gas inlet orifice I facing the first compression stage of the compressor and an outlet orifice O facing the last compression stage.

[0032]In operation, the casing element assembly is intended to be pressurized and immersed and is arranged on a base such that the compressor unit is arranged horizontally.

[0033]In the exemplary embodiment, the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com